An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- My Bibliography

- Collections

- Citation manager

Save citation to file

Email citation, add to collections.

- Create a new collection

- Add to an existing collection

Add to My Bibliography

Your saved search, create a file for external citation management software, your rss feed.

- Search in PubMed

- Search in NLM Catalog

- Add to Search

Rice Flour: A Promising Food Material for Nutrition and Global Health

Affiliation.

- 1 Graduate School of Bioagricultural Sciences, Nagoya University.

- PMID: 31619613

- DOI: 10.3177/jnsv.65.S13

Hunger and malnutrition, especially children, are still global issues today. Rice is a staple food for more than half of the world population and important nutritional source of not only carbohydrate but also protein. In recent aging societies, protein-energy malnutrition in elderly people emerges also as a social issue. Malnutrition in elderly people raises the risk of falling into age-related chronic diseases. Nutritional care can prevent elderly people from such age-related diseases. Rice and rice flour would be good foodstuff for preparation of diet suitable for and preferred by elderly people. Protein content of rice grains, like the other cereal grains, is less than 10% by weight, which is a little lower than meat and cheese, but higher than dairy milk and yoghurt. Nutritional quality of rice proteins is higher than the other cereal grains. Such relatively higher nutritional quality of rice proteins could be due to high copies of glutelin genes evolved from an ancestral gene common to soybean glycinin and resultant high content of legume-type seed storage proteins. Recently, rice flour became to be utilized for various processed food. The rice seed proteins as well as starch are accumulated in specific organelles termed protein bodies and amyloplast in the cells of endosperm and aleurone layer. By milling rice grains to flour particles consisting of protein and starch nanoparticles, processing characteristics of rice starch and proteins could be changed. To develop rice-based processed food for prevention of malnutrition, rice flour particles from various different rice sources could be blended for desired nutritional composition without spoiling the value of product food.

Keywords: 11S globulin; protein body; protein nutrition; rice flour; starch granule.

PubMed Disclaimer

Similar articles

- Nutritional quality and in vitro digestion of immature rice-based processed products. Miraji KF, Linnemann AR, Fogliano V, Laswai HS, Capuano E. Miraji KF, et al. Food Funct. 2020 Sep 23;11(9):7611-7625. doi: 10.1039/d0fo01668c. Food Funct. 2020. PMID: 32966471

- Mutations in the DNA demethylase OsROS1 result in a thickened aleurone and improved nutritional value in rice grains. Liu J, Wu X, Yao X, Yu R, Larkin PJ, Liu CM. Liu J, et al. Proc Natl Acad Sci U S A. 2018 Oct 30;115(44):11327-11332. doi: 10.1073/pnas.1806304115. Epub 2018 Oct 1. Proc Natl Acad Sci U S A. 2018. PMID: 30275307 Free PMC article.

- Tailoring Grain Storage Reserves for a Healthier Rice Diet and its Comparative Status with Other Cereals. Butardo VM Jr, Sreenivasulu N. Butardo VM Jr, et al. Int Rev Cell Mol Biol. 2016;323:31-70. doi: 10.1016/bs.ircmb.2015.12.003. Epub 2016 Feb 10. Int Rev Cell Mol Biol. 2016. PMID: 26944618 Review.

- [Development of bakery products for greater adult consumption based on wheat and rice flour]. Reyes Aguilar MJ, Palomo Pd, Bressani R. Reyes Aguilar MJ, et al. Arch Latinoam Nutr. 2004 Sep;54(3):314-21. Arch Latinoam Nutr. 2004. PMID: 15807208 Spanish.

- Cowpea flour: a potential ingredient in food products. Prinyawiwatkul W, McWatters KH, Beuchat LR, Phillips RD. Prinyawiwatkul W, et al. Crit Rev Food Sci Nutr. 1996 May;36(5):413-36. doi: 10.1080/10408399609527734. Crit Rev Food Sci Nutr. 1996. PMID: 8725672 Review.

- Commercial rice seed production and distribution in Indonesia. Qadir A, Suhartanto MR, Widajati E, Budiman C, Zamzami A, Rosyad A, Diaguna R. Qadir A, et al. Heliyon. 2024 Jan 26;10(3):e25110. doi: 10.1016/j.heliyon.2024.e25110. eCollection 2024 Feb 15. Heliyon. 2024. PMID: 38322973 Free PMC article.

- Effects of a novel rice-based diabetes-specific formula on postprandial glucose and gastrointestinal hormones: a double-blinded multi-arm randomized crossover trial. Chaiyakul S, Ketkham N, Chaichana C, Khumkhana N, Deekum W, Wongshaya P, Suwanmalai T, Hutchinson C, Pramyothin P. Chaiyakul S, et al. Front Endocrinol (Lausanne). 2023 May 24;14:1141497. doi: 10.3389/fendo.2023.1141497. eCollection 2023. Front Endocrinol (Lausanne). 2023. PMID: 37293492 Free PMC article. Clinical Trial.

- Increasing Protein Content of Rice Flour with Maintained Processability by Using Granular Starch Hydrolyzing Enzyme. Zhai J, Li X, Svensson B, Jin Z, Bai Y. Zhai J, et al. Molecules. 2023 Apr 17;28(8):3522. doi: 10.3390/molecules28083522. Molecules. 2023. PMID: 37110757 Free PMC article.

- Cytological, transcriptome and miRNome temporal landscapes decode enhancement of rice grain size. Mahto A, Yadav A, P V A, Parida SK, Tyagi AK, Agarwal P. Mahto A, et al. BMC Biol. 2023 Apr 19;21(1):91. doi: 10.1186/s12915-023-01577-3. BMC Biol. 2023. PMID: 37076907 Free PMC article.

- Integrated transcriptome and metabolome analysis revealed that flavonoids enhanced the resistance of Oryza sativa against Meloidogyne graminicola . Zhang L, Li S, Shan C, Liu Y, Zhang Y, Ye L, Lin Y, Xiong G, Ma J, Adnan M, Shi X, Sun X, Kuang W, Cui R. Zhang L, et al. Front Plant Sci. 2023 Mar 31;14:1137299. doi: 10.3389/fpls.2023.1137299. eCollection 2023. Front Plant Sci. 2023. PMID: 37063174 Free PMC article.

- Search in MeSH

LinkOut - more resources

Full text sources.

- J-STAGE, Japan Science and Technology Information Aggregator, Electronic

- MedlinePlus Health Information

- Citation Manager

NCBI Literature Resources

MeSH PMC Bookshelf Disclaimer

The PubMed wordmark and PubMed logo are registered trademarks of the U.S. Department of Health and Human Services (HHS). Unauthorized use of these marks is strictly prohibited.

- Open access

- Published: 26 April 2022

Influence of replacement of wheat flour by rice flour on rheo-structural changes, in vitro starch digestibility and consumer acceptability of low-gluten pretzels

- Nusrat Jan ORCID: orcid.org/0000-0001-6466-4533 1 ,

- H. R. Naik 1 ,

- Gousia Gani 1 ,

- Omar Bashir 1 ,

- Tawheed Amin 1 ,

- Sajad Mohd Wani 1 &

- Shakeel Ahmad Sofi 2

Food Production, Processing and Nutrition volume 4 , Article number: 9 ( 2022 ) Cite this article

6199 Accesses

Metrics details

This study aimed to access the influence of rice flour incorporation on various quality attributes of low-gluten wheat-based pretzels viz., functional, rheological, starch digestibility, color, textural and sensorial properties. Significant increase in swelling power (18.33 ± 0.51) and bulk density (0.58 ± 0.04) was observed in flour blend upon incorporation of rice flour, whereas, significant decrease in oil absorption capacity (0.62 ± 0.09), solubility index (6.72 ± 0.17), foaming capacity (9.67 ± 0.34), and foaming stability (3.39 ± 0.15) was recorded. Pasting properties of samples were studied using a Rapid Visco Analyser which indicated that all the pasting properties increased with an increase in rice flour incorporation. Fourier transform infrared spectroscopic studies revealed no difference in the basic functional groups of flour blend upon the incorporation of rice flour, however, it had a pronounced effect on elastic modulus (G′) of flour blend. In vitro starch digestion characteristics revealed 7.23% surge in slowly digestible starch and 13.36% reduction in rapidly digestible starch of developed low-gluten pretzels upon the incorporation of rice flour. Apparent amylose content (27.3 ± 1.45) and resistant starch content (6.12 ± 0.97) increased and starch digestibility index (69.87 ± 1.72) decreased in developed low-gluten pretzels. In conclusion, the developed low-gluten pretzels had significantly ( p < 0.05) higher mineral profile and lightness ( L* ) and lower breaking strength in addition to having better overall acceptability. This study indicated that substituting wheat flour with rice flour up to a level of 35% affected the quality attributes of developed low-gluten pretzels.

Graphical abstract

Introduction

Wheat ( Triticum aestivum L.) has been used since time immemorial for the manufacture of several bakery items because of the presence of unique gluten protein which is responsible for providing the viscoelastic characteristics to dough. The two fractions of gluten-gliadins and glutenins give elastic and extensible properties to dough which is essential for producing good quality bakery products (Hamdani et al. 2020 ). Further, gluten is the main component of wheat which is responsible for bread and cake quality. However, gluten is responsible for celiac disease which is an autoimmune digestive disease caused by the digestion of gluten and thus, the sole treatment for this disease is consuming low-gluten or gluten-free diet. Therefore, the development of low-gluten products is imperative, it poses a major technological challenge. Nowadays, efforts are being made to identify now-wheat sources that could be utilized to replace wheat flour for the development of low-gluten bakery products. Such non-wheat flours are obtained from other cereals. Among them, rice flour is the most popular ingredient and could be used as a substitute for wheat flour (Cornejo & Rosell 2015 ).

Rice ( Oryza sativa L.), the principal diet for half of the global population (Amin et al. 2020 ) contains starch as the main ingredient, which is considered the principal constituent for most food preparations (Ashwar et al. 2016 ). The quality characteristics of rice-based foodstuffs including texture (Li et al. 2016 ), pasting, gelatinization (Jane et al. 1999 ), etc. are attributed to the starch structure. The starch molecule consists of amylose and amylopectin. The main factor that determines the functional and physicochemical characteristics of starch is the ratio of amylose and amylopectin (Ritika et al. 2010 ). Keeping the rate of digestion into consideration, starch has often been classified as resistant, slowly digestible, and rapidly digestible starches (Ashwar et al. 2016 ). Rice flour can be used as one of the major components for the manufacture of ready-to-eat (RTE) breakfast cereals and snacks because of the presence of a large amount of starch and excellent expansion characteristics (Ryu 2004 ). Furthermore, rice has various advantages over other cereals viz., low in fat and sodium content, cholesterol-free, non-allergenic, and a high content of easily digestible carbohydrates (Amin et al. 2020 ). The lack of gluten in rice flour gives an additional advantage, making it a promising alternative to wheat flour in bakery products, specifically for those associated with celiac disease (Amin et al. 2020 ).

Pretzels are commonly relished as snacks in various developed countries and are usually made from wheat by cooking followed by baking of the product. Pretzel consumption and production are increasing at a faster rate due to consumers’ demand for substitutes for fried-based snack products. Presently, the production of pretzels in developed countries is fully automized in order to satisfy consumer demands. However, no such product is accessible in India (Naik et al. 2007 ). Furthermore, because consumers demand low-fat, low-sugar, and low-calorie snacks, therefore, the production and consumption of low-gluten pretzels could possibly increase at a very fast rate (Jan et al. 2021 ). In the present study, partial replacement of wheat flour with rice flour is used for developing low-gluten pretzels. Rice flour does not develop into cohesive dough due to the absence of gluten protein (Jeong et al. 2017 ). Therefore, the present study has used wheat flour in combination with rice flour as an approach to lower gluten content and improve its organoleptic properties.

Over the past few years, various flour sources have been used for the replacement of wheat flour for the production of RTE breakfast cereals and snacks (Ding et al. 2005 ; Pardhi et al. 2019 ). However, the substitution of wheat flour cause changes in the concentration of starch and gluten network. Thus, various improvers, enzymes, and hydrocolloids have been employed in order to improve the strengthening and water absorption of dough and enhance its capacity to retain gas. However, if gluten network or concentration is lacking, the pore size of dough will also be affected which in turn could affect heat transfer, mass transfer, and other biochemical reactions including gelatinization of starch and consequently the thickening of dough and therefore, the mechanical properties of dough during baking. Thus, the structural changes in one phase of dough will probably affect other phases. In order to overcome the abovementioned changes, wheat flour was partially substituted with rice flour for the development of low-gluten pretzels without affecting the quality characteristics of dough. Moreover, the possible impact on the gluten content and starch digestion rate of low-gluten pretzels due to the incorporation of rice flour in wheat flour has not been explored so far and could be of significant industrial and nutritional importance. Perusal of literature shows only limited studies elsewhere and no study seems to be available in low-gluten pretzel production from Indian wheats. Therefore, the current research aimed to characterize the functional, and rheological properties of flour blend. Moreover, in vitro starch digestion, color, mineral content, texture, and sensory attributes of low-gluten pretzels were monitored.

Materials and methods

Wheat ( Triticum aestivum L.) flour was purchased from local market of Srinagar Kashmir and paddy (Variety Jhelum ) was obtained from Mountain Research Centre for Field Crops (MRCFC), Khudwani, Anantnag, Jammu & Kashmir, India of SKUAST-K, during the month of October 2018. Paddy was subjected to milling in modern rice mill (ASR RM 209) at the Division of Food Science and Technology, SKUAST-Kashmir, Shalimar, J&K. The small broken grains were ground to a fineness that passed through 200 μm sieve. The flour samples were packed in zipped pouches until further analysis.

Preparation of blend

Blended flour was prepared by replacing wheat flour with rice flour at 35% based on the preliminary trials and sensory evaluation by the expert panelists (Jan et al. 2021 ).

Characterization of raw material

Proximate composition.

The moisture, crude fat, crude protein, crude fiber, and ash content of different samples were analyzed by following the standard AOAC ( 2005 ) protocols.

Functional properties

Water and oil absorption capacities.

The procedure of Ahmad et al. ( 2015 ) was followed for the determination of water absorption and oil absorption capacities.

Swelling power and solubility index

The procedure of Ahmad et al. ( 2015 ) was followed for the determination of swelling power and solubility index. The results were reported using eqs. ( 1 ) and ( 2 ) as given below.

Foaming capacity and stability

The procedure of Shah et al. ( 2016 ) was followed for the determination of foaming capacity and foam stability. The foaming capacity was reported using Eq. ( 3 ) as given below.

The foam stability was reported using Eq. ( 4 ) as given below.

Bulk density

The procedure of Shafi et al. ( 2016 ) was followed for the determination of bulk density.

Pasting properties

The pasting characteristics of flour were analyzed using Rapid Visco Analyzer (RVA TECMASTER, Perten Instruments, Australia) followed the protocol of Nisar et al. ( 2021 ). Briefly, 25 g of water was added to 3.5 g of sample in the RVA canister and mixed properly before starting the analysis. The mixture was equilibrated at 50 °C for 1 min, heated at the rate of 12.2 °C /min to 95 °C, held for 2.5 min, cooled to 50 °C at the rate of 11.8 °C/min and again held at 50 °C for 2 min. A constant paddle rotational speed (160×g) was used throughout the entire analysis, except for rapid stirring at 960×g for the first 10 s to disperse the sample. All the typical pasting properties were defined from the resulting pasting curve viz., pasting temperature, peak time, peak, trough, breakdown, final, and setback viscosities.

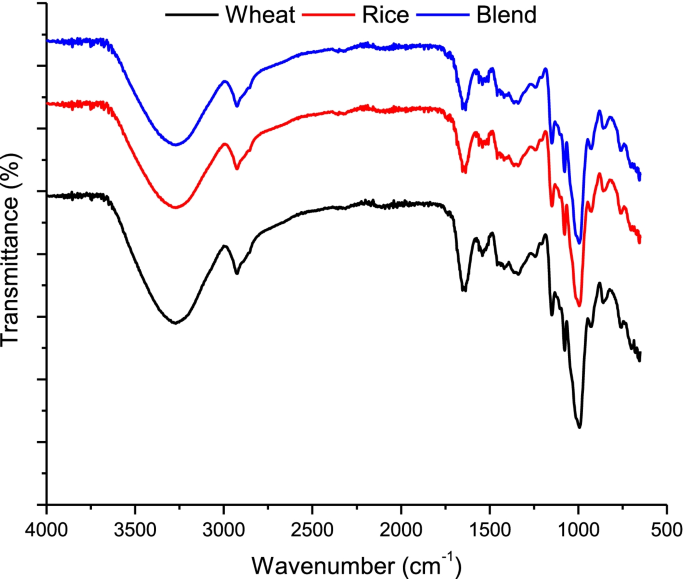

ATR-Fourier transform infrared (FTIR) spectroscopy

The FTIR spectrometer system equipped with an ATR accessory (Cary 630 FTIR, Agilent Technologies, USA) was employed to obtain the ATR-FTIR spectra of the flour samples. The wavelength range was set at 4000-400 cm − 1 with 4 cm − 1 resolution (Ashwar et al. 2016 ).

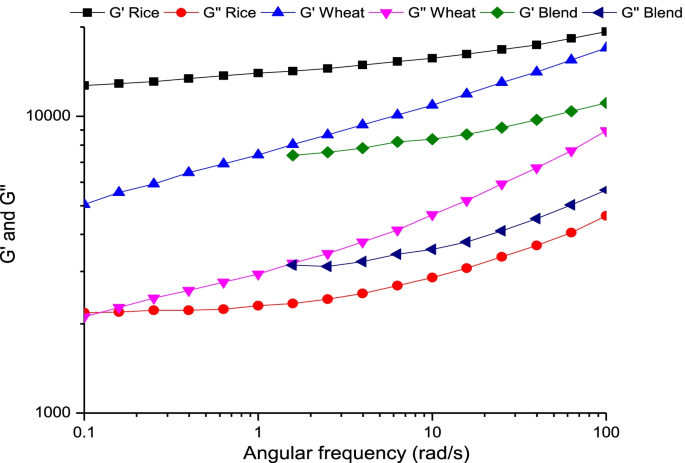

Dynamic rheometry

The rheological measurements of flour dough samples were measured on a dynamic rheometer (MCR-101, Anton Paar, Austria) at ambient temperature (25 ± 1 °C). The viscoelastic behaviour of dough samples was analyzed by determining the storage (G′) and loss (G″) moduli against angular frequency (0.1–100/s) (Hamdani et al. 2020 ).

Preparation of low-gluten pretzels

Low-gluten pretzels were prepared following the method elucidated by Jan et al. ( 2021 ). The pretzels contained wheat-rice flour blend (65:35), salt (2 g), refined oil (3 mL), ammonium bicarbonate (0.4 g), compressed yeast (12 g), malt extract (2 g), and water (50 mL). All the constituents were mixed (7 min) in a dough mixer followed by manual extrusion of the resulting dough through a vermicelli machine equipped with minute pores (4 mm) at the exit. After passing through the extruder, the resulting small dough stands were reduced to 10-15 cm and molded into oval rings manually before arranging them on a tray for the proofing stage (10 min). The resulting product was cooked (81 °C for 15 s) in an alkali solution (1% NaOH) before baking (236 °C for 6 min) followed by drying (103 °C for 25 min) to get the pretzels ( Plate S ). In the case of control, only wheat flour was used.

Quality parameters of low-gluten pretzels

Apparent amylose and amylopectin content.

Apparent amylose and amylopectin contents were estimated following the procedure reported by Amin et al. ( 2018 ).

Total starch and resistant starch

Total and resistant starch contents were estimated following the protocols as elucidated by Amin et al. ( 2018 ) using the Megazyme Assay Kit (Megazyme International, Wicklow, Ireland).

- In vitro starch digestion

The in vitro digestion profile of starch was categorized in the form of very rapidly digestible starch (VRDS), rapidly digestible starch (RDS), and slowly digestible starch (SDS). The VRDS, RDS, and SDS were reported as percent using Eqs. ( 5 ), ( 6 ), and ( 7 ), respectively.

Where, G 0 , G 1 , G 20 , G 120 refers to the amount of free glucose before digest, after 1 min, after 20 min, and after 120 min, respectively and TS refers to the total amount of starch. The factor (0.9) is the glucose to the starch conversion factor.

The difference between total starch (TS) and resistant starch (RS) was reported as Digestible starch (DS). The starch digestibility index (SDI) was calculated following Eq. ( 8 ) (Amin et al. 2018 ).

Mineral profile

Mineral profile analysis of low-gluten pretzels was estimated using Atomic Absorption Spectrophotometer (Labtronics, Model LT-2100) (Wani & Kumar 2015 ). Digestion of the sample (2 g) was carried out in a di-acid blend (HNO 3 :HClO 4 , 5:1, v/v). The digested material was dissolved in double-distilled water which was then filtered using Whatman no. 42. Finally, the volume was made up to 50 mL before subjecting it to mineral estimation.

Color values including luminosity ( L* ), redness ( a* ), and yellowness ( b* ) were measured on a Hunter Lab Colorimeter (A60-1010- 615 Model Colorimeter, Hunter Lab, Reston VA) after calibrating it against a standard white plate.

Texture analysis

Texture analysis of low-gluten pretzels was performed on a TA-XT2i Texture analyzer (Stable Micro System, Texture Technologies Corp., NY, USA). The Force of compression was measured using the P50 compression probe needed for breaking the sample, which indicates the breaking strength. The probe was programmed to travel a distance of 8 mm after touching the surface of pretzels with both the pre-test and test speeds set at 1.5 mm/s, while the post-test speed was set at 10 mm/s (Reshi et al. 2020 ).

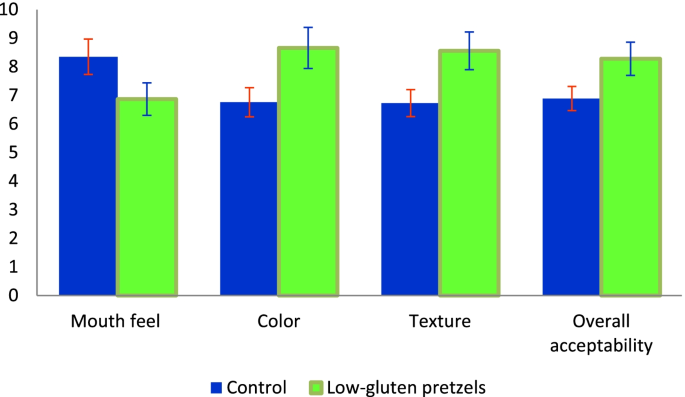

Sensory analysis

Sensory analysis of the product was conducted by 30 semi-trained panelists including 11 males and 19 females. Panelists were trained to evaluate the pretzels for mouthfeel, texture, visual color, and overall acceptability on a 9-point hedonic scale, and results were averaged. Coded samples using random three-digit numbers were served unsystematically to panelists, and sensory evaluation was carried out in well-separated booths. The panelists were provided with a glass of water to rinse their mouths before and after each test and were given a 10 min break post each assessment.

Statistical analysis

The data for each analysis was reported as mean ± standard deviation of at least three determinations. Using SPSS statistical software (version 21), the means were compared by Duncan’s multiple range test of analysis of variance (ANOVA) at 5% level of significance.

Results and discussion

Raw material characterization.

Table 1 presented the composition of wheat flour, rice flour, and wheat-rice flour blend. A significant ( p < 0.05) difference was observed in all the parameters among the samples. The moisture content of the flour blend (9.73 ± 0.56%) was significantly ( p < 0.05) lower than wheat flour (11.72 ± 0.86%) and rice flour (9.95 ± 0.61%). The crude fiber, crude protein, crude fat, and ash contents of the wheat flour were significantly ( p < 0.05) higher than rice flour. Wheat-rice flour blend (65:35) showed fat (1.02 ± 0.11%), protein (10.21 ± 0.59%), fiber (1.14 ± 0.12%), and ash (0.39 ± 0.04%) which differ significantly ( p < 0.05) from both wheat and rice flour. Klunklin and Savage ( 2018 ) reported almost similar findings for the composition of refined wheat flour replaced with purple rice flour.

The results of water and oil absorption capacities are presented in Table 1 . The ability of flour to bind water under limited water addition describes its water absorption capacity (WAC) (Singh et al. 2000 ) whereas the capacity of flour to retain oil ascertains its oil absorption capacity (OAC) which is important with respect to flavor retention and improving the mouthfeel of the foods (Aremu et al. 2007 ). WAC of flour blend varied non-significantly ( p > 0.05) from wheat and rice flour. Compared to wheat flour, flour blend exhibited higher WAC (0.97 ± 0.11 mL/g), whereas its OAC was significantly ( p < 0.05) lower (0.62 ± 0.09 mL/g). Higher WAC of flour blend may be because of more hydrophilic constituents like polysaccharides (Chandra et al. 2015 ) possibly due to the addition of rice flour. Higher WAC of flour blend demonstrates its ability to be used in the formulation of some products like batters, gravies, soups, confectionery, and bakery products (Adebowale et al. 2005 ). Protein is the major component that influences OAC (Nisar et al. 2021 ). The lower OAC of flour blend may be because of the dilution of protein content in wheat flour possibly due to the addition of rice flour. The lower OAC of flour blend demonstrates its feasibility for the development of low oil uptake batters and thus more beneficial to health (Shah et al. 2016 ).

The results of swelling power (SP) and solubility index (SI) are presented in Table 1 . SP and SI denote the associations between starch and water in both amorphous as well as crystalline zones (Ali et al. 2016 ). SP was significantly ( p < 0.05) higher in flour blend (18.33 ± 0.51) than wheat flour (16.15 ± 0.49). The higher SP of flour blend is attributed to its higher WAC (Table 1 ). The higher SP of flour blend suggests good organoleptic characteristics in terms of mouthfeel of several processed foods which in turn indicates better water retention in swollen granules of starch (Falade & Okafor 2015 ). SI of flour blend (6.72 ± 0.17%) was significantly ( p < 0.05) lower than wheat flour (9.63 ± 0.21%). Complexation of starch with proteins or fats in rice flour decreases the soluble components in starch molecules resulting in lowering of SI of flour blend (Jan et al. 2021 ). Lower SI of flour blend suggests its capacity to stabilize food structures during cooking.

Foaming capacity (FC) and stability (FS) are depicted in Table 1 . FC refers to the capacity of flours to form foam and is being governed by the presence of soluble proteins (surface active) in their dispersion aqueous medium (Shah et al. 2016 ) whereas FS refers to the ability of proteins to maintain the formation of foam droplets by producing a thin continuous film around it (Chandra et al. 2015 ). FC (9.67 ± 0.34%) and FS (3.39 ± 0.15%) of flour blend were significantly ( p < 0.05) lower than wheat flour. This might be because of the dilution in protein contents of wheat flour due to the incorporation of rice flour. The lower FC and FS of the flour blend could be helpful for the production of several baked products like crackers and biscuits (Chandra et al. 2015 ).

Bulk density (BD) is mostly used for the estimation of expansion of flour and the porosity of substances apart from depicting the volume of packaging material (Shafi et al. 2016 ). The results of BD are shown in Table 1 . Higher BD of flour blend (0.58 ± 0.04 g/cm 3 ) than wheat flour (0.52 ± 0.04 g/cm 3 ) might be due to the addition of rice flour because the particle size of rice flour is comparatively larger and coarser than wheat flour (Ye et al. 2016 ). The results depict the increase in BD of flour blend with the addition of rice flour. Flour with higher BD is suitable for reducing the paste thickness in food preparations because of its low viscosity and for food products having rough textures whereas, flour with lower BD is feasible for food products having dense and smooth textures (Jamal et al. 2016 ).

Pasting profile presented in Table 2 is primarily related to the swelling and rupturing of starch granules which demonstrates the wider range of viscosity parameters for different flour samples. Pasting temperature (PT) indicates the minimum temperature at which the starch granules gelatinize by forming a viscous paste (Shafi et al. 2016 ). PT of flour blend (86.50 ± 1.31 °C) was lower although non-significantly ( p > 0.05) than wheat flour (87.40 ± 1.42 °C). Peak viscosity (PV) depicts the maximum viscosity acquired by starch during heating in water, reflecting the water-holding ability of starch granules (Shah et al. 2016 ). PV of flour blend (1945 ± 4.00 cp) was significantly ( p < 0.05) higher than wheat flour (1718 ± 3.00 cp). Rice flour had a PV of 2145.00 ± 5.00 cp, therefore, its incorporation into the wheat flour resulted in an increase in its PV. It is also evidenced from the results of PT as PT was slightly higher in wheat flour, indicating its low PV. Trough viscosity (TV) was significantly ( p < 0.05) higher in flour blend (1379 ± 3.00 cp) than wheat flour (1254 ± 2.00 cp). Higher TV of flour blend is due to its higher PV. Breakdown viscosity (BDV) is a measure of the degree of disintegration of swollen granules of starch by heating and physical agitation. Higher BDV indicates a lesser capacity of the starch granules to withstand high temperature and shearing stress during cooking (Shah et al. 2016 ). BDV of flour blend (566 ± 2.00 cp) was significantly ( p < 0.05) higher than wheat flour (464 ± 1.00 cp) which indicates its higher susceptibility to shear-induced degradation during cooking. Final viscosity (FV) depicts the tendency of flour suspension by forming a viscous paste after cooking and cooling. FV of wheat flour was found to be 2199 ± 4.00 cp, and that of rice flour and flour blend was 2687 ± 6.00 cp and 2423 ± 5.00 cp, respectively. This indicates that the FV of flour blend was significantly ( p < 0.05) higher than wheat flour possibly because of its swollen granules of starch which have a capacity to form a viscous paste (Nisar et al. 2021 ). It is also indicated from the results of BDV as BDV was lower in wheat flour, depicting its low FV. Setback viscosity (SBV) denotes the tendency of starchy substances to re-associate and retrograde upon cooling (Shah et al. 2016 ). SBV of wheat flour was found to be 945 ± 2.00 cp, and that of rice flour and flour blend 1265 ± 3.00 cp and 1044 ± 3.00 cp, respectively. This indicates that the SBV of flour blend was significantly ( p < 0.05) higher than wheat flour which reflects its higher retrogradation tendency. Peak time reflects the time required to reach peak in viscosity and ease of cooking a particular sample. Peak time in flour blend (5.71 ± 0.41 min) was found to be non-significantly ( p > 0.05) lower than wheat flour (5.93 ± 0.43 min).

The ATR-FTIR analysis of wheat flour, rice flour, and wheat-rice flour blend is presented in Fig. 1 . The absorption bands at 3270 cm − 1 , 2925 cm − 1 and 1636 cm − 1 correspond to alcoholic O-H, C-H and O-H stretches of water, respectively. The absorption band at 993 cm − 1 corresponds to the C=O stretch of glucose ring. These characteristic functional groups in wheat flour and rice flour have previously been reported by different researchers (Ashwar et al. 2016 ; Bhat et al. 2016 ). The results however revealed that the blending of wheat and rice flour samples did not cause any kind of change in the functional groups studied which is being reflected in their similar absorption bands.

Attenuated total reflectance-Fourier transform infrared (ATR-FTIR) spectra of wheat flour, rice flour and flour blend

The visco-elastic characteristics of dough determine the quality attributes of bakery products (Hamdani et al. 2020 ). The rheological behavior of dough samples was examined and was reported as elastic/storage modulus (G′) and viscous/loss modulus (G″) (Fig. 2 ). The elastic (G′) and viscous (G″) moduli of dough samples were found to increase with angular frequency. G′ of all the samples was higher than G″ throughout the whole range of frequency. This indicates the viscoelastic characteristics of the samples. Higher gap between G′ and G″ values of dough samples indicates that the elastic behavior is predominant over viscous behavior (Hamdani et al. 2020 ). The addition of rice flour diluted the gluten proteins in flour blend, thereby resulting in the lowering of both G′ and G″ (Wang et al. 2003 ). The changes in moduli values after incorporating rice flour to wheat flour were more evident in G′ compared to G″. This depicts that rice flour incorporation had a more proclaimed effect on elastic properties than viscous.

Dynamic viscoelastic measurement of wheat flour, rice flour, and flour blend

Table 3 depicts the in vitro starch digestion properties of raw materials (wheat flour-WF and rice flour-RF) and low-gluten pretzels (LGP). Total starch of LGP (73.4 ± 1.29%) was higher than WF (68.5 ± 1.28%) possibly due to the incorporation of RF which is rich in starch. Due to the addition of 35% RF, the apparent amylose content (AAC) and resistant starch (RS) contents in LGP increased to 27.3 ± 1.45% and 6.12 ± 0.97%, respectively (Table 3 ). Baking results in the hydrolysis of α-D-(1-6) glycosidic bonds of amylopectin molecules, thereby enhancing the AAC which leads to an increase in RS content in baked products due to retrogradation after cooling (Yadav 2011 ). Further, a significant ( p < 0.05) decrease in very rapidly digestible starch (VRDS), rapidly digestible starch (RDS), and significant ( p < 0.05) increase in slowly digestible starch (SDS) was found in developed LGP. Since, both amylose and fat contents of LGP is higher than the raw materials used, therefore, they may have formed the amylose-lipid complex whose susceptibility to enzymatic hydrolysis is considered to be much lower (Li & Zhu 2019 ). This might have resulted in a decrease in RDS. Further, fats and RS contents in food hinder the degradation of starch and delay the rate of gastric emptying in the small intestine (Amin et al. 2018 ), thus contributing to the lowering of RDS. These factors contribute to the slower release of glucose from the developed LGP during enzyme hydrolysis. Thus the developed LGP had higher SDS and lower RDS contents (Table 3 ). In conclusion, it was found that there was a 7.23% increase in SDS and 13.36% decrease in RDS upon the incorporation of rice flour.

Digestible starch was significantly ( p < 0.05) lower in LGP (67.28 ± 1.35%). Starch digestible index (SDI), which indicates the relative rate of digestion of starch was found to be 86.42 ± 2.23%, 83.43 ± 2.14%, and 69.87 ± 1.72% for wheat flour, rice flour, and LGP, respectively. A significantly ( p < 0.05) lower value of SDI was observed in LGP despite its higher TS content as compared to wheat flour. The higher SDS fraction of LGP justifies its low SDI. This confirms the relevance of the starch fractions in food rather than TS (Amin et al., 2018 ).

Data from Table 4 shows significantly ( p < 0.05) higher mineral profile of the developed LGP than wheat and rice flour. This increase may be attributed to the addition of ingredients and capacity of minerals to hold up well during baking (Wani & Kumar 2015 ). Among the macro minerals, sodium content was found in the highest concentration in developed LGP (563.30 ± 4.60 mg/100 g). This is due to the cooking in alkali solution which is in agreement with Naik et al. ( 2007 ). Sodium is required for regulation of cellular membrane potential and nutrition absorption in the small intestine as well as regulation of volume of extracellular fluid which helps to keep blood volume and blood pressure (He & MacGregor 2010 ). Among the micro minerals, zinc was significantly ( p < 0.05) higher in LGP (21.40 ± 1.70 mg/100 g) than wheat flour (18.20 ± 1.10 mg/100 g) and rice flour (11.20 ± 1.20 mg/100 g). Zinc helps in the stabilization of membrane structures and cellular protection by avoiding lipid peroxidation and lowering the generation of free radicals (Coppen et al. 1985 ). Incorporation of rice flour significantly ( p < 0.05) increased the mineral content and thus improved the nutritional quality of the LGP.

The color characteristics of control and LGP are presented in Table 5 . The L* value of LGP (56.49 ± 2.37) was significantly ( p < 0.05) higher while as a* (8.71 ± 1.67) and b* (17.59 ± 1.19) values were significantly ( p < 0.05) lower than control pretzels. LGP had a white crust, whereas the crust of control was yellowish. The lower L* value of control (43.57 ± 2.12) may be due to Maillard’s reaction takes between proteins and reducing sugars during baking which is actually responsible for imparting brown color to baked products (Shafi et al. 2017 ). As the protein content of developed LGP is lower than control, therefore, less development of color due to Maillard’s reaction is expected, thus lower L* value.

Breaking strength (BS) of control and LGP are listed in Table 5 . BS depicts the hardness and is considered an important parameter in terms of extrudates (Ruskova et al. 2015 ). Rice flour incorporation remarkably decreased the BS of LGP. The lower BS of LGP (7.37 ± 1.34 N) could be related to the lower amount of proteins due to which the gluten structure of pretzel dilutes. Further, starch is believed to provide a softer texture to pretzels (Cornejo & Rosell 2015 ). Chevallier et al. ( 2000 ) depicted that BS/hardness is because of the associations through hydrogen bonding between starch and protein. The difference in composition between control and LGP might have influenced the associations between starch and protein, thus resulting in the differences in BS values.

Sensory evaluation

The sensory attributes of LGP and control is presented in Fig. 3 . Mouthfeel, determined as a sensation perceived by the nervous system in the cavity of the mouth (Singh et al. 2019 ), was found higher for control (8.35 ± 0.05) compared to LGP (6.87 ± 0.03). The lower mouthfeel of LGP was possibly due to the bland taste of rice. Highest visual color scores were recorded for the LGP (8.66 ± 0.04) while as control recorded the lowest visual color score (6.76 ± 0.02). The comparatively bright and white color of rice flour could be the possible reason for high visual color score of developed LGP. At the same time, lowest visual color score of control might be due to darker color. LGP was rated highest score by panelists for texture (8.56 ± 0.05) and lowest for control (6.73 ± 0.03) possibly due to the higher starch content in rice flour (Table 3 ) which reduces the hardness of LGP. Ruskova et al. ( 2015 ) reported that extrudates with lower hardness values are desirable. Overall acceptability was found higher for LGP (8.03 ± 0.04) while lower overall acceptability score was recorded for control (7.28 ± 0.02). On the basis of overall acceptability score, LGP was found to be the best compared to those made from wheat flour.

Sensory analysis of control and low-gluten pretzels

Rice-wheat composite flour could be used as a new base material for the preparation of bakery products like pretzels. The product developed was not only low-gluten but also showed better attributes for consumer acceptability. The findings of the present study concluded that replacing wheat flour with rice flour to a level of 35% (w/w) improved functional, pasting, and rheological characteristics of wheat-rice flour blend, suggesting its possible use for the development of low-gluten or gluten-free products. In vitro starch digestion profile revealed that low-gluten pretzels had significantly lower rapidly digestible starch whereas, slowly digestible starch was significantly higher. Mineral profile was higher in low-gluten pretzels indicating improvement in its nutritional status. Lightness ( L* ) of the low-gluten pretzels was comparatively higher than control and breaking strength decreased upon the incorporation of rice flour. Overall acceptability of developed low-gluten pretzels was better than control with enhanced quality characteristics. Thus, the incorporation of rice flour at this concentration is probably the most desirable choice for the development of better low-gluten pretzels.

Availability of data and materials

Not applicable.

Ahmad, M., Baba, W. N., Wani, T. A., Gani, A., Gani, A., Shah, U., … Masoodi, F. A. (2015). Effect of green tea powder on thermal, rheological & functional properties of wheat flour and physical, nutraceutical & sensory analysis of cookies. Journal of Food Science and Technology , 52 (9), 5799–5807.

Article CAS Google Scholar

Adebowale, K. O., Olu-Owolabi, I. O., Olawunmi, E. K., & Lawal, O. S. (2005). Functional properties of native, physically and chemically modified breadfruit ( Artocorpus altilis ) starch. Industrial Crops and Products , 21 (3), 343–351.

Ali, A., Wani, T. A., Wani, I. A., & Masoodi, F. A. (2016). Comparative study of the physico-chemical properties of rice and corn starches grown in Indian temperate climate. Journal of the Saudi Society of Agricultural Sciences , 15 (1), 75–82.

Article Google Scholar

Amin, T., Naik, H. R., Hussain, S. Z., Makroo, H. A., & Rather, S. A. (2020). Effect of storage materials and duration on the physicochemical, pasting and microstructural properties of low glycemic index rice flour. International Journal of Biological Macromolecules , 162 (11), 1616–1626.

Amin, T., Naik, H. R., Hussain, S. Z., Mir, M. A., & Jabeen, A. (2018). In vitro digestion, physicochemical and morphological properties of low glycemic index rice flour prepared through enzymatic hydrolysis. International Journal of Food Properties , 21 (1), 2632–2645.

AOAC (2005). Official methods of analysis , (15th ed., pp. 777–784). Washington, DC: Association of Official Analytical Chemists.

Google Scholar

Aremu, M. O., Olaofe, O., & Akintayo, E. T. (2007). Functional properties of some Nigerian varieties of legume seed flours and flour concentration effect on foaming and gelation properties. Journal of Food Technology , 5 , 109–115.

CAS Google Scholar

Ashwar, B. A., Gani, A., Wani, I. A., Shah, A., Masoodi, F. A., & Saxena, D. C. (2016). Production of resistant starch from rice by dual autoclaving-retrogradation treatment: In vitro digestibility, thermal and structural characterization. Food Hydrocolloids , 56 , 108–117.

Bhat, N. A., Wani, I. A., Hamdani, A. M., Gani, A., & Masoodi, F. A. (2016). Physicochemical properties of whole wheat flour as affected by gamma irradiation. LWT - Food Sci. Technol. , 71 , 175–183.

Chandra, S., Singh, S., & Kumari, D. (2015). Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. Journal of Food Science and Technology , 52 (6), 3681–3688.

CAS PubMed Google Scholar

Chevallier, S., Colonna, P., & Lourdin, D. (2000). Contribution of major ingredients during baking of biscuit dough systems. Journal of Cereal Science , 31 , 241–252.

Coppen, D. E., Cousins, R. J., & Richardson, D. E. (1985). Effect of zinc on chemically induced peroxidation in rat liver parenchymal cells in primary culture. Federation Proceedings , 44 , 6404.

Cornejo, F., & Rosell, C. M. (2015). Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. LWT - Food Sci. Technol. , 62 , 1203–1210.

Ding, Q., Ainsworth, P., Gregory, T., & Hayley, M. (2005). The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice based expanded snacks. Journal of Food Engineering , 66 , 283–289.

Falade, K. O., & Okafor, C. A. (2015). Physical, functional, and pasting properties of flours from corms of two cocoyam ( Colocasia esculenta and Xanthosoma sagittifolium ) cultivars. Journal of Food Science and Technology , 52 (6), 3440–3344.

Hamdani, A. M., Wani, I. A., & Bhat, N. A. (2020). Gluten free cookies from rice-chickpea composite flour using exudate gums from acacia, apricot and karaya. Food Bioscience , 35 , 100541.

He, F. J., & MacGregor, G. A. (2010). Reducing population salt intake worldwide: From evidence to implementation. Progress in Cardiovascular Diseases , 52 , 363–382.

Jamal, S., Qazi, I. M., & Ahmed, I. (2016). Comparative studies on flour proximate compositions and functional properties of selected Pakistani rice varieties. Proceedings of the Pakistan Academy of Sciences , 53 , 47–56.

Jan, N., Naik, H. R., Gani, G., Bashir, O., Hussain, S. Z., Rather, A. H., … Amin, T. (2021). Optimization of process for the development of rice flour incorporated low-gluten wheat based pretzels: Evaluation of its physicochemical, thermal and textural characteristics. Journal of the Saudi Society of Agricultural Sciences , 20 , 116–127.

Jane, J., Chen, Y. Y., Lee, L. F., Mcpherson, A. E., Wong, K. S., & Radosavljevic, M. (1999). Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chemistry , 76 (5), 629–637.

Jeong, S., Kim, H. W., & Lee, S. (2017). Rheological and secondary structural characterization of rice flour-zein composites for noodles slit from gluten-free sheeted dough. Food Chemistry , 221 , 1539–1545.

Klunklin, W., & Savage, G. (2018). Physicochemical, antioxidant properties and in vitro digestibility of wheat–purple rice flour mixtures. International Journal of Food Science and Technology , 53 , 1962–1971.

Li, D., & Zhu, F. (2019). Physicochemical, functional and nutritional properties of kiwifruit flour. Food Hydrocolloids , 92 , 250–258.

Li, H., Prakash, S., Nicholson, T. M., Fitzgerald, M. A., & Gilbert, R. G. (2016). Instrumental measurement of cooked rice texture by dynamic rheological testing and its relation to the fine structure of rice starch. Carbohydr Polym. , 146 , 253–263.

Naik, H. R., Sekhon, K. S., Baljit, S., Kaur, A., & Rather, A. H. (2007). Influence of triticales and wheat classes on pretzel quality. Journal of Food Science and Technology , 44 (5), 495–499.

Nisar, A., Jan, N., Gull, A., Masoodi, F. A., Amin, T., Bashir, O., & Wani, S. M. (2021). Effect of the incorporation of apricot pulp powder on physicochemical, functional, rheological and nutraceutical properties of wheat flour based cookies. British Food Journal. , 123 (11), 3776–3788.

Pardhi, S. D., Singh, B., Nayik, G. A., & Dar, B. N. (2019). Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. Journal of the Saudi Society of Agricultural Sciences , 18 (1), 7–16.

Reshi, M., Shafiq, F., Hussain, S. Z., Naseer, B., & Amin, T. (2020). Physicochemical properties of iron-fortified, low glycemic index (GI) barley based extruded ready-to-eat snacks developed using twin-screw extruder. Journal of Food Processing & Preservation . https://doi.org/10.1111/jfpp.14606 .

Ritika, B. Y., Khatkar, B. S., & Yadav, B. S. (2010). Physicochemical, morphological, thermal and pasting properties of starches isolated from rice cultivars grown in India. International Journal of Food Properties , 13 , 1339–1354.

Ruskova, M., Bakalov, I., Petrova, T., Zsivanovits, G., Ivanova, K., & Penov, N. (2015). Effect of extrusion variables on breaking strength of bean-based extrudates; presented in international scientific- practical conference . Plodiv: Food Technologies and Health, Agricultural Academy.

Ryu, G. H. (2004). Application of extrusion technology on food process. In Paper in the seminar: Innovation of rice puffing , (pp. 21–34).

Shafi, M., Baba, W. N., & Masoodi, F. A. (2017). Composite flour blends: Influence of particle size of water cheshnut flour on nutraceutical potential and quality of Indian flat bread. Journal of Food Measurement Characterization. , 44 , 9486–9495.

Shafi, M., Baba, W. N., Masoodi, F. A., & Bazaz, R. (2016). Wheat-water chestnut flour blends: Effect of baking on antioxidant properties of cookies. Journal of Food Science and Technology , 53 (12), 4278–4288.

Shah, A., Masoodi, F. A., Gani, A., & Ashwar, B. A. (2016). Geometrical, functional, thermal, and structural properties of oat varieties from temperate region of India. Journal of Food Science and Technology , 53 (4), 1856–1866.

Singh, J. P., Kaur, A., Singh, B., Singh, N., & Singh, B. (2019). Physicochemical evaluation of corn extrudates containing varying buckwheat flour levels prepared at various extrusion temperatures. Journal of Food Science and Technology , 56 (4), 2205–2212.

Singh, R., Singh, G., & Chauhan, G. S. (2000). Development of soy-fortified biscuits and shelf-life studies. Journal of Food Science and Technology , 37 , 300–303.

Wang, M., Hamer, R. J., Van Vliet, T., Gruppen, H., Marseille, H., & Weegels, P. L. (2003). Effect of water unextractable solids on gluten formation and properties: Mechanistic considerations. Journal of Cereal Science , 37 , 55–64.

Wani, S. A., & Kumar, P. (2015). Effect of extrusion on the nutritional, antioxidant and microstructural characteristics of nutritionally enriched snacks. Journal of Food Processing & Preservation , 40 , 166–173.

Yadav, B. S. (2011). Effect of frying, baking and storage conditions on resistant starch content of foods. British Food Journal. , 113 (6), 710–719.

Ye, L., Wang, C., Wang, S., Zhou, S., & Liu, X. (2016). Thermal and rheological properties of brown flour from Indica rice. Journal of Cereal Science , 70 , 270–274.

Download references

Acknowledgements

Author information, authors and affiliations.

Division of Food Science and Technology, Sher-e-Kashmir University of Agricultural Sciences and Technology of Kashmir, Srinagar, Jammu and Kashmir, 190025, India

Nusrat Jan, H. R. Naik, Gousia Gani, Omar Bashir, Tawheed Amin & Sajad Mohd Wani

Department of Management Studies, Central University of Kashmir (J&K) India, Green Campus, Ganderbal, India

Shakeel Ahmad Sofi

You can also search for this author in PubMed Google Scholar

Contributions

Nusrat Jan- Acquisition, analysis, interpretation of data, writing, review and editing the original draft; H. R. Naik- conceptualization; Gousia Gani- formal analysis; Omar Bashir- creation of new software used in this work; Tawheed Amin- design of the work; Sajad Mohd Wani-substantially revised it; Shakeel Ahmad Sofi- drafted the work. The author(s) read and approved the final manuscript.

Corresponding author

Correspondence to Nusrat Jan .

Ethics declarations

Ethics approval and consent to participate.

Approval for ethics was not needed for the present research.

Consent for publication

Competing interests.

The authors declare that they have no competing interests.

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: plate s..

Low-gluten pretzels from the blend of wheat flour (65%) and rice flour (35%).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Jan, N., Naik, H.R., Gani, G. et al. Influence of replacement of wheat flour by rice flour on rheo-structural changes, in vitro starch digestibility and consumer acceptability of low-gluten pretzels. Food Prod Process and Nutr 4 , 9 (2022). https://doi.org/10.1186/s43014-022-00088-y

Download citation

Received : 06 December 2021

Accepted : 01 April 2022

Published : 26 April 2022

DOI : https://doi.org/10.1186/s43014-022-00088-y

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Wheat flour

- Low-gluten pretzels

- Overall acceptability

Food Production, Processing and Nutrition

ISSN: 2661-8974

- Submission enquiries: Access here and click Contact Us

- General enquiries: [email protected]

- Journal home

- About the journal

- J-STAGE home

- Journal of Nutritional Science ...

- Volume 65 (2019) Issue Supplement

- Article overview

Graduate School of Bioagricultural Sciences, Nagoya University

Corresponding author

2019 Volume 65 Issue Supplement Pages S13-S17

- Published: October 11, 2019 Received: - Released on J-STAGE: October 16, 2019 Accepted: - Advance online publication: - Revised: -

(compatible with EndNote, Reference Manager, ProCite, RefWorks)

(compatible with BibDesk, LaTeX)

Hunger and malnutrition, especially children, are still global issues today. Rice is a staple food for more than half of the world population and important nutritional source of not only carbohydrate but also protein. In recent aging societies, protein-energy malnutrition in elderly people emerges also as a social issue. Malnutrition in elderly people raises the risk of falling into age-related chronic diseases. Nutritional care can prevent elderly people from such age-related diseases. Rice and rice flour would be good foodstuff for preparation of diet suitable for and preferred by elderly people. Protein content of rice grains, like the other cereal grains, is less than 10% by weight, which is a little lower than meat and cheese, but higher than dairy milk and yoghurt. Nutritional quality of rice proteins is higher than the other cereal grains. Such relatively higher nutritional quality of rice proteins could be due to high copies of glutelin genes evolved from an ancestral gene common to soybean glycinin and resultant high content of legume-type seed storage proteins. Recently, rice flour became to be utilized for various processed food. The rice seed proteins as well as starch are accumulated in specific organelles termed protein bodies and amyloplast in the cells of endosperm and aleurone layer. By milling rice grains to flour particles consisting of protein and starch nanoparticles, processing characteristics of rice starch and proteins could be changed. To develop rice-based processed food for prevention of malnutrition, rice flour particles from various different rice sources could be blended for desired nutritional composition without spoiling the value of product food.

- Add to favorites

- Additional info alert

- Citation alert

- Authentication alert

THE JOURNAL OF VITAMINOLOGY

Register with J-STAGE for free!

Already have an account? Sign in here

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- PubMed/Medline

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

The effect of different milling methods on the physicochemical and in vitro digestibility of rice flour, 1. introduction, 2. materials and methods, 2.1. materials, 2.2. preparation of rice flour, 2.3. physicochemical compositions, 2.4. crystalline structure of rice flour, 2.5. determination of particle size distribution, 2.6. pasting properties of rice flour, 2.7. thermal properties, 2.8. gel properties of rice flour, 2.9. determination of starch digestibility, 2.10. statistic analyse, 3. results and discussion, 3.1. particle size distribution of rice flour, 3.2. damaged starch content and relative crystallinity of rice flour, 3.3. pasting properties, 3.4. thermal properties, 3.5. gel properties, 3.6. starch digestibility, 4. conclusions, author contributions, institutional review board statement, informed consent statement, data availability statement, acknowledgments, conflicts of interest.

- Fradinho, P.; Sousa, I.; Raymundo, A. Functional and thermorheological properties of rice flour gels for gluten-free pasta applications. Int. J. Food Sci. Technol. 2019 , 54 , 1109–1120. [ Google Scholar ] [ CrossRef ]

- Amin, T.; Naik, H.R.; Hussain, S.Z.; Rather, A.H.; Murtaza, I.; Dar, B.N. Structural properties of high-protein, low glycaemic index (GI) rice flour. Int. J. Food Prop. 2017 , 20 , 2793–2804. [ Google Scholar ] [ CrossRef ]

- Gui, Y.; Chen, G.; Tian, W.; Yang, S.; Chen, J.; Wang, F.; Li, Y. Normal rice flours perform better in gluten-free bread than glutinous rice flours. J. Food Sci. 2022 , 87 , 554–566. [ Google Scholar ] [ CrossRef ]

- Wu, T.; Wang, L.; Li, Y.; Qian, H.; Liu, L.; Tong, L.; Zhou, X.; Wang, L.; Zhou, S. Effect of milling methods on the properties of rice flour and gluten-free rice bread. LWT-Food Sci. Technol. 2019 , 108 , 137–144. [ Google Scholar ] [ CrossRef ]

- Leewatchararongjaroen, J.; Anuntagool, J. Effects of Dry-Milling and Wet-Milling on Chemical, Physical and Gelatinization Properties of Rice Flour. Rice Sci. 2016 , 23 , 274–281. [ Google Scholar ] [ CrossRef ]

- Farooq, A.M.; Li, C.; Chen, S.; Fu, X.; Zhang, B.; Huang, Q. Particle size affects structural and in vitro digestion properties of cooked rice flours. Int. J. Biol. Macromol. 2018 , 118 , 160–167. [ Google Scholar ] [ CrossRef ]

- Lu, Z.-H.; Li, L.-T.; Min, W.-H.; Wang, F.; Tatsumi, E. The effects of natural fermentation on the physical properties of rice flour and the rheological characteristics of rice noodles. Int. J. Food Sci. Technol. 2005 , 40 , 985–992. [ Google Scholar ] [ CrossRef ]

- Wang, G.; Yan, X.; Wang, B.; Hu, X.; Chen, X.; Ding, W. Effects of milling methods on the properties of rice flour and steamed rice cakes. LWT-Food Sci. Technol. 2022 , 167 , 113848. [ Google Scholar ] [ CrossRef ]

- Kumar, C.S.; Malleshi, N.G.; Bhattacharya, S. A comparison of selected quality attributes of flours: Effects of dry and wet grinding methods. Int. J. Food Prop. 2008 , 11 , 845–857. [ Google Scholar ] [ CrossRef ]

- Lin, Z.; Huang, J.; Kawakami, K.; Liu, H.; Fujishima, T.; Qin, W.; Geng, D.H.; Wang, L.; Liu, L.; Wang, F.; et al. Effects of particle size of glutinous rice flour on the quality attributes of sweet dumplings. Food Process. Preserv. 2022 , 46 , e16388. [ Google Scholar ] [ CrossRef ]

- Tong, L.-T.; Gao, X.; Lin, L.; Liu, Y.; Zhong, K.; Liu, L.; Zhou, X.; Wang, L.; Zhou, S. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. J. Cereal Sci. 2015 , 62 , 45–49. [ Google Scholar ] [ CrossRef ]

- Zhong, C.; Zu, Y.; Zhao, X.; Li, Y.; Ge, Y.; Wu, W.; Zhang, Y.; Li, Y.; Guo, D. Effect of superfine grinding on physicochemical and antioxidant properties of pomegranate peel. Int. J. Food Sci. Technol. 2016 , 51 , 212–221. [ Google Scholar ] [ CrossRef ]

- Wang, Q.; Li, L.; Zheng, X. A review of milling damaged starch: Generation, measurement, functionality and its effect on starch-based food systems. Food Chem. 2020 , 315 , 126267. [ Google Scholar ] [ CrossRef ]

- Hsu, R.J.C.; Lu, S.; Chang, Y.-H.; Chiang, W. Effects of added water and retrogradation on starch digestibility of cooked rice flours with different amylose content. J. Cereal Sci. 2015 , 61 , 1–7. [ Google Scholar ] [ CrossRef ]

- Geng, D.-H.; Zhou, S.; Wang, L.; Zhou, X.; Liu, L.; Lin, Z.; Qin, W.; Liu, L.; Tong, L.-T. Effects of slight milling combined with cellulase enzymatic treatment on the textural and nutritional properties of brown rice noodles. LWT-Food Sci. Technol. 2020 , 128 , 109520. [ Google Scholar ] [ CrossRef ]

- Geng, D.-H.; Lin, Z.; Liu, L.; Qin, W.; Wang, A.; Wang, F.; Tong, L.-T. Effects of ultrasound-assisted cellulase enzymatic treatment on the textural properties and in vitro starch digestibility of brown rice noodles. LWT-Food Sci. Technol. 2021 , 146 , 111543. [ Google Scholar ] [ CrossRef ]

- Hossen, M.S.; Sotome, I.; Nanayama, K.; Sasaki, T.; Okadome, H. Functional Properties of Submicron-Scale Rice Flour Produced by Wet Media Grinding. Cereal Chem. 2016 , 93 , 53–57. [ Google Scholar ] [ CrossRef ]

- Lee, Y.-T.; Shim, M.-J.; Goh, H.-K.; Mok, C.; Puligundla, P. Effect of jet milling on the physicochemical properties, pasting properties, and in vitro starch digestibility of germinated brown rice flour. Food Chem. 2019 , 282 , 164–168. [ Google Scholar ] [ CrossRef ]

- Qin, W.; Xi, H.; Wang, A.; Gong, X.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L. Ultrasound Treatment Enhanced Semidry-Milled Rice Flour Properties and Gluten-Free Rice Bread Quality. Molecules 2022 , 27 , 5403. [ Google Scholar ] [ CrossRef ]

- Qin, W.; Lin, Z.; Wang, A.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of particle size on the properties of rice flour and quality of gluten-free rice bread. LWT-Food Sci. Technol. 2021 , 151 , 112236. [ Google Scholar ] [ CrossRef ]

- Wang, L.; Zhang, C.; Chen, Z.; Wang, X.; Wang, K.; Li, Y.; Wang, R.; Luo, X.; Li, Y.; Li, J. Effect of annealing on the physico-chemical properties of rice starch and the quality of rice noodles. J. Cereal Sci. 2018 , 84 , 125–131. [ Google Scholar ] [ CrossRef ]

- Fang, S.; Chen, M.; Xu, F.; Liu, F.; Zhong, F. The Possibility of Replacing Wet-Milling with Dry-Milling in the Production of Waxy Rice Flour for the Application in Waxy Rice Ball. Foods 2023 , 12 , 280. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Gao, L.; Yu, C.; Gao, C.; Tang, X. Properties of Rice-Ginkgo Blends and the Quality Properties of Extruded Rice Noodles. J. Chin. Cereals Oils Assoc. Cereal Chem. 2019 , 34 , 1–7. [ Google Scholar ]

- Li, G.; Zhu, F. Physicochemical properties of quinoa flour as affected by starch interactions. Food Chem. 2017 , 221 , 1560–1568. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Syahariza, Z.A.; Sar, S.; Hasjim, J.; Tizzotti, M.J.; Gilbert, R.G. The importance of amylose and amylopectin fine structures for starch digestibility in cooked rice grains. Food Chem. 2013 , 136 , 742–749. [ Google Scholar ] [ CrossRef ]

- Zou, W.; Sissons, M.; Gidley, M.J.; Gilbert, R.G.; Warren, F.J. Combined techniques for characterising pasta structure reveals how the gluten network slows enzymic digestion rate. Food Chem. 2015 , 188 , 559–568. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Awais, M.; Ashraf, J.; Wang, L.; Liu, L.; Yang, X.; Tong, L.-T.; Zhou, X.; Zhou, S. Effect of Controlled Hydrothermal Treatments on Mung Bean Starch Structure and Its Relationship with Digestibility. Foods 2020 , 9 , 664. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Granfeldt, Y.; Björck, I.; Drews, A.; Tovar, J. An in vitro procedure based on chewing to predict metabolic response to starch in cereal and legume products. Eur. J. Clin. Nutr. 1992 , 46 , 649–660. [ Google Scholar ] [ CrossRef ]

- Yi, C.; Zhu, H.; Bao, J.; Quan, K.; Yang, R. The texture of fresh rice noodles as affected by the physicochemical properties and starch fine structure of aged paddy. LWT-Food Sci. Technol. 2020 , 130 , 109610. [ Google Scholar ] [ CrossRef ]

- Dhital, S.; Shrestha, A.K.; Flanagan, B.M.; Hasjim, J.; Gidley, M.J. Cryo-milling of starch granules leads to differential effects on molecular size and conformation. Carbohydr. Polym. 2011 , 84 , 1133–1140. [ Google Scholar ] [ CrossRef ]

- Ngamnikom, P.; Songsermpong, S. The effects of freeze, dry, and wet grinding processes on rice flour properties and their energy consumption. J. Food Eng. 2011 , 104 , 632–638. [ Google Scholar ] [ CrossRef ]

- Heo, S.; Lee, S.M.; Shim, J.-H.; Yoo, S.-H.; Lee, S. Effect of dry- and wet-milled rice flours on the quality attributes of gluten-free dough and noodles. J. Food Eng. 2013 , 116 , 213–217. [ Google Scholar ] [ CrossRef ]

- Marti, A.; Pagani, M.A.; Seetharaman, K. Understanding starch organisation in gluten-free pasta from rice flour. Carbohydr. Polym. 2011 , 84 , 1069–1074. [ Google Scholar ] [ CrossRef ]

- Dang, B.; Zhang, W.-G.; Zhang, J.; Yang, X.-J.; Xu, H.-D. Effect of Thermal Treatment on the Internal Structure, Physicochemical Properties and Storage Stability of Whole Grain Highland Barley Flour. Foods 2022 , 11 , 2021. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT-Food Sci. Technol. 2007 , 40 , 1723–1731. [ Google Scholar ] [ CrossRef ]

- Kim, J.-M.; Shin, M. Effects of particle size distributions of rice flour on the quality of gluten-free rice cupcakes. LWT-Food Sci. Technol. 2014 , 59 , 526–532. [ Google Scholar ] [ CrossRef ]

- Waterschoot, J.; Gomand, S.V.; Willebrords, J.K.; Fierens, E.; Delcour, J.A. Pasting properties of blends of potato, rice and maize starches. Food Hydrocoll. 2014 , 41 , 298–308. [ Google Scholar ] [ CrossRef ]

- Hasjim, J.; Li, E.; Dhital, S. Milling of rice grains: Effects of starch/flour structures on gelatinization and pasting properties. Carbohydr. Polym. 2013 , 92 , 682–690. [ Google Scholar ] [ CrossRef ]

- Ye, L.; Wang, C.; Wang, S.; Zhou, S.; Liu, X. Thermal and rheological properties of brown flour from Indica rice. J. Cereal Sci. 2016 , 70 , 270–274. [ Google Scholar ] [ CrossRef ]

- Wang, S.; Copeland, L. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct. 2013 , 4 , 1564–1580. [ Google Scholar ] [ CrossRef ]

- Liu, R.; Sun, W.; Zhang, Y.; Huang, Z.; Hu, H.; Zhao, M. Preparation of starch dough using damaged cassava starch induced by mechanical activation to develop staple foods: Application in crackers. Food Chem. 2019 , 271 , 284–290. [ Google Scholar ] [ CrossRef ]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 2016 , 191 , 45–51. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Ma, M.; Wen, Y.; Qiu, C.; Zhan, Q.; Sui, Z.; Corke, H. Milling affects rheological and gel textural properties of rice flour. Cereal Chem. 2020 , 97 , 205–215. [ Google Scholar ] [ CrossRef ]

- Qiu, C.; Li, P.; Li, Z.; Corke, H.; Sui, Z. Combined speed and duration of milling affect the physicochemical properties of rice flour. Food Hydrocoll. 2019 , 89 , 188–195. [ Google Scholar ] [ CrossRef ]

- Wang, S.; Wang, J.; Yu, J.; Wang, S. Effect of fatty acids on functional properties of normal wheat and waxy wheat starches: A structural basis. Food Chem. 2016 , 190 , 285–292. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Lin, Z.; Geng, D.-H.; Qin, W.; Huang, J.; Wang, L.; Liu, L.; Tong, L.-T. Effects of damaged starch on glutinous rice flour properties and sweet dumpling qualities. Int. J. Biol. Macromol. 2021 , 181 , 390–397. [ Google Scholar ] [ CrossRef ]

- Chen, H.; Wang, T.; Deng, F.; Yang, F.; Zhong, X.; Li, Q.; Ren, W. Changes in chemical composition and starch structure in rice noodle cultivar influence Rapid Visco analysis and texture analysis profiles under shading. Food Chem. X 2022 , 14 , 100360. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Tian, X.; Sun, B.; Wang, X.; Ma, S.; Li, L.; Qian, X. Effects of milling methods on rheological properties of fermented and non-fermented dough. Grain Oil Sci. Technol. Online 2020 , 3 , 77–86. [ Google Scholar ] [ CrossRef ]

- Srikaeo, K.; Arranz-Martínez, P. Formulating low glycaemic index rice flour to be used as a functional ingredient. J. Cereal Sci. 2015 , 61 , 33–40. [ Google Scholar ] [ CrossRef ]

Click here to enlarge figure

| Sample | DRF | SRF | WRF | JRF |

|---|---|---|---|---|

| D10 (μm) | 13.30 ± 0.00 | 9.66 ± 0.47 | 7.68 ± 0.12 | 4.07 ± 0.06 |

| D50 (μm) | 59.45 ± 0.21 | 39.10 ± 0.09 | 23.43 ± 0.09 | 14.65 ± 0.07 |

| D90 (μm) | 154.50 ± 0.71 | 96.15 ± 4.41 | 107.93 ± 2.52 | 29.15 ± 0.35 |

| Sample | DRF | SRF | WRF | JRF |

|---|---|---|---|---|

| Pasting Properties | ||||

| Pasting Temperature (°C) | 73.50 ± 0.05 | 77.12 ± 0.94 | 80.67 ± 0.06 | 72.68 ± 1.17 |

| Peak Viscosity (cP) | 5466 ± 60 | 5667 ± 25 | 5613 ± 137 | 4960 ± 23 |

| Though Viscosity (cP) | 3443 ± 100 | 3881 ± 102 | 3822 ± 117 | 3581 ± 49 |

| Final Viscosity (cP) | 6705 ± 47 | 6863 ± 61 | 7100 ± 106 | 6118 ± 7 |

| Breakdown (cP) | 2023 ± 43 | 1786 ± 88 | 1790 ± 34 | 1379 ± 25 |

| Setback (cP) | 3262 ± 60 | 2982 ± 48 | 3278 ± 23 | 2536 ± 56 |

| Thermal Properties | ||||

| To (°C) | 61.32 ± 0.09 | 60.75 ± 0.12 | 59.29 ± 0.27 | 64.14 ± 0.06 |

| Tp (°C) | 67.07 ± 0.17 | 66.02 ± 0.09 | 64.68 ± 0.13 | 69.54 ± 0.00 |

| Tc (°C) | 71.46 ± 0.51 | 70.14 ± 0.24 | 69.09 ± 0.20 | 74.69 ± 0.08 |

| c (J/g) | 5.75 ± 0.07 | 7.85 ± 0.13 | 8.21 ± 0.06 | 4.12 ± 0.10 |

| Sample | DRF | SRF | WRF | JRF |

|---|---|---|---|---|

| Hardness (N) | 6.96 ± 0.42 | 5.37 ± 0.20 | 3.50 ± 0.15 | 3.74 ± 0.07 |

| Adhesiveness(N.s) | −17.38 ± 3.39 | −14.40 ± 2.23 | −5.65 ± 0.64 | −11.87 ± 1.25 |

| Resilience (%) | 4.21 ± 0.82 | 5.48 ± 0.49 | 2.49 ± 0.68 | 4.08 ± 0.75 |

| Cohesiveness | 0.54 ± 0.03 | 0.52 ± 0.01 | 0.42 ± 0.03 | 0.58 ± 0.01 |

| Springiness (%) | 94.96 ± 6.18 | 87.76 ± 6.40 | 84.48 ± 8.38 | 96.03 ± 2.92 |

| Gumminess | 384.01 ± 41 | 286.04 ± 8 | 150.31 ± 15 | 220.81 ± 6 |

| Chewiness | 362.38 ± 37 | 250.86 ± 16 | 127.93 ± 26 | 212.14 ± 11 |

| Sample | DRF | SRF | WRF | JRF |

|---|---|---|---|---|

| K (×10 ) | 2.99 ± 0.04 | 2.54 ± 0.15 | 2.08 ± 0.01 | 3.32 ± 0.05 |

| C∞ (%) | 87.20 ± 0.61 | 85.10 ± 0.92 | 83.78 ± 0.38 | 90.59 ± 0.66 |

| AUC | 180.15 ± 1.65 | 170.75 ± 1.28 | 161.00 ± 0.93 | 189.62 ± 1.12 |

| eGI | 94.47 ± 0.79 | 89.97 ± 0.61 | 85.30 ± 0.45 | 99.27 ± 0.59 |

| The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

Share and Cite

Tian, Y.; Ding, L.; Liu, Y.; Shi, L.; Wang, T.; Wang, X.; Dang, B.; Li, L.; Gou, G.; Wu, G.; et al. The Effect of Different Milling Methods on the Physicochemical and In Vitro Digestibility of Rice Flour. Foods 2023 , 12 , 3099. https://doi.org/10.3390/foods12163099

Tian Y, Ding L, Liu Y, Shi L, Wang T, Wang X, Dang B, Li L, Gou G, Wu G, et al. The Effect of Different Milling Methods on the Physicochemical and In Vitro Digestibility of Rice Flour. Foods . 2023; 12(16):3099. https://doi.org/10.3390/foods12163099

Tian, Yaning, Lan Ding, Yonghui Liu, Li Shi, Tong Wang, Xueqing Wang, Bin Dang, Linglei Li, Guoyuan Gou, Guiyun Wu, and et al. 2023. "The Effect of Different Milling Methods on the Physicochemical and In Vitro Digestibility of Rice Flour" Foods 12, no. 16: 3099. https://doi.org/10.3390/foods12163099

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- J Res Med Sci

Gluten-free products in celiac disease: Nutritional and technological challenges and solutions

Seyede marzieh hosseini.

Department of Food Science and Technology, National Nutrition and Food Technology Research Institute, Shahid Beheshti University of Medical Sciences, Tehran, Iran

Nafiseh Soltanizadeh

1 Department of Food Science and Technology, College of Agriculture, Isfahan University of Technology, Isfahan, Iran

Parisa Mirmoghtadaee

2 Specialist in Community and Preventive Medicine, Isfahan University of Medical Sciences, Isfahan, Iran

Parisa Banavand

Leila mirmoghtadaie, saeedeh shojaee-aliabadi.

In celiac patient exposure to even only a small amount of gluten can lead to malabsorption of some important nutrients including calcium, iron, folic acid, and fat-soluble vitamins because of small-intestine inflammation. A strictly followed gluten-free (GF) diet throughout the patient's lifetime is the only effective treatment for celiac disease; however, elimination of gluten from cereal-based product leads to many technological and nutritional problems. This report discusses different substitutes to replace gluten functionality and examines the economic and social impacts of adherence to a GF diet. Better knowledge about the molecular basis of this disorder has encouraged the search for new methods of patient treatment. The new and common GF sources and different challenges encountered in production and consumption of these products and different solutions for improving their properties are discussed in this review.

INTRODUCTION

Celiac disease is a chronic inflammatory disorder of the intestine which being asymptomatic to causing severe malnutrition.[ 1 ] The prevalence of celiac disease is <0.5%–1% worldwide.[ 2 ] Gluten is the storage protein of wheat and includes glutenin and alcohol-soluble gliadin. Gliadin and other prolamins in rye (secalins) and barley (hordeins) are toxic for patients with celiac disease.[ 3 ] A gluten-free diet (GFD) is the mainstay of celiac disease treatment.[ 3 ] Adherence to a GFD improves many clinical and serological symptoms[ 4 ] and reduces the incidence of malignancies.[ 5 ] Furthermore, it can prevent the development of many autoimmune diseases such as hematologic disorders, hepatitis, and inflammatory bowel and insulin-dependent diabetes mellitus diseases.[ 6 ] While a limited amount of gluten is permitted in a celiac patient's diet, the amount of tolerable gluten varies widely between 10 mg and 34–36 mg gluten per day.[ 7 ] This has led to confusion about labeling “GF” products. For example, in Canada, such products must meet standards of <20 ppm gluten (20 mg gluten/1 kg), whereas other countries specify a maximum of 200 ppm.[ 8 ] However, producing food that provides a daily gluten intake of <10 mg is acceptable.[ 7 ] Omitting or reducing gluten lowers the quality of end products; this could be overcome with gluten substitutes. This paper aims to review the current knowledge on different GF cereals and gluten substitutes used for the production of GF food and the recent advances in molecular knowledge of celiac disease which can help in the development of new methods for celiac therapy.

DIFFERENT SOURCE OF GLUTEN-FREE FLOUR

Hitherto, total lifelong avoidance of gluten ingestion has remained the primary treatment for celiac disease. The overall objective of the GFD is maintaining health through the adoption of a well-balanced diet without using gluten. Observing a strict GFD is not easy, not least because it contributes to the social isolation of patients with celiac disease. In addition, nutritional deficiencies in Vitamins D and B, iron, zinc, calcium, magnesium, and fiber may occur. Furthermore, developing good-quality GF products could be challenging due to the unique properties of gluten.[ 9 ]

Several significant properties of rice – it lacks gluten, has a bland taste, is colorless and hypoallergenic, has low levels of protein, sodium, fat, and fiber, and contains high amounts of easily digested carbohydrates – make it suitable for making flour that can be used to prepare GF products. As rice contains a relatively small amount of prolamin, it is necessary to combine it with some sort of gum, emulsifier, enzymes, modified starch, or dairy products to obtain viscoelastic properties.[ 10 ] The color of the crust and texture characteristics of acidic extruded rice-flour bread is been found to be similar to those of wheat bread, but it has a low specific volume.[ 11 ] Rice–noodle products are important foods in many Asian countries. Since rice protein cannot participate in the forming of a cohesive dough structure, gelatinized starch plays a role as a binder.[ 12 ] Rice can also be formed into flakes: rice is cooked, coated with skim milk as a nutritious ingredient, and then partially dried, tempered, passed through flaking rolls, and toasted in an oven. Crackers can be also obtained using either nonwaxy or waxy rice.[ 13 ] Technological characteristics of rice-flour products could be improved by the addition of a protein source such as spirulina.[ 1 , 14 ]