Eight Disciplines of Problem Solving (8D)

– Eight Disciplines of Problem Solving –

⇓ Introduction to 8D

⇓ What is 8D

⇓ Why Apply 8D

⇓ When to Apply 8D

⇓ How to Apply 8D

Introduction to Eight Disciplines of Problem Solving (8D)

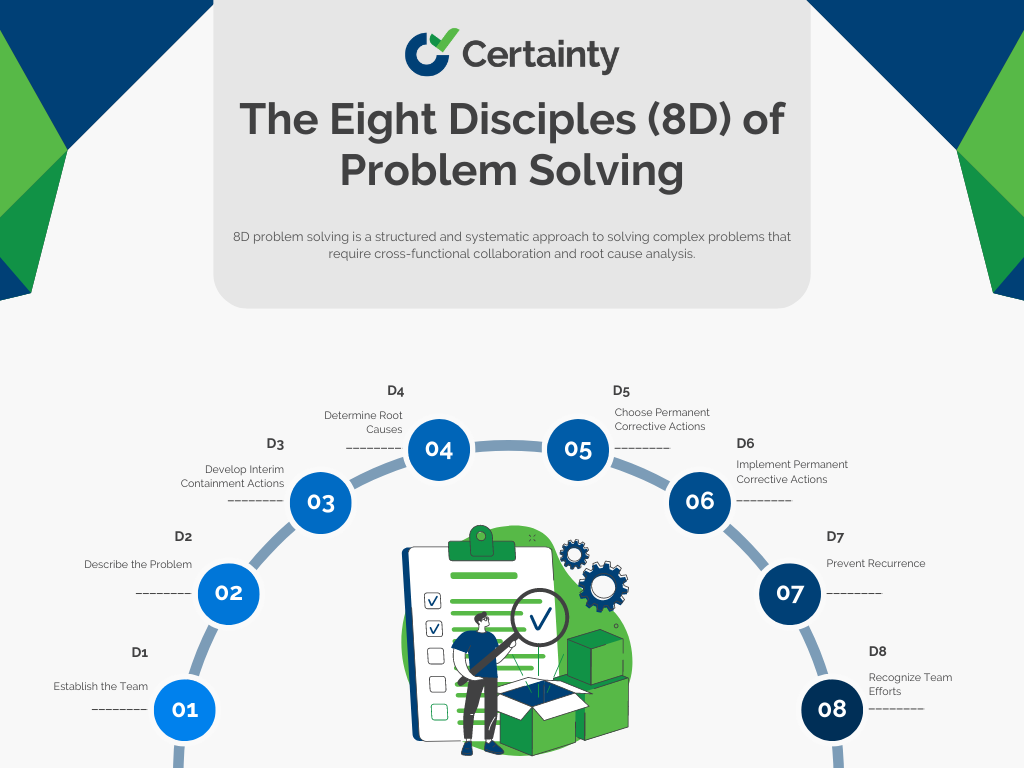

The Eight Disciplines of Problem Solving (8D) is a problem solving methodology designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

8D has become very popular among manufacturers because it is effective and reasonably easy to teach. Below you’ll find the benefits of an 8D, when it is appropriate to perform and how it is performed.

What is Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.

The strength of the 8D process lies in its structure, discipline and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from a systemic failure.

8D has grown to be one of the most popular problem solving methodologies used for Manufacturing, Assembly and Services around the globe. Read on to learn about the reasons why the Eight Disciplines of Problem Solving may be a good fit for your company.

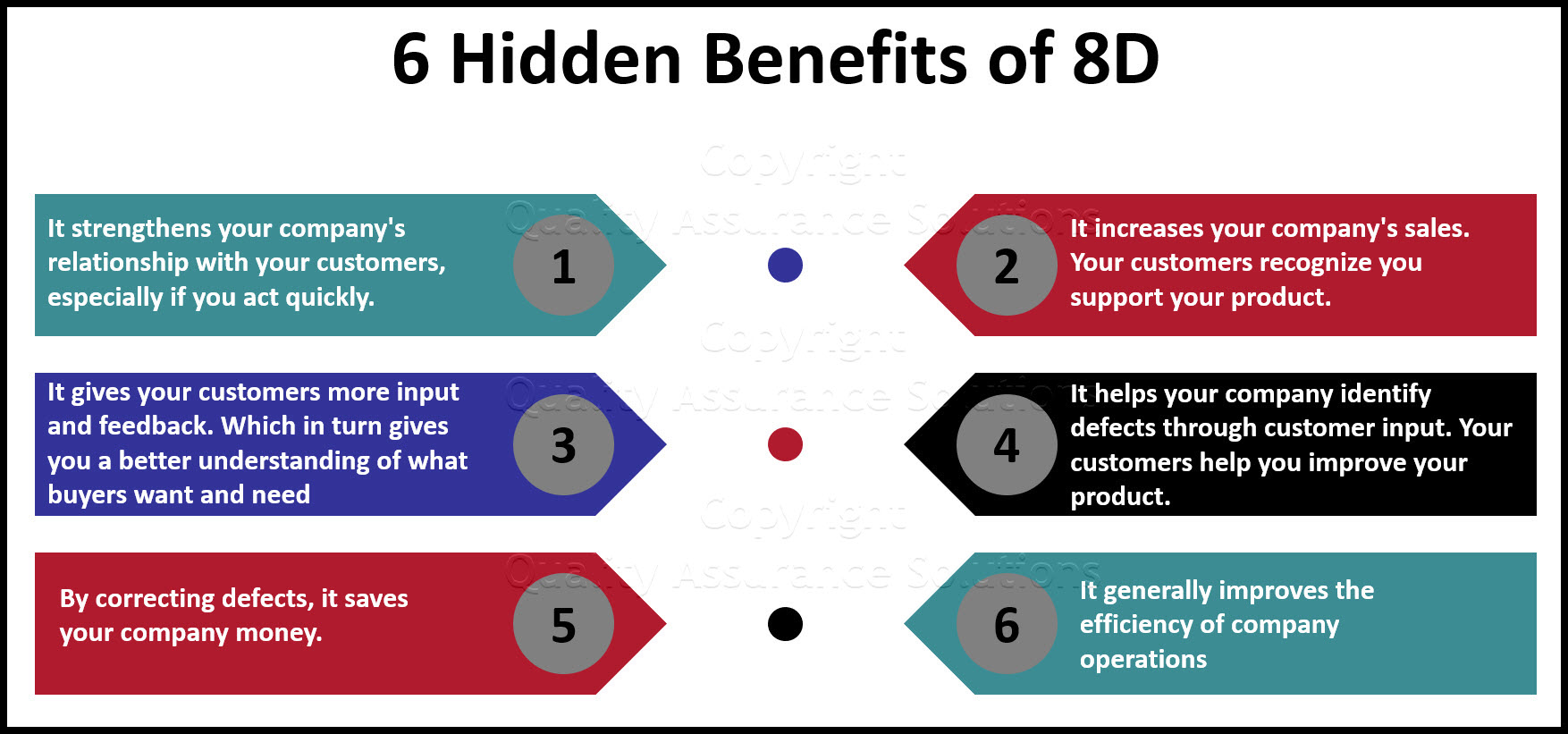

Why Apply Eight Disciplines of Problem Solving (8D)

The 8D methodology is so popular in part because it offers your engineering team a consistent, easy-to-learn and thorough approach to solving whatever problems might arise at various stages in your production process. When properly applied, you can expect the following benefits:

- Improved team oriented problem solving skills rather than reliance on the individual

- Increased familiarity with a structure for problem solving

- Creation and expansion of a database of past failures and lessons learned to prevent problems in the future

- Better understanding of how to use basic statistical tools required for problem solving

- Improved effectiveness and efficiency at problem solving

- A practical understanding of Root Cause Analysis (RCA)

- Problem solving effort may be adopted into the processes and methods of the organization

- Improved skills for implementing corrective action

- Better ability to identify necessary systemic changes and subsequent inputs for change

- More candid and open communication in problem solving discussion, increasing effectiveness

- An improvement in management’s understanding of problems and problem resolution

8D was created to represent the best practices in problem solving. When performed correctly, this methodology not only improves the Quality and Reliability of your products but also prepares your engineering team for future problems.

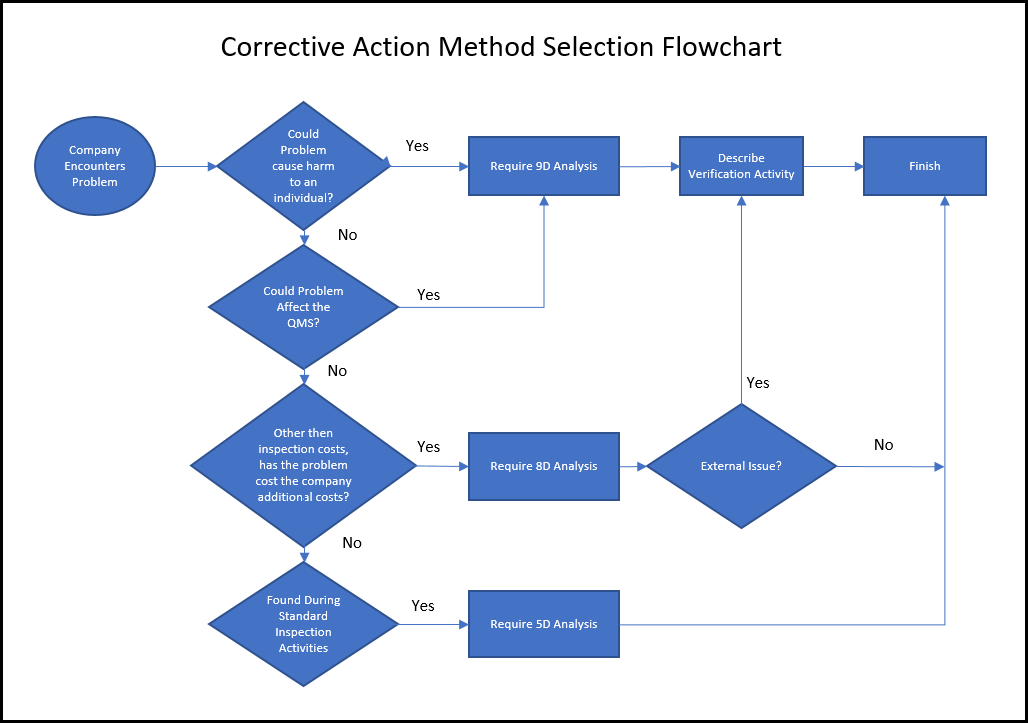

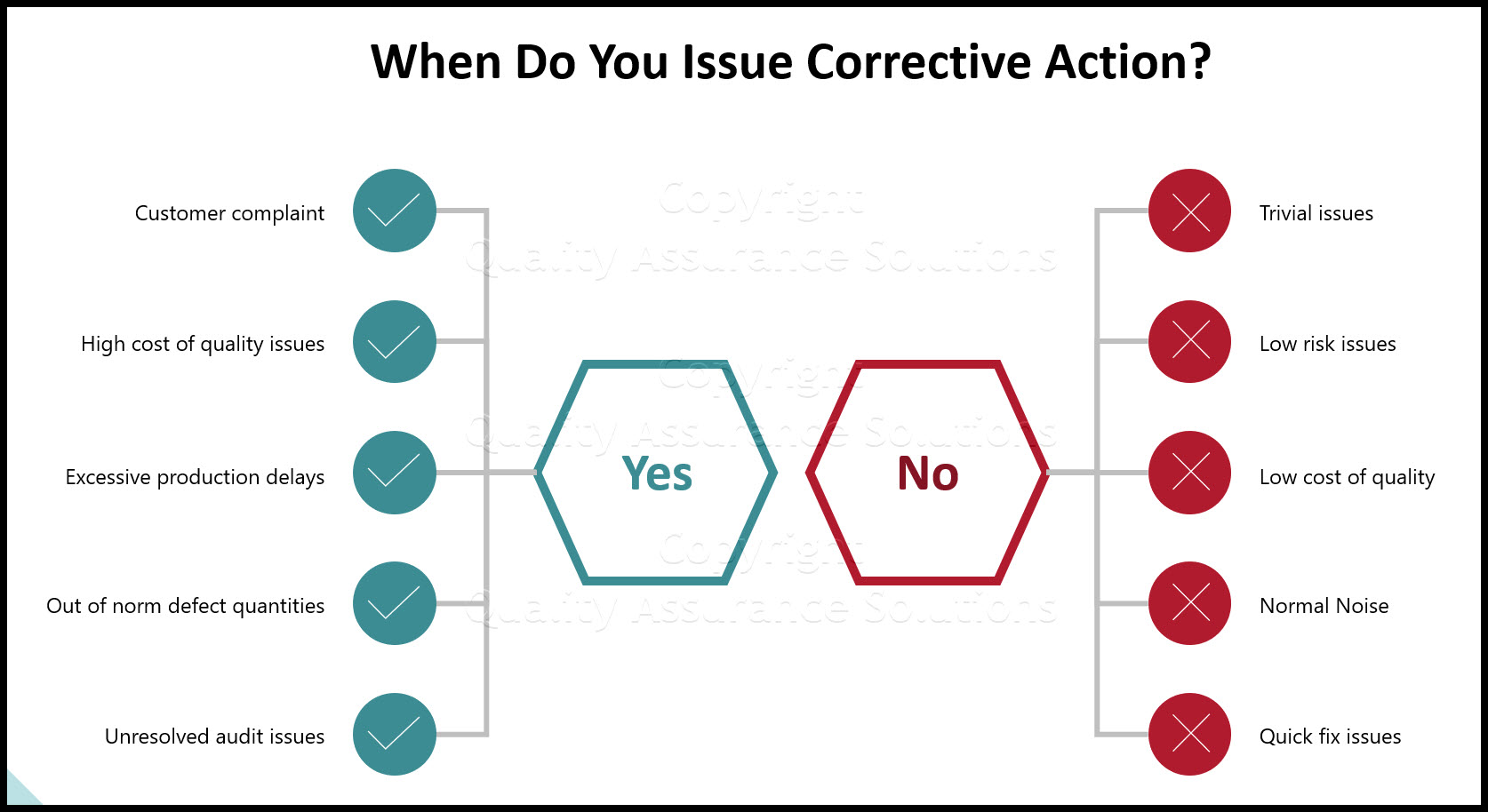

When to Apply Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is typically required when:

- Safety or Regulatory issues has been discovered

- Customer complaints are received

- Warranty Concerns have indicated greater-than-expected failure rates

- Internal rejects, waste, scrap, poor performance or test failures are present at unacceptable levels

How to Apply Eight Disciplines of Problem Solving (8D)

The 8D process alternates inductive and deductive problem solving tools to relentlessly move forward toward a solution. The Quality-One approach uses a core team of three individuals for inductive activities with data driven tools and then a larger Subject Matter Expert (SME) group for the deductive activities through brainstorming, data-gathering and experimentation.

D0: Prepare and Plan for the 8D

Proper planning will always translate to a better start. Thus, before 8D analysis begins, it is always a good idea to ask an expert first for their impressions. After receiving feedback, the following criterion should be applied prior to forming a team:

Collect information on the symptoms

Use a Symptoms Checklist to ask the correct questions

Identify the need for an Emergency Response Action (ERA), which protects the customer from further exposure to the undesired symptoms

D1: Form a Team

A Cross Functional Team (CFT) is made up of members from many disciplines. Quality-One takes this principle one step further by having two levels of CFT:

- The Core Team Structure should involve three people on the respective subjects: product, process and data

- Additional Subject Matter Experts are brought in at various times to assist with brainstorming, data collection and analysis

Teams require proper preparation. Setting the ground rules is paramount. Implementation of disciplines like checklists, forms and techniques will ensure steady progress. 8D must always have two key members: a Leader and a Champion / Sponsor:

- The Leader is the person who knows the 8D process and can lead the team through it (although not always the most knowledgeable about the problem being studied)

- The Champion or Sponsor is the one person who can affect change by agreeing with the findings and can provide final approval on such changes

D2: Describe the Problem

The 8D method’s initial focus is to properly describe the problem utilizing the known data and placing it into specific categories for future comparisons. The “Is” data supports the facts whereas the “Is Not” data does not. As the “Is Not” data is collected, many possible reasons for failure are able to be eliminated. This approach utilizes the following tools:

- Problem Statement

- Affinity Diagram (Deductive tool)

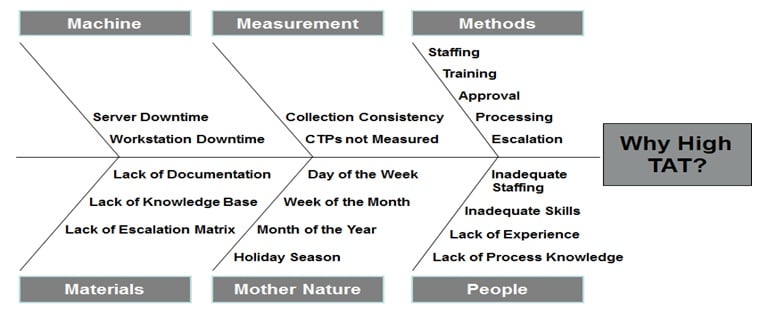

- Fishbone/Ishikawa Diagram (Deductive tool)

- Problem Description

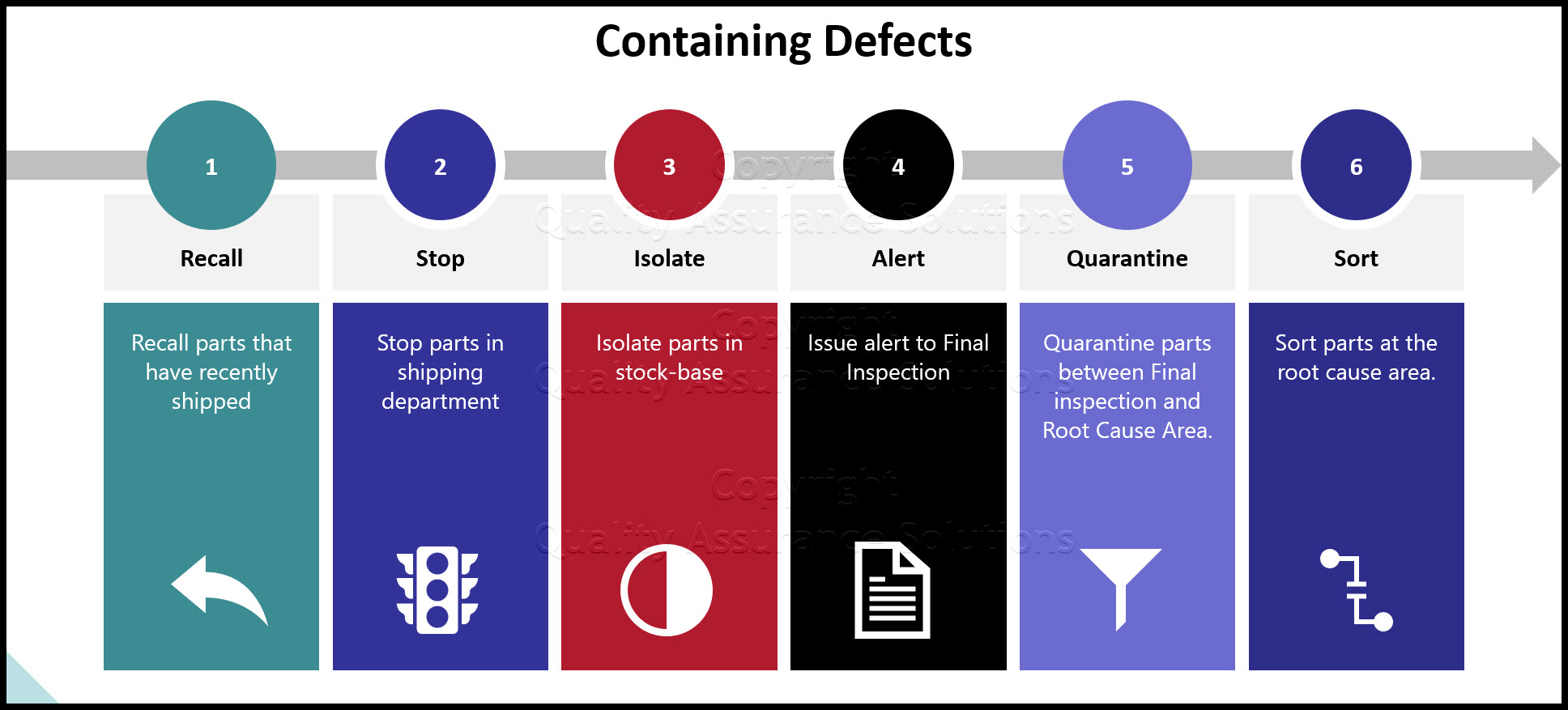

D3: Interim Containment Action

In the interim, before the permanent corrective action has been determined, an action to protect the customer can be taken. The Interim Containment Action (ICA) is temporary and is typically removed after the Permanent Correct Action (PCA) is taken.

- Verification of effectiveness of the ICA is always recommended to prevent any additional customer dissatisfaction calls

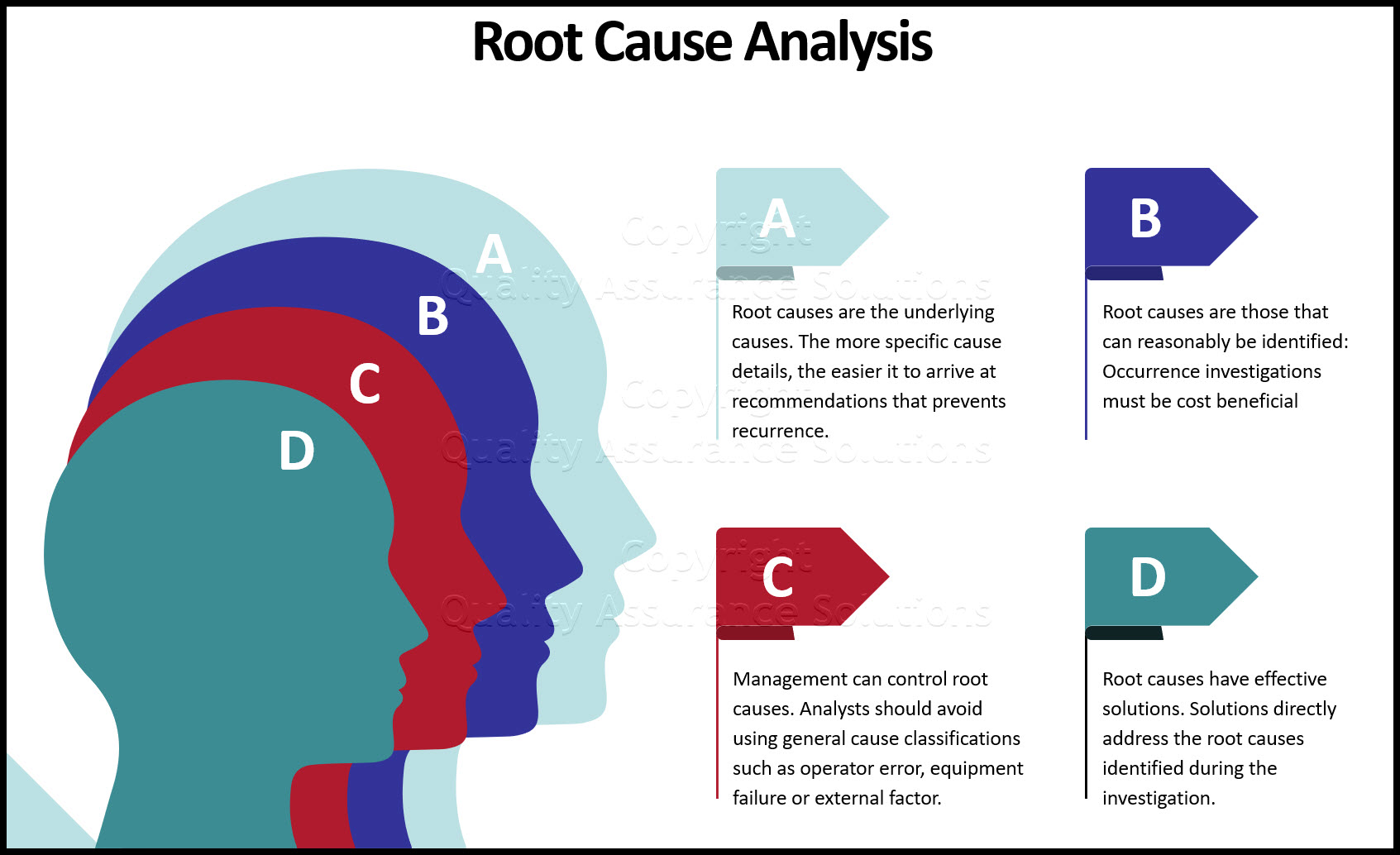

D4: Root Cause Analysis (RCA) and Escape Point

The root cause must be identified to take permanent action to eliminate it. The root cause definition requires that it can be turned on or off, at will. Activities in D4 include:

- Comparative Analysis listing differences and changes between “Is” and “Is Not”

- Development of Root Cause Theories based on remaining items

- Verification of the Root Cause through data collection

- Review Process Flow Diagram for location of the root cause

- Determine Escape Point, which is the closest point in the process where the root cause could have been found but was not

D5: Permanent Corrective Action (PCA)

The PCA is directed toward the root cause and removes / changes the conditions of the product or process that was responsible for the problem. Activities in D5 include:

- Establish the Acceptance Criteria which include Mandatory Requirements and Wants

- Perform a Risk Assessment / Failure Mode and Effects Analysis (FMEA) on the PCA choices

- Based on risk assessment, make a balanced choice for PCA

- Select control-point improvement for the Escape Point

- Verification of Effectiveness for both the PCA and the Escape Point are required

D6: Implement and Validate the Permanent Corrective Action

To successfully implement a permanent change, proper planning is essential. A project plan should encompass: communication, steps to complete, measurement of success and lessons learned. Activities in D6 include:

- Develop Project Plan for Implementation

- Communicate the plan to all stakeholders

- Validation of improvements using measurement

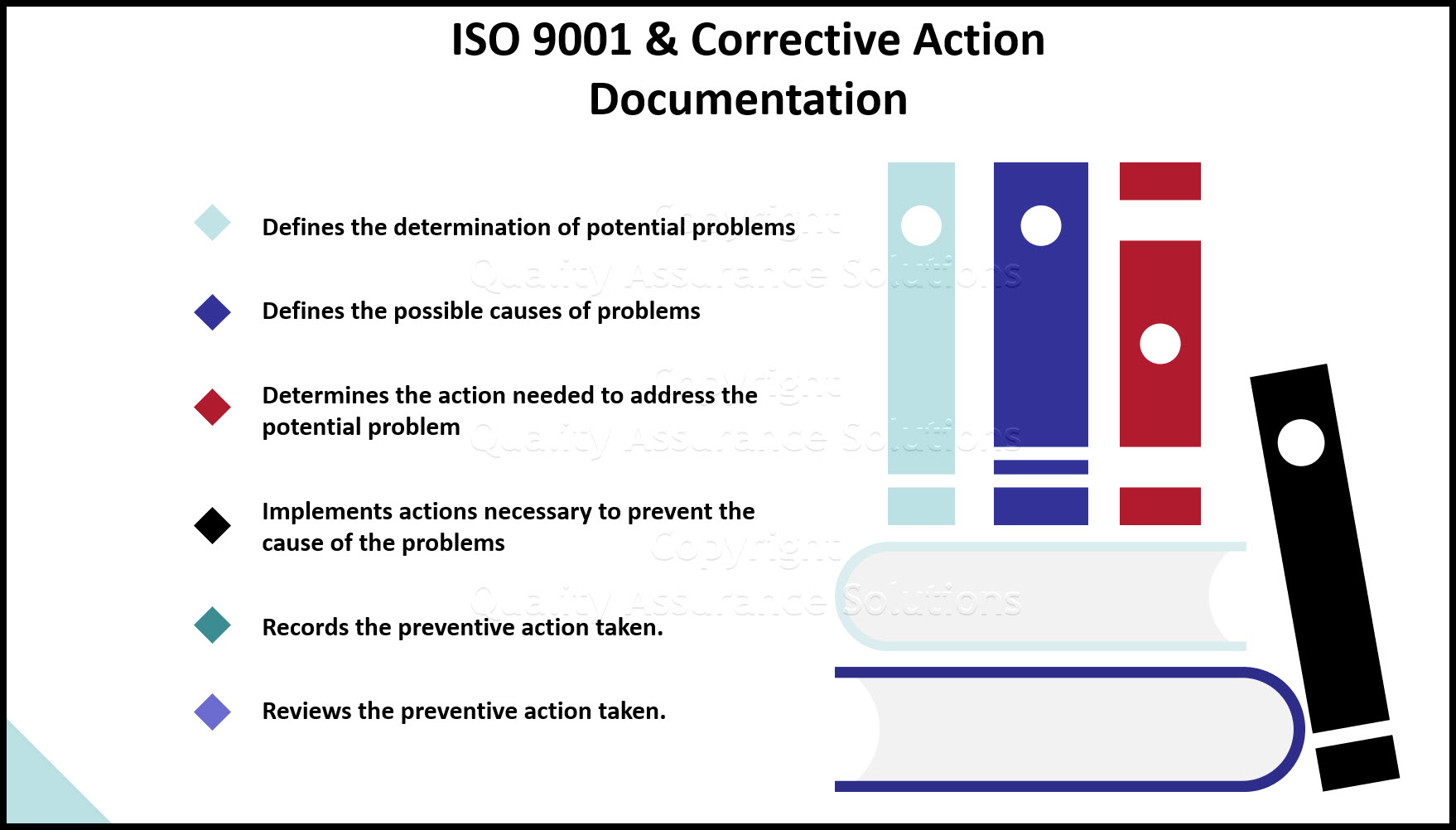

D7: Prevent Recurrence

D7 affords the opportunity to preserve and share the knowledge, preventing problems on similar products, processes, locations or families. Updating documents and procedures / work instructions are expected at this step to improve future use. Activities in D7 include:

- Review Similar Products and Processes for problem prevention

- Develop / Update Procedures and Work Instructions for Systems Prevention

- Capture Standard Work / Practice and reuse

- Assure FMEA updates have been completed

- Assure Control Plans have been updated

D8: Closure and Team Celebration

Teams require feedback to allow for satisfactory closure. Recognizing both team and individual efforts and allowing the team to see the previous and new state solidifies the value of the 8D process. Activities in D8 include:

- Archive the 8D Documents for future reference

- Document Lessons Learned on how to make problem solving better

- Before and After Comparison of issue

- Celebrate Successful Completion

8D and Root Cause Analysis (RCA)

The 8D process has Root Cause Analysis (RCA) imbedded within it. All problem solving techniques include RCA within their structure. The steps and techniques within 8D which correspond to Root Cause Analysis are as follows:

- Problem Symptom is quantified and converted to “Object and Defect”

- Problem Symptom is converted to Problem Statement using Repeated Whys

- Possible and Potential Causes are collected using deductive tools (i.e. Fishbone or Affinity Diagram)

- Problem Statement is converted into Problem Description using Is / Is Not

- Problem Description reduces the number of items on the deductive tool (from step 3)

- Comparative Analysis between the Is and Is Not items (note changes and time)

- Root Cause theories are developed from remaining possible causes on deductive tool and coupled with changes from Is / Is Not

- Compare theories with current data and develop experiments for Root Cause Verification

- Test and confirm the Root Causes

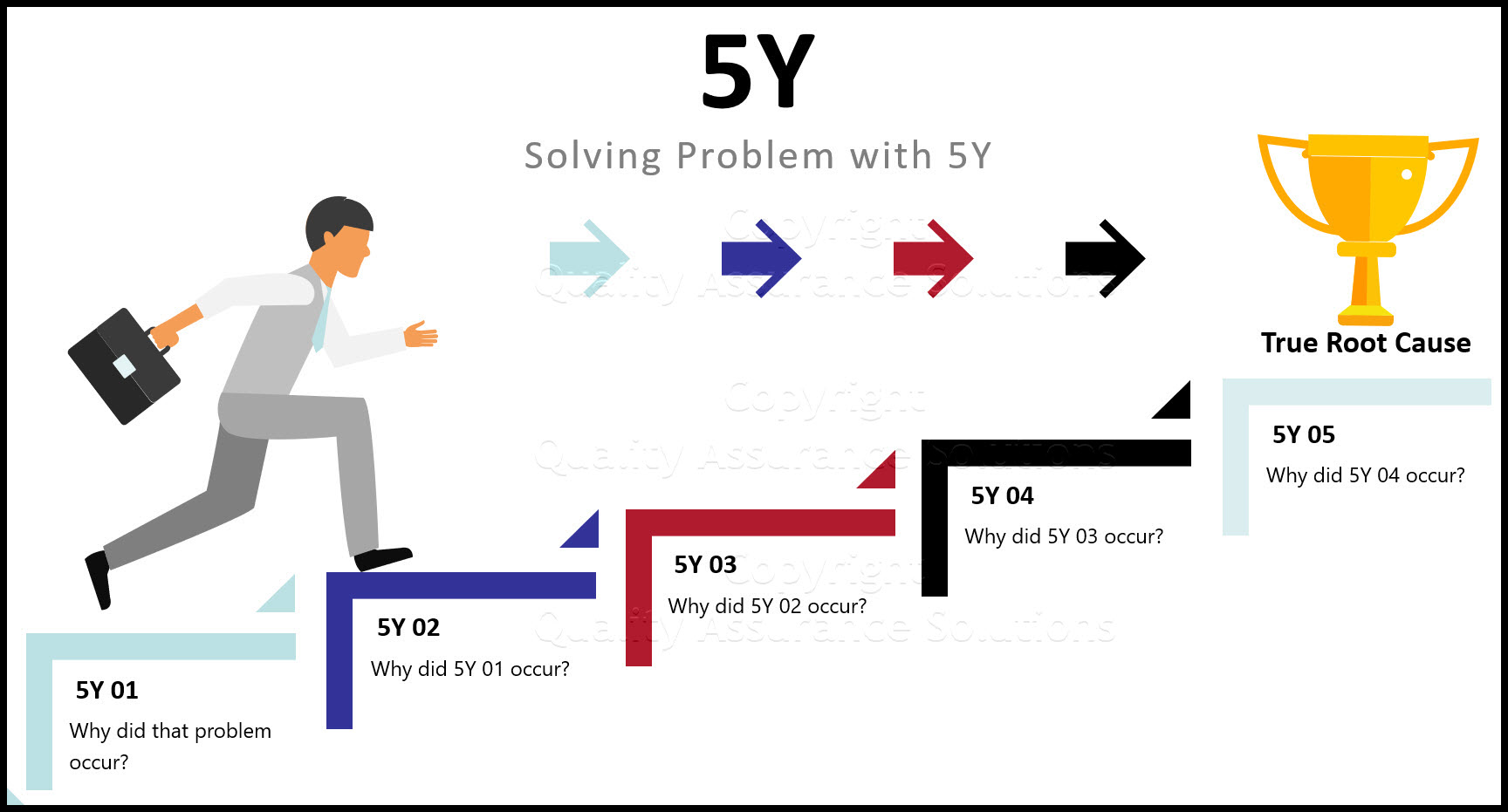

Example: Multiple Why Technique

The Multiple / Repeated Why (Similar to 5 Why) is an inductive tool, which means facts are required to proceed to a more detailed level. The steps required to determine problem statement are:

- Problem Symptom is defined as an Object and Defect i.e. “Passenger Injury”

- Why? In every case “SUV’s Roll Over”

- Why? In every case, it was preceded by a “Blown Tire”

- Why? Many explanations may be applied, therefore the team cannot continue with another repeated why past “Blown Tire”

- Therefore, the Problem Statement is “Blown Tire”

- Why? Low (Air) Pressure, Tire Defect (Degradation of an Interface) and High (Ambient) Temperature

- Counter measures assigned to low pressure and tire defect

This example uses only 4 of the 5 Whys to determine the root causes without going further into the systemic reasons that supported the failure. The Repeated Why is one way to depict this failure chain. Fault Tree Analysis (FTA) could also be used.

Learn More About Eight Disciplines of Problem Solving (8D)

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of 8D Consulting , 8D Training or 8D Project Support .

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

- Don't have an account? Register

- Lost your password? Click here

- Already have an account? Log in

- Product overview

- All features

- App integrations

CAPABILITIES

- project icon Project management

- Project views

- Custom fields

- Status updates

- goal icon Goals and reporting

- Reporting dashboards

- workflow icon Workflows and automation

- portfolio icon Resource management

- Time tracking

- my-task icon Admin and security

- Admin console

- asana-intelligence icon Asana Intelligence

- list icon Personal

- premium icon Starter

- briefcase icon Advanced

- Goal management

- Organizational planning

- Campaign management

- Creative production

- Marketing strategic planning

- Request tracking

- Resource planning

- Project intake

- View all uses arrow-right icon

- Project plans

- Team goals & objectives

- Team continuity

- Meeting agenda

- View all templates arrow-right icon

- Work management resources Discover best practices, watch webinars, get insights

- What's new Learn about the latest and greatest from Asana

- Customer stories See how the world's best organizations drive work innovation with Asana

- Help Center Get lots of tips, tricks, and advice to get the most from Asana

- Asana Academy Sign up for interactive courses and webinars to learn Asana

- Developers Learn more about building apps on the Asana platform

- Community programs Connect with and learn from Asana customers around the world

- Events Find out about upcoming events near you

- Partners Learn more about our partner programs

- Support Need help? Contact the Asana support team

- Asana for nonprofits Get more information on our nonprofit discount program, and apply.

Featured Reads

- Project management |

- What is 8D? A template for efficient pr ...

What is 8D? A template for efficient problem-solving

How you respond when problems arise is one of the most defining qualities of a manager. Luckily, there are tools you can use to master problem-solving. The 8D method of problem-solving combines teamwork and basic statistics to help you reach a logical solution and prevent new issues from arising.

You’ve spent months overseeing the development of your company's newest project. From initiation, planning, and execution, you’re confident this may be your best work yet.

Until the feedback starts rolling in.

There’s no sugar-coating it—things don’t always go as planned. But production or process issues are hardly a signal to throw in the towel. Instead, focus on honing your problem-solving skills to find a solution that keeps it from happening again.

The 8D method of problem solving emphasizes the importance of teamwork to not only solve your process woes but prevent new ones from occurring. In this guide, we’ll break down what 8D is, how to use this methodology, and the benefits it can give to you and your team. Plus, get an 8D template to make solving your issue easier.

What is 8D?

The eight disciplines (8D) method is a problem-solving approach that identifies, corrects, and eliminates recurring problems. By determining the root causes of a problem, managers can use this method to establish a permanent corrective action and prevent recurring issues.

How do you use the 8D method?

The 8D method is a proven strategy for avoiding long-term damage from recurring problems. If you’re noticing issues in your workflow or processes, then it’s a good time to give this problem-solving method a try.

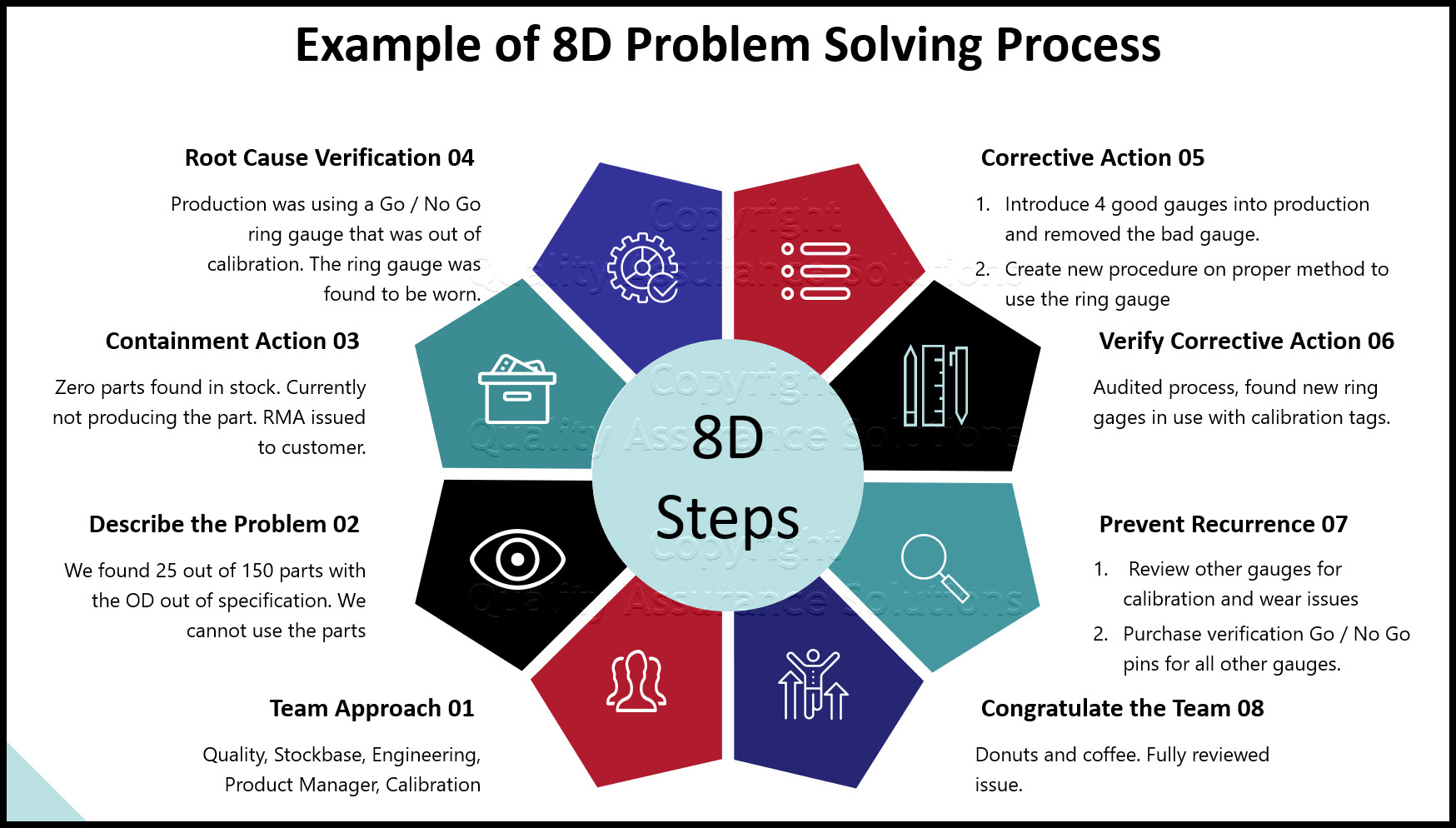

To complete an 8D analysis, follow “the eight disciplines” to construct a statistical analysis of the problem and determine the best solution.

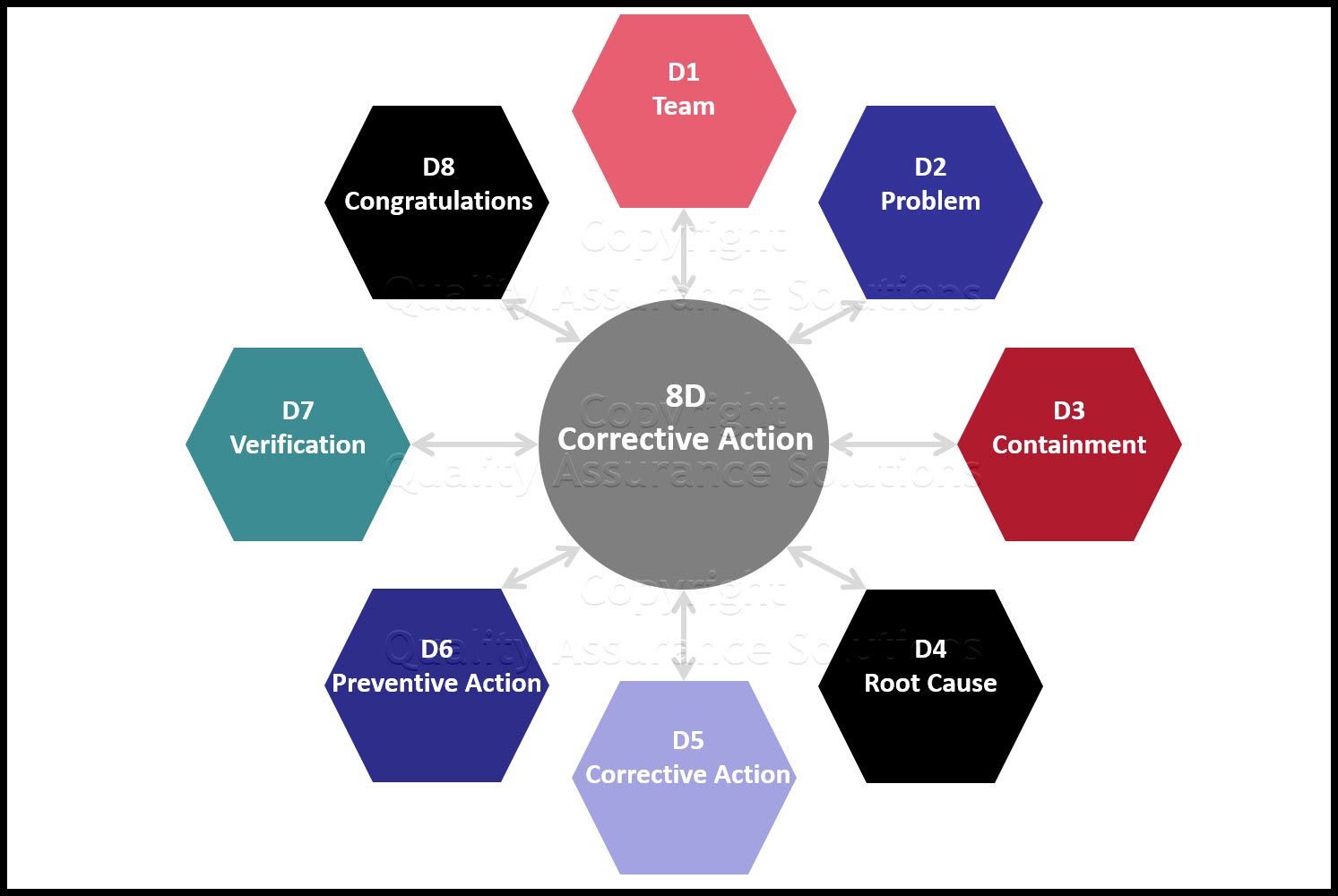

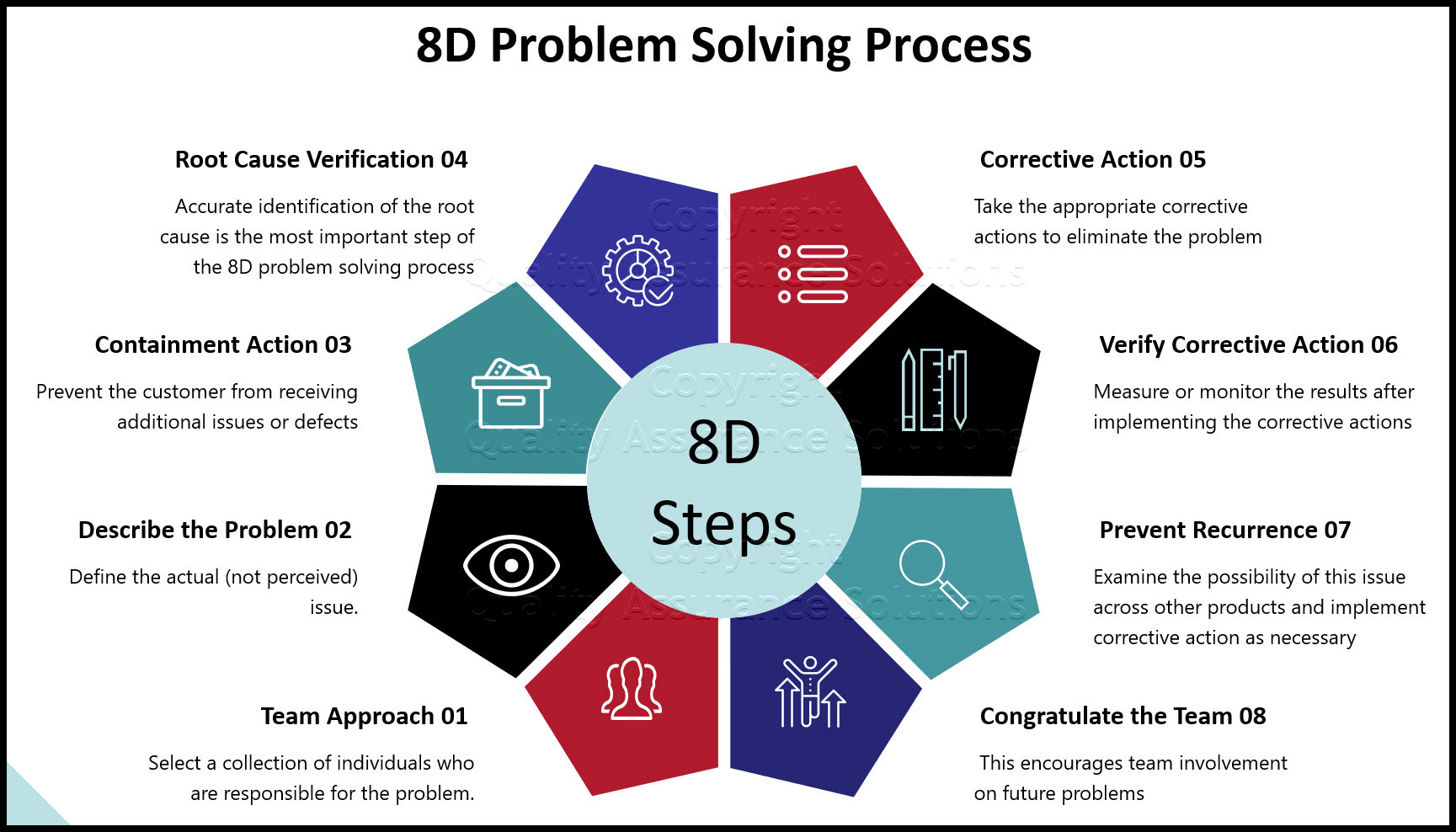

The eight disciplines of problem-solving

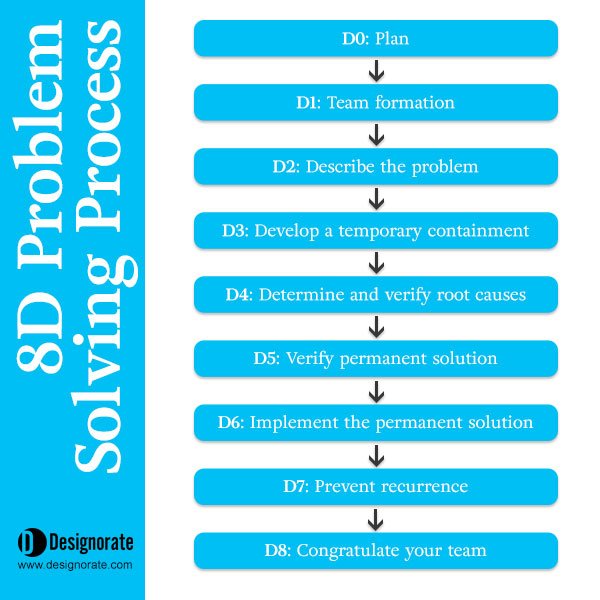

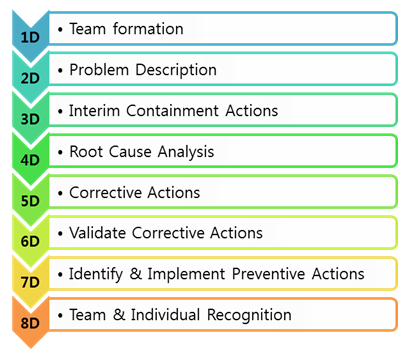

8D stands for the eight disciplines you will use to establish an 8D report. As you may notice, this outline starts with zero, which makes nine total disciplines. The “zero stage” was developed later as an initial planning stage.

To illustrate these steps, imagine your organization experienced a decline in team innovation and productivity this past year. Your stakeholders have noticed and want to see changes implemented within the next six months. Below, we’ll use the 8D process to uncover a morale-boosting solution.

![3d vs 8d problem solving [inline illustration] D8 problem solving approach (infographic)](https://assets.asana.biz/transform/6ab7c188-3258-4d2e-afe6-9a4a084cc09f/inline-productivity-8d-template-1-2x?io=transform:fill,width:2560&format=webp)

D0: Prepare and plan

Before starting the problem-solving process, evaluate the problem you want to solve. Understanding the background of the problem will help you identify the root cause in later steps.

Collect information about how the problem has affected a process or product and what the most severe consequences may be. Planning can include:

Gathering data

Determining the prerequisites for solving the problem

Collecting feedback from others involved

![3d vs 8d problem solving [inline illustration] D0 Planning (example)](https://assets.asana.biz/transform/abc3621d-e1ae-47ff-b731-0ee38cff99e9/inline-productivity-8d-template-2-2x?io=transform:fill,width:2560&format=webp)

If we look back at our example, you may want to figure out whether this decline in morale is organization-wide or only applies to a few departments. Consider interviewing a few employees from different departments and levels of management to gain some perspective. Next, determine what knowledge and skills you will need to solve this lapse in productivity.

D1: Form your team

Create a cross-functional team made up of people who have knowledge of the various products and workflows involved. These team members should have the skills needed to solve the problem and put corrective actions in place.

Steps in this discipline may include:

Appointing a team leader

Developing and implementing team guidelines

Determining team goals and priorities

Assigning individual roles

Arranging team-building activities

![3d vs 8d problem solving [inline illustration] D1 Team members (example)](https://assets.asana.biz/transform/51986017-5150-4dd4-940c-252cd0eb8ba5/inline-productivity-8d-template-3-2x?io=transform:fill,width:2560&format=webp)

From our example, a solid team would consist of people with first-hand experience with the issues—like representatives from all departments and key people close to workshop-level work. You may also want to pull someone in from your HR department to help design and implement a solution. Most importantly, make sure the people you choose want to be involved and contribute to the solution.

D2: Identify the problem

You may have a good understanding of your problem by now, but this phase aims to break it down into clear and quantifiable terms by identifying the five W’s a and two H’s (5W2H):

Who first reported the problem?

What is the problem about?

When did it occur and how often?

Where did it occur (relating to the sector, supplier, machine, or production line involved)?

Why is solving the problem important?

How was the problem first detected?

How many parts/units/customers are affected?

![3d vs 8d problem solving [inline illustration] D2 Problem statement & description (example)](https://assets.asana.biz/transform/9825ecd6-2bd3-4559-a68c-b1ae8aca2e52/inline-productivity-8d-template-4-2x?io=transform:fill,width:2560&format=webp)

Use your team’s insights to answer these questions. From our example, your team may conclude that:

Employees feel overwhelmed with their current workload.

There is no real structure or opportunity to share new ideas.

Managers have had no training for meetings or innovation settings.

Disgruntled employees know they can achieve more—and want to achieve more—even if they seem disengaged.

Once you answer these questions, record an official problem statement to describe the issue. If possible, include photos, videos, and diagrams to ensure all parties have a clear understanding of the problem. It may also help to create a flowchart of the process that includes various steps related to the problem description.

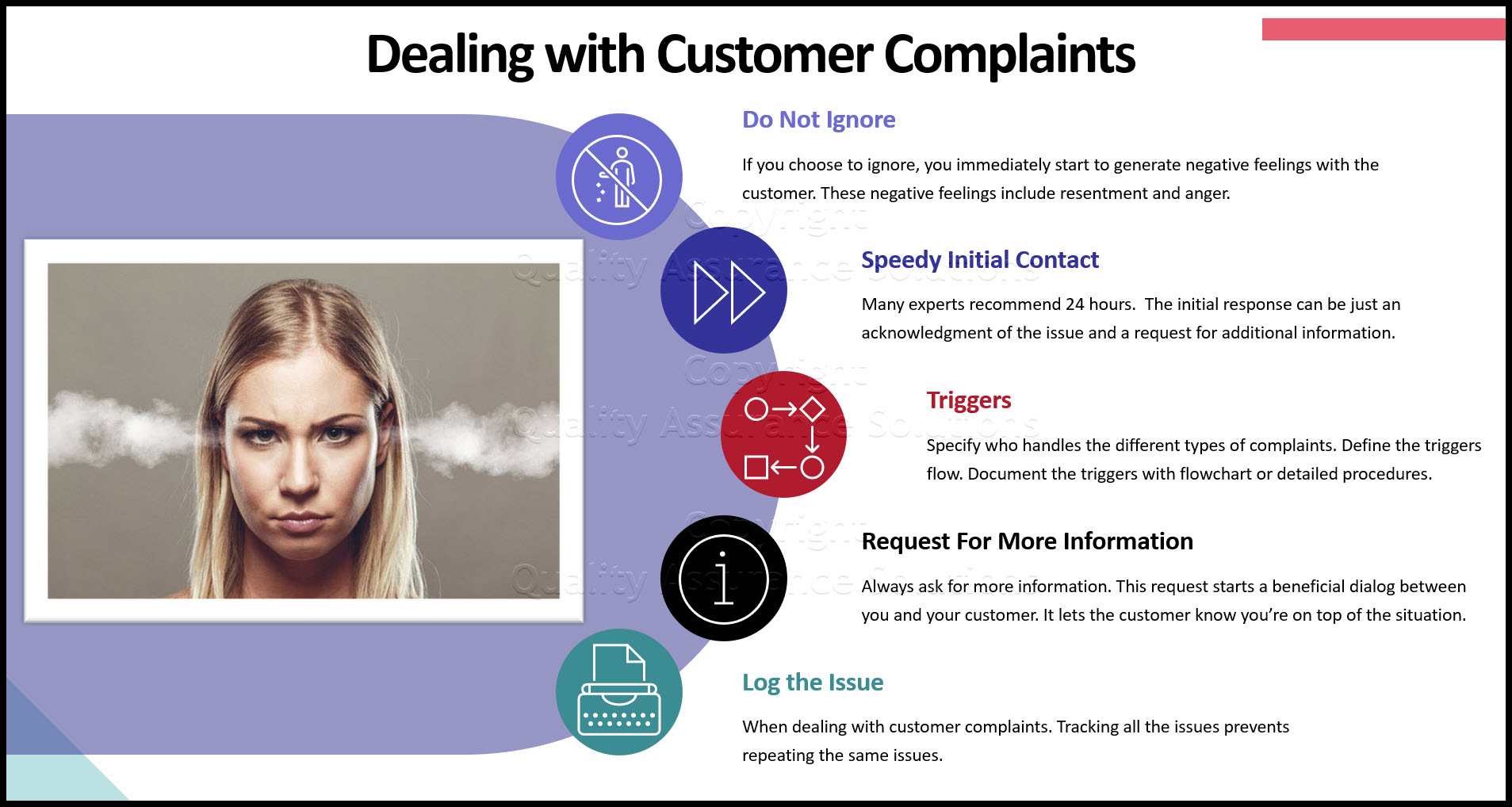

D3: Develop an interim containment plan

Much like we can expect speedy first aid after an accident, your team should take immediate actions to ensure you contain the problem—especially if the problem is related to customer safety.

An interim containment plan will provide a temporary solution to isolate the problem from customers and clients while your team works to develop a permanent corrective action. This band-aid will help keep your customers informed and safe—and your reputation intact.

![3d vs 8d problem solving [inline illustration] D3 Interim containment action (example)](https://assets.asana.biz/transform/d6279c36-ccc6-4de3-89d2-f221632a1059/inline-productivity-8d-template-5-2x?io=transform:fill,width:2560&format=webp)

Because your findings revealed workers were overworked and managers lacked training, your team suggests scheduling a few mandatory training sessions for leaders of each department covering time and stress management and combating burnout . You may also want to have a presentation outlining the topics of this training to get key managers and stakeholders interested and primed for positive upcoming changes.

D4: Verify root causes and escape points

Refer back to your findings and consult with your team about how the problem may have occurred. The root cause analysis involves mapping each potential root cause against the problem statement and its related test data. Make sure to test all potential causes—fuzzy brainstorming and sloppy analyses may cause you to overlook vital information.

![3d vs 8d problem solving [inline illustration] D4 Root cause & escape points (example)](https://assets.asana.biz/transform/301717c6-0434-4c88-addf-d500dc23ae87/inline-productivity-8d-template-6-2x?io=transform:fill,width:2560&format=webp)

In our example, focus on the “why” portion of the 5W2H. You and your team identify six root causes:

Managers have never had any training

There is a lack of trust and psychological safety

Employees don’t understand the objectives and goals

Communication is poor

Time management is poor

Employees lack confidence

In addition to identifying the root causes, try to pinpoint where you first detected the problem in the process, and why it went unnoticed. This is called the escape point, and there may be more than one.

D5: Choose permanent corrective actions

Work with your team to determine the most likely solution to remove the root cause of the problem and address the issues with the escape points. Quantitatively confirm that the selected permanent corrective action(s) (PCA) will resolve the problem for the customer.

Steps to choosing a PCA may include:

Determining if you require further expertise

Ensuring the 5W2Hs are defined correctly

Carrying out a decision analysis and risk assessment

Considering alternative measures

Collecting evidence to prove the PCA will be effective

![3d vs 8d problem solving [inline illustration] D5 Permanent corrective action (example)](https://assets.asana.biz/transform/53509966-18dd-4bb4-88a1-c7ca940fde3f/inline-productivity-8d-template-7-2x?io=transform:fill,width:2560&format=webp)

Your team decides to roll out the training used in the interim plan to all employees, with monthly company-wide workshops on improving well-being. You also plan to implement meetings, innovation sessions, and team-coaching training for managers. Lastly, you suggest adopting software to improve communication and collaboration.

D6: Implement your corrective actions

Once all parties have agreed on a solution, the next step is to create an action plan to remove the root causes and escape points. Once the solution is in effect, you can remove your interim containment actions.

After seeing success with the training in the interim phase, your stakeholders approve all of your team’s proposed PCAs. Your representative from HR also plans to implement periodic employee wellness checks to track employee morale .

![3d vs 8d problem solving [inline illustration] D6 PCA implementation plan (example)](https://assets.asana.biz/transform/ca68af4a-afa7-4be4-93cb-8a8321eb5172/inline-productivity-8d-template-8-2x?io=transform:fill,width:2560&format=webp)

To ensure your corrective action was a success, monitor the results, customer, or employee feedback over a long period of time and take note of any negative effects. Setting up “controls” like employee wellness checks will help you validate whether your solution is working or more needs to be done.

D7: Take preventive measures

One of the main benefits of using the 8D method is the improved ability to identify necessary systematic changes to prevent future issues from occurring. Look for ways to improve your management systems, operating methods, and procedures to not only eliminate your current problem, but stop similar problems from developing later on.

![3d vs 8d problem solving [inline illustration] D7 Preventive measure (example)](https://assets.asana.biz/transform/cdd7b133-fb80-4db7-8935-1285a6b62b69/inline-productivity-8d-template-9-2x?io=transform:fill,width:2560&format=webp)

Based on our example, the training your team suggested is now adopted in the new manager onboarding curriculum. Every manager now has a “meeting system” that all meetings must be guided by, and workloads and projects are managed as a team within your new collaboration software . Innovation is improving, and morale is at an all-time high!

D8: Celebrate with your team

The 8D method of problem-solving is impossible to accomplish without dedicated team members and first-class collaboration. Once notes, lessons, research, and test data are documented and saved, congratulate your teammates on a job well done! Make an effort to recognize each individual for their contribution to uncovering a successful solution.

![3d vs 8d problem solving [inline illustration] 8D Team congratulations & reward (example)](https://assets.asana.biz/transform/d2055965-bf3d-4bf4-a1ea-a0a7c4bf8a32/inline-productivity-8d-template-10-2x?io=transform:fill,width:2560&format=webp)

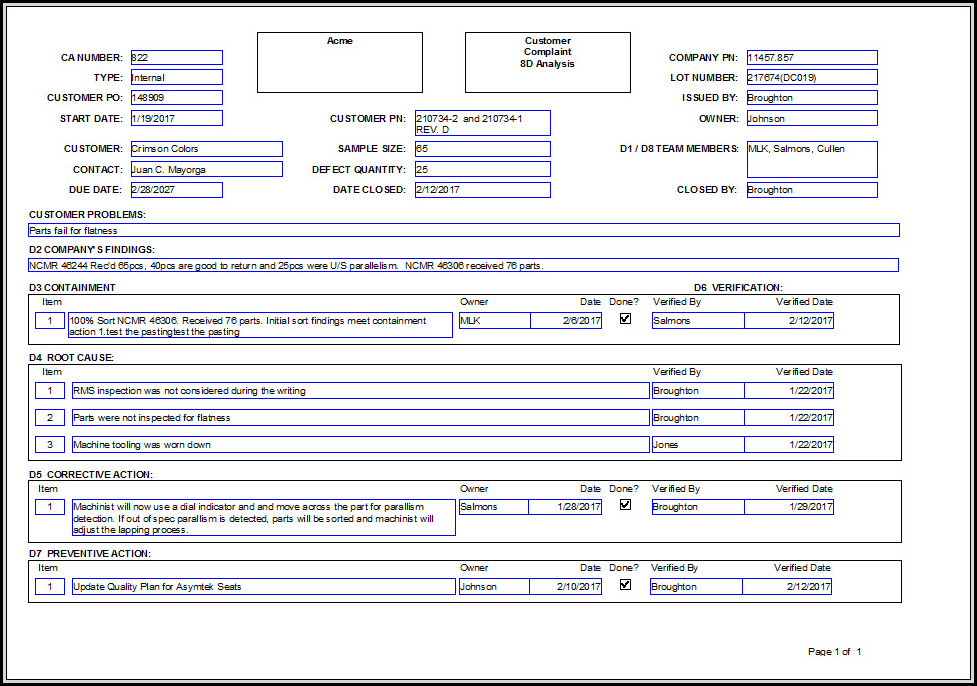

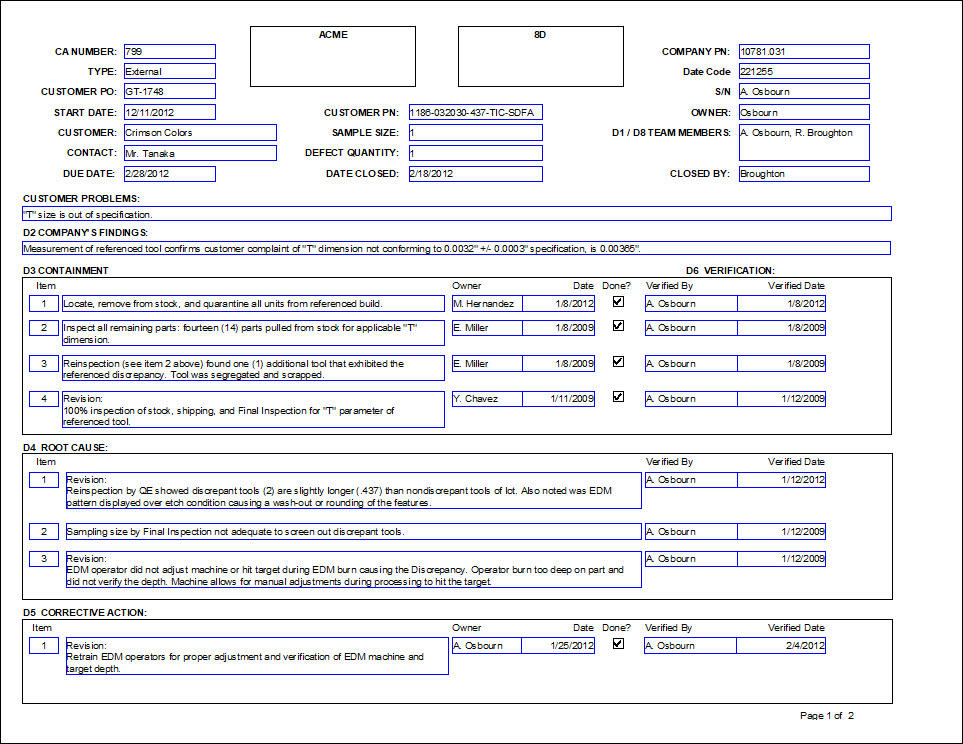

8D report template and example

Check out our 8D report template below to help you record your findings as you navigate through the eight disciplines of problem solving. This is a formal report that can be used as a means of communication within companies, which makes for transparent problem-solving that you can apply to the entire production or process chain.

Benefits of using the 8D method

The 8D method is one of the most popular problem-solving strategies for good reason. Its strength lies in teamwork and fact-based analyses to create a culture of continuous improvement —making it one of the most effective tools for quality managers. The benefits of using the 8D method include:

Improved team-oriented problem-solving skills rather than relying on an individual to provide a solution

Increased familiarity with a problem-solving structure

A better understanding of how to use basic statistical tools for problem-solving

Open and honest communication in problem-solving discussions

Prevent future problems from occurring by identifying system weaknesses and solutions

Improved effectiveness and efficiency at problem-solving

Better collaboration = better problem solving

No matter how good a manager you are, production and process issues are inevitable. It’s how you solve them that separates the good from the great. The 8D method of problem solving allows you to not only solve the problem at hand but improve team collaboration, improve processes, and prevent future issues from arising.

Try Asana’s project management tool to break communication barriers and keep your team on track.

Related resources

What are story points? Six easy steps to estimate work in Agile

What is a flowchart? Symbols and types explained

How to choose project management software for your team

7 steps to complete a social media audit (with template)

How it works

For Business

Join Mind Tools

Article • 8 min read

8D Problem Solving Process

Solving major problems in a disciplined way.

By the Mind Tools Content Team

(Also known as Global 8D Problem Solving)

When your company runs into a major problem, you need to address it quickly. However, you also need to deal with it thoroughly and ensure that it doesn't recur – and this can take a lot of effort and elapsed time.

The 8D Problem Solving Process helps you do both of these seemingly-contradictory things, in a professional and controlled way. In this article, we'll look at the 8D Problem Solving Process, and we'll discuss how you can use it to help your team solve major problems.

Origins of the Tool

The Ford Motor Company® developed the 8D (8 Disciplines) Problem Solving Process, and published it in their 1987 manual, "Team Oriented Problem Solving (TOPS)." In the mid-90s, Ford added an additional discipline, D0: Plan. The process is now Ford's global standard, and is called Global 8D.

Ford created the 8D Process to help teams deal with quality control and safety issues; develop customized, permanent solutions to problems; and prevent problems from recurring. Although the 8D Process was initially applied in the manufacturing, engineering, and aerospace industries, it's useful and relevant in any industry.

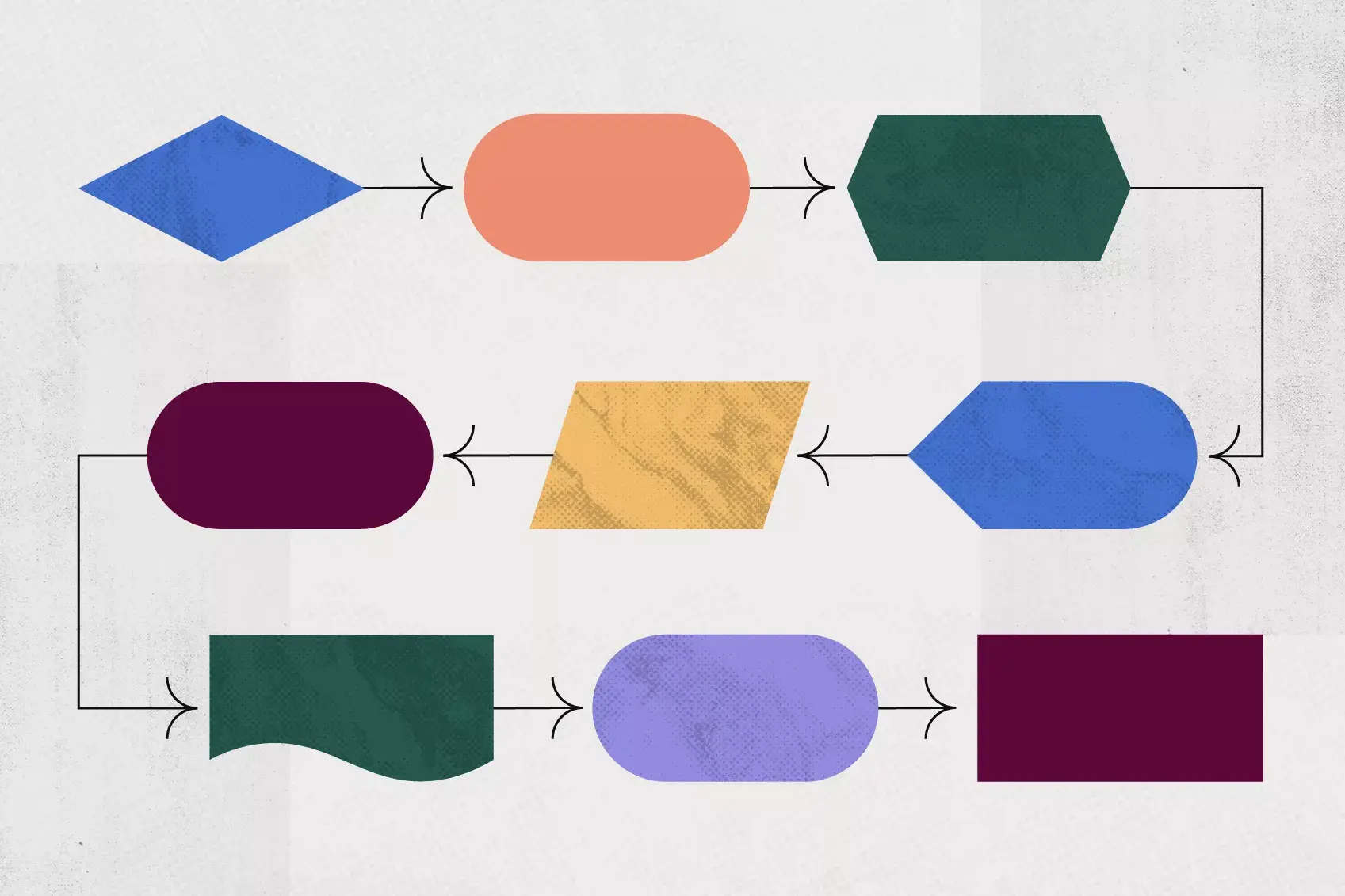

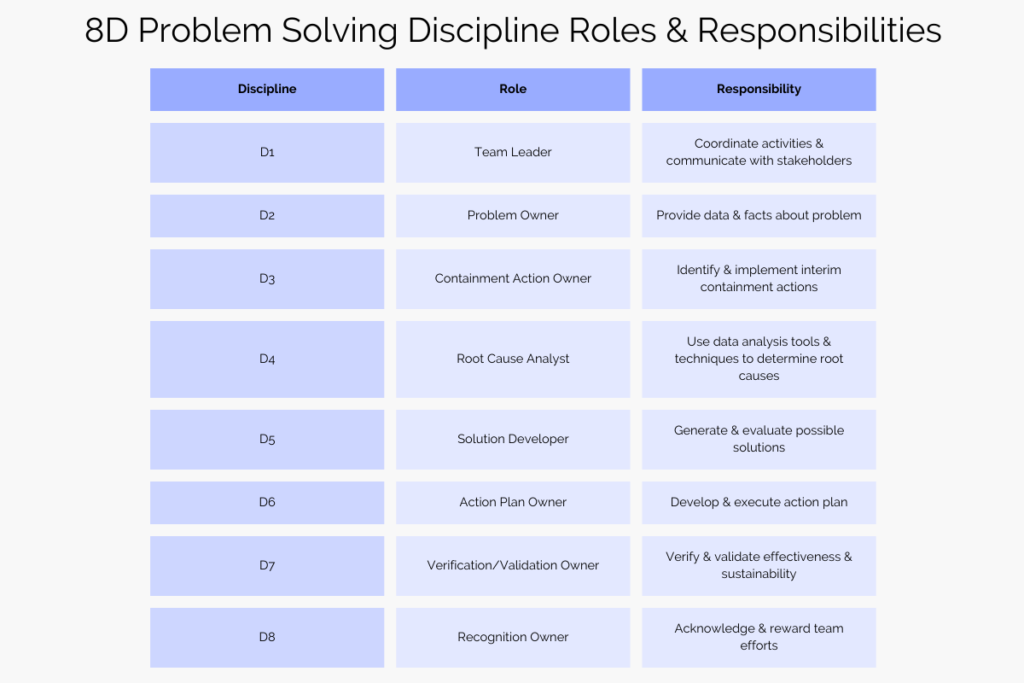

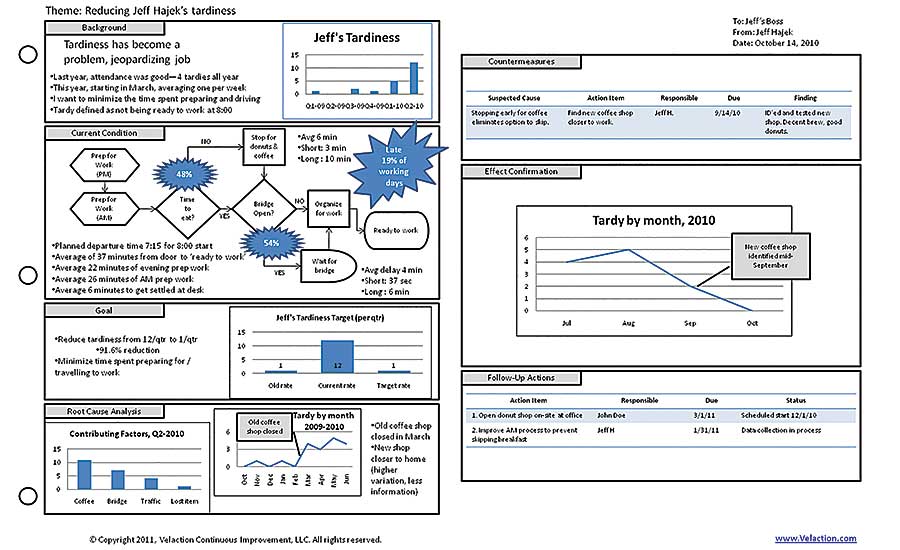

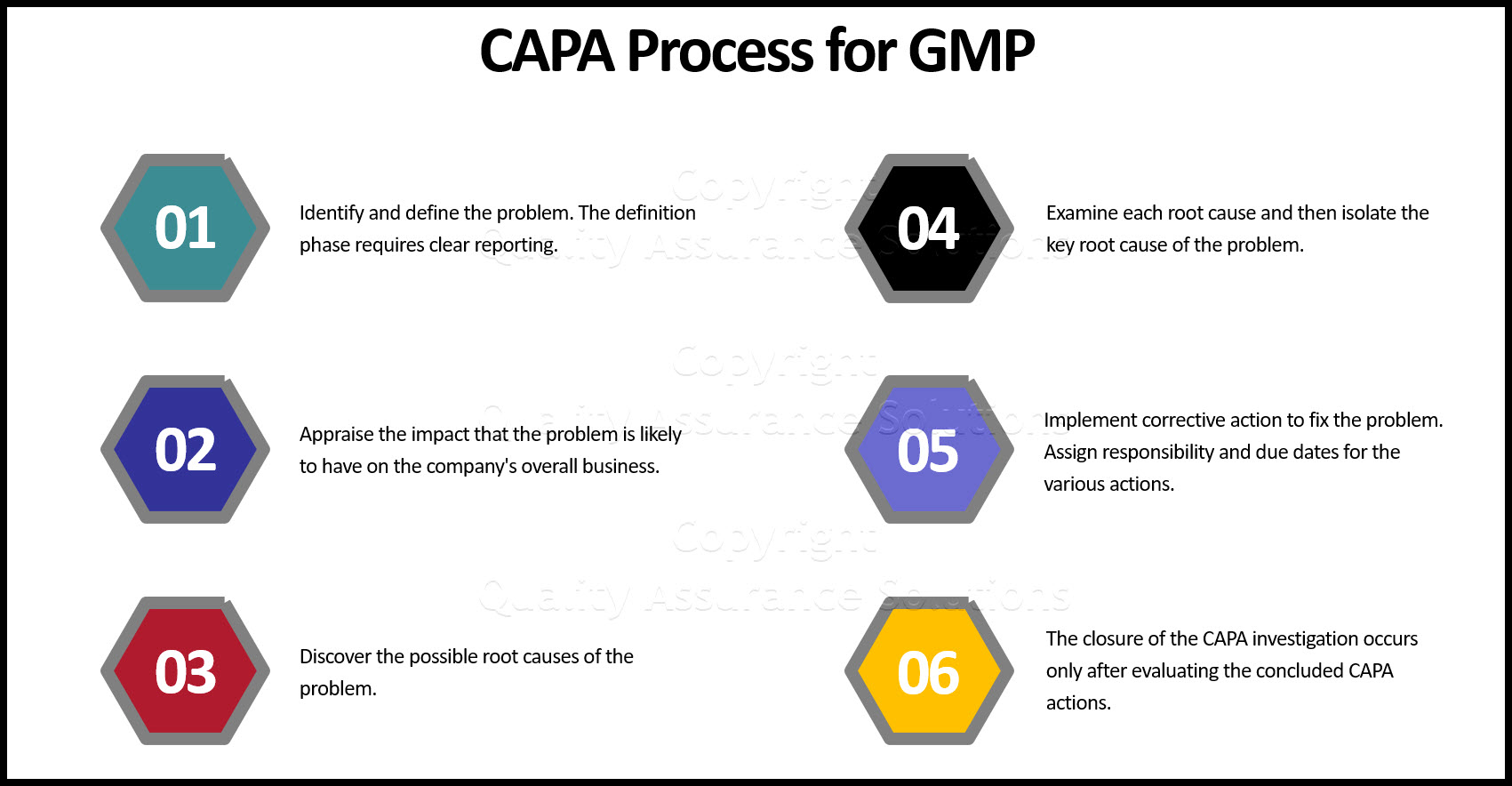

The eight disciplines are shown in figure 1, below:

Figure 1: The 8D Problem Solving Process

The 8D Process works best in teams tasked with solving a complex problem with identifiable symptoms. However, you can also use this process on an individual level, as well.

Applying the Tool

To use the 8D Process, address each of the disciplines listed below, in order. Take care not to skip steps, even when time is limited; the process is only effective when you follow every step.

Discipline 0: Plan

Before you begin to assemble a team to address the problem, you need to plan your approach. This means thinking about who will be on the team, what your time frame is, and what resources you'll need to address the problem at hand.

Discipline 1: Build the Team

You should aim to put together a team that has the skills needed to solve the problem, and that has the time and energy to commit to the problem solving process.

Keep in mind that a diverse team is more likely to find a creative solution than a team of people with the same outlook (although if outlooks are too diverse, people can spend so much time disagreeing that nothing gets done).

Create a team charter that outlines the team's goal and identifies each person's role. Then, do what you can to build trust and get everyone involved in the process that's about to happen.

If your team is made up of professionals who haven't worked together before, consider beginning with team-building activities to ensure that everyone is comfortable working with one another.

Discipline 2: Describe the Problem

Once your team has settled in, describe the problem in detail. Specify the who, what, when, where, why, how, and how many; and use techniques like CATWOE and the Problem-Definition Process to ensure that you're focusing on the right problem.

Start by doing a Risk Analysis – if the problem is causing serious risks, for example, to people's health or life, then you need to take appropriate action. (This may include stopping people using a product or process until the problem is resolved.)

If the problem is with a process, use a Flow Chart , Swim Lane Diagram , or Storyboard to map each step out; these tools will help your team members understand how the process works, and, later on, think about how they can best fix it.

Discovering the root cause of the problem comes later in the process, so don't spend time on this here. Right now, your goal is to look at what's going wrong and to make sure that your team understands the full extent of the problem.

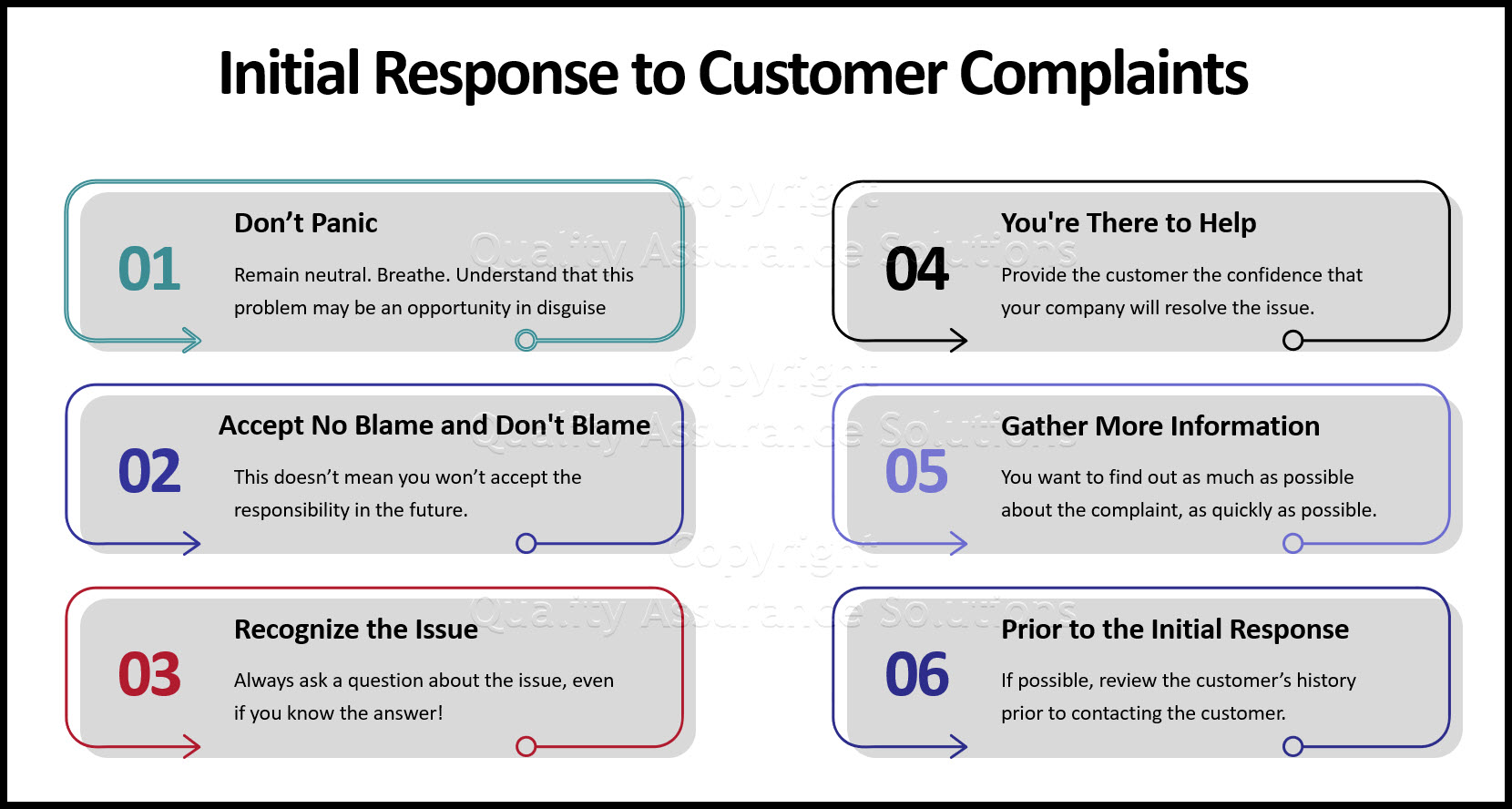

Discipline 3: Implement a Temporary Fix

Once your team understands the problem, come up with a temporary fix. This is particularly important if the problem is affecting customers, reducing product quality, or slowing down work processes.

Harness the knowledge of everyone on the team. To ensure that each person's ideas are heard, consider using brainstorming techniques such as Round Robin Brainstorming or Crawford's Slip Writing Method , alongside more traditional team problem solving discussions.

Once the group has identified possible temporary fixes, address issues such as cost, implementation time, and relevancy. The short-term solution should be quick, easy to implement, and worth the effort.

Discipline 4: Identify and Eliminate the Root Cause

Once your temporary fix is in place, it's time to discover the root cause of the problem.

Conduct a Cause and Effect Analysis to identify the likely causes of the problem. This tool is useful because it helps you uncover many possible causes, and it can highlight other problems that you might not have been aware of. Next, apply Root Cause Analysis to find the root causes of the problems you've identified.

Once you identify the source of the problem, develop several permanent solutions to it.

If your team members are having trouble coming up with viable permanent solutions, use the Straw Man Concept to generate prototype solutions that you can then discuss, tear apart, and rebuild into stronger solutions.

Discipline 5: Verify the Solution

Once your team agrees on a permanent solution, make sure that you test it thoroughly before you fully implement it, in the next step.

- Conducting a Failure Mode and Effects Analysis (FMEA) to spot any potential problems.

- Using Impact Analysis to make sure that there will be no unexpected future consequences.

- Using Six Thinking Hats to examine the fix from several different emotional perspectives.

Last, conduct a Blind Spot Analysis to confirm that you and your team haven't overlooked a key factor, or made an incorrect assumption about this solution.

Discipline 6: Implement a Permanent Solution

Once your team reaches a consensus on the solution, roll your fix out. Monitor this new solution closely for an appropriate period of time to make sure that it's working correctly, and ensure that there are no unexpected side effects.

Discipline 7: Prevent the Problem From Recurring

When you're sure that the permanent solution has solved the problem, gather your team together again to identify how you'll prevent the problem from recurring in the future.

You might need to update your organization's standards, policies, procedures, or training manual to reflect the new fix. You'll likely also need to train others on the new process or standard. Finally, you'll need to consider whether to change your management practices or procedures to prevent a recurrence.

Discipline 8: Celebrate Team Success

The last step in the process is to celebrate and reward your team's success . Say "thank you" to everyone involved, and be specific about how each person's hard work has made a difference. If appropriate, plan a party or celebration to communicate your appreciation.

Before the team disbands, conduct a Post-Implementation Review to analyze whether your solution is working as you thought, and to improve the way that you solve problems in the future.

In the late 1980s, Ford Motor Company developed the 8D (8 Disciplines) Problem Solving Process to help manufacturing and engineering teams diagnose, treat, and eliminate quality problems. However, teams in any industry can use this problem solving process.

The eight disciplines are:

- Build the Team.

- Describe the Problem.

- Implement a Temporary Fix.

- Identify and Eliminate the Root Cause.

- Verify the Solution.

- Implement a Permanent Solution.

- Prevent the Problem From Recurring.

- Celebrate Team Success.

The 8D Problem Solving Process is best used with a team solving complex problems; however, individuals can also use it to solve problems on their own.

Ford is a registered trademark of the Ford Motor Company: https://www.ford.com/

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Win-win negotiation.

Finding Solutions That Work for Everyone

Thomas Davenport and Larry Prusak: Working Knowledge

The Five Modes of Knowledge Generation According to Davenport and Prusak

Add comment

Comments (0)

Be the first to comment!

Gain essential management and leadership skills

Busy schedule? No problem. Learn anytime, anywhere.

Subscribe to unlimited access to meticulously researched, evidence-based resources.

Join today and take advantage of our 30% offer, available until May 31st .

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Latest Updates

Winning Body Language

Business Stripped Bare

Mind Tools Store

About Mind Tools Content

Discover something new today

Nine ways to get the best from x (twitter).

Growing Your Business Quickly and Safely on Social Media

Managing Your Emotions at Work

Controlling Your Feelings... Before They Control You

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

Breaking the glass ceiling video.

How to Smash Through Invisible Barriers

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Team Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

- Guide: 8D Problem Solving

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: June 13, 2023

- Learn Lean Sigma

8D Problem Solving is a systematic and structured approach used to solve business related problems. It names has been given by the fact there are 8 steps or 8 disciplines that are followed to identify, correct and eliminate recurring problems.

8D Problem Solving is regarded as robust methodology that has proven its worth across multiple industries and manufacturing in particular. The methodology was Initially developed within the automotive industry, it has since been widely adopted in manufacturing, logistics and health care to name a few. The 8D approach goes beyond helping team just identify the root cause of problem but also provides a structured approach for implementing and verifying corrective actions.

Table of Contents

What is 8d problem solving.

The 8D Problem-Solving methodology was developed in the late 1980s by Ford Motor Company. The term “8D” stands for “Eight Disciplines,” which represent the eight critical steps in problem-solving.

Initially it was only intended to resolve issues within the automotive manufacturing process. However, over the year since then the methodology has gained universal acceptance and is now applied across various sectors. The 8D approach was heavily influenced by quality management systems like Total Quality Management (TQM) and methodologies like Six Sigma and forms a key part of quality roles and Six sigma qualifications.

8D is also encourages collaborative team based approach to addressing issues in the workplace This methodology was purposefully designed to be a cross-functional effort, ensuring to bring together expertise from different departments or disciplines to comprehensively address an issue by looking at it from all point of view. Here are the key components:

Preparation : Before diving into problem-solving, the team gathers all necessary resources and tools.

Team Establishment : A cross-functional team is assembled, each member having a specific role and responsibility.

Problem Description : The issue at hand is clearly defined to ensure everyone has a shared understanding.

Interim Actions : Short-term solutions are implemented to contain the problem and prevent further damage.

Root Cause Analysis : Various tools and methods are used to identify the real cause of the problem.

Permanent Corrective Actions : Long-term solutions are selected and verified to eliminate the root cause.

Implementation : The long-term solutions are implemented across the board, including necessary changes to policies and procedures.

Prevent Recurrence : Measures are taken to ensure that the problem does not occur again.

Team Recognition : The team is congratulated and acknowledged for their efforts.

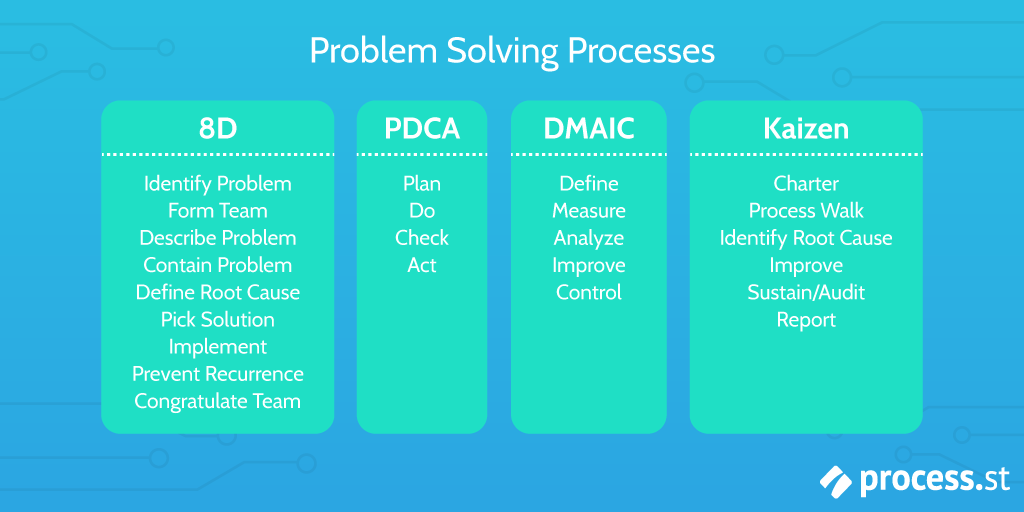

How does 8D Compare to over Problem-Solving Methods?

Between quality management systems and lean six sigma there are several problem-solving methodologies such as PDCA (Plan-Do-Check-Act), DMAIC (Define-Measure-Analyze-Improve-Control), and A3 . However the combination of the 8D steps results in a comprehensive frame work that is:

Team-Oriented : Unlike some methodologies that can be carried out by individuals, 8D strongly emphasizes team collaboration as a core principle as seen in steps D1 and D8.

Structured Framework : 8D provides a very detailed, step-by-step guide for solving complex problems, by breaking it down in to logical steps making it easier to manage and track progress.

Broad Applicability : While some methodologies like DMAIC are closely tied to Six Sigma, 8D can be applied in various contexts without being tied to a particular quality management system.

Focus on Prevention : 8D not only aims to solve the problem but also focuses on implementing changes to prevent its recurrence, making it a complete approach to problem solving.

The 8 Disciplines Explained

D0: prepare for the process.

Before you start 8D you should prepare for the 8D process. This phase sets the foundation for the entire methodology, ensuring that the team is able to tackle the problem effectively. Therefore, effective preparation helps in avoiding unnecessary delays and ensures that you’re not solving the wrong problem.

Within the initial preparation step you should also the time to think about what knowledge, expertise and experience you need within the team. Cross-functional teams are important, as they bring alternative perspectives and skills to the table rather than everyone looking at the problem from one point of view. Make sure you consider expertise, availability, and interest when selecting team members.

D1: Establish the Team

In D1 you should establish the team by clearly defining the roles and responsibilities for each team member. This includes assigning a team leader, subject matter experts, and roles for data collection , analysis, and communication this helps to provide the team members clarity on how they will be involved and contribute to the success of the problems solving activity.

Team Composition

Once roles are defined, where possible ensure that the team is balanced in terms of skills and expertise. A well-rounded team will be more effective in tackling various aspects of the problem.

Communication

Establish clear methods communication, both within the team and with external stakeholders. Such as deciding on regular meeting schedules that everyone can attend, reporting formats, and tools for collaboration.

D2: Describe the Problem

In D2 it is time to create a well formed problem statement. This step is key as it provides a foundation for understanding the problem which will lead to generally more successful problem-solving. It ensures that everyone clearly understands what needs to be addressed, setting the scope for the entire process. Ensure that the problem is clearly understood by everyone in the team at this stage to prevent confusion later on in the process.

5W1H Method of creating a Problem Definition

Use data gathering techniques such as observations, interviews, and document reviews can help to precisely identify the problem. A useful tool to use at this stage could be the 5W1H Problem definition method.

You can find out more about this method with our 5W1H guide .

Problem Definition – is / is not template

When creating your problem definition ensure to be specific, measurable, and unambiguous when stating the problem. You should avoid generalities and ensure that the problem statement is understandable to someone unfamiliar with the issue. If you are new to this process it may be helpful to give the statement to someone unfamiliar to the process and see if they understand it or if they have questions. You can then clarify any questions by adjusting the problem description to improve the claity.

D3: Implement and Verify Interim Actions

In D3 while the team is investigating the root cause, interim actions are must be implement to contain the problem and minimize its impact. This is particularly important in critical situations affecting safety, compliance, or customer satisfaction.

In this step you should identify, plan, and execute short-term fixes that can quickly contain the problem. This could include quarantining the product to ensure it is not sent out to the customer or even pausing production lines that continue to product defects. Ensure these actions are documented for future reference.

Use metrics and KPIs to gauge the effectiveness of the interim actions. Make adjustments as necessary.

D4: Root Cause Analysis

D4 is where you start to understand what is causing the issue by identifying the underlying reason for the problem. The objective is to find the root cause, not just the symptoms.

At this stage there are a range of quality and lean six sigma tools that can be used to conduct root cause analysis , which can include the Fishbone Diagram for structured brainstorming and the 5 Whys technique for causal chain analysis.

We have a range of guides on all of these techniques for you to use.

Once identified, it is important validate the root cause through experimentation or additional data analysis to ensure it’s the actual cause and not a symptom, this can often be an overlook critical step in the root cause process.

D5: Choose and Verify Permanent Corrective Actions

In D5 you need to choose what actions to be taken to prevent the problem reoccurring and any solutions implemented should be verified that the actions correct the problem this can involve trial runs, further data collection and inspections of product or services being produced.

You should also consider factors like cost, impact, and feasibility when choosing a permanent corrective action and should also conduct a risk assessment to evaluate potential negative outcomes of the actions taken

An implementation or action plan is often useful to document at this stage to detail the steps for implementation, assign responsibilities, and set timelines.

D6: Implement Permanent Corrective Actions

Once verified, implement the corrective actions across all relevant departments or processes. This can involved documenting the new process and training out to all stakeholders involved to ensure the new process is followed and that the stakeholders understand the reason for the change.

At this point you should continue to regularly monitor the situation to ensure the corrective actions are sustained and effective, this could be for a period of 30, 60 or 90 days after the problem was resolved to ensure the new process has become a sustained and issues do not reoccur.

D7: Prevent Recurrence

In D7 to prevent recurrent you should review and update organizational policies or standard operating procedures (SOPs) to prevent a recurrence of the problem and document the new standard process

It is important to conduct regular reviews to continuously monitor the process and ensure procedures are being followed but also to identify further opportunities for process improvement.

D8: Congratulate the Team

The final step D8, after the hard work and successful problem resolution, it is important to acknowledging and congratulating the team is vital for morale and future engagement. With the recognition of a successful 8D Problem-solving activity complete you are more likely to encourage future participation as the method gets a reputation as being useful and successful at solving problems.

Whether it’s a team lunch, certificates of achievement, or simply a public acknowledgment, celebrate the success in a way that resonates with your team.

Finally it is always important to conduct a lessons-learned session and document the insights gained during the process for future reference. This can be used as a future point of reference for problem solving activities.

Mastering the art of problem-solving is crucial in today’s complex and fast-paced environment. The 8D Problem-Solving methodology offers a structured, team-based approach to tackling challenges that can arise in any sector, be it manufacturing, public services, or logistics. This guide has walked you through each of the eight disciplines, offering best practices and highlighting common pitfalls to avoid. We’ve also enriched your understanding through real-world case studies that demonstrate the methodology’s versatility and effectiveness. Remember, the strength of 8D lies not just in identifying and resolving problems, but also in preventing their recurrence through systemic improvements. By adhering to the principles and steps outlined in this guide, you’re well on your way to becoming an adept problem solver, capable of driving continuous improvement in your organization.

- Zarghami, A. and Benbow, D.W., 2017. Introduction to 8D problem solving . Quality Press.

- Camarillo, A., Ríos, J. and Althoff, K.D., 2017. CBR and PLM applied to diagnosis and technical support during problem solving in the Continuous Improvement Process of manufacturing plants . Procedia Manufacturing , 13 , pp.987-994.

Q: What is 8D problem solving?

A: 8D problem solving is a systematic approach used to address and resolve complex problems. It is widely utilized in various industries to identify the root causes of issues, develop effective solutions, and prevent their recurrence.

Q: Why is it called "8D" problem solving?

A: The name “8D” refers to the eight disciplines or steps involved in the problem-solving process. Each discipline represents a specific stage in the methodology, allowing for a structured and comprehensive approach to problem resolution.

Q: What are the eight disciplines (8D) in problem solving?

A: The eight disciplines in problem solving, often abbreviated as 8D, are as follows:

- D1: Form a team

- D2: Define the problem

- D3: Implement containment actions

- D4: Determine the root cause

- D5: Develop and implement corrective actions

- D6: Validate the effectiveness of corrective actions

- D7: Prevent recurrence

- D8: Congratulate the team

Q: What is the purpose of forming a team in the 8D problem-solving process?

A: Forming a team at the beginning of the 8D problem-solving process helps ensure that the right individuals with the necessary expertise are involved in addressing the problem. The team collaboratively works towards understanding the issue, analyzing data, and developing effective solutions.

Q: How is the root cause determined in the 8D problem-solving process?

A: Determining the root cause (D4) involves conducting a thorough analysis of the problem. Various tools and techniques, such as cause-and-effect diagrams, 5 Whys, and data analysis, are employed to identify the underlying factors contributing to the problem.

Q: Can the 8D problem-solving methodology be applied to any type of problem?

A: Yes, the 8D problem-solving methodology is a versatile approach that can be applied to various types of problems across different industries. It provides a structured framework for problem resolution and can be tailored to suit the specific needs and requirements of different situations.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Download Template

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

8D Chess: How to Use The 8 Disciplines for Problem Solving

Hospitals have developed something of a reputation for being rife with bad processes . When processes aren’t adequate, the result is an abundance of “workarounds”.

For example, when equipment or supplies are missing, a nurse might waste time running around searching for what is needed, and once the item is found, return to their previous duties.

One study indicates that nurses spend 33 minutes of a 7.5-hour shift completing workarounds that are not part of their job description.

This may well “put out the fire” so-to-speak, but really it is just a hastily applied band-aid that does nothing to treat the root cause of the problem.

More time is wasted and more problems will arise in the future because nothing has been done to prevent the initial problem from happening again.

Individual nurses are not at fault here; workplace culture often values expertise in the form of those who “get the job done”, which tends to pull against the notion of spending time building good processes (time in which the job is perhaps not “getting done”).

So how to approach the problem of problem solving ?

In a lean context, problem solving can be distilled into two simple questions:

- What is the problem and how did it happen?

- How can we make sure that it doesn’t happen again?

The 8D, or eight disciplines methodology, is a problem solving process – most likely one of the most widely used problem solving processes out there. It is used by many different countries, in many different industries, and many different organizations.

8D is designed to help you put out those fires, and make sure they don’t happen again.

In this article, I’ll introduce you to the 8D problem solving methodology and provide you with an outline of the basic process that you can hopefully apply in your own business, plus how you can enhance 8D with other tools and methodologies like Six Sigma , FMEA , and Process Street .

Here’s what I hope you’ll take away after reading:

- An understanding of the basics of 8D

- Advantages of using 8D

- The purpose and objectives of each phase of the 8D process

- An understanding of how to use 8D for problem solving

- How 8D works with other problem solving tools

- How you can use Process Street to maximize the potential of the 8D framework

Let’s begin with the origins of 8D – what is it, and where did it come from?

What is 8D?

8D (sometimes Global 8D or G8D) stands for eight disciplines, and is a problem solving methodology. It’s basically a process for understanding and preventing problems.

Much like how risk management seeks to take a proactive, preventative stance, 8D aims to gain insight into the root causes of why the problems happen, so they won’t happen again.

The 8D process involves eight (sometimes nine) steps to solve difficult, recurring problems. It’s a transparent, team-based approach that will help you solve more problems in your business.

8D origins: Where did it come from?

Despite the popular story that 8D originated at Ford, it was in fact developed in 1974 by the US Department of Defence, ultimately taking the form of the military standard 1520 Corrective Action and Disposition System for Nonconforming Material .

Ford took this military standard, which was essentially a process for quality management , and expanded on it to include more robust problem solving methods.

In 1987, Ford Motor Company published their manual, Team Oriented Problem Solving (TOPS) , which included their first iteration of the 8D methodology.

Initially termed Global 8D (or G8D) standard, it is currently used by Ford and many other companies in the automotive supply chain.

8D, PDSA, & other problem solving processes

The disciplines of 8D follow the same logic as the Deming Cycle (also known as PDSA, and sometimes PDCA).

PDSA stands for Plan, Do, Study, Act (or Check, in the case of PDCA).

The similarity lies in the fact that both PDSA and 8D are designed to be used to improve processes. They’re both examples of cycles of continuous improvement.

Whereas 8D may be painted as a more generic problem-solving framework, structurally speaking both 8D and PDSA share a lot in common.

The simple idea of beginning with a clear objective, or desired output, and then testing, analyzing , and iteratively tweaking in a continuous cycle is the basis for both methodologies.

There are, of course, differences. We’ll cover the different applications of both 8D and PDSA in this article.

8D advantages

One of the main strengths of 8D is its focus on teamwork. 8D philosophy encourages the idea that teams, as a whole, are more powerful than the sum of the individual qualities of each team member.

It’s also an empirical methodology; that is to say that it is a fact-based problem solving process.

A branch of continuous improvement, proper use of 8D will help you coordinate your entire team for effective problem solving and improved implementation of just about all of the processes used in your business.

The 8 disciplines for problem solving

As you may have noticed, we’re starting with zero, which makes nine total disciplines. This “zero” stage was developed as an initial planning step.

D0: Plan adequately

Make comprehensive plans for solving the problem including any prerequisites you might determine.

Be sure to include emergency response actions.

D1: Establish your team

Establish your core team with relevant product or process knowledge. This team will provide you with the perspective and ideas needed for the problem solving process.

The team should consist of about five people, from various cross-functional departments. All individuals should have relevant process knowledge.

A varied group will offer you a variety of different perspectives from which to observe the problem.

It is advisable to establish team structure, roles, and objectives as far ahead in advance as possible so that corrective action can begin as quickly and effectively as possible.

D2: Describe the problem

Have your team gather information and data related to the problem or symptom. Using clear, quantifiable terms, unpack the problem by asking:

D3: Contain the problem (temporary damage control)

Depending on the circumstances, you may need to mobilize some kind of temporary fix, or “firefighting”.

The focus of this stage should be on preventing the problem from getting worse, until a more permanent solution can be identified and implemented.

D4: Identify, describe, and verify root causes

In preparation for permanent corrective action, you must identify, describe, and verify all possible causes that could contribute to the problem happening.

You can use various techniques for this, including a Failure Modes and Effects Analysis , or Ishikawa (fishbone) diagram .

It’s important that the root causes are systematically identified, described in detail, and promptly verified (or proved). How each cause is verified will depend on the data type and the nature of the problem.

Take a look at the section towards the end of this article for some more problem solving tools to help you decide the right approach.

D5: Identify corrective actions

You must verify that the corrective action you identified will in fact solve the problem and prevent it from happening again in the future (or whatever is your desired threshold of recurrence).

The best way to do this is to collect as much data as possible and by performing smaller-scale “pilot” tests to get an idea of the corrective action’s impact.

You can’t begin to identify the optimal corrective action until you have identified the root cause(s) of the problem.

D6: Implement and validate corrective actions

Carry out the corrective actions, and monitor short and long term effects. During this stage, you should assess and validate the corrective actions with empirical evidence.

Discuss and review results with your team.

D7: Take preventative measures (to avoid the problem happening again)

Here is where you make any necessary changes to your processes, standard operating procedures , policies , and anything else to make sure the problem does not happen again.

It may not be possible to completely eliminate any chance of the problem recurring; in that case, efforts should focus on minimizing possibility of recurrence as much as possible.

D8: Congratulate your team

It’s important to recognize the joint contribution of each and every one of the individuals that were involved in the process.

Team members should feel valued and rewarded for their efforts; this is crucial and perhaps the most important step – after all, without the team, the problem would not have been fixed.

Providing positive feedback and expressing appreciation helps to keep motivation high, which in turn improves the sense of process ownership and simply increases the likelihood your team will actually want to improve internal processes in the future.

How to use 8D for problem solving

The 8D method above outlines a proven strategy for identifying and dealing with problems. It’s an effective problem solving and problem prevention process.

In addition to avoiding long-term damage from recurring problems, 8D also helps to mitigate customer impact as much as possible.

More than just a problem-solving methodology, 8D sits alongside Six Sigma and other lean frameworks and can easily be integrated with them to minimize training and maximize efficacy.

8D is definitely a powerful framework on its own, but it really shines when combined with other synergistic concepts of lean and continuous improvement.

More problem solving tools that synergize well with 8D

8D has become a leading framework for process improvement, and in many ways it is more prescriptive and robust than other more simplistic Six Sigma approaches.

However, there are many Six Sigma methodologies, and even more frameworks for problem solving and process improvement .

The following improvement tools are often used within or alongside the 8D methodology.

DMAIC: Lean Six Sigma

DMAIC stands for:

The DMAIC process is a data-driven cycle of process improvement designed for businesses to help identify flaws or inefficiencies in processes.

Simply put, the goal with DMAIC is to improve and optimize existing processes.

Interestingly, the development of the DMAIC framework is credited to Motorola , whose work built upon the systems initially developed by Toyota .

In terms of working alongside 8D, you could use DMAIC to identify root causes as in D4; you could also implement the same techniques to better understand prospects for corrective actions as in D5, and D6.

We have a whole article on the DMAIC process, if you’re interested.

SWOT analysis

Strengths, Weaknesses, Opportunities, and Threats. You can use a SWOT analysis to gain insight into your organization as a whole, or on individual processes.

The main synergy with 8D is in the identification of opportunities, threats, and weaknesses.

These can represent opportunities for process improvements, weaknesses in your process that could produce problems further down the line, and threats, both internal and external, that may be out of your direct control but that could cause problems for you.

Here’s a SWOT analysis checklist you can use to structure your own analysis:

FMEA: Failure Mode and Effects Analysis

FMEA (Failure Mode and Effects Analysis) is a way of understanding the potential for problems and making preemptive preparations in order to avoid them. It is a method of risk management .

It is a type of preventative risk management process, and so works well in the context of identifying causes of problems so you can better deal with them.

FMEA and 8D work well together because:

- 8D can make use of information gathered during an FMEA process, like brainstorming sessions, to identify potential problems and their root causes.

- You can reuse possible cause information gathered during an FMEA process to feed into different representational diagrams like the Ishikawa (fishbone) diagram, which will help in the 8D process.

- 8D brainstorming data is useful for new process design. This allows the FMEA to take actual process failures into account, which produces more effective results.

- FMEA completed in the past can be used as databases of potential root causes of problems to inform 8D process development.

Here’s a free FMEA template for you to get started ASAP:

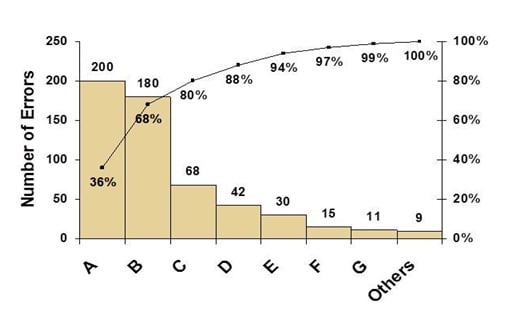

The Pareto Chart

The Pareto Chart helps us understand the impact of different variations of input on our output.

In relation to 8D, Pareto Charts can help us prioritize which root cause to target, based on which will have the greatest impact on improvement (where improvement is the desired output of the 8D process).

Here’s the Six Sigma Institute’s example Pareto Chart :

Here we have a simple deductive reasoning technique that asks “why?” five times to dig into the root cause of a problem.

The logic here is that by asking the same question five times, you work progressively “deeper” into the complexity of the problem from a single point of focus.

Ideally, by the fifth question you should have something that has a high likelihood of being a root cause.

This example from Wikipedia does a great job of conveying how the process works:

- The vehicle will not start. (the problem)

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

Ishikawa diagrams (fishbone diagrams)

Sometimes called “cause-and-effect diagrams”, they are as such used to visualize the cause and effect of problems.

The approach takes six different categories and places information about the problem into different categories to help you understand what factors could be contributing to the problem.

One advantage over the 5 Whys approach is the way this method forces a more holistic perspective, as opposed to the potentially narrow vantage point offered by zooming in on a single aspect or question.

According to the Six Sigma Institute, the 6 key variables pertaining to root causes of problems are:

- Machine: Root causes related to tools used to execute the process.

- Material: Root causes related to information and forms needed to execute the process.

- Nature: Root causes related to our work environment, market conditions, and regulatory issues.

- Measure: Root causes related to the process measurement.

- Method: Root causes related to procedures, hand-offs, input-output issues.

- People: Root causes related people and organizations.

There’s also this useful illustration of a company using a fishbone diagram to better understand what factors contribute to a company’s high turn around time.

Gap analysis

A gap analysis is concerned with three key elements:

- The current situation, or “performance”

- The ideal situation, or “potential”

- What needs to be done in order to get from performance to potential, or “bridging the gap”

The “gap” is what separates your current situation from your ideal situation.

Businesses that perform a gap analysis can improve their efficiency and better understand how to improve processes and products.

They can help to better optimize how time, money, and human resources are spent in business.

There’s a lot that goes into a gap analysis, and quite a few different ways to approach it. Check out our article for a deeper dive into the gap analysis process.

Superpowered checklists

Checklists can be a great way to simplify a complex process into a series of smaller, easy-to-manage tasks. They’re one of the best ways to start using processes in your business.

By using checklists, you can reduce the amount of error in your workflow , while saving time and money by eliminating confusion and uncertainty.

What’s more, if you’re using Process Street, you have access to advanced features like conditional logic , rich form fields and streamlined template editing .

How to use Process Street for 8D problem solving

Good problem solving relies on good process. If you’re trying to solve problems effectively, the last thing you want is your tools getting in your way.

What you want is a seamless experience from start to finish of the 8D methodology.

The best kinds of processes are actionable. That’s why you should consider using a BPM software like Process Street to streamline recurring tasks and eliminate manual work with automation .

Process Street’s mission statement is to make recurring work fun, fast, and faultless. By breaking down a process into bite-sized tasks , you can get more done and stay on top of your workload.

Sign up today for a free Process Street trial!

Problem solving is an invaluable skill. What’s your go-to process for problem solving? We’d love to know how it compares with the 8D method. Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

Designorate

Design thinking, innovation, user experience and healthcare design

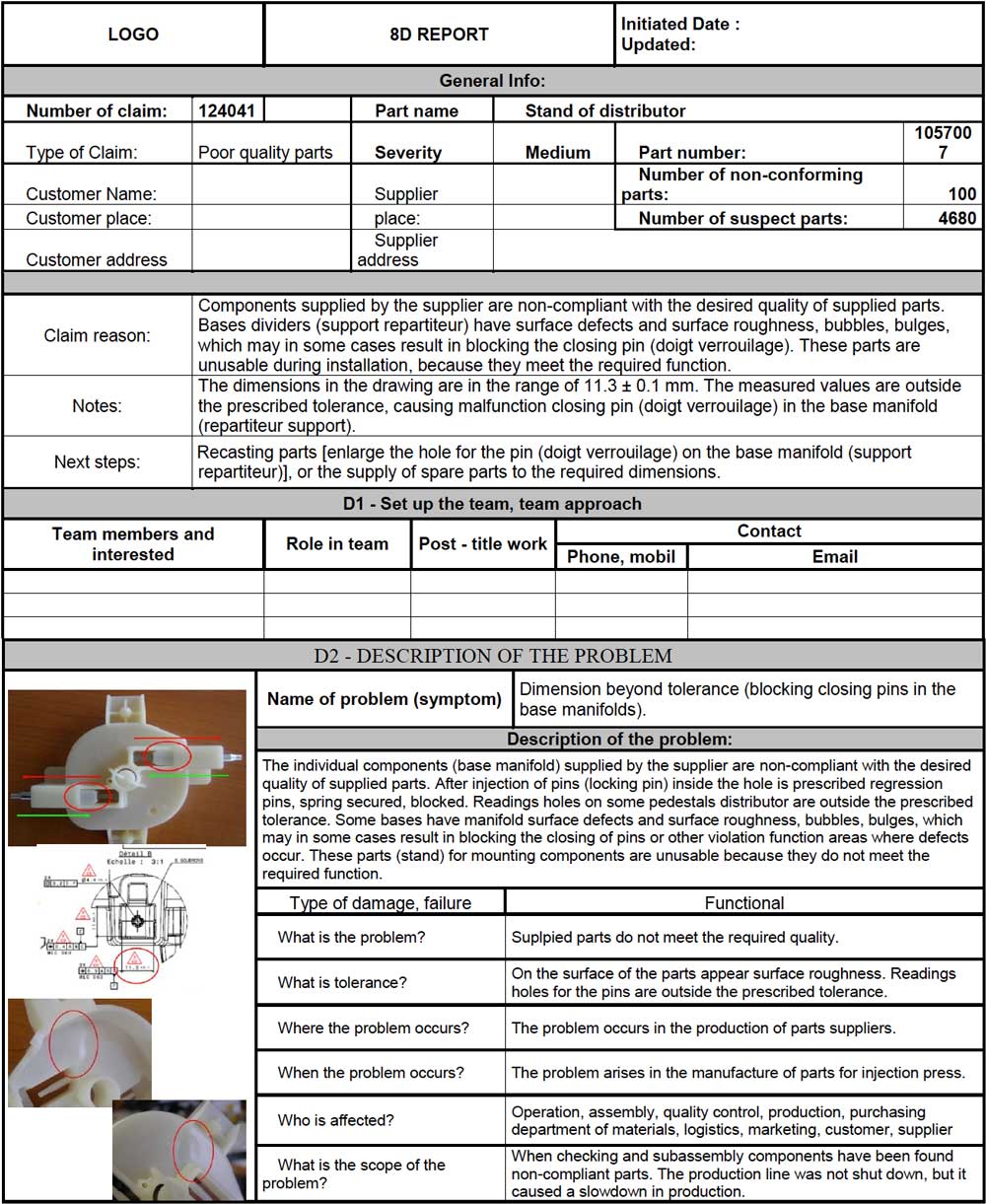

What is the 8D Problem Solving? And How to use the 8D Report?

The 8D problem-solving process (also known as the 8 Disciplines) is very different from previous processes we explored previously, such as the Double Diamond process or the IBM Design Thinking. The 8D process works in a rigid standardised nature to address the crisis caused by problems. The 8D process aims to walk with the team to highlight the problem, its root causes and propose a long-term solution. The process is documented in an 8D report which includes details of each of the eight stages. At the end of this article, we will explore an example report, and you can find a free 8D report template to download.

In times of crisis, companies face the challenge of analysing and solving problems efficiently in a short time to save developed projects. Problem-solving techniques such as the TRIZ method and Hurson’s Production Thinking Model allow companies to overcome crises and solve problems using less effort and time.

- Stage Gate Process: The Complete Practice Guide

- The Double Diamond Design Thinking Process and How to Use it

- A Guide to the SCAMPER Technique for Creative Thinking

- Design Thinking Tools: Reverse Brainstorming

Brief History of the 8D Problem Solving

The 8D method was first implemented by the US government during WW II as a military standard and was referred to as the Army Directive 1520, “Remedies and disposal of nonconforming materials.” In 1987, the demand for a team-oriented problem-solving method increased among the management organisation in the automotive industry to find a way to eliminate recurring issues.

Ford Motor Company published their manual, Team Oriented Problem Solving (TOPS), which includes their 8 Disciplines of the problem-solving process. The process was initially used to deal with quality control and safety issues inside the company but later expanded its role to a team approach problem-solving method. The 8D process is employed by engineers and designers to identify, analyse, and correct problems by eliminating the primary source that caused the problem.

So, what are the eight steps in the 8D methodology? The 8D problem solving process includes 8 Disciplines. In the mid-90s, a D0 step for planning was added to the process. The 8D steps include the following:

- D1: Team formation

- D2: Describe the problem

- D3: Develop a temporary containment plan

- D4: Determine and verify root causes

- D5: Verify the permanent solution

- D6: Implement the permanent solution

- D7: Prevent recurrence

- D8: Congratulate your team

The 8 Disciplines aim to achieve the following targets while solving the specified problem:

- Think as a team while solving the problem

- Isolate the situation and understand its causes

- Identify the factors that contribute to the problem

- Provide a temporary solution to halt the impact of the problem

- Eliminate the causes of the problem and the factors contributing to it

- Prevent the problem from recurring

When Should the 8D Problem Solving be Used?

Based on the above targets, the 8D problem solving process is designed for complex problems whose solution exceeds the ability of one expert. Also, it aims to establish communication for problem resolution through different levels inside the company. In some situations, the consumer or the management team requests the application of the 8D process through several forms or documentation.

While 8D problem solving is suitable for recurring problems that may repeatedly occur within a project or company, it is not ideal for simple issues that can be solved quickly by individual efforts. The process is unsuitable for a problem that can be solved with a straightforward solution. The 8D process is designed for complex issues, which require several weeks to solve and the involvement of at least four people.

8D problem solving provides a systematic process to find and solve problems. Therefore, if the situation requires choosing between alternative solutions, 8D acknowledges that other tools may help solve the problem better than the 8D process.

How to Apply the 8D Problem Solving Process?

The steps below form the 8 Discipline process to achieve targeted problem solving through the eight steps.

This discipline is also known as the Pre 8D because it aims to understand the problem and determine if the 8D process is the correct method to use. At this stage, the team aims to answer general questions such as:

- Is this a new problem, or has it happened before?

- Is this a recurring problem?

- What is the history of this issue?

- What was the method used to solve the problem before?

At this stage, the target is to learn about the problem’s history and decide if the 8D process is the best tool to solve the problem.

D1: Team Formation

Thinking as a team can produce more efficient solutions than trying to solve a problem alone. The team includes all the stakeholders involved in the situation. The team communicates with each other and performs brainstorming to solve the problem (check Design Thinking Tools: Reverse Brainstorming ). If the team does not know each other, the brainstorming time can be used to learn how to teach members to explore ideas together. Methods can be used in brainstorming sessions such as mind mapping , Six Thinking Hats , and Lego Serious Play.

D2: Describe the Problem