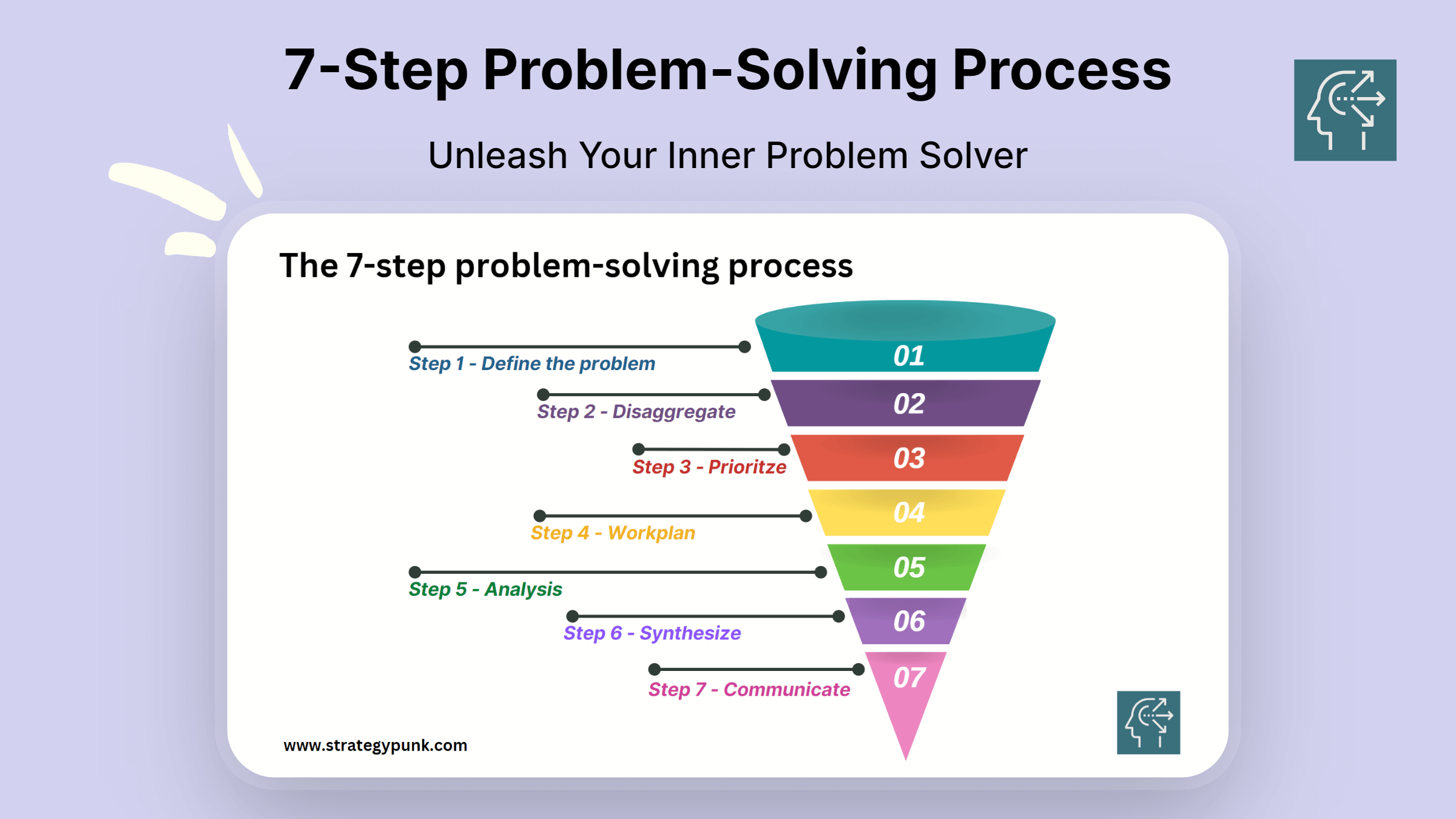

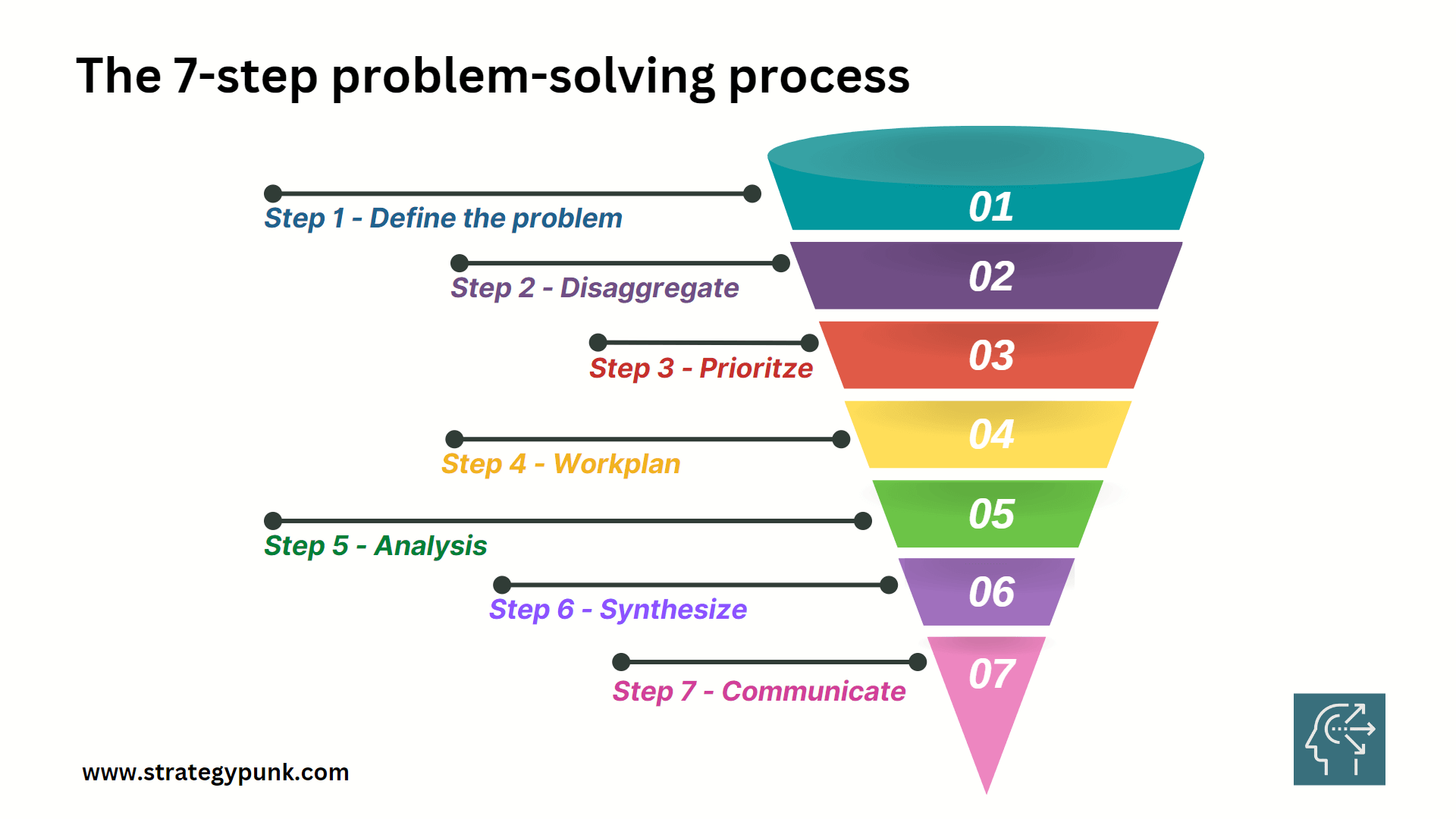

QC story – Complete guide (QC story 7 steps)

QC story is one of the known methodologies to work on problem-solving. Here in this post, you will find the complete 7 steps of the QC story.

As a quality engineer, you will be working on problem-solving scenarios in the organization.

And the concept of QC story is the same to solve problems using the step-by-step approach to solve the problem by assigning the project and completion.

Table of Contents

Introduction to QC Story

Before going for the detailed concept the application of QC Story is not only to quality problems but also to increase productivity, process cost, process performance , supply chain, etc., problems.

It is a means of communication, therefore QC story is both a problem-solving tool and also often a communication tool.

Why QC Story? | What is the purpose of QC story?

QC story is the way of problem presentation and demonstrates in a clear and easy manner to all organization levels.

It will benefit all employees who can understand the problems, their possible root causes , and the work processes. And all the responsible persons are included in the problem-solving.

Therefore a QC story is the documented process for better understanding to explain work procedures during the improvement efforts.

“QC STORY” is a problem-solving technique based on the examination of facts and data, with no speculation, intended for problems caused by a number of issues.

Years later, Nissan introduced it throughout the company, and the QC Story became one of the indispensable methods for Nissan’s increasing quality and productivity.

On the European continent, QC Story was introduced in 1992 at the Nissan factory in Sunderland (G.B.) later in Barcelona.

The Renault-Nissan Alliance is the occasion, within the framework of the SPR. to understand the reasons for this successful generalization of QC Story and to apply for its benefits.

So let’s dive into the steps involved in QC Story

Step1: Problem Definition / Problem justification – Emergency response

1.1 brief description of problem:.

It should include details of 5W-2H ; present level and target

- What…happened?

- Where…did it happen?

- When…did it happen?

- Who…is complaining?

- Why…is ‘who’ complaining?

- How…was it discovered?

- How big…from the problem?

Here you need to specify the Current level based on the average data for the last 4 to 6 months.

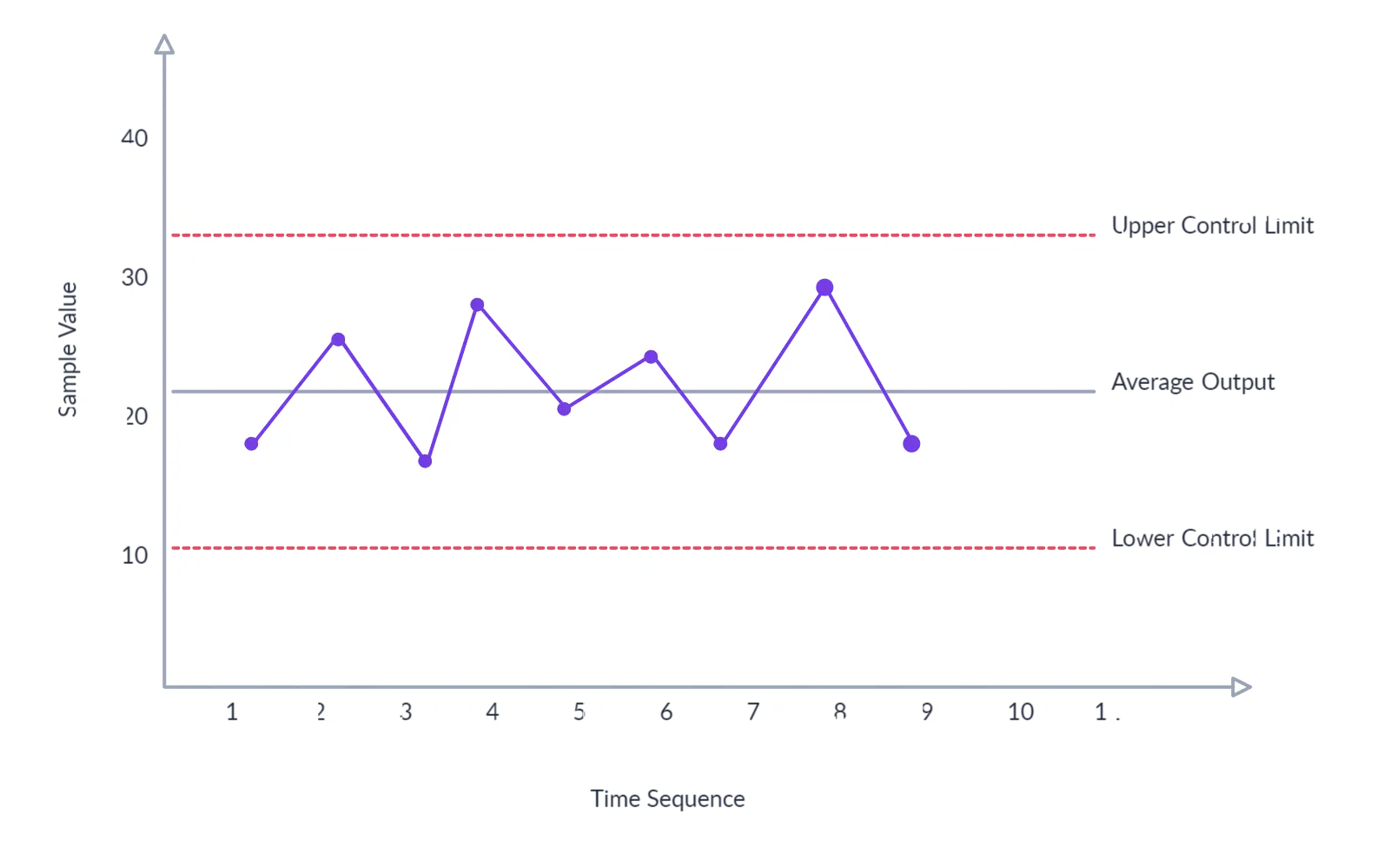

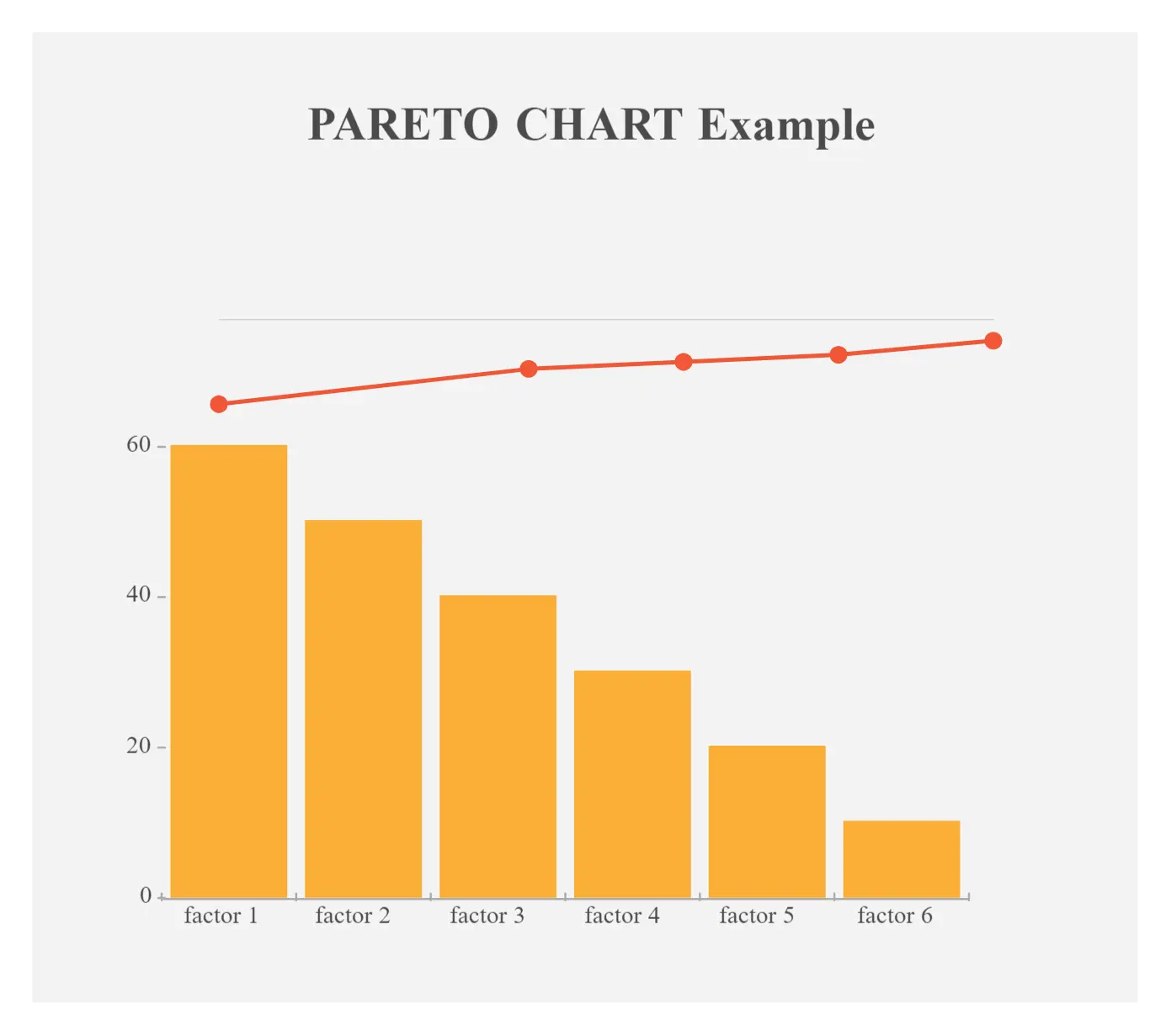

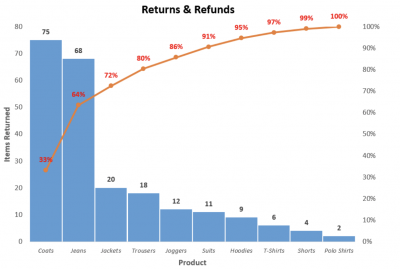

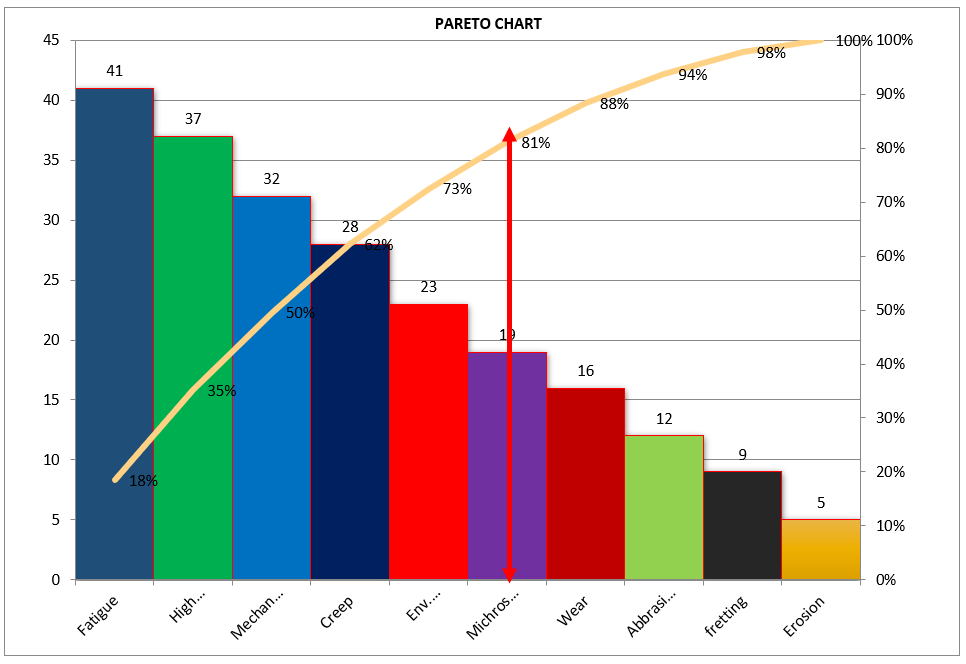

1.2 Justification Use Trend graph or Pareto, Occurrence and/or severity as applicable

In this section, you will explain why we are working on this problem. And we have here the complete justification that for the purpose of solving this problem we will work to resolve the same.

We need to show how we know this is a problem.

1.3 Emergency Response:

If immediate protection of the customer is required, then this step can be included. Otherwise, it can be ignored. It can include containment action and immediate action to all over the operations and supply chain.

On successful implementation of step 4, this action should be removed.

Step 2: Observation of process – Understand the current situation

2.1 Observation of process

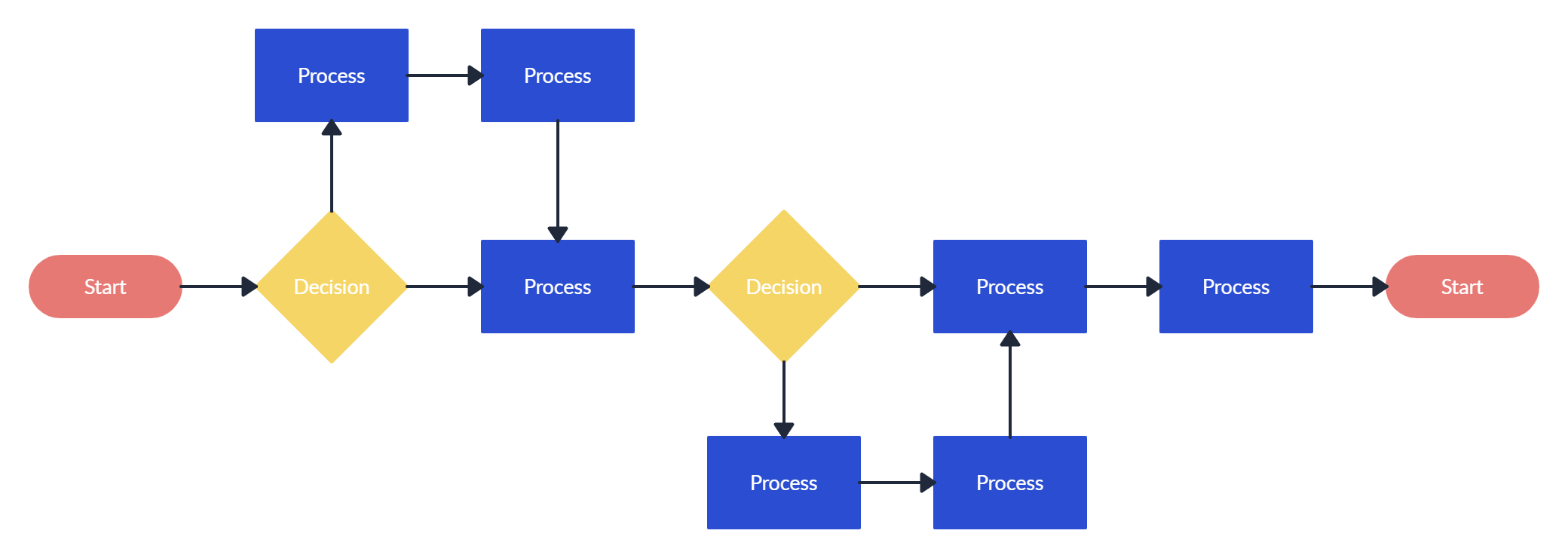

Prepare/use process flow diagram if required

Perform process walkthrough to verify if there is any non-adherence to standard practice, Specification/ SOP/ Control plan, etc.

2.2 Understand the current situation

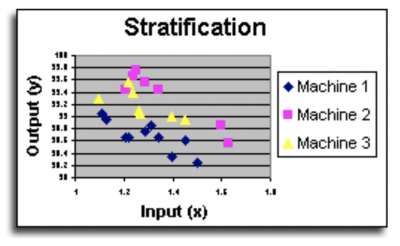

Understand the situation based on Time-to-time, person-to-person, stream-to-stream, location-to-location, changes as applicable in the study.

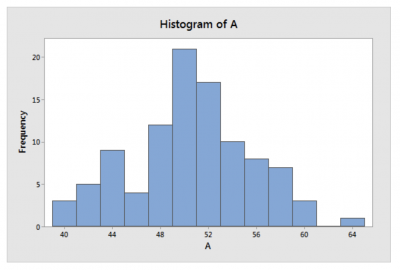

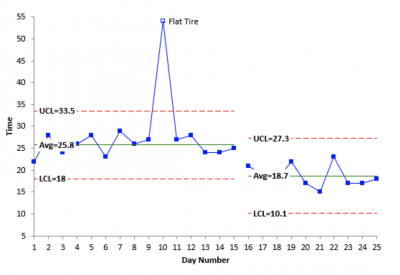

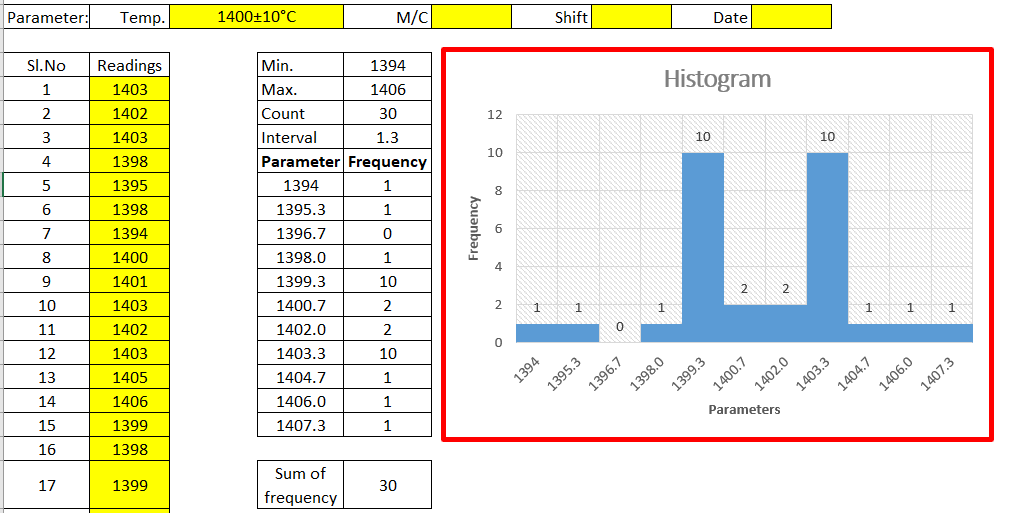

Use of Sketches, photos, stratification , run chart, concentration diagram, histogram , control chart , etc as applicable

Here is where we explained the status of the issue before we started working to improve it.

Step 3: Analysis: Possible causes, probable causes – Testing of hypothesis and root causes

3.1 identify the possible & probable causes.

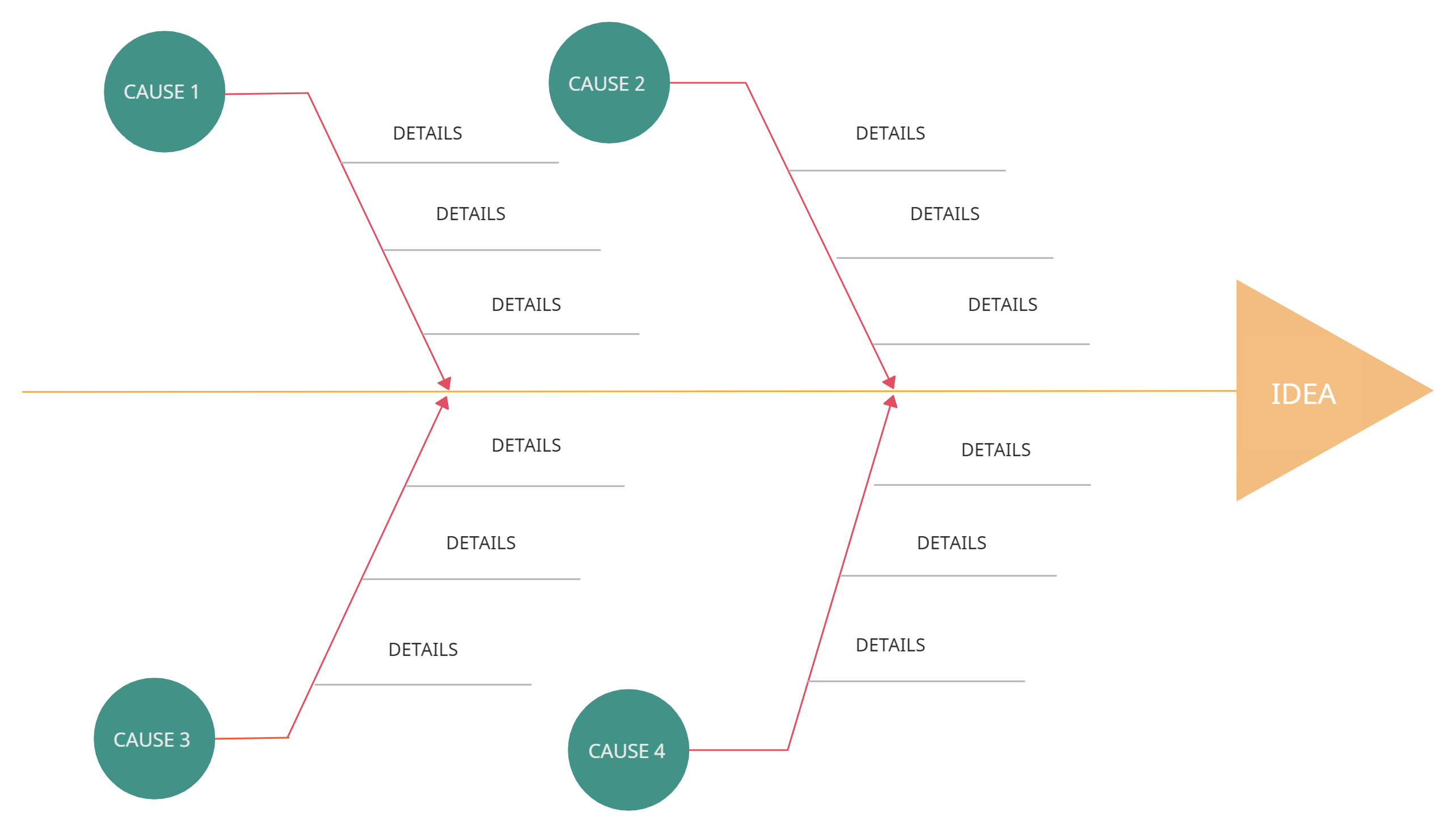

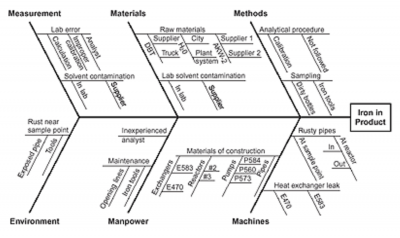

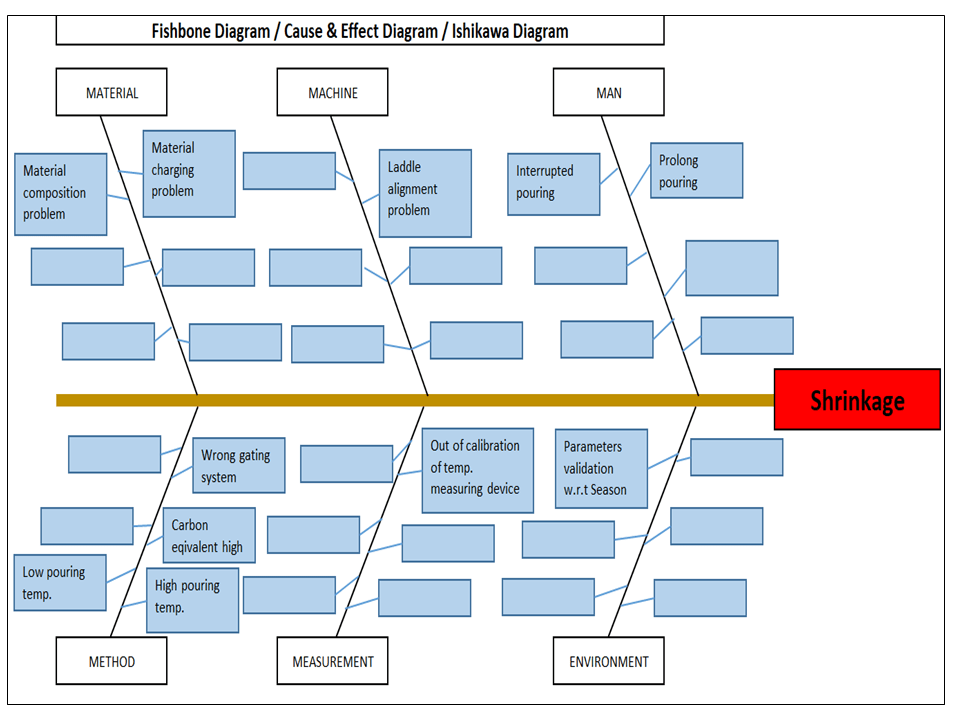

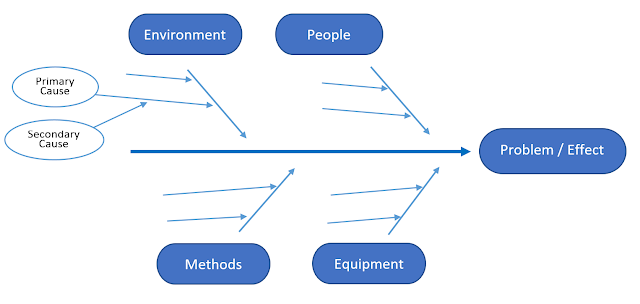

Use Cause & Effect diagram to identify possible causes

Use Experience, Engineering Judgment, Practical check on possible causes and eliminate invalid causes and arrive at the probable cause

3.2 Confirm the probable causes

Carry out Test of Hypothesis on Probable causes:

Apply Test of hypothesis based on the factual data. Decide validation of cause logically. You can use

- Good and bad product comparison

- Statistical comparative tools

- Change analysis on product or process since product/process launch

- Any other appropriate data-based tool

3.3 Identify the root causes

List the validated causes based on the above step using the root cause analysis .

Step 4: Actions

Carry out why-why analysis on valid causes & identify actions. Consider various probable actions.

Assign each corrective action a priority and stick to it. Involve the operators.

The use of color, limits, graphics, and instructions at the place where the corrective measure is to be applied are effective means of drawing attention to it.

Share the results with all interested parties!

Consider effectiveness expected, cost, ease of implementation, productivity, etc. to prioritize the solution

Step 5: Check

5.1 verify the results.

- Represent the data in the same way as in step 1.2

- Check the result in comparison with If expected result.

- If the expected result is not achieved seek an alternate action plan.

5.2 Carry out full-scale implementation :

Include appropriate data and graph to verify the results as mentioned in the justification (before & after etc)

5.3 Quantify Tangible benefits

a) return on investment b) annualized savings

If the effects can be convert into gains (financial), this is preferable e.g. Return on investment, annualized savings

As far as possible, the effect of each action on the final result must be shown (by numbering them).

Step 6: Standardization

6.1 updating of documents.

Update all the relevant documents like Drawings/specifications, PFD, PFMEA , Control Plan, SOP, Checklist , etc. & mention the reference of the same.

6.2 Training

If the problem stems from the operating procedure, train the operator on the new standard.

Train people on new/modified SOP.

Train people to modify/develop SOS.

6.3 Additional audit or check

Check the quality level and how the operator functions with the new method/procedure for at least two weeks.

Carry out additional audits/checks to ensure adherence to the new

system & monitoring results achieved

we explain the steps that were to ensure that the implemented solution remains effective. We want to prevent the process from reverting to its previous so we can continue to hold the gains achieved by the process improvement.

Step 7: Conclusion

Finally, once we take all necessary actions and solve the problem, all results with progress are report to management. And an action plan is drawn for the causes that cannot be resolved now.

7.1 Horizontal deployment

Do the horizontal deployment by implementing the same actions to similar product and process steps.

7.2 Lessons learned

Summarize the learning from the project and in this last section, we list the problems that could be addressed next and the issue that has been selected to be the next project.

7 Step QC story

Related Posts

Cost of Quality | Quality engineer essential guide

Total Quality Management (TQM) Fundamentals

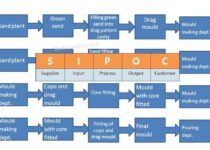

SIPOC – The complete guide

Root cause analysis

7 Management and Planning Tools

CAPA | Corrective Action & Preventive Action

The QC Story Procedure

by: Quest Claire

I understand the importance of the role of my supervisor, VP Merchandising, with a primary objective of putting merchandise on the retail floor and having products ready to be shipped from the warehouse when customers’ orders come. Any recommended process improvement actions must be clearly understood, backed by reasons, and supported by evidence. If there is a possibility that a process improvement action may delay or may add costs to the process, such an impact must be reviewed carefully with relevant quality cost analysis. Process improvement actions should only be taken when the company management sees an overall cost reduction. Otherwise, recommended actions will be recognised simply as imagination or desk theory and perceived as bad for the business.

People in the manufacturing industry often say quality is everybody’s business. A consumer product can easily contain dozens of parts and materials contributing to product quality. If any of them is located out of its tolerance for its intended use, the product will be defective. Unless a process improvement plan is clear and logical, getting management support for implementation won’t be easy. In other words, the management wants to understand how a program is implemented. The next question is what tool is available. To impress the management, I DO have a program that has been carefully designed, will be carried out step-by-step, will provide opportunities to verify its effectiveness during its rollout, and will complete with measurable goals. Therefore, I consider that the QC Story Procedure tool is the right one as it is easy to understand and use. I expect that the management would likely be convinced about the plan’s effectiveness and render necessary support. I believe the tool contains clear concepts and maintains a fluid flow of thoughts followed by logical conclusions. The QC Story Procedure tool is explained as follows:

The QC Story Procedure is designed for problem-solving. A problem is defined in the QC Story as:

A problem is the undesirable result of a job.

- Show that the problem being handled is of much greater importance than any other problems.

- Show what the background of the problem is and what its cause has been so far.

- Express in concrete terms only the undesirable results of poor performance. Demonstrate the performance loss in the present situation and how much it should be improved.

- Set up a theme and a target, and sub-themes if necessary.

- Nominate a person to take charge of the task officially. When a team carries out the study, nominate the members and the leader.

- Present an estimated budget for the improvement.

- Make a schedule for the improvement.

2 Observation

Investigate the specific features of the problem from a wide range of different viewpoints.

- Investigate four points (time, place, type, and symptom) to discover the features of the problem.

- Then investigate from many different points of view to discover the variation in the results.

- Go to the site and collect the necessary information that cannot be put into a data form.

Find out what the main causes are.

- Write down a cause-and-effect diagram (a diagram that contains all elements seemingly related to the problem) to collect all knowledge concerning possible causes.

- Use the information obtained in the observation step and delete any elements that are not relevant; revise the cause-and-effect diagram using the remaining elements.

- Mark those elements in the latter diagram which seem to have a high possibility of being the main causes.

- From elements with a high possibility of being caused, devise a new plan to ascertain the effect those elements have on the problem by obtaining new data or carrying out experiments.

- Integrate all the information investigated and decide which are the main possible causes.

- If possible, intentionally reproduce the problem.

- A strict distinction must be made between actions taken to cure phenomena (immediate remedy) and activities brought to eliminate cause factors (preventing recurrence).

- Ensure the actions do not produce other problems (side effects). If they do, adopt other measures or devise remedies for the side effects.

- Devise several different proposals for action, examine the advantage and disadvantages of each and select those to which the people involved agree.

Make sure the problem is prevented from occurring again.

- In the same format (tables, graphs, charts), compare the data obtained on the problem (undesirable results in the theme) before and after the action has been taken.

- Convert the effects into monetary terms and compare the result with the target value.

- If there are any other effects, good or bad, list them.

6 Standardization

Eliminate the cause of the problem permanently.

- The five Ws and one H: who, when, where, what, why and how, for the improved job must be identified and used as a standard.

- Necessary preparation and communication regarding the standards should be carried out correctly.

- Education and training should be implemented.

- A responsibility system must be set up to check whether the standards are being observed.

7 Conclusion

Review the problem-solving procedure and plan future work

- Sum up the problems remaining.

- Plan what is to be done to solve those problems.

- Think about what has gone well and badly in the improvement activities.

- DAM – Daily Audit Management

- APS – Advanced Problem Solving

- TMM – Total Maintenance Management

- SAM – Small Activity Management

- PMB – Performance Management Board

- ESB – Enterprise Schedule Builder

- EPP – Enterprise Project Planner

- VCB – Visual communication board

- BDM – Business Document Management

- 5 Whys Analysis

- TPM – Total Productive Maintenance

- PDCA and DEMING CYCLE

- Work Standardization

- Lean production

QC STORY and PROBLEM SOLVING

QC Story is a tool of TQM (Total Quality Management) , which is intended to solve problems in a structured way . QC story is based on the principle of PDCA , where the nine steps can present the full story of the choice of the case to complete solutions.

QC Story tool is not among the most popular in the world, although in content and purpose, it is the same or identical to the more familiar A3 analysis . Usually, it is formalized on a sheet of paper or even on a billboard or poster. Larger formats, such as 2x2 meters, are popular especially in companies with well-developed visual management .

For a clear and visually displayed case in the form of the story , it allows for a better breakdown of the problem and resolution and especially understanding.

The disadvantage of such impressions is that there is relatively difficult to control information and the database. Therefore we developed a DIGITAL LEAN tool , which facilitates managing information and displaying them on each occasion, on any media, like a computer, or LCD screen.

The solution we named APS - Advanced Problem Solving and made it universal since it can be used in addition to the QC story and also replace other traditional tools such as A3, 8D report . Even more, with APS tool we can implement the projects of chronic losses elimination and other projects based on the PDCA, DMAIC …, more structured and efficient.

What is the purpose of the tools QC story?

Problem-solving is now crucial for any company that wants to be competitive. Instead of merely a corrective or fire campaign, we want to determine the root causes of why a problem occurred and found solutions. This means that we are focused on continuous improvement in all areas, from quality, safety, reliability, cost ...

QC story, however, is not merely a problem-solving tool, but also a communication tool . It's a way to present the problem in a clear and understandable manner to a wider range of employees. So all employees understand the work processes and the root causes of the caused problems. Gradually, in solving problems, all employees begin to include, including operators, which means for them the new challenges in the workplace and creating new higher value-added.

Related posts

How to find the root cause for major breakdown.

Failure-based root cause analysis is a method of problem-solving used for identifying the root causes of failure analysis for those employed in engineering and maintenance. TMM - Total Maintenance Management is an innovative computer tool for solving major breakdowns or...

LEAN ACADEMY

LEAN ACADEMY We are happy to share some highlights from our LEAN ACADEMY event. We thank all participants for their presence and support. We especially thank Mr Boris Šturm from the company Polycom for a fascinating and informative presentation of...

PROJECT MANAGEMENT

5 PHASES of PROJECT MANAGEMENT You probably know Benjamin Franklin's famous quote, "If you fail to plan, you are planning to fail." Planning is a prerequisite for successful work and successful projects. However, in practice, we usually pay too little...

7 Basic Tools of Quality for Process Improvement

Japan is known worldwide for its quality products and services. One of the many reasons for this is its excellent quality management. How did it become so? Japan has Dr. Kaoru Ishikawa to thank for that.

Postwar Japan underwent a major quality revolution. Companies were focused on training their employees in statistical quality control. But soon they realized that the complexity of the subject itself could intimidate most of the workers; so they wanted more basic tools.

Dr. Kaoru Ishikawa, a member of the Japanese Union of Scientists and Engineers (JUSE), took it to his hands to make quality control easier for everyone – even those with little knowledge of statistics – to understand. He introduced the 7 basic tools of quality. They were soon adopted by most companies and became the foundation of Japan’s astonishing industrial resurgence after World War 2.

This post will describe the 7 basic quality tools, how to use them and give you access to templates that you can use right away.

Quality Tools: What Are They?

How can teams and organizations use the 7 basic quality tools, cause and effect diagram, scatter diagram, check sheets.

- Control chart

- Pareto chart

The 7 basic tools of quality, sometimes also referred to as 7 QC tools – represent a fixed set of graphical tools used for troubleshooting issues that are related to quality.

They are called basic quality tools because they can be easily learned by anyone even without any formal training in statistics. Dr. Kaoru Ishikawa played the leading role in the development and advocacy of using the 7 quality tools in organizations for problem-solving and process improvement.

The 7 basic quality tools include;

- Cause-and-effect diagram

- Scatter diagram

- Check sheet

The 7 quality tools were first emphasized by Kaoru Ishikawa a professor of engineering at the University of Tokyo, who is also known as the father of “Quality Circles” for the role he played in launching Japan’s quality movement in the 1960s. During this time, companies were focused on training their employees in statistical quality control realized that the complexity of the subject could intimidate most of the workers; hence they opted for simpler methods that are easy to learn and use. 7 basic tools of quality were thus incorporated company-wide.

Quality tools are used to collect data, analyze data, identify root causes, and measure results in problem-solving and process improvement. The use of these tools helps people involved easily generate new ideas, solve problems, and do proper planning.

- Structured approach: They provide a systematic approach to problem-solving and process improvement, ensuring that efforts are well-organized and focused.

- Data-driven decision making: The tools enable data collection, analysis, and visualization, empowering teams to make informed decisions based on evidence.

- Improved communication and collaboration: Visual representations and structured tools facilitate effective communication and collaboration among team members, leading to shared understanding and alignment.

- Problem identification and prioritization: The tools help identify and prioritize problems or improvement opportunities, enabling teams to allocate resources efficiently and address critical issues first.

- Continuous improvement: By using these tools, teams can establish a culture of continuous improvement, as they provide a framework for ongoing monitoring, analysis, and refinement of processes.

7 Basic Quality Tools Explained with Templates

The 7 quality tools can be applied across any industry. They help teams and individuals analyze and interpret the data they gather and derive maximum information from it.

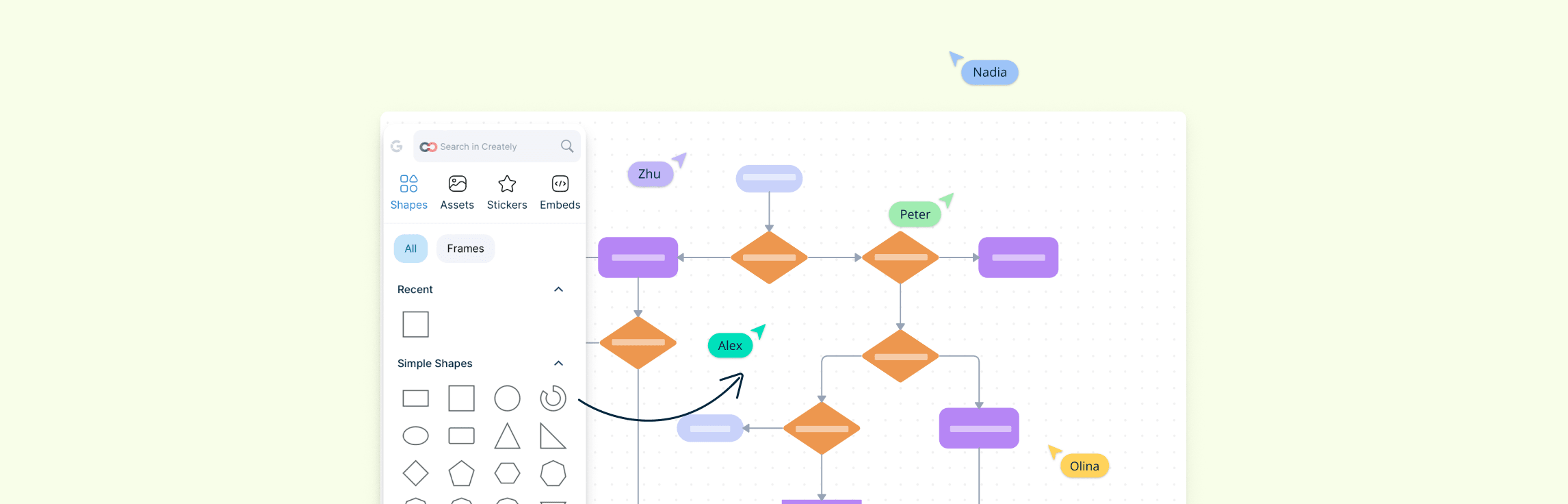

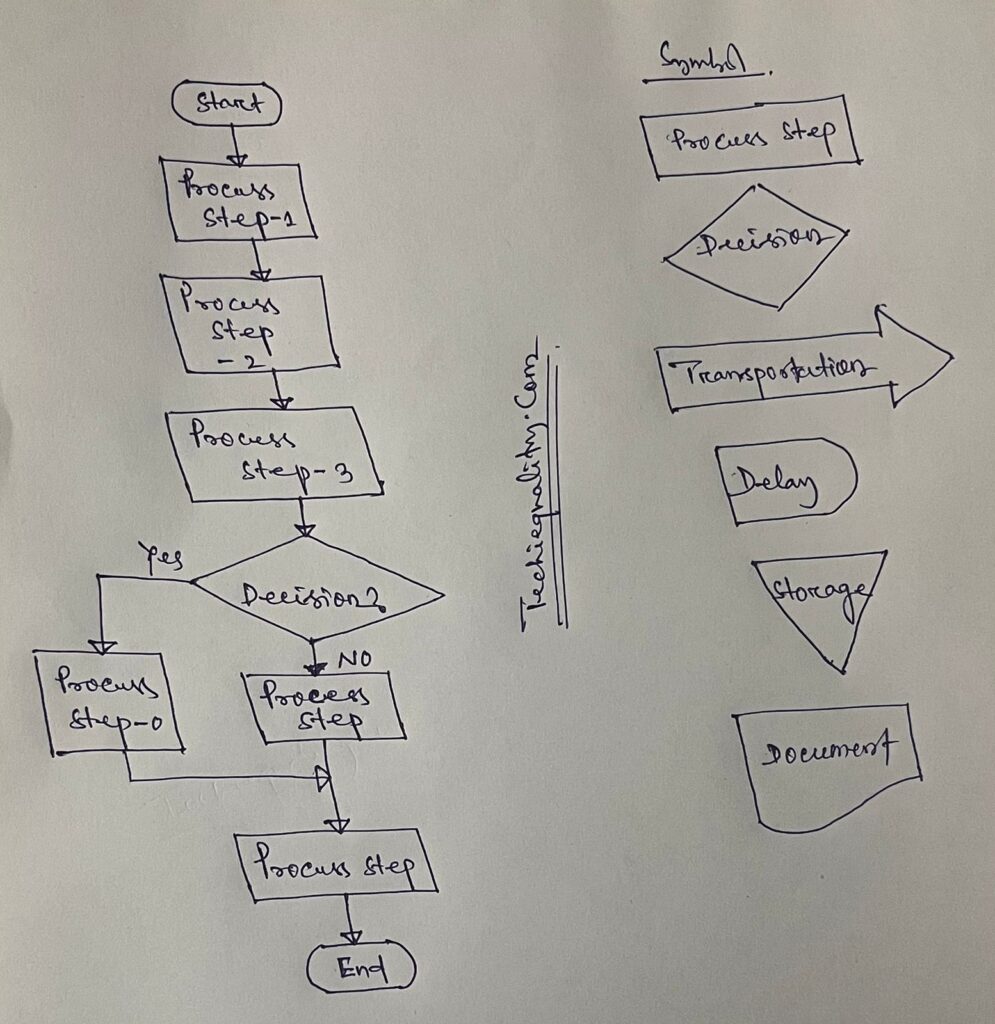

Flowcharts are perhaps the most popular out of the 7 quality tools. This tool is used to visualize the sequence of steps in a process, event, workflow, system, etc. In addition to showing the process as a whole, a flowchart also highlights the relationship between steps and the process boundaries (start and end).

Flowcharts use a standard set of symbols, and it’s important to standardize the use of these symbols so anyone can understand and use them easily. Here’s a roundup of all the key flowchart symbols .

- To build a common understanding of a process.

- To analyze processes and discover areas of issues, inefficiencies, blockers, etc.

- To standardize processes by leading everyone to follow the same steps.

Real-world examples of usage

- Documenting and analyzing the steps involved in a customer order fulfillment process.

- Mapping out the workflow of a software development lifecycle.

- Visualizing the process flow of patient admissions in a hospital.

Enhances process understanding, highlights bottlenecks or inefficiencies, and supports process optimization and standardization efforts.

How to use a flowchart

- Gather a team of employees involved in carrying out the process for analyzing it.

- List down the steps involved in the process from its start to end.

- If you are using an online tool like Creately , you can first write down the process steps and rearrange them later on the canvas as you identify the flow.

- Identify the sequence of steps; when representing the flow with your flowchart, show it from left to write or from top to bottom.

- Connect the shapes with arrows to indicate the flow.

Who can use it?

- Process improvement teams mapping and documenting existing processes for analysis.

- Business analysts or consultants analyzing workflow and process optimization opportunities.

- Software developers or system designers documenting the flow of information or interactions in a system.

To learn more about flowcharts, refer to our Ultimate Flowchart Tutorial .

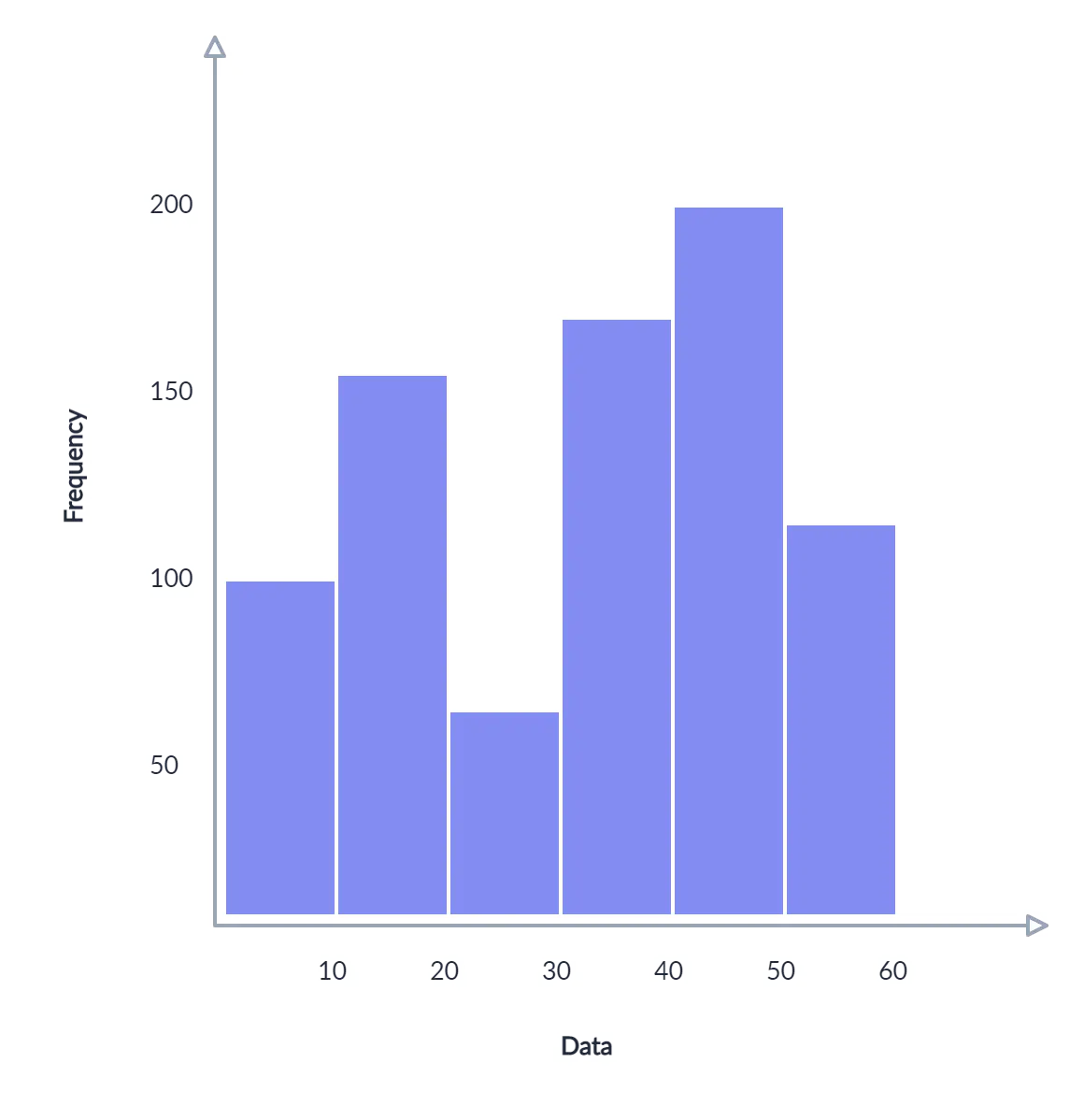

A histogram is a type of bar chart that visualizes the distribution of numerical data. It groups numbers into ranges and the height of the bar indicates how many fall into each range.

It’s a powerful quality planning and control tool that helps you understand preventive and corrective actions.

- To easily interpret a large amount of data and identify patterns.

- To make predictions of process performance.

- To identify the different causes of a quality problem.

- Analyzing the distribution of call wait times in a call center.

- Assessing the distribution of product weights in a manufacturing process.

- Examining the variation in delivery times for an e-commerce business.

Provides insights into process performance and variation, enabling teams to target areas for improvement and make data-driven decisions.

How to make a histogram

- Collect data for analysis. Record occurrences of specific ranges using a tally chart.

- Analyze the data at hand and split the data into intervals or bins.

- Count how many values fall into each bin.

- On the graph, indicate the frequency of occurrences for each bin with the area (height) of the bar.

- Process engineers or data analysts examining process performance metrics.

- Financial analysts analyzing expenditure patterns or budget variances.

- Supply chain managers assessing supplier performance or delivery times.

Here’s a useful article to learn more about using a histogram for quality improvement in more detail.

This tool is devised by Kaoru Ishikawa himself and is also known as the fishbone diagram (for it’s shaped like the skeleton of a fish) and Ishikawa diagram.

They are used for identifying the various factors (causes) leading to an issue (effect). It ultimately helps discover the root cause of the problem allowing you to find the correct solution effectively.

- Problem-solving; finding root causes of a problem.

- Uncovering the relationships between different causes leading to a problem.

- During group brainstorming sessions to gather different perspectives on the matter.

- Investigating the potential causes of low employee morale or high turnover rates.

- Analyzing the factors contributing to product defects in a manufacturing process.

- Identifying the root causes of customer complaints in a service industry.

Enhances problem-solving by systematically identifying and organizing possible causes, allowing teams to address root causes rather than symptoms.

How to use the cause and effect diagram

- Identify the problem area that needs to be analyzed and write it down at the head of the diagram.

- Identify the main causes of the problem. These are the labels for the main branches of the fishbone diagram. These main categories can include methods, material, machinery, people, policies, procedures, etc.

- Identify plausible sub-causes of the main causes and attach them as sub-branches to the main branches.

- Referring to the diagram you have created, do a deeper investigation of the major and minor causes.

- Once you have identified the root cause, create an action plan outlining your strategy to overcome the problem.

- Cross-functional improvement teams working on complex problems or process improvement projects.

- Quality engineers investigating the root causes of quality issues.

- Product designers or engineers seeking to understand the factors affecting product performance.

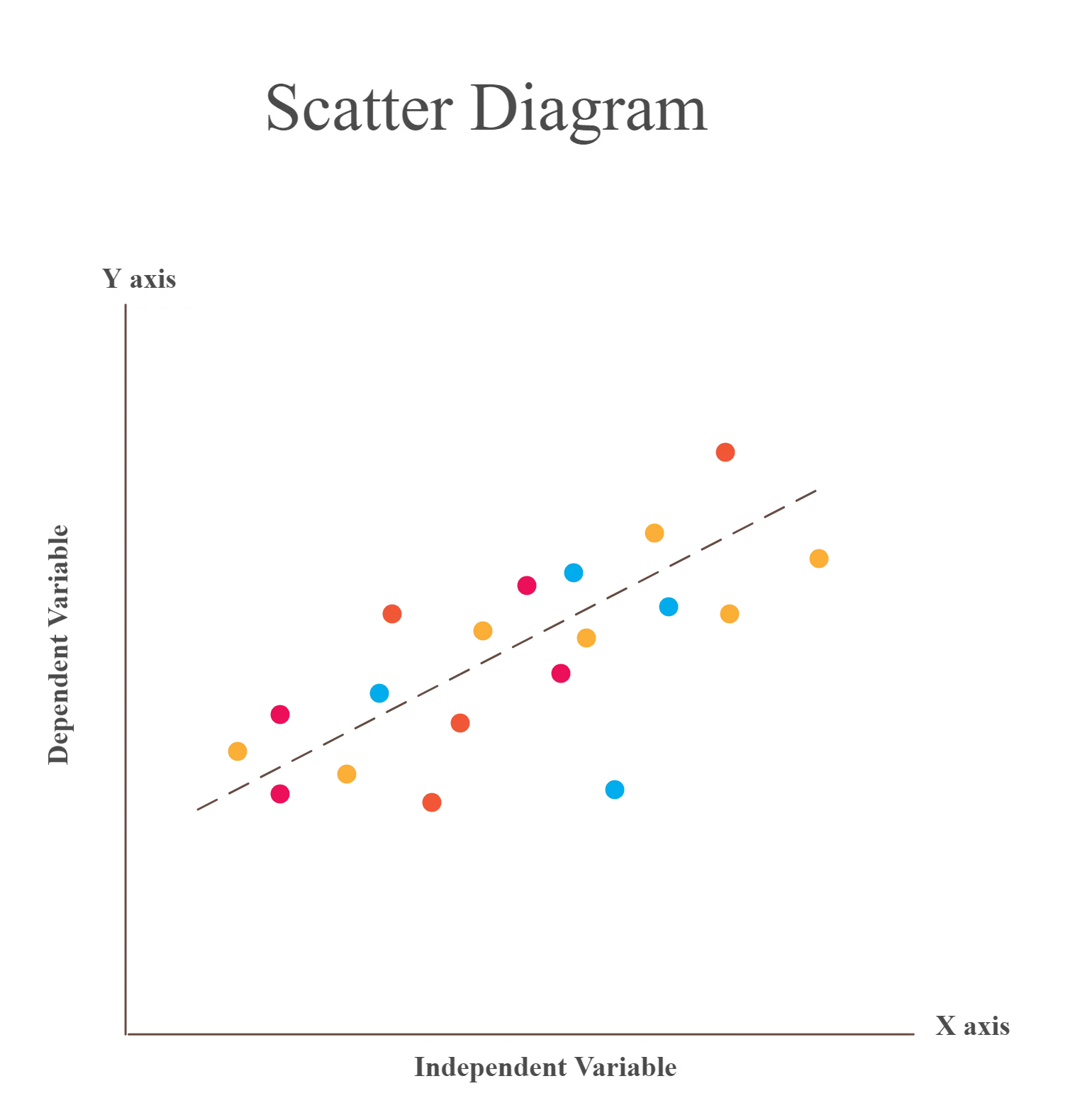

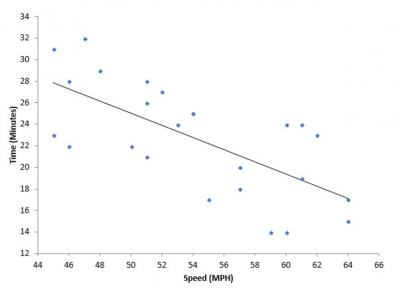

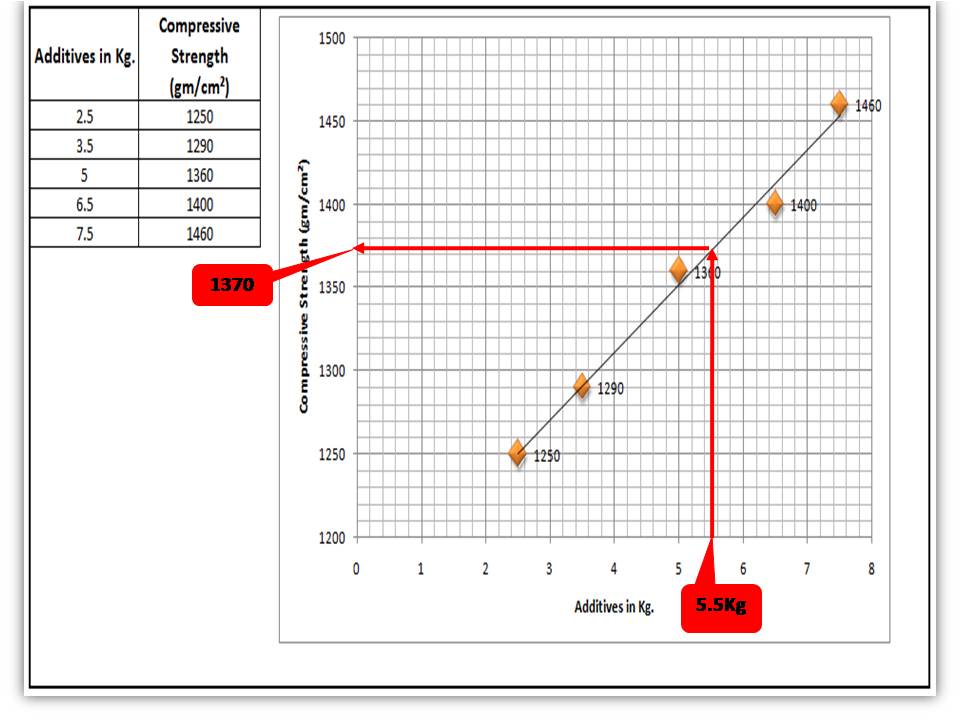

The scatter diagram (scatter charts, scatter plots, scattergrams, scatter graphs) is a chart that helps you identify how two variables are related.

The scatter diagram shows the values of the two variables plotted along the two axes of the graph. The pattern of the resulting points will reveal the correlation.

- To validate the relationship between causes and effects.

- To understand the causes of poor performance.

- To understand the influence of the independent variable over the dependent variable.

- Exploring the relationship between advertising expenditure and sales revenue.

- Analyzing the correlation between employee training hours and performance metrics.

- Investigating the connection between temperature and product quality in a production line.

Helps identify correlations or patterns between variables, facilitating the understanding of cause-and-effect relationships and aiding in decision-making.

How to make a scatter diagram

- Start with collecting data needed for validation. Understand the cause and effect relationship between the two variables.

- Identify dependent and independent variables. The dependent variable plotted along the vertical axis is called the measures parameter. The independent variable plotted along the horizontal axis is called the control parameter.

- Draw the graph based on the collected data. Add horizontal axis and vertical axis name and draw the trend line.

- Based on the trend line, analyze the diagram to understand the correlation which can be categorized as Strong, Moderate and No Relation.

- Data analysts exploring relationships between variables in research or analytics projects.

- Manufacturing engineers investigating the correlation between process parameters and product quality.

- Sales or marketing teams analyzing the relationship between marketing efforts and sales performance.

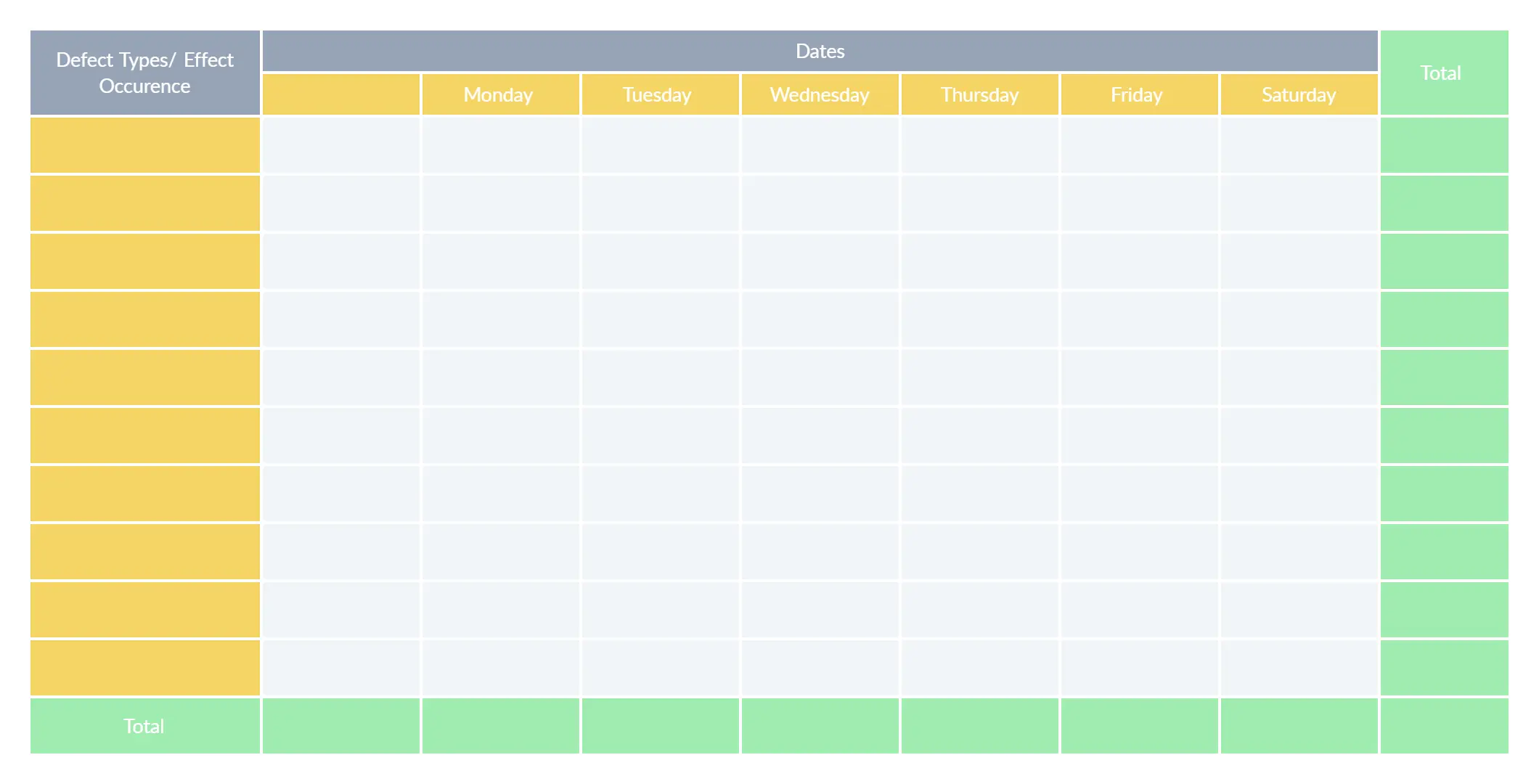

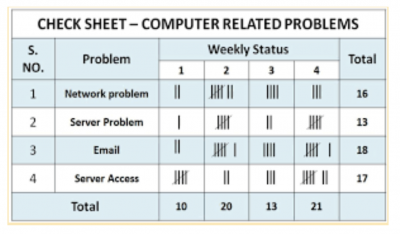

Check sheets provide a systematic way to collect, record and present quantitative and qualitative data about quality problems. A check sheet used to collect quantitative data is known as a tally sheet.

It is one of the most popular QC tools and it makes data gathering much simpler.

- To check the shape of the probability distribution of a process

- To quantify defects by type, by location or by cause

- To keep track of the completion of steps in a multistep procedure (as a checklist )

- Tracking the number of defects or errors in a manufacturing process.

- Recording customer complaints or inquiries to identify common issues.

- Monitoring the frequency of equipment breakdowns or maintenance needs.

Provides a structured approach for data collection, making it easier to identify trends, patterns, and areas for improvement.

How to make a checksheet

- Identify the needed information.

- Why do you need to collect the data?

- What type of information should you collect?

- Where should you collect the data from?

- Who should collect the data?

- When should you collect the data?

- How should you measure the data?

- How much data is essential?

Construct your sheet based on the title, source information and content information (refer to the example below).

Test the sheets. Make sure that all the rows and columns in it are required and relevant and that the sheet is easy to refer to and use. Test it with other collectors and make adjustments based on feedback.

- Quality inspectors or auditors who need to collect data on defects or issues.

- Process operators or technicians responsible for tracking process parameters or measurements.

- Customer service representatives who record customer complaints or inquiries.

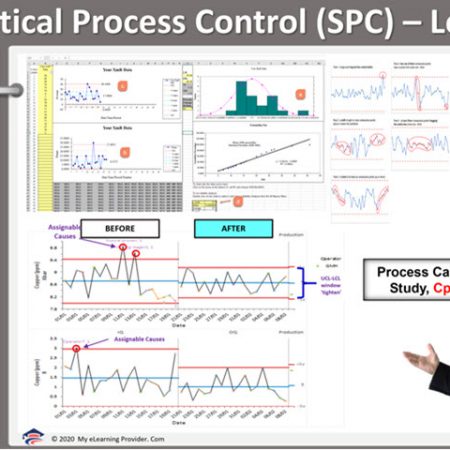

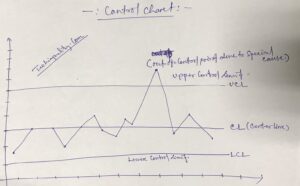

Control Chart

The control chart is a type of run chart used to observe and study process variation resulting from a common or special cause over a period of time.

The chart helps measure the variations and visualize it to show whether the change is within an acceptable limit or not. It helps track metrics such as defects, cost per unit, production time, inventory on hand , etc.

Control charts are generally used in manufacturing, process improvement methodologies like Six Sigma and stock trading algorithms.

- To determine whether a process is stable.

- To monitor processes and learn how to improve poor performance.

- To recognize abnormal changes in a process.

- Monitoring the variation in product dimensions during a manufacturing process.

- Tracking the number of customer complaints received per day.

- Monitoring the average response time of a customer support team.

Enables real-time monitoring of process stability, early detection of deviations or abnormalities, and prompt corrective actions to maintain consistent quality.

How to create a control chart

- Gather data on the characteristic of interest.

- Calculate mean and upper/lower control limits.

- Create a graph and plot the collected data.

- Add lines representing the mean and control limits to the graph.

- Look for patterns, trends, or points beyond control limits.

- Determine if the process is in control or out of control.

- Investigate and address causes of out-of-control points.

- Regularly update the chart with new data and analyze for ongoing improvement.

- Production supervisors or operators monitoring process performance on the shop floor.

- Quality control or assurance personnel tracking variation in product quality over time.

- Service managers observing customer satisfaction levels and service performance metrics.

Pareto Chart

The Pareto chart is a combination of a bar graph and a line graph. It helps identify the facts needed to set priorities.

The Pareto chart organizes and presents information in such a way that makes it easier to understand the relative importance of various problems or causes of problems. It comes in the shape of a vertical bar chart and displays the defects in order (from the highest to the lowest) while the line graph shows the cumulative percentage of the defect.

- To identify the relative importance of the causes of a problem.

- To help teams identify the causes that will have the highest impact when solved.

- To easily calculate the impact of a defect on the production.

- Analyzing customer feedback to identify the most common product or service issues.

- Prioritizing improvement efforts based on the frequency of quality incidents.

- Identifying the major causes of delays in project management.

Helps focus improvement efforts on the most significant factors or problems, leading to effective allocation of resources and improved outcomes.

How to create a Pareto chart

- Select the problem for investigation. Also, select a method and time for collecting information. If necessary create a check sheet for recording information.

- Once you have collected the data, go through them and sort them out to calculate the cumulative percentage.

- Draw the graph, bars, cumulative percentage line and add labels (refer to the example below).

- Analyze the chart to identify the vital few problems from the trivial many by using the 80/20 rule . Plan further actions to eliminate the identified defects by finding their root causes.

- Quality managers or improvement teams looking to prioritize improvement initiatives.

- Project managers seeking to identify and address the most critical project risks.

- Sales or marketing teams analyzing customer feedback or product issues.

What’s Your Favorite Out of the 7 Basic Quality Tools?

You can use these 7 basic quality tools individually or together to effectively investigate processes and identify areas for improvement. According to Ishikawa, it’s important that all employees learn how to use these tools to ensure the achievement of excellent performance throughout the organization.

Got anything to add to our guide? Let us know in the comments section below.

Join over thousands of organizations that use Creately to brainstorm, plan, analyze, and execute their projects successfully.

FAQs about 7 Basic Quality Tools

Quality problems in an organization can manifest in various forms and affect different areas of operations.

- Product defects: Products may have defects or non-conformities that deviate from quality specifications, leading to customer dissatisfaction, returns, or warranty claims.

- Service errors: Service errors can occur when services do not meet customer expectations, such as incorrect billing, delays in delivery, or inadequate customer support.

- Process inefficiencies: Inefficient processes can lead to delays, errors, or rework, resulting in increased costs, decreased productivity, and customer dissatisfaction.

- Poor design or innovation: Inadequate product design or lack of innovation can lead to products that do not meet customer needs, lack competitive features, or have usability issues.

- Supplier quality issues: Poor quality materials or components from suppliers can affect the overall quality of the final product or service.

- Ineffective quality management systems: Inadequate quality management systems, such as lack of quality standards, processes, or documentation, can contribute to quality problems throughout the organization.

The basic quality improvement steps typically follow a systematic approach to identify, analyze, implement, and monitor improvements in processes or products.

- Clearly articulate the problem or identify the area for improvement.

- Collect relevant data and information related to the problem.

- Analyze the collected data to identify patterns, root causes, and opportunities for improvement.

- Brainstorm and generate potential improvement ideas or solutions.

- Assess the feasibility, impact, and effectiveness of the generated improvement ideas.

- Develop an action plan to implement the chosen solution.

- Continuously monitor and measure the results of the implemented solution.

- Based on the monitoring results, evaluate the effectiveness of the implemented solution.

- Once the improvement is successful, document the new processes, best practices, or standard operating procedures (SOPs).

- Iterate through the steps to continuously improve processes and products.

More Related Articles

Amanda Athuraliya is the communication specialist/content writer at Creately, online diagramming and collaboration tool. She is an avid reader, a budding writer and a passionate researcher who loves to write about all kinds of topics.

7 QC Tools: Your Ultimate Guide To Quality Improvement

Introduction to 7 QC tools

Quality management is an important aspect of any organization, and achieving it requires effective problem-solving strategies. In this regard, the 7 QC tools offer a comprehensive approach to problem-solving and quality improvement. These tools are designed to help organizations identify the root cause of problems, make data-driven decisions, and ultimately improve the quality of their products or services. In this post, we will explore the importance of the 7 QC tools, their history and evolution, how to select the right tool for quality control, and detailed explanations of each of the 7 QC tools.

Importance of 7 QC tools in quality management

The importance of 7 QC tools in quality management cannot be overstated. These tools help organizations to improve quality by providing a systematic approach to problem-solving. They enable organizations to analyze data, identify problem areas, and make data-driven decisions. By using these tools, organizations can reduce costs, increase productivity, and improve customer satisfaction. The 7 QC tools are widely used in various industries, including manufacturing, healthcare, and service sector. They are easy to use, cost-effective, and can be applied to various types of problems.

History and evolution of 7 QC tools

The history and evolution of the 7 QC tools can be traced back to the early 1920s when Dr. Walter A. Shewhart introduced the concept of statistical process control (SPC). Over time, additional techniques were added to the original seven, and the tools evolved to include Pareto charts, cause-and-effect diagrams, check sheets, histograms, scatter diagrams, and control charts. Today, the 7 QC tools are widely used in quality management and have become an integral part of Lean and Six Sigma methodologies.

How to select the right tool for quality control

Here are some points to consider when selecting the right tool for quality control:

- Identify the problem: Before selecting a tool, it is important to clearly identify the problem at hand. This will help determine which tool is best suited for the job.

- Understand the data: Understanding the data available is crucial for selecting the right tool. Some tools are better suited for qualitative data, while others work best with quantitative data.

- Determine the scope: Consider the scope of the problem and the level of detail required to solve it. Some tools are better suited for analyzing specific details, while others provide a more holistic view of the problem.

- Consider the complexity: Some problems are more complex than others, and require more sophisticated tools to solve. Consider the level of complexity and choose a tool that is appropriate for the problem at hand.

- Evaluate the strengths and limitations: Each tool has its own strengths and limitations. It is important to understand these before selecting a tool, so that you can choose one that is best suited for the problem at hand.

- Seek expert advice: If you are unsure which tool to use, seek advice from experts in the field. They can provide valuable insights and help you select the right tool for the job.

By considering these factors, you can select the right tool for quality control and ensure that your problem-solving efforts are effective and efficient.

7 QC Tools Explained

1. Pareto Chart

A Pareto chart is a graph that displays the relative frequency or size of problems in descending order of importance. It is a tool for identifying the most significant causes of a problem or the largest sources of variation in a process. The chart uses a vertical bar graph to show the frequency or size of each problem, with the bars arranged in order of decreasing importance. The chart also includes a cumulative percentage line that shows the cumulative percentage of problems accounted for by each cause. Pareto charts are useful for prioritizing problems and identifying the root causes that should be addressed to have the most significant impact on process improvement.

2. Cause-and-effect diagram

A cause-and-effect diagram, also known as a fishbone diagram or Ishikawa diagram, is a tool used to identify the root causes of a problem. It is a structured approach that helps to identify and categorize the possible causes of a problem, based on the various factors that could contribute to it. The diagram starts with a problem statement at the head of the diagram and uses a structured approach to identify the possible causes, grouping them into categories such as people, process, equipment, materials, and environment. Cause-and-effect diagrams are useful for identifying the root causes of a problem and for organizing and structuring the potential causes in a way that can be easily analyzed and addressed.

3. Check sheet

A check sheet is a tool used to collect data in a structured way. It is a simple form that is used to record data in a standardized format, making it easy to collect and analyze data across different processes or situations. Check sheets can be used to track defects or errors, record the frequency of events, or collect other types of data. They are useful for identifying patterns and trends in data, as well as for tracking progress and improvement over time.

4. Histogram

A histogram is a graph that shows the distribution of data. It is a visual representation of how frequently certain values occur within a set of data, using a series of vertical bars. The bars are grouped into categories or ranges of values, with the height of each bar representing the number of data points that fall within that category. Histograms are useful for identifying the shape of the distribution, including the mean and standard deviation, and for identifying outliers or unusual data points.

5. Scatter diagram

A scatter diagram also known as a scatter plot, is a graph that shows the relationship between two variables. It is a visual representation of how one variable changes in response to changes in the other variable. Each data point is plotted on the graph as a point, with one variable represented on the x-axis and the other variable represented on the y-axis. Scatter diagrams are useful for identifying correlations or patterns in data, and for identifying outliers or unusual data points. They are commonly used in quality control and process improvement to identify relationships between process variables and product quality or performance.

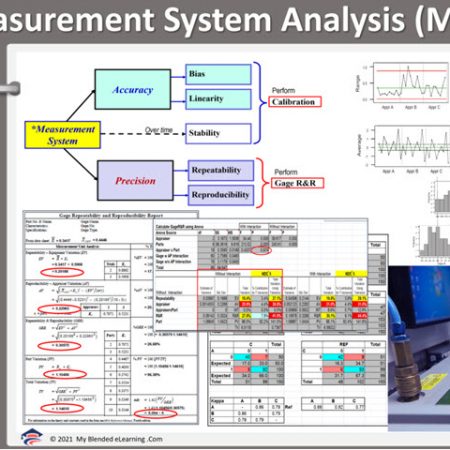

6. Control Charts

A control chart is a tool used to monitor and control a process over time. It is a graphical representation of data collected from a process, plotted against established control limits. The chart shows how the process is performing and alerts the user to any changes or variations that may occur. Control charts are useful for identifying trends, detecting shifts or changes in the process, and for identifying the sources of variation that may be causing problems. They can be used to monitor any process that produces data, from manufacturing to healthcare to financial services.

7. Flow Charts

A flow chart is a diagram that shows the steps in a process or system. It is a visual representation of the sequence of activities involved in a process, from start to finish. Flow charts are used to help understand a process, identify bottlenecks or inefficiencies, and to design or improve a process. The chart consists of boxes, symbols, and arrows that indicate the flow of the process. Boxes represent steps or actions in the process, while arrows represent the flow of materials or information between steps. Flow charts are useful for analyzing and improving any process, from simple to complex, and can be used in a variety of industries, including manufacturing, healthcare, and software development.

7 QC Tools: A Summary Table

These 7 QC tools are often used in combination with each other and with other quality management tools to improve quality and productivity, reduce costs and waste, and enhance customer satisfaction. The 7 QC Tools can be applied across various industries, including manufacturing, healthcare, finance, and service industries. These tools help to identify problems, analyze data, and improve processes, leading to better quality control and customer satisfaction. Knowing how and when to use each tool is essential to their effectiveness and achieving process improvement.

7 QC Tools Limitations:

While the 7 QC tools are widely used and effective for quality management, there are some limitations to their application. Here are some of the common limitations:

- Limited scope: The 7 QC tools are primarily focused on identifying and analyzing data related to quality issues and do not address other important aspects of quality management such as customer satisfaction, process improvement, and strategic planning.

- Lack of guidance: While the 7 QC tools provide a structured approach to data analysis, they do not provide guidance on how to implement solutions or make improvements based on the results.

- Data interpretation: The accuracy and usefulness of the data analyzed using the 7 QC tools depend on the quality and reliability of the data collected. Incorrect data or incomplete data can lead to incorrect conclusions and ineffective solutions.

- Limited application: The 7 QC tools are designed for use in manufacturing and industrial settings, and may not be as relevant or applicable in service industries or other non-manufacturing settings.

- Insufficient for complex problems: The 7 QC tools are useful for identifying and analyzing simple quality problems with a single cause or factor, but may be insufficient for more complex problems that have multiple causes and variables.

- Overreliance on data: The 7 QC tools rely heavily on data analysis and may overlook other important factors that contribute to quality, such as employee involvement, leadership, and culture.

Alternative Approach to 7QC Tools:

There are several other quality management tools and methodologies that organizations can use in addition to or instead of the 7 QC tools. Some of these alternatives include:

- Six Sigma: A data-driven approach to quality management that aims to minimize defects and variability in processes and products by using statistical methods and tools.

- Lean Manufacturing: A methodology focused on reducing waste and improving efficiency in manufacturing processes by eliminating non-value-added activities, streamlining production flows, and increasing responsiveness to customer demands.

- Root Cause Analysis (RCA): A problem-solving technique used to identify the underlying causes of a problem or failure, and develop solutions to prevent recurrence.

- Failure Mode and Effects Analysis (FMEA): A proactive risk management tool that helps identify and mitigate potential failures and defects in products or processes before they occur.

- Statistical Process Control (SPC): A method for monitoring and controlling a process by using statistical techniques to identify and correct deviations and abnormalities in the process.

- Kaizen: A continuous improvement philosophy that emphasizes small, incremental changes in processes and systems, and encourages employee involvement and empowerment.

These tools and methodologies can be used alone or in combination with each other, depending on the specific needs and goals of the organization.

In conclusion, the 7 QC tools offer a comprehensive approach to problem-solving and quality improvement. They are data-driven, cost-effective, and provide a systematic approach to quality management. By using these tools, organizations can reduce costs, increase productivity, and improve customer satisfaction. However, it is important to select the right tool for the problem at hand, and to understand the strengths and limitations of each tool. The 7 QC tools have a rich history and have become an integral part of Lean and Six Sigma methodologies, making them an essential tool for any organization that wants to improve the quality of its products or services.

References:

Goetsch, D. L., & Davis, S. B. (2014). Quality management for organizational excellence. Upper Saddle River, NJ: Pearson.

Ishikawa, K. (1985). What is Total Quality Control? The Japanese Way. Englewood Cliffs, NJ: Prentice Hall.

Batch vs. One Piece Flow Manufacturing: Which Is Right For Your Business?

Maximizing Quality And Efficiency: The Power Of Design For Six Sigma (DFSS)

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Reach out to us

Our proven process equips individuals with proven method and skills to create positive change and improve efficiency while reducing errors

© 2024 leansixsigmamadeeasy.com

7 Step QC Story Workshop

Learning objectives:.

To help Process & Engineering Managers to appreciate the principles & concept of 7 step QC Story approach for problem solving and how to can be applied to different problems

Expected Outcomes:

- Understand the concept of QC story and steps involved and how it can be used to solve problems

- Learn the tools and techniques that are used as a part of QC story problem solving approach

- Step by step process applying QC Story approach for different scenarios

- Practical strategies to manage problem solving teams

Target Audience:

Engineering Leadership Team, Manufacturing Managers, Supply Chain Managers, Quality Engineers, Process Improvement Professionals

One day interactive workshop

Broad Curriculum:

Broad scope is include here:

- 7 step QC approach and its benefits

- Linkage to Lean principles, Policy, DWM and PDCA

- Step-by-step hands-on training on QC Story tools & techniques

- Problem statement

- Process Flow Diagram

- Cause & Effect Analysis

- Data & Graphical Analysis Tools

- 5Why analysis

- Decision Matrix

- Brainstorming

- Pilot Planning & Results

- Mistake Proofing

- Control Plan & link to DWM

- Standard Work

- Control Charts

- Recognizing Team Efforts

All the methods to be covered in the training will be Application, Analysis or Synthesis as per Bloom’s taxonomy.

Aimed at encouraging exploratory learning, in this this workshop a full-fledged case study will be provided that the team will workshop from start to finish covering all the aspects covered above followed by facilitated group discussions to understand the QC Story principles & tools.

To conduct QC Story workshop in Chennai, Bangalore, Mumbai, Delhi and across India and to know more about the curriculum & structure & customization to your needs, contact us .

Sign-up for collaborat newsletter

Where We Can Help

- Client Centricity & Value Creation

- Sales Transformation

- Experience Design

- Enterprise Agility

- Data & Analytics

- Quality & Productivity Improvement

How We Can Help

- Strategic Workshops

- Implementation & Co-creation

- Training & Mentoring

- Client Research

- Data based Insights

- [email protected]

- +91-9176615766

Streamlining Six Sigma Projects with The 7 QC Tools

Updated: September 26, 2023 by Ken Feldman

As in any tool chest, you can have dozens, if not hundreds, of different tools for all types of specialized tasks. Such is the case with Six Sigma. There are many tools available for your use depending on what you want to accomplish. However, like your home tool chest, there are a small set of basic tools that are your go-to tools you will use most often and on most projects.

Let’s review the 7 QC tools that are most commonly used in Six Sigma , the benefits of those tools, and some best practices for using them.

Overview: What are the 7 QC tools?

It is believed that the 7 QC tools were introduced by Kaoru Ishikawa in postwar Japan, inspired by the seven famous weapons of Benkei. Benkei was a Japanese warrior monk who armed himself with seven weapons and was on a personal quest to take 1,000 swords from samurai warriors who he believed were arrogant and unworthy.

Ishikawa was influenced by a series of lectures on statistical quality control given by Dr. W. Edwards Deming in 1950 to a group of Japanese scientists and engineers. Unfortunately, the complexity of the subject intimidated most workers, so Ishikawa focused primarily on a reduced set of tools that would suffice for most quality-related issues.

The 7 QC tools are:

- Check sheet

- Fishbone diagram (cause and effect diagram, or Ishikawa diagram)

- Pareto chart

- Control chart

- Scatter diagram

- Stratification

Let’s explore each in a little more detail.

Check sheet: A form to collect and tally data for further analysis.

Image source: techqualitypedia.com .

Fishbone diagram: Fishbone diagrams are used to drill down to find the root cause of a problem. As the name implies, the diagram looks like the bones of a fish, where each main bone represents a specific category of possible root cause, and the subsequent drilling down is shown as smaller and smaller bones.

Image source: asq.org .

Histogram: This is a bar graph showing the frequency of a set of data, usually continuous data. The histogram allows you to see the center of the data, the range of the data, and the distribution of the data. It is a very useful snapshot. The downside is that you can’t see the sequence or order of the data.

Image source: statisticsbyjim.com .

Pareto chart: This chart is based on the 80/20 principle that says 80% of your effect is caused by 20% of your causes. For example, 80% of your sales comes from 20% of your customers. Dr. Joseph Juran, who developed this chart, often referred to this principle as the vital few and trivial many . He later revised that to the vital few and useful many . The Pareto chart lists the causes in descending order of frequency or magnitude. It is used to prioritize what you should look at first to improve your process.

Image source: www.automateexcel.com .

Control chart: A control chart is a statistical tool that looks at your process data over time for the purpose of distinguishing between special cause and common cause variation.

Image source: www.spcforexcel.com .

Scatter diagram: These are also known as scatter plots. They’re used to show a graphical correlation between a set of paired data on an X and Y axis. It is the graphical representation of what you would use for regression analysis.

Image source: www.spcforexcel.com .

Stratification: This is a graph that shows data that has been stratified when the data comes from different sources. It is useful to view the data by certain strata such as shift, gender, geographic location, machines, or suppliers.

Image source: www.systems2win.com .

3 benefits of the 7 QC tools

These seven tools are easy to understand and apply and will help you understand what is going on in your process.

1. Easy

These 7 QC tools are easy to understand and implement yet powerful in identifying root causes, in discriminating between types of variation, and as a visual description of your data. A picture is truly worth 10,000 words (or statistical calculations).

2. Software-driven

Gone are the days when you had to draw all of your graphs by hand. There are many simple and cost-effective software packages that will take your data and quickly produce graphs.

3. 80/20

The Pareto principle applies to the 7 QC tools as well. 80% of your quality issues can be addressed by using 20% of the most common tools.

Why are the 7 QC tools important to understand?

The key thing to understand is when to use each tool — which one is appropriate for your specific situation?

Tools address different issues

The more familiar you are with these common tools, the quicker you’ll be able to select the right one to help you solve your problem or answer your question. The Fishbone diagram is used to search for root causes of your problem. A control chart is used to distinguish between common and special cause variation. A scatter diagram is used to look for correlation or relationship between an X and Y variable.

Graphs don’t tell the whole story

Graphs and diagrams are useful for providing an overview and directional indicator of your process, but statistical analysis will provide greater confidence than a graph alone.

Flexibility

These seven tools can be used for different types of data and across any type of function. Their flexibility makes them useful in myriad situations and industries, so becoming familiar with them can be a wise investment.

3 best practices when thinking about the 7 QC tools

Use these tools for as many applications as is feasible. Keep it simple, and only use the more sophisticated and complex tools if you need the additional information and analysis.

1. Have a clear idea of what question you’re trying to answer

Since each of the tools can be used to answer different data and process questions, be sure you’ve clearly defined the question you’re trying to answer.

2. Use them as your primary presentation

Use the 7 QC tools and their accompanying graphs and diagrams as your primary presentation format. Reserve the statistical analysis for questions that go beyond what’s answered in the graphs.

3. Make sure they’re self-explanatory

Be sure your graphs are succinct and self-explanatory so people can understand what you’re trying to tell them without the need for a long-winded explanation.

Frequently Asked Questions (FAQ) about the 7 QC tools

What is meant by stratification .

If you collected production data throughout the day across all three shifts and five machines, you might want to stratify or separate your data and look at it by shift and by machine. This would allow you to understand whether there were any differences between the strata. This might indicate the source of a root cause or an opportunity to improve the other shifts if one is found to be doing better than the others.

What are the 7 basic QC tools?

Scatter diagrams, Pareto charts, control charts, histograms, stratification, fishbone diagrams and check sheets.

Do I have to draw the graphs and diagrams for the 7 QC tools by hand?

With the use of current software and computer technology, you will rarely be required to create the graphs by hand. Still, it might be interesting to do it by hand once to fully appreciate the tools and software available to us.

Let’s review what’s in your tool belt

The 7 QC tools are basic graphical representations of your data. They can be used to answer a wide variety of questions about your data and your process. Use them as your primary presentation format when talking about what your data is telling you. While they are not a complete list of tools, they should be robust enough to address many of your improvement issues.

The 7 QC tools, while basic, are foundational to the Six Sigma methodology and have stood the test of time. Their simplicity and versatility make them indispensable for professionals across industries. As businesses evolve and data becomes more integral to decision-making, the importance of these tools only grows. They bridge the gap between raw data and actionable insights, allowing teams to make informed decisions. Moreover, in today’s digital age, with the integration of AI and machine learning, these tools can be further enhanced to provide even deeper insights. However, the essence remains the same: understanding and improving processes through data visualization.

Key Points About The 7 QC Tools:

Origin and Influence: Introduced by Kaoru Ishikawa, inspired by Benkei’s seven weapons and influenced by Dr. W. Edwards Deming’s lectures on statistical quality control.

List of 7 QC Tools: Check sheet, Fishbone diagram, Histogram, Pareto chart, Control chart, Scatter diagram, and Stratification.

Benefits: These tools are easy to understand, software-driven, and adhere to the 80/20 principle, addressing 80% of quality issues with 20% of the most common tools.

Importance: They address different issues, provide an overview of processes, and offer flexibility across data types and functions.

Best Practices: Clearly define the question, use the tools as the primary presentation format, and ensure graphs are self-explanatory.

About the Author

Ken Feldman

- All courses

Productivity

7 qc tools for quality improvement.

*Optional training delivery method for this course: Remote Online Training (ROT) or Face-to-Face (F2F) !

COURSE DESCRIPTION

7 QC Tools For Quality Improvement course provides an in-depth study of the 7 Basic QC (Quality Control) Tools. They are scientific management tools, used worldwide by almost every organizations to collect and analyze data/facts for the purpose of quality improvements. The 7 QC Tools are simple tools, low-cost and easy-to-use; but they are powerful tools that forms the critical foundation for all problem solving and quality improvement activities. Once mastered, these tools will serve as the solid foundation for individuals’ and team’s root cause analyses, problem solving sessions, and continuous improvement projects.

Manufacturing and service industry professionals, quality technicians and auditors, and industrial engineers will all benefit from understanding these tools. In addition to the foundational principles and concepts, this training examines practical real-world applications of the 7 QC Tools in the workplace. Participants will be provided with value-added MS Excel templates. These templates will help construct those QC Tools fast, easy and accurately.

This course is a MUST for all Quality Assurance staff such as Quality Engineers, Technicians, QC Leaders and also serve as a foundational course for Data Analysis & Lean Six Sigma practitioners.

CERTIFICATION

No certification.

Certificate of Achievement (for those who scored 80% and above for post-test) or Certificate of Attendance.

LEARNING OUTCOMES

At the end of the course, participants will be able to:

- Describe the benefits and power of each of the 7 QC Tools and its applications.

- Construct the QC tools accurately and fast using Microsoft Excel templates.

- Interpret , analyze and make accurate quality improvement decisions using the correct tools

- Perform data analysis and process monitoring using the QC tools

- Solve problems systematically and effectively.

- Experience the Quality Control Circle (QCC) team dynamics in solving problems.

- Make convincing presentations with the data collected from their workplace.

COURSE OUTLINE

Please see eBrochure above for more information.

To register, please Whatsapp : +60-19-502 2718 or email us at [email protected]

Course Features

- Skill level All level

- Language English

- Students 1632

- Assessments Yes

You May Like

Root cause analysis (rca).

Quality Control Circle (QCC) / Innovative & Creative Circle (ICC)

KAIZEN Strategies for Quality and Productivity Improvement

Measurement System Analysis (MSA)

Statistical Process Control -Level 1 (SPC1)

Modal title.

Message modal

TECHIEQUALITY

7qc tools for problem solving | what are 7 qc tools.

7QC Tools for Problem Solving techniques are generally used in manufacturing, Non-manufacturing industries, and service sectors to resolve problems.

Download 7-QC Tools Template/ Format

Definition and History:-

The 7QC Tools (Also Known as “Seven Basic Tools of Quality”) originated in Japan. First emphasized by Kaoru Ishikawa, a professor of engineering at Tokyo University and the father of “quality circles”. These tools are used to solve critical quality-related issues. You can use the 7 basic tools of quality to help understand and solve problems or defects in any industry. With the help of Excel, you can plot the graphs / Diagrams to resolve the daily quality problems. I will help you to understand the basic ideas and knowledge of 7QC Tools and their usage.

For solving problems seven QC tools are used Pareto Chart, Cause & Effect Diagram, Histogram, Control Charts, Scatter Diagrams, Graphs/Process Flow Diagram, and Check Sheets. All these tools are important tools used widely in the manufacturing field to monitor the overall operation and continuous process improvement. seven QC tools are used to find out the Root cause of the problem and implement the action plan to improve the process efficiency.

7QC tools are:-

- Pareto Chart

- Cause and effects diagram

- Scatter Diagram

- Control Chart

- Check Sheet

- PFD(Process Flow diagram)/Graphs

Benefits of 7QC Tools:-

- Improve management decisions.

- Simple and easy for implementation

- Continuous quality improvement

- Quick results

- Enhances customer satisfaction through improved quality product

- Reduce cycle time and improve efficiency

- Control cost of poor quality / Cost of quality

- Reduce defects and optimize the production

- Reduce variations and improve the quality of Products

- Encouragement of teamwork and confidence

- Enhancement of customer focus.

Pareto Chart:-

A Pareto Chart is named after the Italian Economist Vilfredo Pareto. It is a type of chart that contains both bars and a line graph, where the individual values are represented in the bar graph in descending order (largest to smallest value) and the cumulative percentage is represented in the line graph.

Click here to learn “How to Plot Pareto Chart In Excel”.

Understanding the Pareto Chart principle (The 80/20 rule):

The Pareto principle is also known as the 80/20 rule derived from the Italian Economist Vilfredo,

The principle is understood as –

20% of the input creates 80% of the results

80 % of the effects come from 20% of the causes.

In the above Pareto Chart[Figure-1], we can see the cumulative% in the line graph, According to the Pareto Chart principle 80/20 rule, the 80% cumulative in the line graph is filling under the low hardness, which means BH, Damage, SH and Low hardness defers are coving the 80% of contribution over total types of defects. And those 80 % of contributions were due to the 20% caused.

Histogram:-

The histogram is one of the 7QC tools, which is the most commonly used graph to show frequency distribution.

Helps summarize data from a process that has been collected over a period of time.

Click here to know the “How to Plot Histogram in Excel:

Fish-bone Diagram/Cause and Effects /Ishikawa Diagram:-

The cause and Effects Diagram looks like a fish that’s why it’s called Fish-bone Diagram, also called the Ishikawa diagram.

It’s a visualization tool for categorizing the potential causes of a problem in order to identify its root causes.

CFT members are identifying the potential cause through the Brainstorming process of individuals and together.

The Potential cause is related w.r.t below as

- Environment

- Measurement

Scatter diagram:-

The scatter diagram graphs pairs of variable data, with one variable on each axis, to look for a relationship between them. If the variables correlate, the points will fall along a line or curve. The better the correlation, the more points will strongly cluster to the line. It generally gives the idea of the correlation between the variables.

In the above figure-4, the positive and Negative correlation is only due to the direction, and in both the correlation, points are clustered to the line but in the last figure in figure-4, Points are not clustered to the line but spread over the X and Y-axis.

Control Chart:-

A line on a control chart is used as a basis for judging the stability of a process. If the observed points are beyond a control limit then it is evidence that special causes are affecting the process.

Control Charts can be used to monitor or evaluate a process.

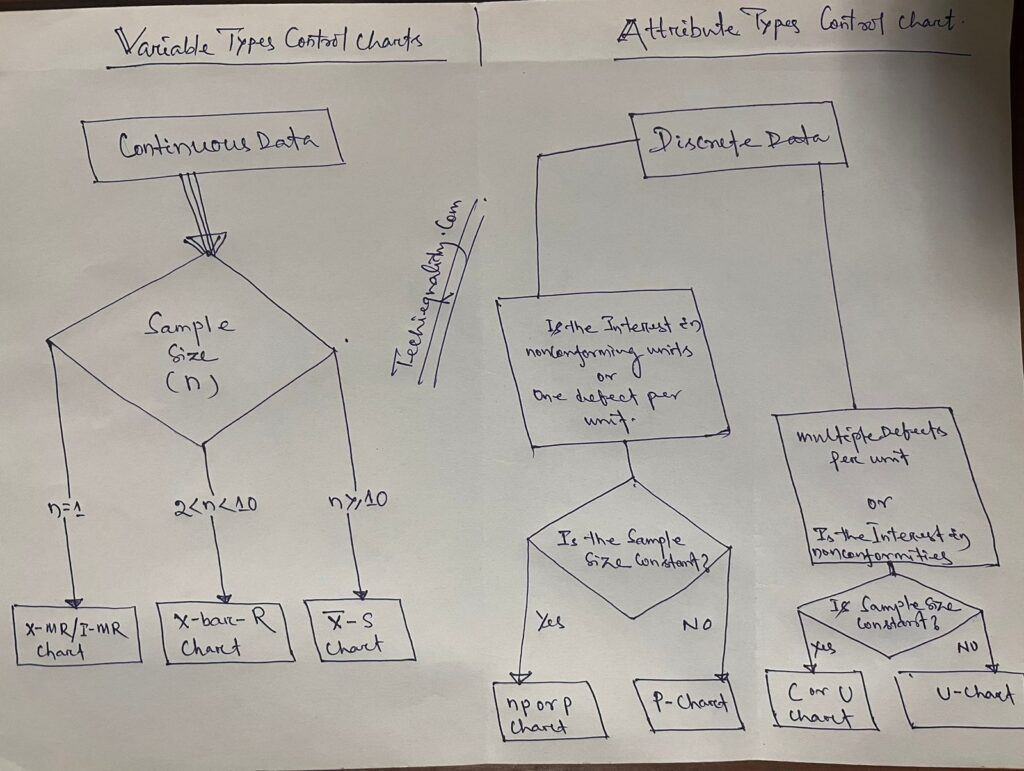

There are basically two types of control charts, those for variable data and those for attributes data.

Click here to learn more about the Control Chart and Statistical Process Control.

Benefits: -Higher Quality, Lower Unit Cost, Higher effective Capability, etc.

Selection of Control Charts based on Attribute / Variable Type Data:-

Calculation of Average and Range Charts-

Click here to know the details.

The formula of the Attributes Control Chart:-

Click here to learn the formula and calculation.

Nomenclature of Control Chart:-

Check Sheet:-

Check Sheet is a simple document used for collecting data in real time. Variable or Attribute type data is collected through a Check sheet. A check sheet generally helps to make the decision on the basis of a fact and to collect the data for analysis and evaluation.

Sample check Sheet:-

Process Flow diagram/Graphs:-

A process flow diagram is a diagram used to indicate the general flow of plant processes and equipment.

The 7QC tools are the most commonly used tool in the industry for improvement, With the help of the 7QC tools you can understand the process/activities, analyze the data, and interpret the result/graph/output.

Which are the 7 QC tools?

The seven QC tools are

- Fishbone diagram

- PFD(Process Flow diagram)/Graphs /Stratification

Useful Article:

why why analysis methodology | 5-why analysis step by step guide

Rework vs Repair |IATF Requirement for Control of Reworked/ Repaired Product

How to plot the Run Chart in Minitab

Run Chart Example | Concept & Interpretation of Result with Case Study | Industrial Example:

Thank you for reading..keep visiting Techiequality.Com

I hope the above article “7QC Tools for Problem Solving” is useful to you…

Popular Post:

Related Posts

The Author is an Expert in Quality Management System, Operation Management, Business Excellence, Process Excellence, IATF 16949, ISO 9001, ISO 14001, ISO 45001, ISO 17025, TQM, TPM & QA. He is Certified as an IA for ISO 9001, IATF 16949, ISO 14001, ISO 17025 & ISO 45001 Standard.

Your email address will not be published. Required fields are marked *

Email Address: *

Save my name, email, and website in this browser for the next time I comment.

How to master the seven-step problem-solving process

In this episode of the McKinsey Podcast , Simon London speaks with Charles Conn, CEO of venture-capital firm Oxford Sciences Innovation, and McKinsey senior partner Hugo Sarrazin about the complexities of different problem-solving strategies.

Podcast transcript

Simon London: Hello, and welcome to this episode of the McKinsey Podcast , with me, Simon London. What’s the number-one skill you need to succeed professionally? Salesmanship, perhaps? Or a facility with statistics? Or maybe the ability to communicate crisply and clearly? Many would argue that at the very top of the list comes problem solving: that is, the ability to think through and come up with an optimal course of action to address any complex challenge—in business, in public policy, or indeed in life.

Looked at this way, it’s no surprise that McKinsey takes problem solving very seriously, testing for it during the recruiting process and then honing it, in McKinsey consultants, through immersion in a structured seven-step method. To discuss the art of problem solving, I sat down in California with McKinsey senior partner Hugo Sarrazin and also with Charles Conn. Charles is a former McKinsey partner, entrepreneur, executive, and coauthor of the book Bulletproof Problem Solving: The One Skill That Changes Everything [John Wiley & Sons, 2018].

Charles and Hugo, welcome to the podcast. Thank you for being here.

Hugo Sarrazin: Our pleasure.

Charles Conn: It’s terrific to be here.

Simon London: Problem solving is a really interesting piece of terminology. It could mean so many different things. I have a son who’s a teenage climber. They talk about solving problems. Climbing is problem solving. Charles, when you talk about problem solving, what are you talking about?

Charles Conn: For me, problem solving is the answer to the question “What should I do?” It’s interesting when there’s uncertainty and complexity, and when it’s meaningful because there are consequences. Your son’s climbing is a perfect example. There are consequences, and it’s complicated, and there’s uncertainty—can he make that grab? I think we can apply that same frame almost at any level. You can think about questions like “What town would I like to live in?” or “Should I put solar panels on my roof?”

You might think that’s a funny thing to apply problem solving to, but in my mind it’s not fundamentally different from business problem solving, which answers the question “What should my strategy be?” Or problem solving at the policy level: “How do we combat climate change?” “Should I support the local school bond?” I think these are all part and parcel of the same type of question, “What should I do?”

I’m a big fan of structured problem solving. By following steps, we can more clearly understand what problem it is we’re solving, what are the components of the problem that we’re solving, which components are the most important ones for us to pay attention to, which analytic techniques we should apply to those, and how we can synthesize what we’ve learned back into a compelling story. That’s all it is, at its heart.

I think sometimes when people think about seven steps, they assume that there’s a rigidity to this. That’s not it at all. It’s actually to give you the scope for creativity, which often doesn’t exist when your problem solving is muddled.

Simon London: You were just talking about the seven-step process. That’s what’s written down in the book, but it’s a very McKinsey process as well. Without getting too deep into the weeds, let’s go through the steps, one by one. You were just talking about problem definition as being a particularly important thing to get right first. That’s the first step. Hugo, tell us about that.

Hugo Sarrazin: It is surprising how often people jump past this step and make a bunch of assumptions. The most powerful thing is to step back and ask the basic questions—“What are we trying to solve? What are the constraints that exist? What are the dependencies?” Let’s make those explicit and really push the thinking and defining. At McKinsey, we spend an enormous amount of time in writing that little statement, and the statement, if you’re a logic purist, is great. You debate. “Is it an ‘or’? Is it an ‘and’? What’s the action verb?” Because all these specific words help you get to the heart of what matters.

Want to subscribe to The McKinsey Podcast ?

Simon London: So this is a concise problem statement.

Hugo Sarrazin: Yeah. It’s not like “Can we grow in Japan?” That’s interesting, but it is “What, specifically, are we trying to uncover in the growth of a product in Japan? Or a segment in Japan? Or a channel in Japan?” When you spend an enormous amount of time, in the first meeting of the different stakeholders, debating this and having different people put forward what they think the problem definition is, you realize that people have completely different views of why they’re here. That, to me, is the most important step.

Charles Conn: I would agree with that. For me, the problem context is critical. When we understand “What are the forces acting upon your decision maker? How quickly is the answer needed? With what precision is the answer needed? Are there areas that are off limits or areas where we would particularly like to find our solution? Is the decision maker open to exploring other areas?” then you not only become more efficient, and move toward what we call the critical path in problem solving, but you also make it so much more likely that you’re not going to waste your time or your decision maker’s time.

How often do especially bright young people run off with half of the idea about what the problem is and start collecting data and start building models—only to discover that they’ve really gone off half-cocked.

Hugo Sarrazin: Yeah.

Charles Conn: And in the wrong direction.

Simon London: OK. So step one—and there is a real art and a structure to it—is define the problem. Step two, Charles?

Charles Conn: My favorite step is step two, which is to use logic trees to disaggregate the problem. Every problem we’re solving has some complexity and some uncertainty in it. The only way that we can really get our team working on the problem is to take the problem apart into logical pieces.

What we find, of course, is that the way to disaggregate the problem often gives you an insight into the answer to the problem quite quickly. I love to do two or three different cuts at it, each one giving a bit of a different insight into what might be going wrong. By doing sensible disaggregations, using logic trees, we can figure out which parts of the problem we should be looking at, and we can assign those different parts to team members.