Imagine a symphony orchestra where each musician plays their own tune without listening to others. The result would be chaotic and dissonant, right? Similarly, in the business world, when decision-making happens in silos and planning processes are disconnected, it’s like having a group of individuals playing their own instruments without any coordination. The harmony is lost, and the organization becomes inefficient, misses opportunities, and struggles to keep up with the fast-paced market.

Integrated Business Planning (IBP) addresses these challenges by providing a comprehensive framework that integrates strategic, operational and financial planning, analysis, and reporting to drive better business outcomes. A retail company experiences a sudden surge in online sales due to a viral social media campaign. Integrated planning incorporates supply chain planning, demand planning, and demand forecasts so the company can quickly assess the impact on inventory levels, supply chain logistics, production plans, and customer service capacity. By having real-time data at their fingertips, decision-makers can adjust their strategies, allocate resources accordingly, and capitalize on the unexpected spike in demand, ensuring customer satisfaction while maximizing revenue. This blog explores the significance of IBP in today’s modern business landscape and highlights its key benefits and implementation considerations.

Integrated business planning framework

Integrated Business Planning (IBP) is a holistic approach that integrates strategic planning, operational planning, and financial planning within an organization. IBP brings together various functions, including sales, marketing, finance, supply chain, human resources, IT and beyond to collaborate across business units and make informed decisions that drive overall business success. The term ‘IBP’ was introduced by the management consulting firm Oliver Wight to describe an evolved version of the sales and operations planning (S&OP process) they originally developed in the early 1980s.

Making up the Integrated Business Planning framework are six key pillars:

1. strategic planning.

Integrated Business Planning starts with strategic planning. The management team defines the organization’s long-term goals and objectives. This includes analyzing market trends, competitive forces, and customer demands to identify opportunities and threats. Strategic planning sets the direction for the entire organization and establishes the foundation for subsequent planning roadmap.

2. Operational planning

Operational planning focuses on translating strategic goals into actionable plans at the operational level. This involves breaking down the strategic objectives into specific targets and initiatives that different departments and functions need to execute.

For example, the sales department might develop a plan to enter new markets or launch new products, while the supply chain department focuses on inventory optimization and ensuring efficient logistics. The key is to align operational plans with the broader strategic objectives to ensure consistency and coherence throughout the organization.

3. Financial planning

Financial planning ensures that the organization’s strategic and operational plans are financially viable. It involves developing detailed financial projections, including revenue forecasts, expense budgets, and cash flow forecasts. By integrating financial planning with strategic and operational planning, organizations can evaluate financial profitability, identify potential gaps or risks, and make necessary adjustments to achieve financial targets.

4. Cross-functional collaboration

A fundamental aspect of IBP is the collaboration and involvement of various functions and departments within the organization. Rather than working in isolation, departments such as sales, marketing, finance, supply chain, human resources, and IT come together to share information, align objectives, and make coordinated decisions.

5. Data integration and analytics

IBP relies on the integration of data from different sources and systems. This may involve consolidating data from enterprise resource planning (ERP) systems, customer relationship management (CRM) systems, supply chain management systems, and other relevant sources. Advanced analytics and business intelligence tools are utilized to analyze and interpret the data, uncovering insights and trends that drive informed decision-making.

6. Continuous monitoring and performance management

The Integrated Business Planning process requires continuous monitoring of performance against plans and targets. Key performance indicators (KPIs) are established to measure progress and enable proactive management. Regular performance reviews and reporting enable organizations to identify deviations, take corrective actions, and continuously improve their planning processes.

What are the benefits of Integrated Business Planning?

By integrating strategic, operational, and financial planning organizations can unlock the full potential of IBP and drive business success and achieve their goals.

Enhanced decision-making

IBP facilitates data-driven decision-making by providing real-time insights into various aspects of the business. By bringing together data from various departments, organizations can develop a holistic view of their operations, enabling them to make better-informed decisions.

Improved alignment

By aligning strategic objectives with operational plans and financial goals, IBP ensures that every department and employee is working towards a common vision. This alignment fosters synergy and drives cross-functional collaboration.

Agility and responsiveness

In the rapidly changing business landscape, agility is crucial. IBP allows organizations to quickly adapt to market shifts, demand fluctuations, and emerging opportunities. By continuously monitoring and adjusting plans, businesses can remain responsive and seize competitive advantages.

Optimal resource allocation

Integrated Business Planning enables organizations to optimize resource allocation across different functions. It helps identify bottlenecks, allocate resources effectively, and prioritize initiatives that yield the highest returns, leading to improved efficiency and cost savings.

Risk management

IBP facilitates proactive risk management by considering various scenarios and identifying potential risks and opportunities. By analyzing data and conducting what-if analyses, companies can develop contingency plans and mitigate risks before they materialize.

Essential steps for implementing Integrated Business Planning

Implementing an effective IBP process requires careful planning and execution that may require substantial effort and a change of management, but the rewards are well worth it. Here are some essential strategic steps to consider:

1. Executive sponsorship

Establish leadership buy-in; gain support from top-level executives who understand the value of Integrated Business Planning and can drive the necessary organizational changes. Leadership commitment, led by CFO, is crucial for successful implementation.

2. Continuous improvement

Continuously monitor and adjust; implement mechanisms to monitor performance against plans and targets. Regularly review key performance indicators (KPIs), conduct performance analysis, and generate timely reports and dashboards. Identify deviations, take corrective actions, and continuously improve the planning processes based on feedback and insights.

3. Integration of people and technology

To foster cross-functional collaboration, the organization must identify key stakeholders, break down silos, and encourage open communication among departments. Creating a collaborative culture that values information sharing and collective decision-making is essential.

Simultaneously, implementing a robust data integration system, encompassing ERP, CRM, and supply chain management systems, ensures seamless data flow and real-time updates. User-friendly interfaces, data governance, and training provide the necessary technological support. Combining these efforts cultivates an environment of collaboration and data-driven decision-making, boosting operational efficiency and competitiveness.

4. Technology

Implement advanced analytics and business intelligence solutions to streamline and automate the planning process and assist decision-making capabilities. These solutions provide comprehensive functionality, data integration capabilities, scenario planning and modeling, and real-time reporting.

Integrated Business Planning software

From a tech perspective, organizations need advanced software solutions and systems that facilitate seamless data integration and collaboration to support IBP. Here are some key components that contribute to the success of integrated business planning:

1. Corporate performance management

A platform that serves as the backbone of integrated business planning by integrating data from different departments and functions. It enables a centralized repository of information and provides real-time visibility into the entire business.

2. Business intelligence (BI) tools

Business intelligence tools play a vital role in analyzing and visualizing integrated data from multiple sources. These tools provide comprehensive insights into key metrics and help identify trends, patterns, and opportunities. By leveraging BI tools, decision-makers can quickly evaluate financial performance, make data-driven business decisions and increase forecast accuracy.

3. Collaborative planning and forecasting solutions

Collaborative planning and forecasting solutions enable cross-functional teams to work together in creating and refining plans. These planning solutions facilitate real-time collaboration, allowing stakeholders to contribute their expertise and insights. With end-to-end visibility, organizations can ensure that plans are comprehensive, accurate, and aligned with business strategy.

4. Data integration and automation

To ensure seamless data integration, organizations need to invest in data integration and automation tools. These tools enable the extraction, transformation, and loading (ETL) of data from various sources. Automation streamlines data processes reduces manual effort and minimizes the risk of errors or data discrepancies.

5. Cloud-based solutions

Cloud computing offers scalability, flexibility, and accessibility, making it an ideal choice for integrated business planning. Cloud-based solutions provide a centralized platform where teams can access data, collaborate, and make real-time updates from anywhere, at any time. The cloud also offers data security, disaster recovery, and cost efficiencies compared to on-premises infrastructure.

6. Data governance and security

As organizations integrate data from multiple sources, maintaining data governance and security becomes crucial. Establishing data governance policies and ensuring compliance with data protection regulations are vital steps in maintaining data integrity and safeguarding sensitive information. Implementing robust data security measures, such as encryption and access controls, helps protect against data breaches and unauthorized access.

IBM Planning Analytics for Integrated Business Planning

IBM Planning Analytics is a highly scalable and flexible solution for Integrated Business Planning. It supports and strengthens the five pillars discussed above, empowering organizations to achieve their strategic goals and make better data-driven decisions. With its AI- infused advanced analytics and modeling capabilities, IBM Planning Analytics allows organizations to integrate strategic, operational, and financial planning seamlessly. The solution enables cross-functional collaboration by providing a centralized platform where teams from various departments can collaborate, share insights, and align their plans. IBM Planning Analytics also offers powerful data integration capabilities, allowing organizations to consolidate data from multiple sources and systems, providing a holistic view of the business. The solutions’s robust embedded AI predictive analytics uses internal and external data and machine learning to provide accurate demand forecasts. IBM Planning Analytics supports continuous monitoring and performance management by providing real-time reporting, dashboards, and key performance indicators (KPIs) that enable organizations to track progress and take proactive actions. As the business landscape continues to evolve, embracing Integrated Business Planning is no longer an option but a necessity for organizations. To succeed in this dynamic environment, businesses need an integrated approach to planning that brings all the departments and data together, creating a symphony of collaboration and coordination.

More from Artificial intelligence

Ai transforms the it support experience.

5 min read - We know that understanding clients’ technical issues is paramount for delivering effective support service. Enterprises demand prompt and accurate solutions to their technical issues, requiring support teams to possess deep technical knowledge and communicate action plans clearly. Product-embedded or online support tools, such as virtual assistants, can drive more informed and efficient support interactions with client self-service. About 85% of execs say generative AI will be interacting directly with customers in the next two years. Those who implement self-service search…

Bigger isn’t always better: How hybrid AI pattern enables smaller language models

5 min read - As large language models (LLMs) have entered the common vernacular, people have discovered how to use apps that access them. Modern AI tools can generate, create, summarize, translate, classify and even converse. Tools in the generative AI domain allow us to generate responses to prompts after learning from existing artifacts. One area that has not seen much innovation is at the far edge and on constrained devices. We see some versions of AI apps running locally on mobile devices with…

Chat with watsonx models

3 min read - IBM is excited to offer a 30-day demo, in which you can chat with a solo model to experience working with generative AI in the IBM® watsonx.ai™ studio. In the watsonx.ai demo, you can access some of our most popular AI models, ask them questions and see how they respond. This gives users a taste of some of the capabilities of large language models (LLMs). AI developers may also use this interface as an introduction to building more advanced…

IBM Newsletters

What Is Integrated Business Planning and Why Is It Important?

Think of modern integrated business planning, or IBP, as a mashup of supply chain optimization, financial planning and analysis (FP&A) and operational best practices, powered by a companywide culture that’s all about delivering the speed, savings and responsiveness today’s consumers demand while managing risk.

Note that IBP as a fuzzy, buzzword-laden process methodology has been around for years. It’s usually implemented by expensive consultants in sprawling, global corporations that know they need to unify siloed sales, supply, financial and operational resources — before more nimble competitors relegate them to the former Fortune 500 list.

We’re here to argue that IBP deserves a second look for any company that wants to maximize profits and minimize the risks associated with growth. No six-figure consultant required.

What Is Integrated Business Planning?

On paper, IBP is a process for aligning a company’s business goals with its finance, supply chain, product development, marketing and other operational functions. Think parts suppliers that work with automakers and need to constantly retool to accommodate design changes, or food producers operating on razor-thin margins that must manage both uncertain supply chains and fickle customer tastes.

Lag, and a competitor is standing by to take that business. Move quickly but in a disjointed manner and you may keep customers, but at the expense of higher cost of goods sold (COGS) and lower profitability.

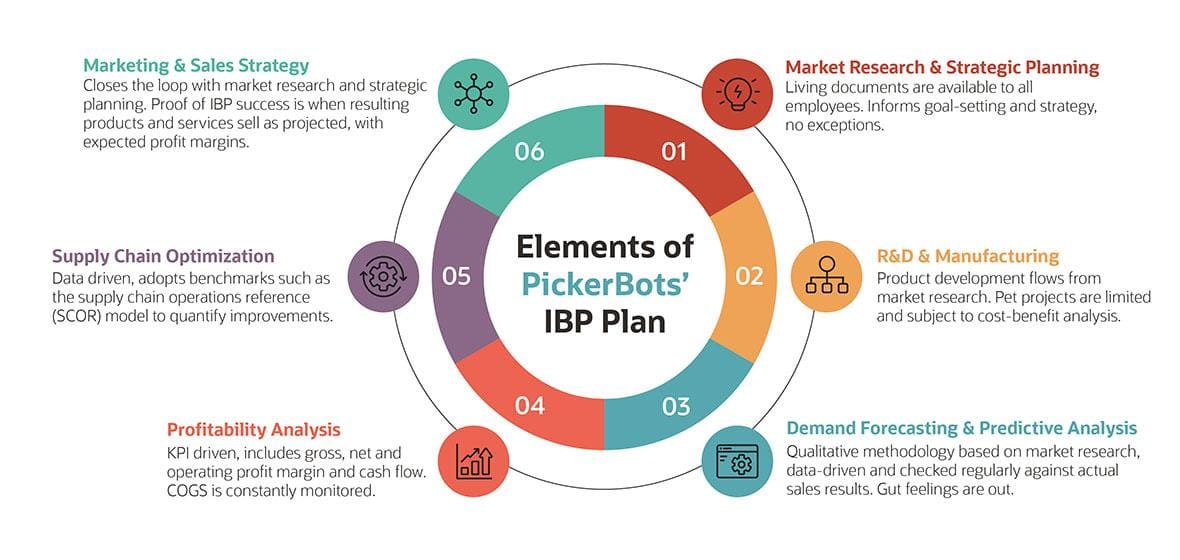

For example, consider PickerBots, a fictional maker of custom machinery for manufacturing and warehouse operations. When the company launched in 2017, it found a niche in restaurant supply, but when that business slowed significantly in 2020 the founders decided to retool. Rather than simply changing up its marketing, the firm set out to revamp its business strategy. A top-down scenario planning exercise led to realigning its R&D, demand forecasting, profitability and revenue analysis, supply chain planning and marketing and sales strategy.

The company culture was already strong on innovative thinking, but the founders realized that the link between strategic planning and day-to-day operations could use improvement. Enter a new COO with the chops to align operations with product demand planning and sales and marketing while weighing in on financial targets and budgets.

Key Takeaways

- In a company that embraces IBP, there’s a direct line from purchasing, production and inventory to sales and marketing to financial targets and budgets.

- A key IBP benefit is that materials are bought at the right price, at the right time and in just the right quantity to fulfill market demand.

- Successful IBP delivers closer collaboration and more trust among departments, leading to improved decision-making.

- IBP may require significant cultural change and cannot be successful without unwavering commitment from the executive team.

Integrated Business Planning Explained

Many organizations mistake IBP for a supply-chain-centric exercise. While linking supply chain planning with other departments, from sales and operations through finance, is important, that’s just one element.

IBP aligns business g oals and financial t argets with decisions and execution across the entire business.

There is overlap with financial planning and analysis (FP&A). Because an IBP initiative gathers data from across the enterprise, companies get better at predictive analysis. Now, when purchasing forecasts a parts shortage, supply and operations can adjust before customers are affected.

It’s also not a one-and-done exercise. PickerBots’ new COO advises looking a minimum of 36 months out. Leaders will need to keep their eyes on that long-range plan while continually reviewing, revising and communicating financial and operating results. What supply chain gaps have opened up, and how can we close them? Do we need to update our scenario planning? Are we tracking the right financial KPIs?

A crucial element of IBP is that it integrates financials with operations. Here’s a structure that PickerBots plans to follow.

Why Is Integrated Business Planning Important?

Companies that undertake IBP realize a number of practical benefits, including reduced holding costs, more responsive customer service and demand fulfillment, shorter time to market for new products and an improved correlation between demand planning and fulfillment.

After PickerBot’s scenario planning and strategy session, the company decided to jump into the emerging collaborative robot, or cobot, market. A collaborative robot is designed to safely interact with human workers. PickerBot’s leaders believe demand will increase for “pick and place” cobots with fine motor skills for use on manufacturing lines as well as in agricultural settings.

Now that the company has its strategic direction, the COO wants to focus on three higher-level concepts before delving into more practical areas, like financial planning and analysis and supply chain optimization. That’s because without goal-setting, PickerBots won’t be able to define success.

Alignment and accountability

All executives must agree on three things: What are our corporate goals? What does success look like for each? How will I and my team contribute and be accountable?

The company’s goals are grouped into four areas: industry-focused, operations and supply chain, financial and marketing and sales. The management team will review all goals to make sure they align with strategy and are both actionable and achievable.

Industry-focused goal: Offer the most innovative cobots on the market

What success looks like: Develop a product that can match or exceed a human worker in its ability to pick fragile crops without damage.

Who will execute: The R&D team

Financial goal: Diversify revenue streams

What success looks like: Minimize dependence on one market/industry. Add a services arm to generate recurring revenue from maintenance contracts, powered by sensors built in to all new products.

Who will execute: Cross-functional led by CEO and finance

Other goals might be “control costs at each step and deliver cobots to customers on time and to specifications” with an expectation to lower COGS by 10% and raise the company’s Net Promoter Score by 25% within one year. Or for sales, “find 10 new customers for the company’s agricultural cobots and bundle maintenance contracts with each sale.” That ties back to revenue diversification.

An important point: Every manager is accountable for every goal, not just those that lie within their purviews.

Informed decisions and actions

Planning across PickerBots’ supply chain was disjointed, with engineers purchasing materials direct and little central planning or cost control. As part of the IBP process, the company will adopt sales and operations planning (S&OP) principles to improve its supply chain and logistics.

Actionable goals here include building visibility into how each department is working and tying the impact of decisions to financial goals. For example, by having R&D build in sensors that can automatically collect and transmit data on a cobot’s operational status, PickerBots can proactively perform preventative maintenance so the devices are almost never down — an important selling point and a way to contribute to maintenance income.

Organizationwide, divisions need to focus less on their own needs and view actions through the lens of all goals. That means the company needs to collect a lot of timely data and use it to issue reports so managers can make better decisions, more quickly. That may require an investment in ERP and other software.

Transparency/visibility

All department heads will take part in a monthly business review, where the group will assess progress in achieving the company’s objectives. The strategic plan is also available to all staff members, and quarterly all-hands meetings will be held to gather ideas and insights and walk through KPIs.

Four success metrics for the IBP process include:

1. Getting all stakeholders to buy in to corporate goals so that everyone agrees and understands what the business wants to achieve and how it will get there. There are clear responsibilities for each function in the pursuit of goals.

2. Basing business decisions on data. The integration of finance into product, demand and supply functions is key here, as are selecting the right KPIs.

3. Tying decision-making to outcomes and improving accountability. Because every department is responsible for providing accurate numbers and projections, there’s less risk that the CFO and finance team are left holding the bag if revenues fall short.

4. Shifting the culture to embrace cross-functional collaboration. An IBP process encourages openness and trust, and as a result more deeply engages and empowers employees. As an action item, each R&D and manufacturing team member will spend a week annually accompanying sales reps on customer calls.

What Is the Difference Between S&OP and IBP?

The term “IBP” was coined by management consultancy Oliver Wight to describe the next iteration of the sales and operations planning (S&OP) process Wight developed in the early 1980s.

The big difference between IBP and S&OP is that the latter has become the domain of supply chain and logistics specialists, particularly those involved in supply-and-demand balancing and planning. S&OP is execution-focused and involves a traditional budgeting process.

In contrast, IBP takes a more cross-functional and holistic approach to weaving business goals through every function. As a result, in theory, supply chain management is proactive and optimized.

IBP includes S&OP processes but because it involves cultural change, without executive buy-in, IBP will not be successful.

Some major differences between S&OP and IBP are:

6 Steps in the Integrated Business Planning Process

Now that its goals are set, PickerBots can take the next steps in its IBP journey.

1. Determine what is holding the company back. Is it a lack or growth or profitability? Is the product portfolio too complex? Has the business lost competitiveness in its space? For our manufacturing firm, the main problem was overfocus on one niche market.

2. Engage and educate employees. Once leadership buys in to goals, that enthusiasm must trickle down through the ranks. Unless everyone is committed to integrated business planning, success will be elusive. The COO recognizes that a formal employee engagement program will keep workers invested in the success of the business and actively working to meet strategic goals.

3. Set up a tiger team. IBP success comes from tight coordination, constant communication and accountability for KPIs. It’s a cultural shift that will take time to propagate throughout the business. To jumpstart things, PickerBots identified engaged employees within each functional area and assigned them to a daily 20-minute standup call. Now, say a shipment of RFID readers needed by manufacturing will be two weeks late. The purchasing team member shares that information promptly so that sales can manage customer expectations and finance can account for delayed revenue. If the problem recurs, the company can seek out new suppliers. No more surprises.

4. Establish a project/product prioritization process. IBP takes discipline. Only projects that forward the company’s strategic goals get resources. Same for products. That might mean sunsetting a line that’s still selling but lacks growth potential. All managers who require resources or have a product or service launch idea fill out a cost-benefit analysis template that is tailored to reveal whether expected benefits and costs align with goals. Leadership prioritizes using this process. No more sacred cows.

5. Expand the finance team’s influence. Finance needs to sit in on product planning, supply chain optimization and sales strategy meetings. Specifically, choose a finance team member well-versed in FP&A functions. FP&A professionals inform major decisions made by the executive team and collect and analyze financial data from across the organization to create reports that reveal whether goals are being met — and if not, why not? How do we fix the problem? Like many smaller firms, PickerBots doesn’t have a dedicated FP&A staffer, so the head of finance assigns an accounting team member who knows the business and has an aptitude for data collection and number crunching.

6. Adopt technology and tools to support IBP. If the forecasting process is seen as a quarterly or annual exercise imposed by finance and yielding little benefit to departments, IBP can’t succeed. Companies with static, point-in-time budgets need to adopt rolling forecasts to make sure the business stays on track. And, finance teams need to be able to easily access the data they need from each operational area. Both rolling forecasts and better use of data require technology and a commitment to transparency. You can’t manage what you can’t measure.

Traditional vs. Rolling Forecasts

5 tips to succeed at integrated business planning.

Some ways the COO plans to set PickerBots up for success include:

1. Sell IBP as a way to bring order from chaos. For example, large companies, especially those that have engaged in a number of mergers and acquisitions, may have thousands of SKUs and product codes. One big manufacturer Oliver Wight worked with used IBP to whittle 120,000 item numbers down to about 10,000 and reduce inventories by 50% while improving on-time, in-full delivery by up to 20%. For a smaller company, IBP can prevent ever getting in a situation where it needs to slash 90% of SKUs.

2. Adopt a continuous improvement mindset. All parts of any production or service system, particularly people, are interconnected, inform one another and are mutually dependent on generating successful outcomes. This practice’s origin comes from Kaizen, a Japanese term meaning “change for the better.” Originating in Japan, the business philosophy looks to continuously improve operations and involve all employees, from assembly line workers to the CEO. It’s a way to reinforce IBP.

3. Get buy-in from the CIO. PickerBots’ CIO came up through the ranks of manufacturing IT and is familiar with the concept of Total Quality Management (TQM), which has overlap with IBP. That went a long way in communicating the benefits of IBP and freeing up budget for technologies that can make IBP work, like ERP, enterprise performance management (EPM), supply chain management and real-time-capable accounting and finance software — especially important to realize the “one set of numbers” value proposition.

4. Apply risk management principles. Disasters large and small happen. While the zen of IBP skews toward positive and upbeat, make sure department heads are doing scenario planning and what-if analyses to model operational risk — like overdependence on one market. Consider assigning your tiger team a secondary function as a crisis management strike force.

5. Don’t forget HR. Labor is likely your company’s biggest operating expense, so ensure that it’s working for your IBP effort, not against it. A human resources professional can identify traits in applicants — like team players who are data driven and comfortable with transparency — that predict whether they will be contributors to IBP success.

Benefits of Integrated Business Planning

Research shows that the main benefit of implementing IBP is increased revenue, followed by forecast accuracy and improved Perfect Order Delivery rates.

Three additional key benefits:

Real-time insights: Once companies have instituted rolling forecasts, for example, finance can more quickly and accurately answer questions on spending and cash flow. Expect more accurate KPIs across the board.

Ownership: The flip side of accountability is that in a company fully embracing IBP, all employees assume responsibility for meeting all goals. So you’d better make sure that authority to make decisions is decentralized and tied to responsibility for outcomes, because there are few bigger morale killers than accountability without the power to effect success. Companies can further nurture a culture of ownership by tying rewards to meeting or exceeding goals.

Improved customer satisfaction: While more on-time, in-full deliveries make customers happy, that’s not the only way IBP improves Net Promoter Scores. Better planning yields better insights into what customers want, and a strong company culture often leads to improved customer empathy and its associated benefits.

Integrated Business Planning Adoption Challenges

Where a business starts with IBP depends on its maturity. Companies with dog-eat-dog cultures and highly siloed processes have a lot of work to do. These tend to be firms with traditional top-down management structures, static annual budgeting with little ability to generate forward-looking projections and dated business plans that are misaligned with current customer needs.

While all are thorny structural challenges, a leadership team that’s averse to placing trust and decision-making authority at lower levels of the organization is in even worse shape. Companies with autocratic, command-and-control styles must be willing to decentralize authority if they hope to realize IPB’s benefits.

Even businesses with mature, integrated processes and egalitarian cultures often get tripped up by “top down” versus “bottom up” KPI reporting and budgeting. IBP requires businesses to focus less on finance developing a top-line budget and then handing departmental budgets down from on high. Rather, they need to become comfortable with a bottom-up process, where departments start with a plan of what they want to achieve, calculate what it will cost and then feed a number up to the finance team, which uses that input to calculate the total budget.

Companies not already using at least a somewhat flexible budgeting process are likely to find this shift difficult. One way to jump-start the transformation might be a modern form of zero-based budgeting.

Steps of Zero-Based Budgeting for 2021

- Create a strategic vision for ZBB: Identify cost targets, relevant KPIs and goals.

- Evaluate business units to select ZBB candidates (also referred to as “decision units,” or any organ of the business that operates independently with its own budget).

- Start selected budgets from scratch (i.e., from zero).

- Each decision unit provides “decision packages,” which break down each activity in terms of its objective, funding needs, justification in the context of company goals, technical viability and alternative courses of action.

- Evaluate each proposed item to determine its value-add to the company and whether the entire cost is justified. What does the expenditure bring back to the company?

- Prioritize costs based on company goals. Reduce or cut expenses in areas that no longer produce significant value.

- Allocate funds among areas that are productive and aligned with the business’s growth drivers.

Elements of Integrated Business Planning

Integrated business planning takes place at a regular cadence; every month is most common, so we’ll use that in our example.

These steps are standard for IBP consultants, adaptable to most industries and bake in the PickerBots COO’s virtuous cycle of market research and strategic planning, R&D and manufacturing, demand forecasting and predictive analysis, profitability analysis, supply chain optimization and marketing and sales strategy.

1. Product management review. This includes all elements of product portfolio management. A cross-functional team meets monthly to review the overall status of all of product-related projects: Are they on track? Have we identified new risks and opportunities? Are the most high-value products or services prioritized? The goal is aligning the product portfolio with business goals and making sure needed raw materials and manufacturing floor capacity are lined up. Product managers revise as needed and publish an updated master plan, along with the resources it’ll take to deliver any changes.

2. Demand planning picks it up. This is a cross-functional process that helps businesses meet customer demand for products while minimizing excess inventory and avoiding supply chain disruptions. Demand planning can increase profitability and customer satisfaction and lead to efficiency gains. This team brings together members of sales, marketing and finance to determine whether they’re targeting the right markets, the right way. They work up an optimized demand plan. Relevant KPIs include sales forecast accuracy, inventory turns, fill rates and order fulfillment lead times.

3. Then, the ball goes to the supply planning team. These supply chain experts work out the optimal way to meet projected demand in a cost-effective way. The key is to have visibility into complex supply chains; a formal supply chain visibility (SCV) project helps spot and fix weaknesses, such as inventory shortfalls or order fulfillment issues, before they become major problems. Lower cost of goods sold (COGS) is the North star.

4. The integrated reconciliation team pulls together the initial product, demand and supply plans and consolidates them into one holistic business plan based on a 24- or 36-month projection; for iterative updates, teams highlight material changes. Decisions that could not be made by individual teams are prepared for executive review.

5. The executive team resolves conflicts and rolls the updated plan out to the entire company.

Integrated Business Planning Components

The components of integrated business planning comprise three buckets: Plan, execute and monitor and adjust.

Specific actions falling into each bucket vary depending on the consultancy or technology supplier. Some are more aligned with supply chain planning, while others center on S&OP or financial planning with plug-ins to other functional areas. Others are very industry-specific.

Let’s look at Oracle’s IBPX (Integrated Business Planning and Execution) for Manufacturing solution as an example. Key components include:

- Top-down and bottom-up, driver-based planning and forecasting

- Risk modeling for M&A and strategic initiatives

- Full financial statement structure for strategic and operational planning

- Predictive and prescriptive analytics and planning

- A preseeded S&OP process

- Near-real-time demand and supply balancing

- Real-time backlog management

- Automation of predictions and correction actions based on actuals

- AI-enabled operational planning, such as for sales territories and quotas

- IoT and sensor data flows integrated with automated decisions

Items like backlog management and enhanced support for IoT and sensor data are important to manufacturers like PickerBots. A retailer might be more interested in advanced inventory management. What’s important is that any solution, whether purchased as a suite or pulled together by an integrator or in-house team, supports the ability to do long- and medium-range and short-term planning based on a single, up-to-date data set that’s accessible to all authorized stakeholders.

Also look for the ability to easily model “what-if” scenarios, robust budgeting and costing and a roadmap to advanced technologies like AI and predictive analytics.

Integrated Business Planning Examples

We mentioned the Oliver Wight customer that whittled 120,000 SKUs down to about 10,000. That firm, Uponor Group, looked to IBP after a string of acquisitions left it with swelling inventories, an extremely complex portfolio and a lack of communication between siloed functions and far-flung locations. The Finnish company sells products for drinking water delivery as well as radiant heating and cooling equipment and has 3,900 employees in 30 countries. Uponor had a hard time getting a singular view of financial information across its subsidiaries, and each unit had its own practices for inventory management. Small events, such as holidays, would drive some sites to build up “just in case” inventory, and double-stocking in warehouses was common. Subsidiaries in different countries had different SKUs for the same items, and R&D was localized, with no collaboration across the company.

Upinor focused first on its supply chain and implemented S&OP processes, then advanced to IBP the following year. The results have been an increase in net sales of $1.1 billion euros, a 30% improvement in on-time in-full deliveries, a 50% reduction in inventories and increased visibility.

U.S.-based technology provider Juniper Networks also undertook an IBP project focused on implementing a digital supply chain with IBP, where the business planning process would extend S&OP throughout the supply chain, product and customer portfolios, customer demand and strategic planning.

Since undertaking the project, Juniper’s lead-time attainment is up 55%. and its inventory costs are down by 15%, allowing it to realize a positive ROI on the IBC project.

History of Integrated Business Planning

Oliver Wight developed S&OP in the 1980s as a methodology for a client that wanted to balance supply-and-demand volume. In the years since, the process evolved to integrate financials, inventory and new-product introductions.

The consultancy renamed S&OP as integrated business planning in the late 1990s to reflect the process of integrating all functions of the business behind one optimized plan. Since then, a newer term, “enterprise integrated business planning,” has emerged. EIBP includes scenario planning and extended supply chain collaboration and discusses how large companies will adopt new technologies, such as AI, big data and advanced analytics.

#1 Cloud ERP Software

Applications of Integrated Business Planning

IBP makes planning and operations much more transparent, so it’s ideal for companies moving to “just in time” manufacturing. It’s also predictive, once a company builds up some data. That can help with customer satisfaction.

PickerBots, as an example, found that it typically sees constrained supply chain capacity for motherboards in Q3. With that insight, sales and marketing can work to encourage customers to take delivery of systems in Q2 or Q4, manufacturing can prebuild products and supply chain leaders can work on alternate sources for parts that pose challenges.

Looking ahead to the future of IBP, we expect it to help companies:

- Work on ever-longer-range strategy planning, modeling and M&A activities with a higher degree of confidence.

- Detect and notify stakeholders of unanticipated events before they impact the business by using advanced technologies, including real-time sensor information and machine learning (ML) pattern recognition.

As companies build comfort with automation, advanced IBP systems can be set to take action based on analysis without human intervention. Consider a chain of bakeries; a system plugged into a long-range weather forecast system might detect a tropical storm that could raise the price of vanilla and automatically order extra.

Cloud-based technology such as ERP underpins all these advances. For example, PickerBots always set its sales goals monthly. But often these plans were delayed to let the executive team review and approve any changes, meaning operations was caught unawares. A tool like NetSuite Planning and Budgeting automates planning processes and centralizes company financial and operational data, so finance teams can disseminate updates quickly.

The next frontier? Expending IBP to business partners and suppliers, even customers. But first, companies need to get their own cultural and technology houses in order.

Business Strategy

Business Process Automation: Ultimate Guide

A well-run business is always analyzing business processes and finding ways to make them more efficient. It also searches for ways to review, update, change, replace or eliminate its processes on a regular basis in order to…

Trending Articles

Learn How NetSuite Can Streamline Your Business

NetSuite has packaged the experience gained from tens of thousands of worldwide deployments over two decades into a set of leading practices that pave a clear path to success and are proven to deliver rapid business value. With NetSuite, you go live in a predictable timeframe — smart, stepped implementations begin with sales and span the entire customer lifecycle, so there’s continuity from sales to services to support.

Before you go...

Discover the products that 37,000+ customers depend on to fuel their growth.

Before you go. Talk with our team or check out these resources.

Want to set up a chat later? Let us do the lifting.

NetSuite ERP

Explore what NetSuite ERP can do for you.

Business Guide

Complete Guide to Cloud ERP Implementation

Integrated Business Planning

Accelerating supply chain planning and orchestration

Integrated Business Planning for modern, dynamic supply chains

Integrated Business Planning (IBP) is a comprehensive planning solution developed to provide core analytics, visibility, collaboration, and execution capabilities. IBP helps organizations across industries achieve real orchestration of their supply chain in order to retain control of costs and services delivered.

Featured Integrated Business Planning Resources

Product overviews, discover more about integrated business planning, optimize costs.

Reduce transportation, overtime, and inventory holding costs

Supply chain orchestration

Coordinate stakeholders from across operations and the business unit

Rapid insights

Accelerated time-to-value analytics and development pipelines

Maximum data growth

Reduced data complexity and sourcing introduces high levels of data maturity and consensus

Unified solutions

Centralized data across Infor OS and apps, your API ecosystem, and third-party application data

Synchronize supply and demand imbalances

Align production with demand

Miminize risks

Reduce stockouts and associated service fines or lost sales

S&OP process workflows

Align departments and stakeholders.

- Multi-tenant cloud solution

- Integrated notes functionality

- Embedded S&OP process

- Integrated geography reports

Industry templates and aligned KPIs

Edit existing widgets, workbenches, and workflows or create new ones.

- 180+ pre-builts views

- 40+ pre-built workflows

- Prebuilt workflows

Highly configurable sales & operations planning environment

Balance demand and supply plans with robust tools.

- Collaborative, social platform

- S&OP process workflow and alerts

- Advanced scenario management

- Financial reconciliation

- Assumptions and amendment auditability

IBP productivity by the numbers

Additional ibp resources.

Infor Supply Chain Planning

EXECUTIVE BRIEF

Achieving end-to-end supply chain collaboration and visibility in F&B manufacturing

A buyer’s guide to supply chain management software

Related products, infor demand planning.

Achieve superior forecast accuracy

Infor Supply Planning

Optimize operations across the supply chain

Infor Production Scheduling

Improve agility and operational efficiency across the supply chain

Achieve perfect order fulfillment at the lowest possible cost

Infor Nexus

Connect supply chain partners with a single source of truth

Industry ERP solutions

Transform business-critical operations with a cloud ERP solution made for your industry

A robust cloud operating platform for accelerating innovation throughout the enterprise ecosystem

Let's Connect

Contact us and we'll have a Business Development Representative contact you within 24 business hours

By clicking “Submit” you agree that Infor will process your personal data provided in the above form for communicating with you as our potential or actual customer or a client as described in our Privacy Policy .

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Solving your most complex planning challenges

Explore Industry Research

What do Gartner, Forrester, and IDC have in common? They all named Anaplan a planning leader.

Your success is the heart of our success

Hear from our customers at Anaplan Connect 2024

Join us for a day of connected inspiration from your industry-leading peers who have found the answer in agile, connected enterprise planning.

Transform how you see, plan and lead your business

Get started today.

Explore on-demand demos to discover how our modeling and planning capabilities are designed to meet the specific and unique needs of your business.

Transform how you see, plan, and lead your business

We’d love to find out how we can help you

Events, training, and content for your planning journey

Visit our blog and newsroom

Your hub for Anaplan updates, insights, perspectives, and innovations.

Powerful partnerships to drive your digital transformation and deliver game-changing strategies.

Solutions for your business, your industry, from the world’s leading alliances.

- wrappers --> Finance

Three essentials for choosing integrated business planning software

- Share on Twitter

- Share on Facebook

- Share on LinkedIn

The platform for orchestrating performance.

When it comes to planning and budgeting methodologies, integrated business planning (IBP) is the nirvana to which many organizations aspire. At a time when corporate agility and a deep insight into business performance are paramount, its attraction is that it weaves together all the disparate strands of strategic, operational, and financial planning typically managed in a plethora of stand-alone spreadsheets and siloed applications into a single system.

While organizations can incrementally work towards full integrated business planning by first introducing driver-based models for all forms of planning and budgeting then linking them together, achieving fully functional IBP can still prove difficult. Until recently, there were no solutions allowing companies to follow an evolutionary path and grow into IBP. The only alternative was for companies to set out on an expensive, enterprise-wide implementation on the scale of a full enterprise resource planning (ERP) replacement. Understandably, most organizations parked the idea and made do with other tools.

Today, all that has changed. Platforms such as Anaplan provide functionality for all aspects of financially oriented EPM along with sales and operations planning (S&OP) and all other facets of enterprise planning. This allows finance professionals to collaborate with their colleagues in other lines of business to steadily work towards the common goal of integrated business planning and deliver transformational benefits in terms of agility and insight, which are sought after capabilities in today’s uncertain world.

Essential functionality in integrated business planning software

That is not to say implementing integrated business planning is now a walk in the park. It still involves manipulating and managing a huge amount of highly variable data — everything from pack sizes through individual employees to organizational structures. It is not just big data; it is rapidly changing data, so models need to be constantly replenished to stay aligned with changing inventory levels. The assumptions underpinning the business rules that connect strategic, operational, and financial plans are constantly changing, too. They also need to be easily flexible so users can analyze the outcomes of different scenarios before committing to a particular course of action.

If finance and operations are going to share a single planning and forecasting platform to deliver integrated business planning, then it needs to meet these exacting requirements by providing these three critical elements of functionality:

- User-friendly modeling . Embedded modeling logic users can manage themselves is essential. With a few clicks, no coding, and no dependence on IT, users can adjust business rules, update drivers, and refresh dimensions and hierarchies.

- Process a lot of data . The ability to process large volumes of data across multiple dimensions is also key. Data is growing by the second, across the world but also within individual businesses. The ideal system can grow with you, handling millions or billions of pieces of data, without you having to rip and replace when your company grows as big as you want to be

- Immediate ripple effect . Beyond data roll-up, you want real-time calculation so changes instantly ripple through all connected plans to reveal the impact right across the enterprise — all the way to the profit and loss account and cash flow forecast.

From a tactical point of view, having both finance and line of business users work with the same solution reduces the cost of ownership and eliminates many non-value-added activities that result from fragmented EPM and S&OP processes and systems. Working with a single, self-managed solution across all parts of the enterprise also makes it easier for members of the finance team to provide decision support to their peers and finally fulfill their long-held promise to become strategic business partners.

However, having finance and operations working together to achieve a common vision of end-to-end integrated business planning is far from inevitable. Unless the leadership team establish a vision to work towards, individual departments still tend to go off and adopt a localized solution for their planning needs. You could argue that such behavior is reinforced by software vendors who tend to focus on a single line of business, and by industry analysts who continue to evaluate EPM, S&OP and supply-chain software separately. Such parochialism misses the bigger opportunity of getting far more value that would be delivered by pursuing integrated business planning.

Some people believe if they use software vendors providing both EPM and S&OP applications, IBP nirvana will be inevitable. Others believe in-memory processing will be their savior. Neither of these beliefs stands up to scrutiny. IBP only works when financial and operational planning models share the same embedded logic. Without that as a foundation, in-memory calculation engines simply generate unreal answers in real time.

See how the functionality of the Anaplan platform is designed to address the planning needs of all parts of the enterprise.

SAP Integrated Business Planning for Supply Chain

Learn how to synchronize planning and ensure business continuity in times of supply chain disruption., what's it all about.

To minimize the impact of disruptions, improve customer satisfaction, and promote sustainability, organizations rely on fast and flexible supply chain planning. SAP Integrated Business Planning for Supply Chain enables businesses to centralize demand, supply, inventory, sales, and operations planning on one platform to create more efficient and resilient supply chains. With embedded analytics, what-if simulations, alerts, and other machine learning capabilities, you can quickly identify and respond to disruptions, reduce costs, optimize inventory, and improve forecasting.

Explore how to coordinate and automate AI and analytics capabilities to maintain sustainable and risk-resilient supply chains.

New to the topic?

- SAP Learning Journey

Discover SAP Integrated Business Planning for Supply Chain

Sap ibp platform features and time series based heuristics planning, popular courses, sap ibp advanced configuration, sap ibp for inventory, sap ibp for demand, time series based supply planning optimizer, looking to get certified, sap learning group.

Join our SAP Learning Group moderated by an SAP Learning expert. Ask your questions about your digital learning journeys, prepare successfully for your SAP Certification exams, and collaborate with other learners to reach your learning goals.

- Webinar Replays

- News & Press

- User Groups

- Brand Ambassadors

- OneStream Press

- Solution Exchange

- PartnerStream

- Financial Close & Consolidation

- Financial Signaling

- Reporting & Analytics

- Financial Data Quality

- Account Reconciliations

- Transaction Matching

- Compliance Solutions

- Tax Provision

- ESG Reporting & Planning

- Planning, Budgeting & Forecasting

- AI Financial Forecasting

- People Planning

- Capital Planning

- Sales Planning

- Profitability Analysis

- Manufacturing

- Financial Services

- Public Sector

- Higher Education

- Oracle Hyperion Conversion

- SAP ERP Customers

- Consulting Services

- Certification Program

- ONECommunity

- Customer Success

- News & Press

What is Integrated Business Planning and What Are The Benefits?

If there is one thing any business analyst can forecast is this: sustained uncertainty. And organizations can’t do much to change this. What organizations can do though, is to prepare to deal with market variability by addressing the business challenges internal organizations may have: disconnected and lengthy planning processes, an insane amount of time collating data, siloed decision-making, lack of forecasting accuracy, poor sight into operational assumptions and what is driving margin. That’s what Integrated Business Planning is aiming for.

What is Integrated Business Planning (IBP)?

Integrated Business Planning aims to unify business strategy with planning, budgeting and forecasting activity for all business lines and functions – providing one version of the numbers. A trusted, common view of the numbers provides a robust baseline for agile decision-making and keeps all teams together, collectively trying to achieve the same corporate objectives while staying focused on specific KPIs. In other words, the different teams maintain their independence while working in unison to achieve corporate success by leveraging the same trusted and governed data.

The bottom line is that IBP is about aligning strategy intent, unifying planning processes and bringing the organization together.

IBP Process: How Does it Work

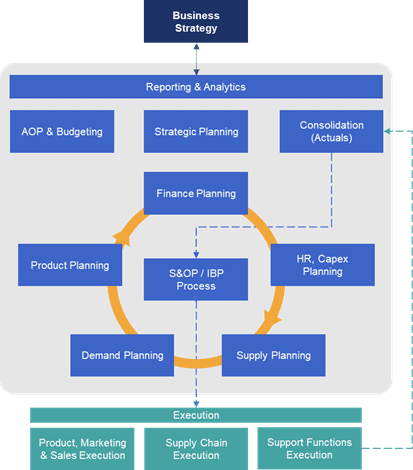

The Integrated Business Planning process is a framework to address the C-suite needs and help them implement the business strategy and manage uncertainty to improve decision-making. The secret sauce of IBP is a collaboration between the different teams under a single view of the numbers that must unequivocally be tied to financial performance, that’s how the C-suite gets value from it. Consequently, finance plays a central role within IBP.

IBP typically focuses on 24- 60 months horizons, as opposed to short term: that’s Integrated Tactical Planning or Sales and Operations Planning and Execution. The process must be fully integrated, so it should remove the departmental silos and it must adapt to the organizational construct of every business (it is not a one size fits all type of process).

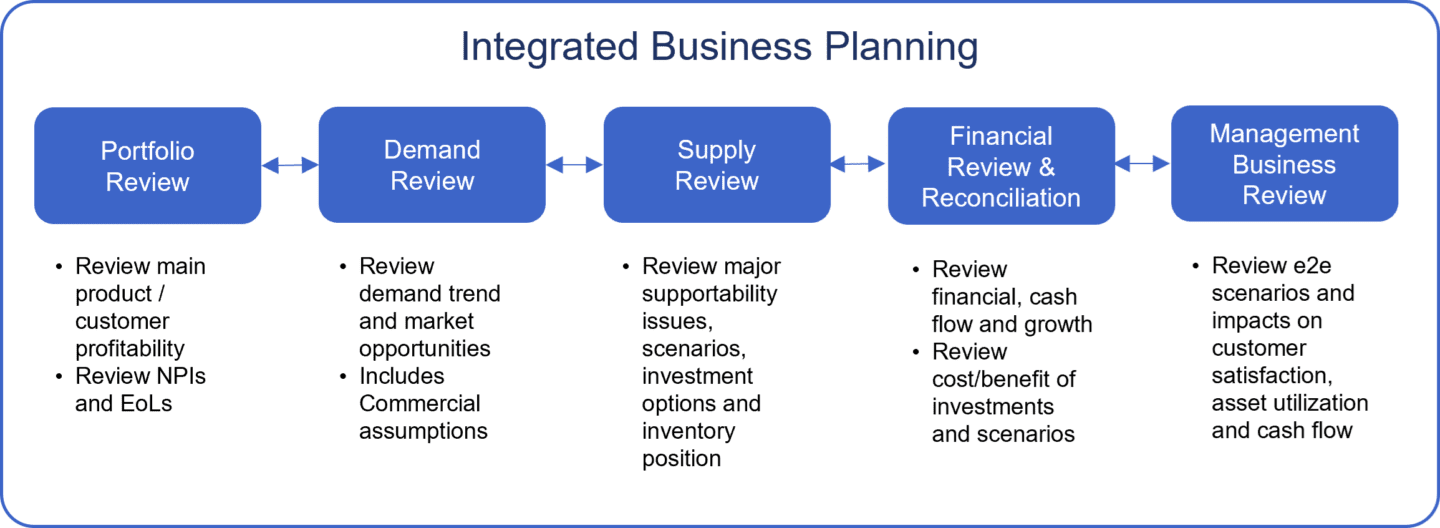

Figure 1 outlines the five core elements of the IBP cycle with its responsibilities:

The most efficient way to foster this collaboration is by having a unified solution and data model that caters the needs of the various agents involved on each review. Figure 2 shows how one solution gathering all the capabilities in the greyed area under a unified data model is the most efficient approach to IBP.

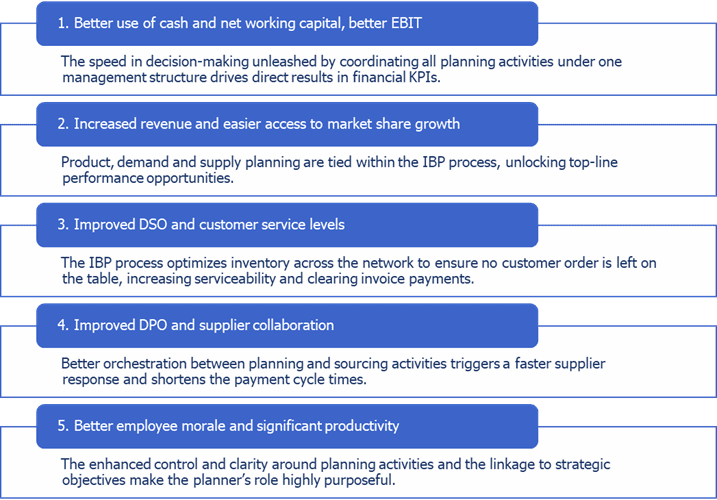

IBP Business Benefits

The benefits an organization can expect from an IBP implementation are diverse. In the big picture, IBP can certainly improve financial and business performance. Figure 3 outlines some of the most remarkable KPI improvements.

Want to learn how you can maximize the benefits of your IBP process and get your CEO onboard, read our blog on the 5 Considerations to Help Your CEO Trust the IBP Process .

Get Started With a Personal Demo

Streamline Financial Processes

IMAGES

VIDEO