Imagine a symphony orchestra where each musician plays their own tune without listening to others. The result would be chaotic and dissonant, right? Similarly, in the business world, when decision-making happens in silos and planning processes are disconnected, it’s like having a group of individuals playing their own instruments without any coordination. The harmony is lost, and the organization becomes inefficient, misses opportunities, and struggles to keep up with the fast-paced market.

Integrated Business Planning (IBP) addresses these challenges by providing a comprehensive framework that integrates strategic, operational and financial planning, analysis, and reporting to drive better business outcomes. A retail company experiences a sudden surge in online sales due to a viral social media campaign. Integrated planning incorporates supply chain planning, demand planning, and demand forecasts so the company can quickly assess the impact on inventory levels, supply chain logistics, production plans, and customer service capacity. By having real-time data at their fingertips, decision-makers can adjust their strategies, allocate resources accordingly, and capitalize on the unexpected spike in demand, ensuring customer satisfaction while maximizing revenue. This blog explores the significance of IBP in today’s modern business landscape and highlights its key benefits and implementation considerations.

Integrated business planning framework

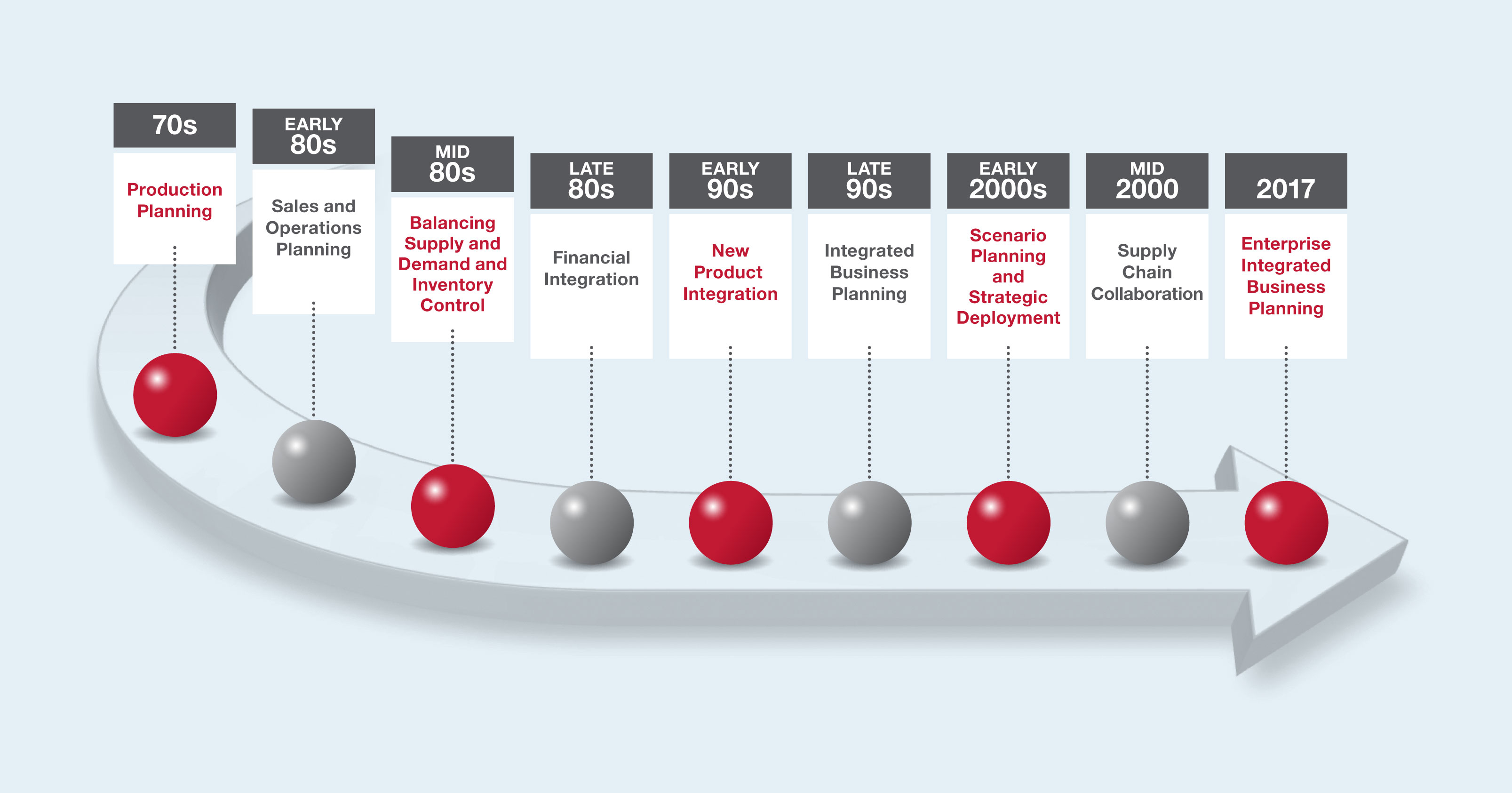

Integrated Business Planning (IBP) is a holistic approach that integrates strategic planning, operational planning, and financial planning within an organization. IBP brings together various functions, including sales, marketing, finance, supply chain, human resources, IT and beyond to collaborate across business units and make informed decisions that drive overall business success. The term ‘IBP’ was introduced by the management consulting firm Oliver Wight to describe an evolved version of the sales and operations planning (S&OP process) they originally developed in the early 1980s.

Making up the Integrated Business Planning framework are six key pillars:

1. strategic planning.

Integrated Business Planning starts with strategic planning. The management team defines the organization’s long-term goals and objectives. This includes analyzing market trends, competitive forces, and customer demands to identify opportunities and threats. Strategic planning sets the direction for the entire organization and establishes the foundation for subsequent planning roadmap.

2. Operational planning

Operational planning focuses on translating strategic goals into actionable plans at the operational level. This involves breaking down the strategic objectives into specific targets and initiatives that different departments and functions need to execute.

For example, the sales department might develop a plan to enter new markets or launch new products, while the supply chain department focuses on inventory optimization and ensuring efficient logistics. The key is to align operational plans with the broader strategic objectives to ensure consistency and coherence throughout the organization.

3. Financial planning

Financial planning ensures that the organization’s strategic and operational plans are financially viable. It involves developing detailed financial projections, including revenue forecasts, expense budgets, and cash flow forecasts. By integrating financial planning with strategic and operational planning, organizations can evaluate financial profitability, identify potential gaps or risks, and make necessary adjustments to achieve financial targets.

4. Cross-functional collaboration

A fundamental aspect of IBP is the collaboration and involvement of various functions and departments within the organization. Rather than working in isolation, departments such as sales, marketing, finance, supply chain, human resources, and IT come together to share information, align objectives, and make coordinated decisions.

5. Data integration and analytics

IBP relies on the integration of data from different sources and systems. This may involve consolidating data from enterprise resource planning (ERP) systems, customer relationship management (CRM) systems, supply chain management systems, and other relevant sources. Advanced analytics and business intelligence tools are utilized to analyze and interpret the data, uncovering insights and trends that drive informed decision-making.

6. Continuous monitoring and performance management

The Integrated Business Planning process requires continuous monitoring of performance against plans and targets. Key performance indicators (KPIs) are established to measure progress and enable proactive management. Regular performance reviews and reporting enable organizations to identify deviations, take corrective actions, and continuously improve their planning processes.

What are the benefits of Integrated Business Planning?

By integrating strategic, operational, and financial planning organizations can unlock the full potential of IBP and drive business success and achieve their goals.

Enhanced decision-making

IBP facilitates data-driven decision-making by providing real-time insights into various aspects of the business. By bringing together data from various departments, organizations can develop a holistic view of their operations, enabling them to make better-informed decisions.

Improved alignment

By aligning strategic objectives with operational plans and financial goals, IBP ensures that every department and employee is working towards a common vision. This alignment fosters synergy and drives cross-functional collaboration.

Agility and responsiveness

In the rapidly changing business landscape, agility is crucial. IBP allows organizations to quickly adapt to market shifts, demand fluctuations, and emerging opportunities. By continuously monitoring and adjusting plans, businesses can remain responsive and seize competitive advantages.

Optimal resource allocation

Integrated Business Planning enables organizations to optimize resource allocation across different functions. It helps identify bottlenecks, allocate resources effectively, and prioritize initiatives that yield the highest returns, leading to improved efficiency and cost savings.

Risk management

IBP facilitates proactive risk management by considering various scenarios and identifying potential risks and opportunities. By analyzing data and conducting what-if analyses, companies can develop contingency plans and mitigate risks before they materialize.

Essential steps for implementing Integrated Business Planning

Implementing an effective IBP process requires careful planning and execution that may require substantial effort and a change of management, but the rewards are well worth it. Here are some essential strategic steps to consider:

1. Executive sponsorship

Establish leadership buy-in; gain support from top-level executives who understand the value of Integrated Business Planning and can drive the necessary organizational changes. Leadership commitment, led by CFO, is crucial for successful implementation.

2. Continuous improvement

Continuously monitor and adjust; implement mechanisms to monitor performance against plans and targets. Regularly review key performance indicators (KPIs), conduct performance analysis, and generate timely reports and dashboards. Identify deviations, take corrective actions, and continuously improve the planning processes based on feedback and insights.

3. Integration of people and technology

To foster cross-functional collaboration, the organization must identify key stakeholders, break down silos, and encourage open communication among departments. Creating a collaborative culture that values information sharing and collective decision-making is essential.

Simultaneously, implementing a robust data integration system, encompassing ERP, CRM, and supply chain management systems, ensures seamless data flow and real-time updates. User-friendly interfaces, data governance, and training provide the necessary technological support. Combining these efforts cultivates an environment of collaboration and data-driven decision-making, boosting operational efficiency and competitiveness.

4. Technology

Implement advanced analytics and business intelligence solutions to streamline and automate the planning process and assist decision-making capabilities. These solutions provide comprehensive functionality, data integration capabilities, scenario planning and modeling, and real-time reporting.

Integrated Business Planning software

From a tech perspective, organizations need advanced software solutions and systems that facilitate seamless data integration and collaboration to support IBP. Here are some key components that contribute to the success of integrated business planning:

1. Corporate performance management

A platform that serves as the backbone of integrated business planning by integrating data from different departments and functions. It enables a centralized repository of information and provides real-time visibility into the entire business.

2. Business intelligence (BI) tools

Business intelligence tools play a vital role in analyzing and visualizing integrated data from multiple sources. These tools provide comprehensive insights into key metrics and help identify trends, patterns, and opportunities. By leveraging BI tools, decision-makers can quickly evaluate financial performance, make data-driven business decisions and increase forecast accuracy.

3. Collaborative planning and forecasting solutions

Collaborative planning and forecasting solutions enable cross-functional teams to work together in creating and refining plans. These planning solutions facilitate real-time collaboration, allowing stakeholders to contribute their expertise and insights. With end-to-end visibility, organizations can ensure that plans are comprehensive, accurate, and aligned with business strategy.

4. Data integration and automation

To ensure seamless data integration, organizations need to invest in data integration and automation tools. These tools enable the extraction, transformation, and loading (ETL) of data from various sources. Automation streamlines data processes reduces manual effort and minimizes the risk of errors or data discrepancies.

5. Cloud-based solutions

Cloud computing offers scalability, flexibility, and accessibility, making it an ideal choice for integrated business planning. Cloud-based solutions provide a centralized platform where teams can access data, collaborate, and make real-time updates from anywhere, at any time. The cloud also offers data security, disaster recovery, and cost efficiencies compared to on-premises infrastructure.

6. Data governance and security

As organizations integrate data from multiple sources, maintaining data governance and security becomes crucial. Establishing data governance policies and ensuring compliance with data protection regulations are vital steps in maintaining data integrity and safeguarding sensitive information. Implementing robust data security measures, such as encryption and access controls, helps protect against data breaches and unauthorized access.

IBM Planning Analytics for Integrated Business Planning

IBM Planning Analytics is a highly scalable and flexible solution for Integrated Business Planning. It supports and strengthens the five pillars discussed above, empowering organizations to achieve their strategic goals and make better data-driven decisions. With its AI- infused advanced analytics and modeling capabilities, IBM Planning Analytics allows organizations to integrate strategic, operational, and financial planning seamlessly. The solution enables cross-functional collaboration by providing a centralized platform where teams from various departments can collaborate, share insights, and align their plans. IBM Planning Analytics also offers powerful data integration capabilities, allowing organizations to consolidate data from multiple sources and systems, providing a holistic view of the business. The solutions’s robust embedded AI predictive analytics uses internal and external data and machine learning to provide accurate demand forecasts. IBM Planning Analytics supports continuous monitoring and performance management by providing real-time reporting, dashboards, and key performance indicators (KPIs) that enable organizations to track progress and take proactive actions. As the business landscape continues to evolve, embracing Integrated Business Planning is no longer an option but a necessity for organizations. To succeed in this dynamic environment, businesses need an integrated approach to planning that brings all the departments and data together, creating a symphony of collaboration and coordination.

More from Artificial intelligence

Gen ai: your new creative partner.

3 min read - As artificial intelligence continues to reshape industries, its impact on creativity has been a hot topic of debate. Can machines truly be creative? Or will they simply mimic human ingenuity? A new study published in Nature Human Behaviour sheds light on this question, suggesting that generative AI might be more of a creative collaborator than a replacement. Researchers put ChatGPT, the popular AI chatbot, through its paces, pitting it against Google searches and unaided human thinking. The result? Large language…

Examining synthetic data: The promise, risks and realities

3 min read - As artificial intelligence reshapes industries worldwide, developers are grappling with an unexpected challenge: a shortage of high-quality, real-world data to train their increasingly sophisticated models. Now, a potential solution is emerging from an unlikely source—data that doesn't exist in reality at all. Synthetic data, artificially generated information designed to mimic real-world scenarios, is rapidly gaining traction in AI development. It promises to overcome data bottlenecks, address privacy concerns, and reduce costs. However, as the field evolves, questions about its limitations…

Advance your enterprise Journey to Hybrid Cloud and AI powered by AIOps on Z

2 min read - Thanks to rising costs, skills shortages and ever-growing security threats, businesses must adapt quickly to shifts in demand patterns brought on by a digital workforce and rapidly changing buyer behavior. That requires putting extra emphasis on the resiliency and performance of your business processes and supporting applications. For larger IT organizations with increasingly hybrid and complex application landscapes that often include IBM Z®, it’s essential to take a comprehensive approach to IT operations. The challenge becomes “How do you effectively sift through terabytes of…

IBM Newsletters

A better way to drive your business

Managing the availability of supply to meet volatile demand has never been easy. Even before the unprecedented challenges created by the COVID-19 pandemic and the war in Ukraine, synchronizing supply and demand was a perennial struggle for most businesses. In a survey of 54 senior executives, only about one in four believed that the processes of their companies balanced cross-functional trade-offs effectively or facilitated decision making to help the P&L of the full business.

That’s not because of a lack of effort. Most companies have made strides to strengthen their planning capabilities in recent years. Many have replaced their processes for sales and operations planning (S&OP) with the more sophisticated approach of integrated business planning (IBP), which shows great promise, a conclusion based on an in-depth view of the processes used by many leading companies around the world (see sidebar “Understanding IBP”). Assessments of more than 170 companies, collected over five years, provide insights into the value created by IBP implementations that work well—and the reasons many IBP implementations don’t.

Understanding IBP

Integrated business planning is a powerful process that could become central to how a company runs its business. It is one generation beyond sales and operations planning. Three essential differentiators add up to a unique business-steering capability:

- Full business scope. Beyond balancing sales and operations planning, integrated business planning (IBP) synchronizes all of a company’s mid- and long-term plans, including the management of revenues, product pipelines and portfolios, strategic projects and capital investments, inventory policies and deployment, procurement strategies, and joint capacity plans with external partners. It does this in all relevant parts of the organization, from the site level through regions and business units and often up to a corporate-level plan for the full business.

- Risk management, alongside strategy and performance reviews. Best-practice IBP uses scenario planning to drive decisions. In every stage of the process, there are varying degrees of confidence about how the future will play out—how much revenue is reasonably certain as a result of consistent consumption patterns, how much additional demand might emerge if certain events happen, and how much unusual or extreme occurrences might affect that additional demand. These layers are assessed against business targets, and options for mitigating actions and potential gap closures are evaluated and chosen.

- Real-time financials. To ensure consistency between volume-based planning and financial projections (that is, value-based planning), IBP promotes strong links between operational and financial planning. This helps to eliminate surprises that may otherwise become apparent only in quarterly or year-end reviews.

An effective IBP process consists of five essential building blocks: a business-backed design; high-quality process management, including inputs and outputs; accountability and performance management; the effective use of data, analytics, and technology; and specialized organizational roles and capabilities (Exhibit 1). Our research finds that mature IBP processes can significantly improve coordination and reduce the number of surprises. Compared with companies that lack a well-functioning IBP process, the average mature IBP practitioner realizes one or two additional percentage points in EBIT. Service levels are five to 20 percentage points higher. Freight costs and capital intensity are 10 to 15 percent lower—and customer delivery penalties and missed sales are 40 to 50 percent lower. IBP technology and process discipline can also make planners 10 to 20 percent more productive.

When IBP processes are set up correctly, they help companies to make and execute plans and to monitor, simulate, and adapt their strategic assumptions and choices to succeed in their markets. However, leaders must treat IBP not just as a planning-process upgrade but also as a company-wide business initiative (see sidebar “IBP in action” for a best-in-class example).

IBP in action

One global manufacturer set up its integrated business planning (IBP) system as the sole way it ran its entire business, creating a standardized, integrated process for strategic, tactical, and operational planning. Although the company had previously had a sales and operations planning (S&OP) process, it had been owned and led solely by the supply chain function. Beyond S&OP, the sales function forecast demand in aggregate dollar value at the category level and over short time horizons. Finance did its own projections of the quarterly P&L, and data from day-by-day execution fed back into S&OP only at the start of a new monthly cycle.

The CEO endorsed a new way of running regional P&Ls and rolling up plans to the global level. The company designed its IBP process so that all regional general managers owned the regional IBP by sponsoring the integrated decision cycles (following a global design) and by ensuring functional ownership of the decision meetings. At the global level, the COO served as tiebreaker whenever decisions—such as procurement strategies for global commodities, investments in new facilities for global product launches, or the reconfiguration of a product’s supply chain—cut across regional interests.

To enable IBP to deliver its impact, the company conducted a structured process assessment to evaluate the maturity of all inputs into IBP. It then set out to redesign, in detail, its processes for planning demand and supply, inventory strategies, parametrization, and target setting, so that IBP would work with best-practice inputs. To encourage collaboration, leaders also started to redefine the performance management system so that it included clear accountability for not only the metrics that each function controlled but also shared metrics. Finally, digital dashboards were developed to track and monitor the realization of benefits for individual functions, regional leaders, and the global IBP team.

A critical component of the IBP rollout was creating a company-wide awareness of its benefits and the leaders’ expectations for the quality of managers’ contributions and decision-making discipline. To educate and show commitment from the CEO down, this information was rolled out in a campaign of town halls and media communications to all employees. The company also set up a formal capability-building program for the leaders and participants in the IBP decision cycle.

Rolled out in every region, the new training helps people learn how to run an effective IBP cycle, to recognize the signs of good process management, and to internalize decision authority, thresholds, and escalation paths. Within a few months, the new process, led by a confident and motivated leadership team, enabled closer company-wide collaboration during tumultuous market conditions. That offset price inflation for materials (which adversely affected peers) and maintained the company’s EBITDA performance.

Our research shows that these high-maturity IBP examples are in the minority. In practice, few companies use the IBP process to support effective decision making (Exhibit 2). For two-thirds of the organizations in our data set, IBP meetings are periodic business reviews rather than an integral part of the continuous cycle of decisions and adjustments needed to keep organizations aligned with their strategic and tactical goals. Some companies delegate IBP to junior staff. The frequency of meetings averages one a month. That can make these processes especially ineffective—lacking either the senior-level participation for making consequential strategic decisions or the frequency for timely operational reactions.

Finally, most companies struggle to turn their plans into effective actions: critical metrics and responsibilities are not aligned across functions, so it’s hard to steer the business in a collaborative way. Who is responsible for the accuracy of forecasts? What steps will be taken to improve it? How about adherence to the plan? Are functions incentivized to hold excess inventory? Less than 10 percent of all companies have a performance management system that encourages the right behavior across the organization.

By contrast, at the most effective organizations, IBP meetings are all about decisions and their impact on the P&L—an impact enabled by focused metrics and incentives for collaboration. Relevant inputs (data, insights, and decision scenarios) are diligently prepared and syndicated before meetings to help decision makers make the right choices quickly and effectively. These companies support IBP by managing their short-term planning decisions prescriptively, specifying thresholds to distinguish changes immediately integrated into existing plans from day-to-day noise. Within such boundaries, real-time daily decisions are made in accordance with the objectives of the entire business, not siloed frontline functions. This responsive execution is tightly linked with the IBP process, so that the fact base is always up-to-date for the next planning iteration.

A better plan for IBP

In our experience, integrated business planning can help a business succeed in a sustainable way if three conditions are met. First, the process must be designed for the P&L owner, not individual functions in the business. Second, processes are built for purpose, not from generic best-practice templates. Finally, the people involved in the process have the authority, skills, and confidence to make relevant, consequential decisions.

Design for the P&L owner

IBP gives leaders a systematic opportunity to unlock P&L performance by coordinating strategies and tactics across traditional business functions. This doesn’t mean that IBP won’t function as a business review process, but it is more effective when focused on decisions in the interest of the whole business. An IBP process designed to help P&L owners make effective decisions as they run the company creates requirements different from those of a process owned by individual functions, such as supply chain or manufacturing.

One fundamental requirement is senior-level participation from all stakeholder functions and business areas, so that decisions can be made in every meeting. The design of the IBP cycle, including preparatory work preceding decision-making meetings, should help leaders make general decisions or resolve minor issues outside of formal milestone meetings. It should also focus the attention of P&L leaders on the most important and pressing issues. These goals can be achieved with disciplined approaches to evaluating the impact of decisions and with financial thresholds that determine what is brought to the attention of the P&L leader.

The aggregated output of the IBP process would be a full, risk-evaluated business plan covering a midterm planning horizon. This plan then becomes the only accepted and executed plan across the organization. The objective isn’t a single hard number. It is an accepted, unified view of which new products will come online and when, and how they will affect the performance of the overall portfolio. The plan will also take into account the variabilities and uncertainties of the business: demand expectations, how the company will respond to supply constraints, and so on. Layered risks and opportunities and aligned actions across stakeholders indicate how to execute the plan.

Would you like to learn more about our Operations Practice ?

Trade-offs arising from risks and opportunities in realizing revenues, margins, or cost objectives are determined by the P&L owner at the level where those trade-offs arise—local for local, global for global. To make this possible, data visible in real time and support for decision making in meetings are essential. This approach works best in companies with strong data governance processes and tools, which increase confidence in the objectivity of the IBP process and support for implementing the resulting decisions. In addition, senior leaders can demonstrate their commitment to the value and the standards of IBP by participating in the process, sponsoring capability-building efforts for the teams that contribute inputs to the IBP, and owning decisions and outcomes.

Fit-for-purpose process design and frequency

To make IBP a value-adding capability, the business will probably need to redesign its planning processes from a clean sheet.

First, clean sheeting IBP means that it should be considered and designed from the decision maker’s perspective. What information does a P&L owner need to make a decision on a given topic? What possible scenarios should that leader consider, and what would be their monetary and nonmonetary impact? The IBP process can standardize this information—for example, by summarizing it in templates so that the responsible parties know, up front, which data, analytics, and impact information to provide.

Second, essential inputs into IBP determine its quality. These inputs include consistency in the way planners use data, methods, and systems to make accurate forecasts, manage constraints, simulate scenarios, and close the loop from planning to the production shopfloor by optimizing schedules, monitoring adherence, and using incentives to manufacture according to plan.

Determining the frequency of the IBP cycle, and its timely integration with tactical execution processes, would also be part of this redesign. Big items—such as capacity investments and divestments, new-product introductions, and line extensions—should be reviewed regularly. Monthly reviews are typical, but a quarterly cadence may also be appropriate in situations with less frequent changes. Weekly iterations then optimize the plan in response to confirmed orders, short-term capacity constraints, or other unpredictable events. The bidirectional link between planning and execution must be strong, and investments in technology may be required to better connect them, so that they use the same data repository and have continuous-feedback loops.

Authorize consequential decision making

Finally, every IBP process step needs autonomous decision making for the problems in its scope, as well as a clear path to escalate, if necessary. The design of the process must therefore include decision-type authority, decision thresholds, and escalation paths. Capability-building interventions should support teams to ensure disciplined and effective decision making—and that means enforcing participation discipline, as well. The failure of a few key stakeholders to prioritize participation can undermine the whole process.

Decision-making autonomy is also relevant for short-term planning and execution. Success in tactical execution depends on how early a problem is identified and how quickly and effectively it is resolved. A good execution framework includes, for example, a classification of possible events, along with resolution guidelines based on root cause methodology. It should also specify the thresholds, in scope and scale of impact, for operational decision making and the escalation path if those thresholds are met.

Transforming supply chains: Do you have the skills to accelerate your capabilities?

In addition to guidelines for decision making, the cross-functional team in charge of executing the plan needs autonomy to decide on a course of action for events outside the original plan, as well as the authority to see those actions implemented. Clear integration points between tactical execution and the IBP process protect the latter’s focus on midterm decision making and help tactical teams execute in response to immediate market needs.

An opportunity, but no ‘silver bullet’

With all the elements described above, IBP has a solid foundation to create value for a business. But IBP is no silver bullet. To achieve a top-performing supply chain combining timely and complete customer service with optimal cost and capital expenditures, companies also need mature planning and fulfillment processes using advanced systems and tools. That would include robust planning discipline and a collaboration culture covering all time horizons with appropriate processes while integrating commercial, planning, manufacturing, logistics, and sourcing organizations at all relevant levels.

As more companies implement advanced planning systems and nerve centers , the typical monthly IBP frequency might no longer be appropriate. Some companies may need to spend more time on short-term execution by increasing the frequency of planning and replanning. Others may be able to retain a quarterly IBP process, along with a robust autonomous-planning or exception engine. Already, advanced planning systems not only direct the valuable time of experts to the most critical demand and supply imbalances but also aggregate and disaggregate large volumes of data on the back end. These targeted reactions are part of a critical learning mechanism for the supply chain.

Over time, with root cause analyses and cross-functional collaboration on systemic fixes, the supply chain’s nerve center can get smarter at executing plans, separating noise from real issues, and proactively managing deviations. All this can eventually shorten IBP cycles, without the risk of overreacting to noise, and give P&L owners real-time transparency into how their decisions might affect performance.

P&L owners thinking about upgrading their S&OP or IBP processes can’t rely on textbook checklists. Instead, they can assume leadership of IBP and help their organizations turn strategies and plans into effective actions. To do so, they must sponsor IBP as a cross-functional driver of business decisions, fed by thoughtfully designed processes and aligned decision rights, as well as a performance management and capability-building system that encourages the right behavior and learning mechanisms across the organization. As integrated planning matures, supported by appropriate technology and maturing supply chain–management practices, it could shorten decision times and accelerate its impact on the business.

Elena Dumitrescu is a senior knowledge expert in McKinsey’s Toronto office, Matt Jochim is a partner in the London office, and Ali Sankur is a senior expert and associate partner in the Chicago office, where Ketan Shah is a partner.

Explore a career with us

Related articles.

To improve your supply chain, modernize your supply-chain IT

Supply-chain resilience: Is there a holy grail?

By Whitney Gillespie April 16, 2024

Complete guide to integrated business planning (ibp).

Integrated Business Planning, or IBP for short, is a strategic management process that connects various organizational departments to align business operations with financial goals. How? By integrating business functions – such as Sales, Marketing, Finance, Supply Chain and Operations – to create a holistic view of the company's performance and future direction. This blog post offers a comprehensive guide to discuss what precisely IBP entails and how Finance can drive business results and collaboration within the organization via a robust and comprehensive IBP process.

What Is Integrated Business Planning?

While the business world and Finance have always had shared language and acronyms, some new (and reimagined) acronyms may now be flooding your feed. One such topic you may be hearing a lot about lately is Integrated Business Planning (IBP). Yet the concept of IBP isn't new. In fact, it's related to Sales & Operations Planning (S&OP) , a concept that's been around awhile.

Still, IBP may seem overwhelming in the context of all the different acronyms related to financial and operational planning floating around lately. For example, IBP, S&OP, eXtended Planning and Analysis (xP&A) and others are just a few acronyms muddying the waters. But this comprehensive guide to all things IBP aims to help demystify the process.

So what, exactly, is IBP?

IBP ultimately aims to unify business strategy with planning, budgeting and forecasting activity for all business lines and functions – providing one version of the numbers. In turn, a trusted, common view of the numbers provides a robust baseline for agile decision-making. That common view also keeps all teams collectively trying to achieve the same corporate objectives while staying focused on specific KPIs. In other words, the different teams maintain their independence while working in unison to achieve corporate success by leveraging the same trusted and governed data.

The bottom line? IBP is about aligning strategy intent, unifying planning processes and bringing the organization together.

How Integrated Business Planning Works

The IBP process is a framework to address the C-suite needs and help implement the business strategy and manage uncertainty to improve decision-making. So what's the secret sauce of IBP to make all of that happen? A collaboration between the different teams under a single view of the numbers that must unequivocally be tied to financial performance. That's how the C-suite gets value from IBP. Consequently, Finance plays a central role in the IBP process.

IBP typically focuses on horizons of 24-60 months, as opposed to the short term. That focus equates to Integrated Tactical Planning or Sales and Operations Planning and Execution. Since the process must be fully integrated, it removes the departmental silos. Plus, the IBP process must adapt to the organizational construct of every business (IBP isn't a one-size-fits-all type of process).

A typical IBP process involves several stages:

- Data Collection and Analysis : Gathering relevant data (e.g., sales forecasts, production capacities, inventory levels and financial projections) from different departments.

- Demand Planning: Predicting future demand based on historical data, market trends, customer feedback and sales forecasts.

- Supply Planning: Determining the resources and capabilities (e.g., materials, production capacity and distribution channels) needed to meet the forecasted demand.

- Financial Planning : Developing financial plans and budgets aligned with the demand and supply forecasts, considering factors such as revenue targets, cost structures and investment requirements.

- Scenario Planning: Creating alternative scenarios to assess how different strategies, market conditions or external factors impact business outcomes.

- Management Business Review : Collaborating across departments to make informed decisions on resource allocation, investments, pricing strategies and operational adjustments.

- Execution and Monitoring : Implementing the plans, tracking performance against targets, and continuously monitoring key metrics to identify deviations and take corrective actions.

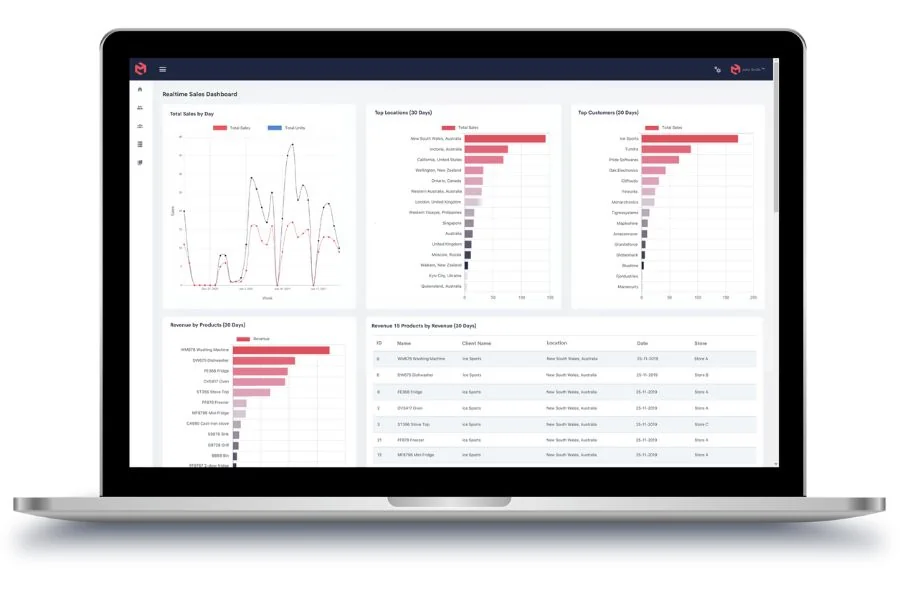

The most efficient way to foster this collaboration is through a unified solution and data model that caters to the needs of the various agents involved on each review. In fact, Figure 1 shows how one solution gathering all the capabilities in the greyed area under a unified data model is the most efficient approach to IBP.

Figure 1: A Unified Data Model for IBP

Core Elements and Stages of the Integrated Business Planning Process

The IBP process includes the following core elements:

- Governance Structure : Establishing a cross-functional team with representatives from key departments to oversee the IBP process, define roles and responsibilities, and ensure alignment with organizational goals.

- Data Integration : Integrating data from different systems and sources to create a single source of truth for decision-making, using technologies such as enterprise resource planning (ERP) systems, Corporate Performance Management (CPM) tools, business intelligence (BI) tools and data analytics platforms.

- Collaborative Planning : Encouraging collaboration and communication between departments to share insights, align objectives and develop consensus-based plans that support overall business objectives.

- Continuous Improvement : Implementing feedback loops, performance reviews and process refinements to enhance the effectiveness and agility of the IBP process over time.

Key Performance Indicators (KPIs) for Integrated Business Planning

Some key KPIs to measure the effectiveness of an IBP process include:

- Forecast Accuracy : Comparing actual sales or demand with forecasted figures to assess the accuracy and reliability of forecasting models.

- Inventory Turnover : Calculating how often inventory is sold and replaced within a specific period indicates efficiency in inventory management.

- Customer Service Levels : Monitoring metrics like on-time delivery, order fulfillment rates, and customer satisfaction scores to measure service performance.

- Financial Metrics : Evaluating financial KPIs such as revenue growth, gross margin, operating profit, and return on investment (ROI) to gauge overall business performance.

- Supply Chain Performance : Assessing metrics like lead times, supplier performance, inventory levels, and supply chain costs to optimize supply chain operations.

Technological Enablers for Integrated Business Planning

Several technological enablers support a robust IBP process:

- ERP Systems : Integrated ERP systems consolidate data from different departments, automate processes, and provide real-time visibility into business operations.

- BI and Analytics Tools : Business intelligence tools and analytics platforms enable data visualization, trend analysis, scenario modeling, and predictive analytics for informed decision-making.

- Collaboration Platforms : Cloud-based collaboration tools facilitate communication, document sharing, and workflow management among cross-functional teams involved in IBP.

- Advanced Planning Software : Specialized IBP software solutions offer capabilities for demand planning, supply chain optimization, financial modeling, scenario planning, and performance monitoring.

- AI and Machine Learning : AI-driven algorithms and machine learning techniques can enhance forecasting accuracy, identify patterns, optimize resource allocation, and automate repetitive tasks in IBP processes.

By leveraging these technological enablers, finance professionals can streamline the IBP process, improve decision-making, and drive business growth.

In conclusion, Integrated Business Planning (IBP) is a strategic approach that aligns business functions, integrates data-driven insights and fosters collaboration to achieve operational excellence, financial stability, and competitive advantage. By implementing a robust IBP process supported by technology and focused on continuous improvement, finance professionals can effectively drive sustainable growth, mitigate risks, and adapt to evolving market dynamics.

Want to learn how you can maximize the benefits of your IBP process and get leadership on board with the plan? Check out our eBook Unifying Integrated Business Planning Across Finance and Supply Chain . You'll learn how to unify IBP across Finance and Supply Chain teams and read about use cases as proof points. Plus, you'll gain an understanding of the unique capabilities OneStream's Intelligent Finance Platform brings to unify Finance and Supply Chain planning activities.

Related Resources

No products in the cart.

The Ultimate Guide To Integrated Business Planning

Are you looking for a way to streamline your business planning process? Integrated Business Planning (IBP) is the perfect solution. It’s an approach that combines all aspects of business planning into one comprehensive strategy, allowing you to make decisions quickly and accurately. This guide will help you understand how IBP works and how it can benefit your organization.

With IBP, you can save time by having all of your data in one place, making it easier to identify trends and opportunities as they arise. You’ll also be able to make more informed decisions based on real-time data analysis instead of relying on outdated information or guesswork.

What Is Integrated Business Planning?

Integrated business planning (IBP) is a powerful process that could become central to how a company runs its business. It is one generation beyond traditional sales and operations planning (S&OP) and combines financial and operational data from across the organization to create an aligned, cross-functional plan for the future. IBP enables businesses to make decisions based on key assumptions that are documented and updated regularly, helping them to achieve corporate goals.

IBP solutions help align financial and operations plans, giving companies greater planning accuracy and operational performance. This process also incorporates forecasting and demand response , demand-driven supply management, inventory optimization, production scheduling, transportation optimization, and more. With business planning processes in place, companies can make better decisions faster by leveraging real-time data from across their organization.

What Is the Difference Between Sales & Operations Planning and IBP?

Sales And Operations Planning (S&OP) and Integrated Business Planning (IBP) are two different integrated processes used to manage the supply chain. S&OP is a cross-functional process that focuses on aligning demand forecasts and supply in volumes in a tactical range, while IBP has a broader scope that looks at aligning all aspects of the business to ensure better decision-making.

Sales and operations planning processes typically have medium-term planning horizons that rarely extend beyond 18 months, while IBP naturally has a longer time scale. Additionally, IBP starts at the executive level, and each month or planning cycle culminates in a performance review against plans.

Both S&OP and IBP are important for managing the supply chain and ensuring successful operations. However, it’s important to understand their differences to choose which process best meets your needs.

What is an example of an integrated business model?

An example of an integrated business model is a supply chain management system. This type of system links different parts of the organization, from the production and inventory to customer service and sales. It leverages data to streamline operations, improve efficiency, and reduce costs. By integrating processes across departments, businesses can gain greater visibility into their operations and make better decisions faster than ever before.

Benefits Of Integrated Business Planning

The main benefit of implementing IBP is increased revenue, followed by forecast accuracy and improved Perfect Order Delivery. Other benefits include creating transparency between strategic goals and financial and operational activities, unlocking P&L performance through coordinating strategies and tactics across traditional business functions, creating more collaborative decision-making, providing higher agility in responding quickly to the business environment and market volatility, and generating insights on developments in the market.

IBP is important because functional and technical silos across organizations can result in flawed decision-making. Transitioning to IBP can help companies enhance their performance by improving their ability to respond quickly to changes in the market.

Challenges Of Integrated Business Planning

Integrated Business Planning (IBP) is a powerful process that can revolutionize how companies run their business. However, it is not without its challenges. IBP requires an organization with the right technology, processes, and people to succeed.

One of the biggest challenges of IBP is getting all departments within an organization on board with the process. It requires buy-in from all levels of the organization, including executives, operations, and finance teams. Without this unified approach and skilled and experienced employees, getting everyone working together towards a common goal can be difficult.

Another challenge of IBP is data integration. In order for IBP to be successful, data must be collected from multiple sources and integrated into one system. This can be difficult due to different systems used by different departments or even different countries within an organization. It also requires a high level of accuracy and consistency in order for the results to be meaningful and actionable.

Finally, IBP requires constant monitoring and adjustment as market conditions change over time. Companies must stay up-to-date on changes in demand, supply chain disruptions, and other factors that could affect their plans. Without regular monitoring and adjustments, companies risk making decisions based on outdated information, which could lead to costly mistakes down the line.

Why Is Integrated Business Planning Important?

Integrated Business Planning (IBP) is an important process for businesses to align their goals with their financial, supply chain, product development, marketing, and other operations. It helps companies to create a unified plan that can be used to make better decisions and reach corporate objectives.

IBP is a powerful tool that allows businesses to consider all the different elements of their operations when making decisions. This means they can make more informed choices about allocating resources, developing products and services, and managing their finances. By taking into account all these factors, IBP enables companies to make better decisions and more informed strategic plans that will lead them toward success in the long run.

Another benefit of an Integrated Business Planning process is that it helps businesses become more agile and responsive to changes in the market. With IBP in place, companies are able to quickly adjust their plans based on new information or changing customer needs. This allows them to stay ahead of the competition and remain competitive in an ever-changing business landscape.

Overall, Integrated Business Planning is essential for businesses looking to stay ahead of the competition and reach their goals. By considering all aspects of operations when making decisions, IBP provides companies with a unified plan that can help them succeed in the long run.

Elements Of Integrated Business Planning

The three main parts of integrated business planning are categorized as “Plan,” which involves creating a strategy, “Execute,” which involves carrying out the plan; and “Monitor and Adjust,” which involves reviewing and making changes as needed.

The Plan element involves the initial step of creating a strategy. This includes identifying key goals, objectives, and expectations around the company’s products and services to understand better how those should be used in an overall strategy. Additionally, it includes developing plans for specific initiatives that will help advance those goals.

The Execute element is about carrying out those plans. This includes everything from setting timelines, allocating resources, and developing procedures to ensure the plan is implemented properly.

Finally, the Monitor and Adjust element involves reviewing progress on the strategy and business performance and making any necessary changes or adjustments. This could include changing timelines for certain initiatives, modifying business processes, or introducing new initiatives to stay ahead of competitors. This element is important to ensure the plan remains up-to-date and relevant in an ever-changing business environment.

The Integrated Business Planning Process

To be successful, integrated business planning needs to occur on a regular basis, usually every month or every quarter. This strategic planning process should be undertaken to align the different parts of the business and create a unified plan that everyone can work towards.

1. Product Management

A cross-functional team meets monthly to review the status of all product-related projects. This includes managing the entire product portfolio, identifying any new risks or opportunities, prioritizing high-value products, and aligning them with business goals. The ultimate aim is to ensure that raw materials and manufacturing floor capacity are available as needed. Whenever necessary, product managers update and publish a master plan that outlines the required resources for delivering the changes.

2. Demand Planning

Demand planning is a team effort that involves members from sales, marketing, and finance. Its goal is to meet customer demand and reduce excess inventory while avoiding supply chain operations issues. Improving profitability, customer satisfaction, and efficiency are all benefits of demand planning. The team works to create a demand plan that accurately estimates future demand, tailored to the right markets and methods. KPIs such as sales forecast accuracy, inventory turns, fill rates, and order fulfillment lead times are used to measure success.

3. Supply Chain Planning

Supply chain professionals aim to find a cost-effective way to meet expected demand efficiently. To achieve this goal, having visibility into complex supply chains is crucial. One way to accomplish this is through a formal supply chain optimization project, which helps identify and fix potential weaknesses, such as low inventory levels or order fulfillment challenges. The ultimate goal of supply chain management is to reduce the cost of goods sold (COGS) .

Supply chain leaders should deeply understand the production process from raw materials to finished goods. By understanding upstream and downstream processes, supply chain professionals can better anticipate customer needs, uncover new opportunities for cost savings, and mitigate risks. Additionally, they should build relationships with key suppliers and develop strategies to ensure a consistent flow of materials.

4. Financial Planning

Financial planning involves setting short-term and long-term goals for a company that are achievable through the best use of resources. This includes understanding financial trends, managing budgets, monitoring cash flow , financial forecasting, and making decisions about investments.

Financial planning gives organizations an understanding of their current economic environment and helps them create plans to achieve their objectives. It also helps to reduce risk and maximize profits. Ultimately, financial planning is essential for success in any organization.

Integrated planning can be challenging for organizations used to a traditional budgeting process. However, companies can improve their overall financial performance and better meet customer needs by taking a more strategic approach. This requires data-driven insights to inform decisions and the ability to quickly shift resources in response to changing market conditions. The finance team’s influence is driven by their ability to analyze and recommend quickly.

5. Customer And Channel Plan Development

Customer and channel planning are integral components of a successful business. These plans involve researching customer needs, segmenting target audiences and creating strategies to reach them. Additionally, customer and channel plans help determine the most effective marketing tactics for each target audience with the goal of increasing sales and brand loyalty.

This includes selecting the best delivery channels (offline or online) that suit certain markets and target audiences and considering customer preferences when designing products or services. Through customer and channel planning, organizations can create a more successful marketing strategy and reach their desired goals.

4. The Integration Team

The integration team, which is usually composed of individuals from the finance organization, combines the initial product, demand, and supply plans into a single strategic plan that covers a 24- or 36-month period. As necessary updates are made, significant changes are identified by the teams. Decisions that require higher-level approval are prepared for executive review.

The integration team also leads scenario planning . This process involves considering different potential business plan outcomes and helping identify risks. The teams then help develop strategies to mitigate risk, thereby ensuring the success of the overall planning process.

5. The Executive Team

The executive leadership team addresses disagreements and shares the revised plan with the entire organization. This management team is responsible for making final decisions on the plan and ensuring it reflects the organization’s objectives. Additionally, they review progress made against the plan and make adjustments as needed.

The executive team also considers external factors such as market conditions, customer expectations, competitive environment, and other factors to ensure the organization is on track to reach its desired goals.

6. Supporting Software

Many organizations use software to support their IBP process. This software may include budgeting and forecasting tools , customer relationship management (CRM) systems, financial analysis programs , and inventory tracking applications. Such software assists in streamlining the process of gathering data from multiple sources and increasing overall efficiency within the organization. It can also assist with scenario planning.

7. KPI Assessment

At regular intervals, organizations assess the performance of their plans using key performance indicators (KPIs). These KPIs provide a snapshot of progress and help determine whether or not the plan is on track to achieve its desired outcomes. By evaluating KPIs on an ongoing basis, organizations can identify areas that need improvement and adjust their plans accordingly.

Software To Support IBP

Software solutions are available to support Integrated Business Planning processes. These enterprise performance management solutions provide a comprehensive view of the entire business, allowing you to analyze financial data in real-time data analysis from multiple sources. This helps organizations make informed decisions based on accurate information and forecasts. Additionally, software solutions can automate many of the manual processes associated with IBP, such as data collection and analysis, which helps streamline operations and reduce costs.

Organizations looking to transition to Integrated Business Planning should consider investing in cloud based technology and software solutions supporting their IBP initiatives. Many software solutions can support financial forecasting processes with new tools like predictive analytics ,and feed right into your financial plan.

Related Posts

- Your Flux Analysis Step-By-Step Survival Guide

- How To Do Account Reconciliation Without Pulling Your Hair Out

- Taking Vertical Analysis To The Next Level

- Your Unconventional Guide To Managing Working Capital

- The Easy Way You Can Calculate Free Cash Flow

- Crafting Your Business Plan Financials: A Step-by-Step Guide

FP&A Leader | Digital Finance Advocate | Small Business Founder

Mike Dion brings a wealth of knowledge in business finance to his writing, drawing on his background as a Senior FP&A Leader. Over more than a decade of finance experience, Mike has added tens of millions of dollars to businesses from the Fortune 100 to startups and from Entertainment to Telecom. Mike received his Bachelor of Science in Finance and a Master of International Business from the University of Florida, laying a solid foundation for his career in finance and accounting. His work, featured in leading finance publications such as Seeking Alpha, serves as a resource for industry professionals seeking to navigate the complexities of corporate finance, small business finance, and finance software with ease.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

Supply Chain Trend

Shaping the world of s&op and supply chain.

Integrated Business Planning: A New Narrative for an Old Process

Integrated Business Planning (IBP) has been a valuable business process since its incarnation as Sales & Operations Planning in the mid-1980s. The monthly cycle of S&OP meetings has been the forum in which a firm’s forecasts have been presented and reconciled across functional areas. Authors Niels van Hove and Hein Regeer explain that while planning and forecasting technologies have benefitted from significant innovations since then, today’s IBP seems unhinged from the day-to-day operations of the business. They call for a reinvention of traditional IBP that more fully integrates its governing meetings and reporting into operations, enabling faster decision making, better responsiveness to disruption, and liberation for planners to work on more strategic issues.

- Many IBP cycles around the world are based on a 20-year-old process definition supported by 20-year-old planning concepts. This traditional IBP is not set up for a fast-changing world, where speed of decision making confers a competitive advantage. New Wave 3 Technology can empower a more efficient and responsive planning process.

- We propose that IBP be segmented by decision type into execution, operational, planning, and strategy/culture. For the execution and operational decisions, modern planning technology can largely automate processes and decisions. For the longer-term decisions on planning and strategy, technology will augment the quality of human-centric decisions and nurture human-machine collaboration.

- IBP should be converted from a separate, sequential, monthly planning cycle to an integrated component of day-to-day business. This will be feasible as new technology enables more autonomous decision making, freeing the planner to focus more fully on designing policies and targets

TRADITIONAL IBP AND PLANNING TECHNOLOGY

If we look back over the history of supply-chain planning, we can properly say we are in the third wave of integrated supply-chain planning software (Van Hove, 2019).

- Wave 1, Enterprise Resource Planning (ERP), started in the 1980s with a focus on automating transactional business processes, but less so on planning.

- Wave 2, Advanced Planning Systems (APS), first adopted in the 1990s, facilitated a forward view of the business, integrated plans with other functions, and optimized supply-chain metrics such as forecast accuracy, inventory holdings, and customer service.

- Wave 3 systems, now gaining momentum, will provide intelligent automation that replaces the human planning process as well as cognitive automation that augments a planner’s decision making with predictions, insights, and recommendations.

Wave 3 systems will enable fully automated planning, decision making, and execution. By bringing together several technologies that have matured separately over the last decade, it is becoming a system of intelligence, seamlessly integrating the following capabilities:

- Integration and harmonization of data from internal and external sources, with transactional data self-cleansed and planning parameters self-maintained.

- Automation of descriptive, diagnostic, predictive, and prescriptive analytics, including self-selecting machine-learning models for a library of predefined problems.

- Smart process flow through a digital twin that can be configured to mimic any business user during forecasting, planning, decision making, and execution processes.

- Prescriptive analysis and recommendations that provide business users with advice on why, how, and when to act.

- Automatic decision making and writeback of actions to underlying systems of record.

- Digitization of every decision made, using an automated loop that learns from both human and machine decisions.

At about the same time that Wave 2 was gaining momentum, we saw publication of the book Enterprise Sales & Operations Planning: Synchronizing Demand, Supply and Resources for Peak Performance (Palmatier and Crum, 2002). The authors detailed a sequential S&OP cycle around a

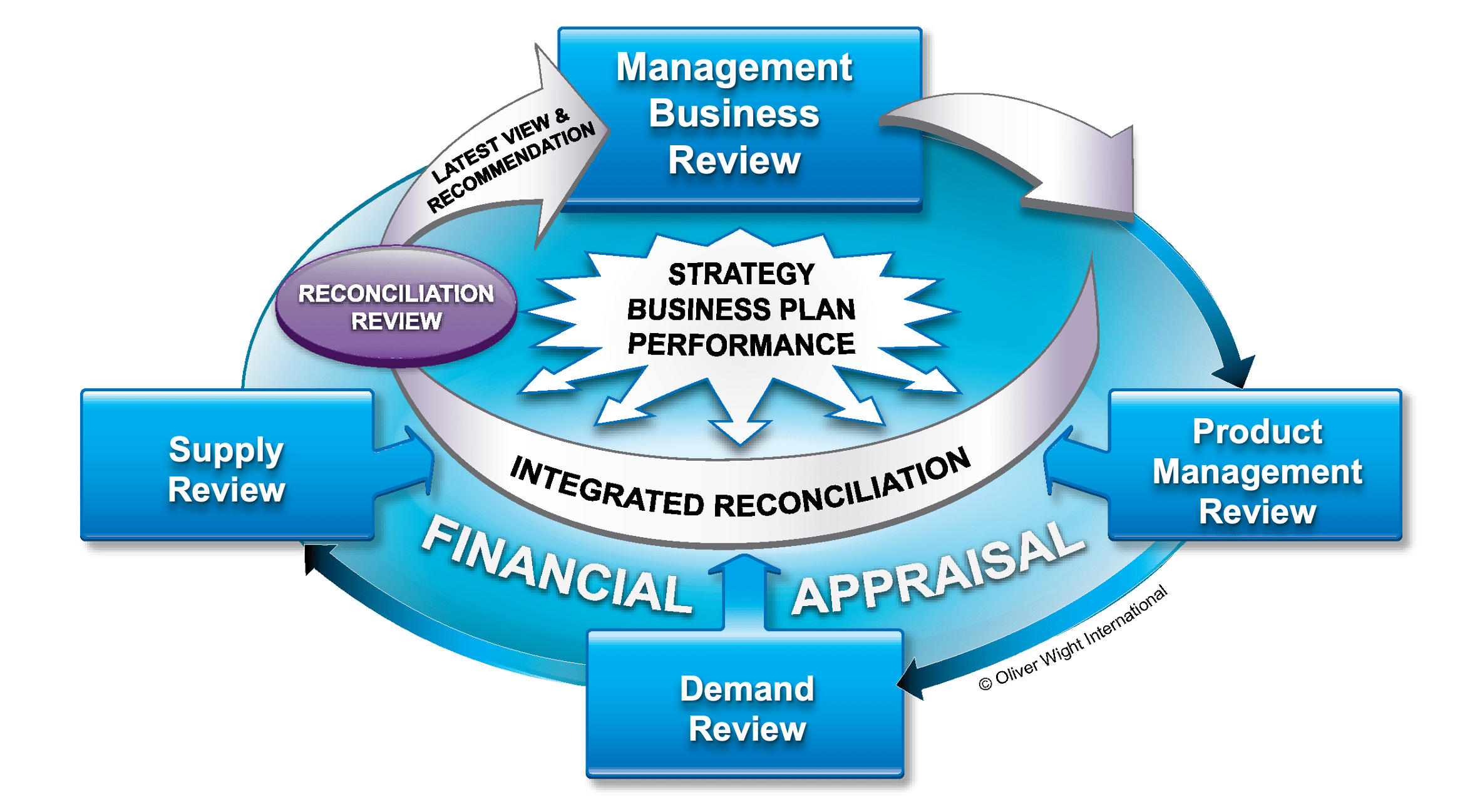

New Product Review, a Demand Review, a Supply Review, and a Management Business Review. Figure 1 is an image from the cover of the book.

Figure 1. The IBP Cycle According to Palmatier and Crum

A whitepaper by Coldrick, Ling, and Turner (2003) entitled “Evolution of Sales & Operations Planning – From Production Planning to Integrated Decision Making” presented the five-step process – shown in Figure 2 – which is still the foundation of most planning processes today, even though the scope of S&OP has expanded into IBP.

Figure 2. The Five Key Steps of Integrated Business Management / Integrated Decision Making

In his 2009 Foresight article, Bob Stahl emphasizes the five-step sequential monthly process. Similar to the other publications, he asserts that executive S&OP is first and foremost a decision-making process.

The planning processes and governing S&OP meetings described in these publications have been widely implemented across the world, supported by Wave 1 and Wave 2 planning technology. These technologies focused on transactions, planning, and insights, but were never built for automated planning, decision making, and execution. Many of today’s IBP processes are still rooted in this prior generation of planning concepts, reflecting a notable absence of progress, especially considering that supply-chain executives expect to see autonomous supply chains by 2025 (Steinberg, 2019).

Autonomous supply chains, where decisions and actions will largely be made by machines rather than by humans, cannot be realized by Wave 1 and Wave 2 systems as these systems are aimed at automating processes rather than decisions. To become autonomous, supply chains require the new technology of Wave 3 planning systems, which we think of as systems of intelligence

LIMITATIONS OF TRADITIONAL IBP

As IBP managers, we have facilitated well over a hundred IBP meetings and, as consultants, we have implemented IBP processes across many countries and companies. We acknowledge the value of IBP in support of an organization’s effort to deploy and execute its strategy (Van Hove, 2016). However, we’ve seen the shortcomings of these processes as well, including reliance on old technology.

While IBP comes in many shapes and forms, it is based on a few foundational concepts.

- Cross-functional, human decision making. IBP seeks to align key stake[1]holders from multiple functions on “a single version of the truth”; that is, a common understanding of matters that need to be addressed and the collaboration needed in decision making.

- Periodic planning cycles. Most common is the weekly Sales & Operations Execution (S&OE) cycle to address immediate operational issues, and a monthly cycle for medium- to long[1]term issues. This dichotomy facilitates responsiveness in short-term planning while freeing senior management to focus on high-impact decisions over the longer-term horizon (and only by exception on operational issues).

- Sequential process steps. Both the weekly and monthly cycles follow a strict cadence of sequential meetings and activities. The outcome of one step (for example, the Demand Review) is required input for the next step (Supply Review). An IBP team typically drives the process and strives to maintain adherence to it within the organization. While these general concepts are straight[1]forward, implementation can be challenging. Even after decades of experience, companies struggle with persistent shortcomings:

- Excessive focus on short-term issues. Despite weekly S&OE meetings for operational issues, IBP meetings still become distracted by acute short-term issues. And even though the planning is designed to encompass a rolling 24-month horizon, IBP discussions are heavily skewed toward the first few months.

- Information and process focus, rather than decisions focus. Many IBP meetings take on an “information sharing” character rather than a decision-making focus. The meetings should mark the moments in the month where we “synchronize the watches” in terms of demand and supply plans. Because IBP managers are incentivized to adhere to the process – follow the agenda, attendance, data availability and standardized templates – the time spent policing process compliance steals from the time devoted to high-value decision making.

- Limited attention to high-value decision making. In a traditional IBP cycle, there may not be adequate time to prepare advanced simulations and business continuity plans, or to seek cross-functional alignment in time for executive-level decision making. One of the key reasons is the excessive number of meetings.

- Excessive meetings. Typical IBP cycles span a month’s time, but this can stretch to six weeks because of pre[1]meetings in which we prepare for meetings. Planners are now committed to prepare for the pre-meeting and then replan for the real meeting, all while trying to keep stakeholders aligned. It is not uncommon for an IBP meeting to take four to eight hours.

- Inability to deal with disruptions. In IBP cycles that span many weeks, executives cannot respond quickly to market disruptions. COVID exposed the inability of companies to make rapid strategic choices, such as in days or weeks – impactful decisions such as closing a factory, entering or exiting a product category, or reallocating limited resources in their supply chain. Some companies actively bypassed IBP by installing executive-led COVID war rooms to more rapidly implement strategic decisions.

- Lacking insights. Meeting notes and actions might be published after every IBP meeting; however, actions and outcomes are often not properly recorded, not measurable, or not easily accessible. This omission limits continuous learning and restricts the creation of corporate insights around decisions. Was the plan the right plan and the decision the right decision under

the circumstances? Was the right action taken by the properly authorized person? The authors believe these shortcomings can largely be addressed by aligning the IBP process with Wave 3 planning technology.

MACHINE-CENTRIC VS HUMAN-CENTRIC DECISION MAKING

While IBP has become nearly synonymous with “the S&OP monthly cycle,” there really is no compelling justification for this monthly frequency. By automating aspects of the process, Wave 3 technology can decouple decision making from this arbitrary cadence, allowing planners to concentrate more fully on goal setting and oversight of policies and systems, while providing the knowledge augmentation for these human-centric decisions.

Planning Horizons

This new technology will support decision making in different planning horizons. In earlier Foresight articles (Van Hove, 2020, 2021), Niels distinguishes decision automation from knowledge augmentation and examines the relative desirability of these features across different planning horizons. Longer planning horizons, for example, require human-centric decisions, while shorter-term operational decisions are more amenable to automation.

Figure 3 summarizes the possible enhancements to IBP from Wave 3 technology. The key is to segment IBP along decision type and then differentiate between machine-based IBP, which runs under highly automated planning and decision making with human involvement only by exception, and human-centric IBP, which will benefit from decision augmentation and human-machine collaboration.

Figure 3. IBP Segmentation by Planning Horizon, Automation, and Augmentation

Machine-Centric IBP Decisions

As shown in Figure 3, machine-centric decisions will be well suited for automation of both Sales & Operations Execution (S&OE) and Operational IBP.

In the short-term horizon (0-3 months), operational decisions are frequent, repetitive, low value, and granular (e.g. at the SKU/location level). These include demand and supply balancing, inventory change, order purchase and allocation, stock transfer, and product pricing. Such decisions require limited human alignment and sign-off. Hence, they can be automated to sense change or disruption in the supply chain and respond to it. Humans will still set policies and rules to structure the automated process.

Operational IBP decisions (4-12 months ahead) are less frequent and time urgent than in the S&OE horizon, but still have low impact/value and apply at a detailed level so that planning and decision making can be automated as well. Figure 3. IBP Segmentation by Planning Horizon, Automation

Demand-planning tasks, including data gathering and cleansing, statistical/ML forecasting, and detection of variances to targets and budgets, can be actioned automatically with only limited human-machine collaboration required. Human input will be required to set goals and policies to help the machine optimize promotions, price settings, and phasing of new-product introduction to reach certain targets. Supply-planning processes in this horizon can be partly automated. Due to the longer decision horizon and higher uncertainty, supply-planning decisions become more probabilistic in nature, and so will be amenable to medium levels of automation and augmentation.

Based on demand input, optimized supply plans can be automated to run concurrently across an entire network and pro – vide planning outputs for distribution, replenishment, and production. Even changes to planning parameters such as lead times, safety stocks, capacities, and batch quantities can be automatically updated, and gaps to service levels or cost structures in the supply chain will be detected and actioned automatically.

Many operational decisions that might look complex can be solved through business rules, machine learning, and probabilities. For example, when planning to introduce a new product to the market, the system can calculate a probability of hitting the introduction date and so automatically update the phase-out planning of the predecessor product.

For both machine-centric IBP segments, while many decisions can be automated, decisions above a certain value or probabilistic threshold will require crossfunctional collaboration and sign-off. Yet cross-functional meetings can become more agile by acting upon exceptions suggested by the machine.

Human-Centric IBP Decisions

Planning decisions in this category address higher levels of aggregation (e.g. product families) and normally have high impact/value. Since these decisions are more complex, they require human alignment and sign-off and so are less amenable to automation. The role of the machine is to support the planner in decision making, resulting in human-machine collaboration.

The machine can support the planner with probabilistic simulations and what-if scenarios, network or price optimization, multisourcing, new-product development, and innovation updates. It will detect gaps in revenue, margin, or cost versus targets and budgets automatically and provide recommendations for gaps closure. These recommendations will be actioned functionally for the most part, as pre-agreed policies and functional tradeoffs have been incorporated in the recommendation. In this way, IBP will morph into an aspect of business as usual rather than a distinct and dogmatic process.

At the strategic level, decisions are complex, infrequent, and high in granularity, as well as in value/impact on the business. They can also be cultural and value-based, requiring human alignment and sign-off at the executive level. These decisions are too complex and important to be automated, and they likely require human capabilities that the machine doesn’t possess. The human-centric nature of strategic IBP decisions means that a greater emphasis should be placed on governance – that is alignment, decision rights, rewards, and culture (Sorenson, 2020) – instead of automation.

Machines, however, can develop recommendations for executives around strategic scenarios, mergers and acquisitions, network risks assessments, geopolitical war games, category changes, onshoring versus offshoring, and large CAPEX in – vestments, thus providing probabilities and financial impacts.

A NEW SET OF IBP CONCEPTS AND ASSUMPTIONS

Segmented by decision type as is Figure 3 and supported by new Wave 3 technology, the new IBP will improve a firm’s ability to address many traditional IBP challenges and create structures that are far more aligned with current times. These are summarized in the table below:

To start the transition to this new type of IBP, we need to establish a fresh IBP mindset, supported by new aspirations and assumptions. We suggest replacing the foundational concepts discussed earlier by the following:

Data and Analytics

- IBP will automatically gather and cleanse relevant internal and external data and distribute these across the business in one common data layer, near real time. This will permit sales to change prices and demand forecasts up to a certain threshold (say 25%) w/o consulting finance or operations.

- It will automatically provide descriptive and diagnostic analytics and make these available at any time throughout the business.

- Planners will guide the machine with policies, goals, and targets.

- Planning will take place continuously and require human input only upon matters that exceed certain impact or complexity thresholds.

- The machine will identify variations and gaps to plan and automatically action these up to a defined threshold. Above that threshold it provides recommendations to be decided upon by humans.

Process & Meetings

- The frequency and duration of IBP meetings will be driven by decision requirements, not process requirements.

- IBP teams will be incentivized to provide strategic business scenarios and improve decision making, not to police process compliance.

Decisions & Execution

- IBP decisions and impacts will be recorded digitally, applied to self-learning, and accessible to all IBP stakeholders.

- Such decisions will be executed automatically where possible, as all con[1]textual information available will be stored.

- Human adjustments made to the system-generated recommendations will benefit from feedback, reducing the impact of human biases.

For a company to transform from a traditional planning process to one segmented by human and machine decision making can be quite a journey. Changes will be required to operating models and systems, roles and organizational structure, rewards, and incentives. Additionally, planner capabilities will need to adjust to collaboration with the machine. Still, it can be done.