- Case Studies

- Free Coaching Session

Production Plan in Business Plan: A Comprehensive Guide to Success

Last Updated:

February 26, 2024

In any business venture, a solid production plan is crucial for success. A production plan serves as a roadmap that outlines the steps, resources, and strategies required to manufacture products or deliver services efficiently. By carefully crafting a production plan within a business plan, entrepreneurs can ensure optimal utilisation of resources, timely delivery, cost efficiency, and customer satisfaction. In this article, we will delve into the intricacies of creating an effective production plan in a business plan , exploring its key components, strategies, and the importance of aligning it with overall business objectives .

Key Takeaways on Production Plans in Business Planning

- A production plan : a detailed outline that guides efficient product manufacturing or service delivery.

- Importance of a production plan : provides a roadmap for operations, optimises resource utilisation, and aligns with customer demand.

- Key components : demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance.

- Strategies : lean manufacturing, JIT inventory, automation and technology integration, supplier relationship management, and continuous improvement.

- Benefits of a well-executed production plan : improved efficiency, reduced costs, enhanced product quality, and increased profitability.

What is a Production Plan?

A production Seamless Searches plan is a detailed outline that specifies the processes, resources, timelines, and strategies required to convert raw materials into finished goods or deliver services. It serves as a blueprint for the entire production cycle, guiding decision-making and resource allocation. The production plan considers factors such as demand forecasting, capacity planning, inventory management, and quality assurance to ensure efficient operations and optimal customer satisfaction.

Why is a Production Plan Important in a Business Plan?

The inclusion of a production plan in a business plan is vital for several reasons. First and foremost, it provides a clear roadmap for business operations, helping entrepreneurs and managers make informed decisions related to production processes. A well-developed production plan ensures that resources are utilised efficiently, minimising wastage and optimising productivity.

Additionally, a production plan allows businesses to align their production capabilities with customer demand. By forecasting market trends and analysing customer needs, businesses can develop a production plan that caters to current and future demands, thus avoiding overstocking or understocking situations.

Furthermore, a production plan helps businesses enhance their competitive advantage. By implementing strategies such as lean manufacturing and automation, companies can streamline their production processes, reduce costs, improve product quality, and ultimately outperform competitors.

Key Components of a Production Plan

To create an effective production plan, it is crucial to consider several key components. These components work together to ensure efficient operations and successful fulfilment of customer demands. Let's explore each component in detail.

Demand Forecasting

Demand forecasting is a critical aspect of production planning. By analysing historical data, market trends, and customer behaviour, businesses can predict future demand for their products or services. Accurate demand forecasting allows companies to optimise inventory levels, plan production capacity, and ensure timely delivery to customers.

One approach to demand forecasting is quantitative analysis, which involves analysing historical sales data to identify patterns and make predictions. Another approach is qualitative analysis, which incorporates market research, customer surveys, and expert opinions to gauge demand fluctuations. By combining both methods, businesses can develop a robust demand forecast, minimising the risk of underproduction or overproduction. Utilising a free notion template for demand forecasting can further streamline this process, allowing businesses to organise and analyse both quantitative and qualitative data efficiently in one centralised location.

Capacity Planning

Capacity planning involves determining the optimal production capacity required to meet projected demand. This includes assessing the production capabilities of existing resources, such as machinery, equipment, and labour, and identifying any gaps that need to be addressed. By conducting a thorough capacity analysis, businesses can ensure that their production capacity aligns with customer demand, avoiding bottlenecks or excess capacity.

An effective capacity plan takes into account factors such as production cycle times, labour availability, equipment maintenance, and production lead times. It helps businesses allocate resources efficiently, minimise production delays, and maintain a consistent level of output to meet customer expectations.

Inventory Management

Efficient inventory management is crucial for a successful production plan. It involves balancing the cost of holding inventory with the risk of stockouts. By maintaining optimal inventory levels, businesses can reduce carrying costs while ensuring that sufficient stock is available to fulfil customer orders.

Inventory management techniques, such as the Economic Order Quantity (EOQ) model and Just-in-Time (JIT) inventory system, help businesses strike the right balance between inventory investment and customer demand. These methods consider factors such as order frequency, lead time, and carrying costs to optimise inventory levels and minimise the risk of excess or insufficient stock.

Resource Allocation

Resource allocation plays a pivotal role in a production plan. It involves assigning available resources, such as labour, materials, and equipment, to specific production tasks or projects. Effective resource allocation ensures that resources are utilised optimally, avoiding underutilisation or overutilisation.

To allocate resources efficiently, businesses must consider factors such as skill requirements, resource availability, project timelines, and cost constraints. By conducting a thorough resource analysis and implementing resource allocation strategies, businesses can streamline production processes, minimise bottlenecks, and maximise productivity.

Quality Assurance

Maintaining high-quality standards is essential for any production plan. Quality assurance involves implementing measures to monitor and control the quality of products or services throughout the production process. By adhering to quality standards and conducting regular inspections, businesses can minimise defects, ensure customer satisfaction, and build a positive brand reputation.

Quality assurance techniques, such as Total Quality Management (TQM) and Six Sigma , help businesses identify and rectify any quality-related issues. These methodologies involve continuous monitoring, process improvement, and employee training to enhance product quality and overall operational efficiency.

In addition to the core components of a production plan, it's also important for businesses to consider the broader aspects of their business strategy, including marketing and advertising. Understanding the costs and returns of different marketing approaches is crucial for comprehensive business planning. For instance, direct response advertising costs can vary significantly, but they offer the advantage of measurable responses from potential customers. This type of advertising can be a valuable strategy for businesses looking to directly engage with their target audience and track the effectiveness of their marketing efforts.

Strategies for Developing an Effective Production Plan

Developing an effective production plan requires implementing various strategies and best practices. By incorporating these strategies into the production planning process, businesses can optimise operations and drive success. Let's explore some key strategies in detail.

Lean Manufacturing

Lean manufacturing is a systematic Seamless Searches approach aimed at eliminating waste and improving efficiency in production processes. It emphasises the concept of continuous improvement and focuses on creating value for the customer while minimising non-value-added activities.

By adopting lean manufacturing principles, such as just-in-time production, standardised work processes, and visual management, businesses can streamline operations, reduce lead times, and eliminate unnecessary costs. Lean manufacturing not only improves productivity but also enhances product quality and customer satisfaction.

Just-in-Time (JIT) Inventory

Just-in-Time (JIT) inventory is a strategy that aims to minimise inventory levels by receiving goods or materials just when they are needed for production. This strategy eliminates the need for excess inventory storage, reducing carrying costs and the risk of obsolete inventory.

By implementing a JIT inventory system, businesses can optimise cash flow, reduce storage space requirements, and improve overall supply chain efficiency. However, it requires robust coordination with suppliers, accurate demand forecasting, and efficient logistics management to ensure timely delivery of materials.

Automation and Technology Integration

Automation and technology integration play a crucial role in modern production planning. By leveraging technology, businesses can streamline processes, enhance productivity, and reduce human error. Automation can be implemented in various aspects of production, including material handling, assembly, testing, and quality control.

Continuous Improvement

Continuous improvement is a fundamental principle of effective production planning. It involves regularly evaluating production processes, identifying areas for improvement, and implementing changes to enhance efficiency and quality.

By fostering a culture of continuous improvement, businesses can drive innovation, optimise resource utilisation, and stay ahead of competitors. Techniques such as Kaizen, Six Sigma, and value stream mapping can help businesses identify inefficiencies, eliminate waste, and streamline production workflows.

Frequently Asked Questions (FAQs)

What is the role of a production plan in business planning.

A1: A production plan plays a crucial role in business planning by providing a roadmap for efficient production processes. It helps align production capabilities with customer demand, optimise resource utilisation, and ensure timely delivery of products or services.

How does a production plan affect overall business profitability?

A2: A well-developed production plan can significantly impact business profitability. By optimising production processes, reducing costs, and enhancing product quality, businesses can improve their profit margins and gain a competitive edge in the market.

What are the common challenges faced in production planning?

A3: Production planning can present various challenges, such as inaccurate demand forecasting, capacity constraints, supply chain disruptions, and quality control issues. Overcoming these challenges requires robust planning, effective communication, and the implementation of appropriate strategies and technologies.

What is the difference between short-term and long-term production planning?

A4: Short-term production planning focuses on immediate production requirements, such as daily or weekly schedules. Long-term production planning, on the other hand, involves strategic decisions related to capacity expansion, technology investments, and market expansion, spanning months or even years.

How can a production plan be adjusted to accommodate changes in demand?

A5: To accommodate changes in demand, businesses can adopt flexible production strategies such as agile manufacturing or dynamic scheduling. These approaches allow for quick adjustments to production levels, resource allocation, and inventory management based on fluctuating customer demand.

In conclusion, a well-crafted production plan is essential for business success. By incorporating a production plan into a comprehensive business plan, entrepreneurs can optimise resource utilisation, meet customer demands, enhance product quality, and drive profitability. Through effective demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance, businesses can streamline production processes and gain a competitive edge in the market.

Related Articles:

Client Success!! Watch THIS >>>

Client Success - Case Study

© 2016 - 2024 Robin Waite. All rights reserved.

- Search Search Please fill out this field.

- Building Your Business

- Becoming an Owner

- Business Plans

How To Write the Operations Plan Section of the Business Plan

Susan Ward wrote about small businesses for The Balance for 18 years. She has run an IT consulting firm and designed and presented courses on how to promote small businesses.

:max_bytes(150000):strip_icc():format(webp)/SusanWardLaptop2crop1-57aa62eb5f9b58974a12bac9.jpg)

Stage of Development Section

Production process section, the bottom line, frequently asked questions (faqs).

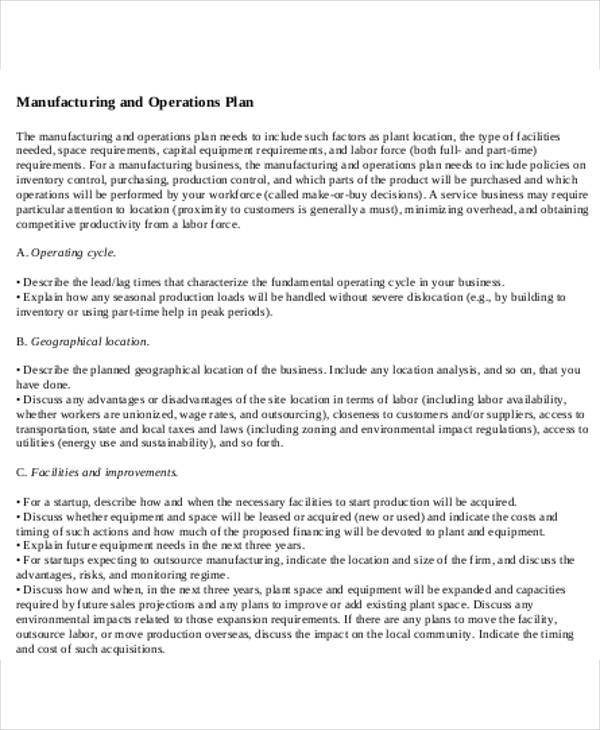

The operations plan is the section of your business plan that gives an overview of your workflow, supply chains, and similar aspects of your business. Any key details of how your business physically produces goods or services will be included in this section.

You need an operations plan to help others understand how you'll deliver on your promise to turn a profit. Keep reading to learn what to include in your operations plan.

Key Takeaways

- The operations plan section should include general operational details that help investors understand the physical details of your vision.

- Details in the operations plan include information about any physical plants, equipment, assets, and more.

- The operations plan can also serve as a checklist for startups; it includes a list of everything that must be done to start turning a profit.

In your business plan , the operations plan section describes the physical necessities of your business's operation, such as your physical location, facilities, and equipment. Depending on what kind of business you'll be operating, it may also include information about inventory requirements, suppliers, and a description of the manufacturing process.

Keeping focused on the bottom line will help you organize this part of the business plan.

Think of the operating plan as an outline of the capital and expense requirements your business will need to operate from day to day.

You need to do two things for the reader of your business plan in the operations section: show what you've done so far to get your business off the ground and demonstrate that you understand the manufacturing or delivery process of producing your product or service.

When you're writing this section of the operations plan, start by explaining what you've done to date to get the business operational, then follow up with an explanation of what still needs to be done. The following should be included:

Production Workflow

A high-level, step-by-step description of how your product or service will be made, identifying the problems that may occur in the production process. Follow this with a subsection titled "Risks," which outlines the potential problems that may interfere with the production process and what you're going to do to negate these risks. If any part of the production process can expose employees to hazards, describe how employees will be trained in dealing with safety issues. If hazardous materials will be used, describe how these will be safely stored, handled, and disposed.

Industry Association Memberships

Show your awareness of your industry's local, regional, or national standards and regulations by telling which industry organizations you are already a member of and which ones you plan to join. This is also an opportunity to outline what steps you've taken to comply with the laws and regulations that apply to your industry.

Supply Chains

An explanation of who your suppliers are and their prices, terms, and conditions. Describe what alternative arrangements you have made or will make if these suppliers let you down.

Quality Control

An explanation of the quality control measures that you've set up or are going to establish. For example, if you intend to pursue some form of quality control certification such as ISO 9000, describe how you will accomplish this.

While you can think of the stage of the development part of the operations plan as an overview, the production process section lays out the details of your business's day-to-day operations. Remember, your goal for writing this business plan section is to demonstrate your understanding of your product or service's manufacturing or delivery process.

When writing this section, you can use the headings below as subheadings and then provide the details in paragraph format. Leave out any topic that does not apply to your particular business.

Do an outline of your business's day-to-day operations, including your hours of operation and the days the business will be open. If the business is seasonal, be sure to say so.

The Physical Plant

Describe the type, site, and location of premises for your business. If applicable, include drawings of the building, copies of lease agreements, and recent real estate appraisals. You need to show how much the land or buildings required for your business operations are worth and tell why they're important to your proposed business.

The same goes for equipment. Besides describing the equipment necessary and how much of it you need, you also need to include its worth and cost and explain any financing arrangements.

Make a list of your assets , such as land, buildings, inventory, furniture, equipment, and vehicles. Include legal descriptions and the worth of each asset.

Special Requirements

If your business has any special requirements, such as water or power needs, ventilation, drainage, etc., provide the details in your operating plan, as well as what you've done to secure the necessary permissions.

State where you're going to get the materials you need to produce your product or service and explain what terms you've negotiated with suppliers.

Explain how long it takes to produce a unit and when you'll be able to start producing your product or service. Include factors that may affect the time frame of production and describe how you'll deal with potential challenges such as rush orders.

Explain how you'll keep track of inventory .

Feasibility

Describe any product testing, price testing, or prototype testing that you've done on your product or service.

Give details of product cost estimates.

Once you've worked through this business plan section, you'll not only have a detailed operations plan to show your readers, but you'll also have a convenient list of what needs to be done next to make your business a reality. Writing this document gives you a chance to crystalize your business ideas into a clear checklist that you can reference. As you check items off the list, use it to explain your vision to investors, partners, and others within your organization.

What is an operations plan?

An operations plan is one section of a company's business plan. This section conveys the physical requirements for your business's operations, including supply chains, workflow , and quality control processes.

What is the main difference between the operations plan and the financial plan?

The operations plan and financial plan tackle similar issues, in that they seek to explain how the business will turn a profit. The operations plan approaches this issue from a physical perspective, such as property, routes, and locations. The financial plan explains how revenue and expenses will ultimately lead to the business's success.

Want to read more content like this? Sign up for The Balance's newsletter for daily insights, analysis, and financial tips, all delivered straight to your inbox every morning!

Business Plan Template for Manufacturing Company

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

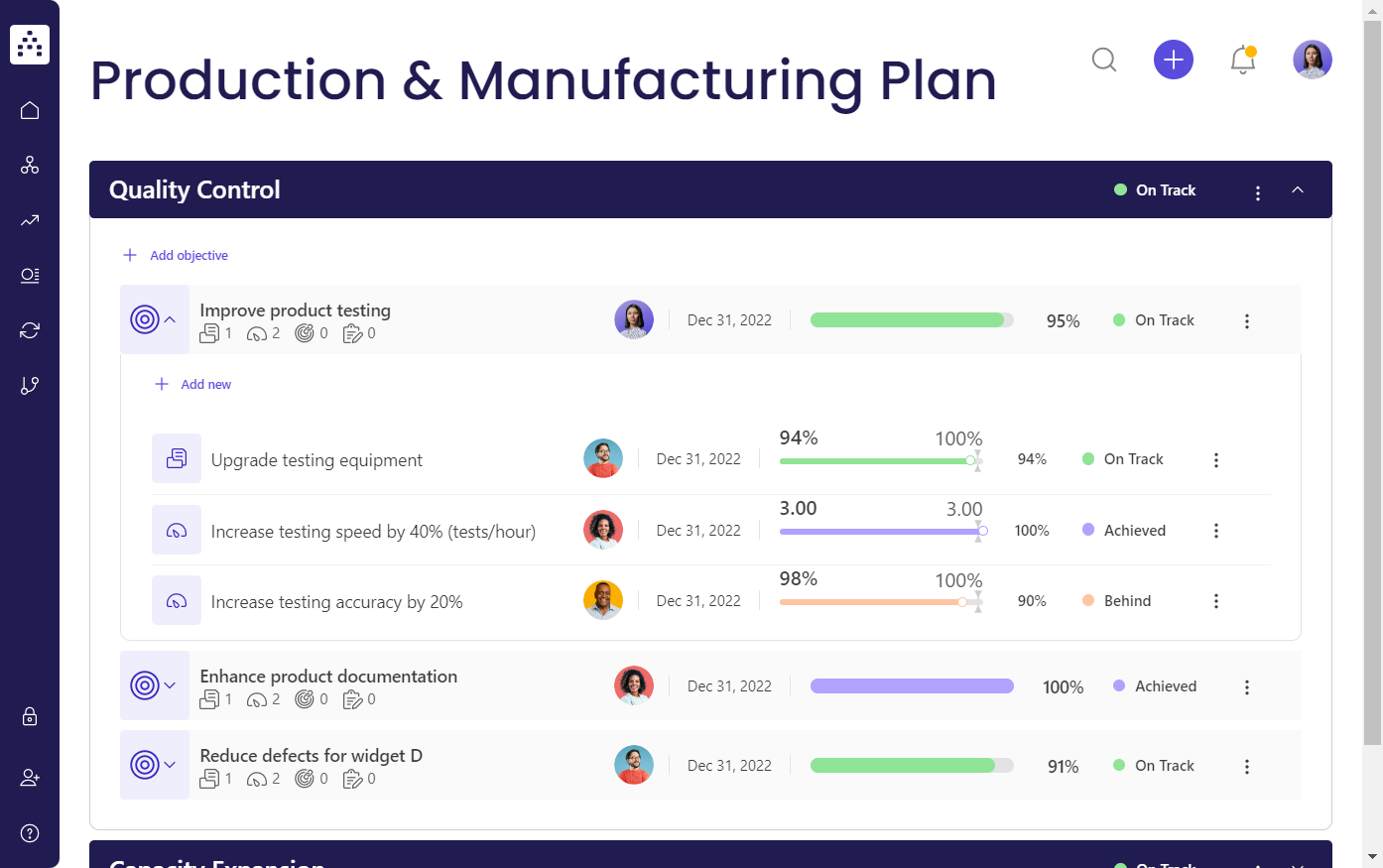

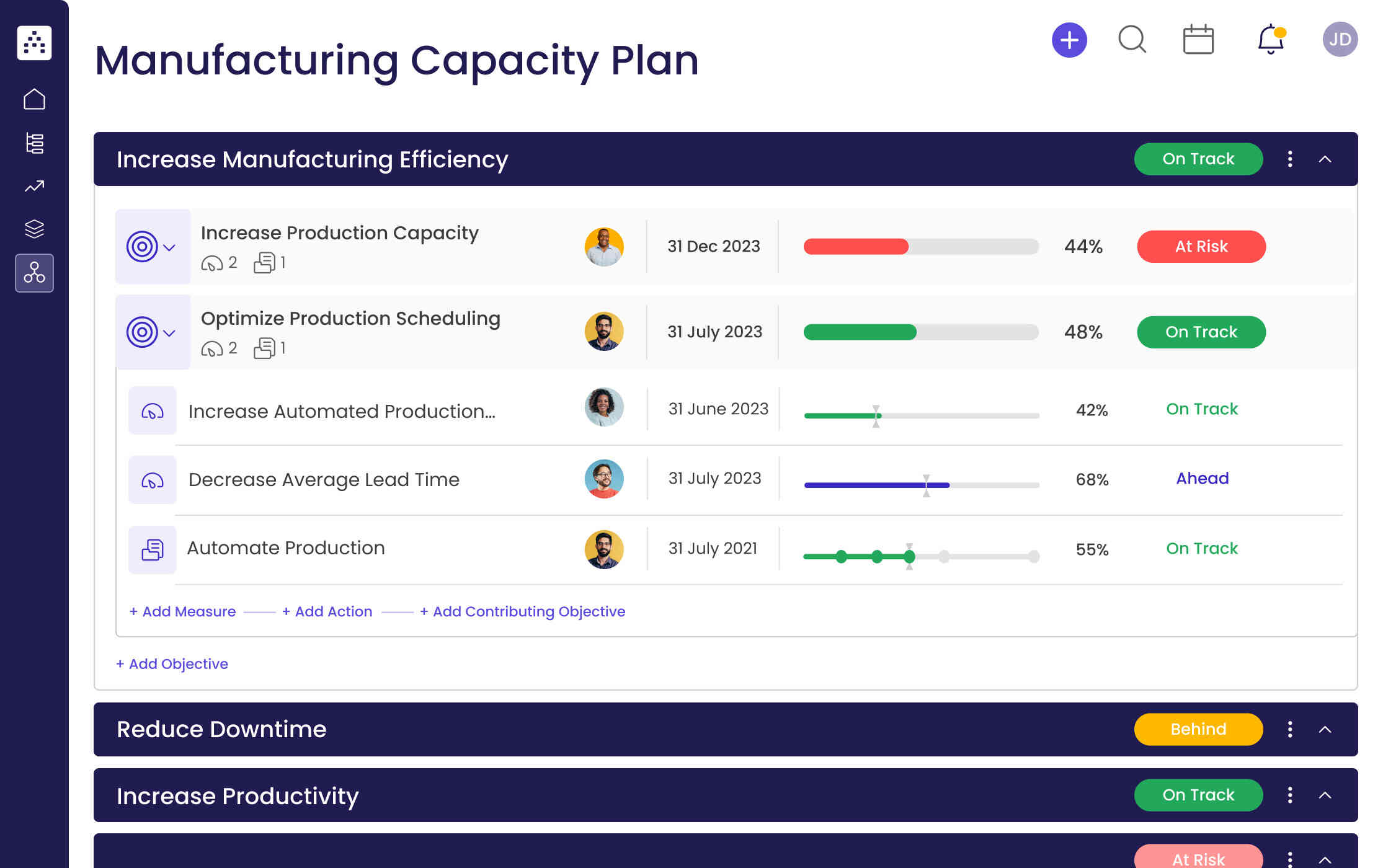

Starting a manufacturing company can be an exciting but challenging endeavor. To ensure success, you need a solid business plan that covers all the essential aspects of your operations. That's where ClickUp's Business Plan Template for Manufacturing Companies comes in!

Our template provides a comprehensive framework for outlining your company's goals, conducting market analysis, projecting finances, and strategizing your operations. With ClickUp's Business Plan Template, you'll be able to:

- Clearly define your company's vision, mission, and objectives

- Conduct a thorough market analysis to understand your target audience and competitors

- Develop financial projections and budgets to secure funding and attract investors

- Create operational strategies to optimize production, logistics, and quality control

Whether you're a seasoned entrepreneur or just starting out, our Business Plan Template will guide you through the process of building a successful manufacturing company. Don't miss out on the opportunity to turn your vision into reality—get started with ClickUp today!

Business Plan Template for Manufacturing Company Benefits

Creating a solid business plan is crucial for success in the manufacturing industry. By using the Business Plan Template for Manufacturing Company, you can:

- Clearly define your company's vision, mission, and goals

- Conduct a thorough market analysis to identify target customers and competitors

- Develop a comprehensive financial plan, including revenue projections and cost analysis

- Outline your manufacturing processes, supply chain management, and quality control measures

- Present a professional and well-structured document to potential investors and lenders

- Guide strategic decision-making and ensure alignment with your long-term objectives

- Monitor and track progress towards your business milestones and objectives

Main Elements of Manufacturing Company Business Plan Template

When it comes to creating a comprehensive business plan for your manufacturing company, ClickUp has you covered with its Business Plan Template. Here are the main elements you'll find in this template:

- Custom Statuses: Keep track of the progress of different sections of your business plan with statuses like Complete, In Progress, Needs Revision, and To Do.

- Custom Fields: Add important details to your business plan using custom fields such as Reference, Approved, and Section, allowing you to easily organize and categorize information.

- Custom Views: Access different perspectives of your business plan using views like Topics, Status, Timeline, Business Plan, and Getting Started Guide, making it easy to navigate and present your plan effectively.

- Document Collaboration: Collaborate with your team in real-time using ClickUp's Docs feature to work together on your business plan.

- Task Management: Break down your business plan into actionable tasks, assign them to team members, set due dates, and track progress using ClickUp's powerful task management features.

How To Use Business Plan Template for Manufacturing Company

If you're looking to create a business plan for your manufacturing company, follow these 6 steps using ClickUp's Business Plan Template:

1. Define your company's mission and vision

Start by clearly defining the mission and vision of your manufacturing company. What do you aim to achieve and how do you plan to do it? This will serve as the guiding principles for your business plan.

Use a Doc in ClickUp to outline your company's mission and vision statements.

2. Conduct market research

Thorough market research is essential to understand your target audience, competitors, and industry trends. Identify your niche, analyze customer needs, and assess the competitive landscape. This will help you position your manufacturing company effectively.

Use the Table view in ClickUp to compile and analyze market data, including customer demographics, competitor analysis, and industry trends.

3. Develop your product offerings

Outline the products and services your manufacturing company will offer. Determine the unique selling points of your offerings and how they address customer needs. Consider factors such as pricing, quality, and delivery timelines.

Use tasks in ClickUp to create a product development plan and assign tasks to team members responsible for designing, manufacturing, and testing the products.

4. Create a marketing and sales strategy

Define your marketing and sales strategies to promote your manufacturing company. Identify the channels and tactics you will use to reach your target audience. This may include digital marketing, trade shows, partnerships, or direct sales.

Use Goals in ClickUp to set specific marketing and sales objectives, such as lead generation targets or revenue goals.

5. Establish operational processes

Develop a plan for your manufacturing processes, including procurement, production, quality control, and logistics. Define the roles and responsibilities of your team members and ensure smooth coordination across departments.

Use Automations in ClickUp to streamline your operational processes by automating repetitive tasks and setting up notifications for key milestones.

6. Create financial projections

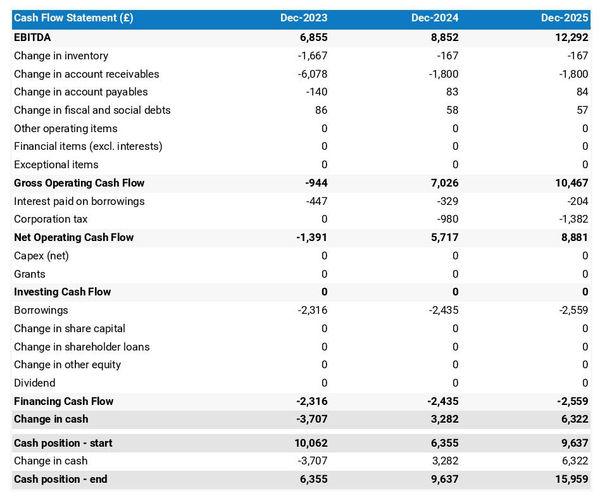

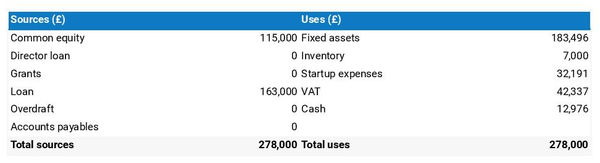

Project your financials, including revenue, expenses, and cash flow projections for the next few years. Consider factors such as production costs, pricing, sales volume, and market demand. This will help you assess the viability and profitability of your manufacturing company.

Use Dashboards in ClickUp to track and visualize your financial projections, allowing you to monitor your company's performance and make informed decisions.

By following these steps and utilizing ClickUp's Business Plan Template, you'll be well-equipped to create a comprehensive and effective business plan for your manufacturing company.

Get Started with ClickUp’s Business Plan Template for Manufacturing Company

Entrepreneurs and business owners in the manufacturing industry can use the Business Plan Template for Manufacturing Company to create a comprehensive plan for their business.

First, hit "Add Template" to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you'd like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to create a solid business plan:

- Use the Topics View to outline and organize the different sections of your business plan, such as Executive Summary, Market Analysis, Financial Projections, and Operational Strategies.

- The Status View will help you track the progress of each section, with statuses like Complete, In Progress, Needs Revision, and To Do.

- The Timeline View will allow you to set deadlines and visualize the timeline for completing each section of your business plan.

- Use the Business Plan View to have a comprehensive overview of your entire plan, with all the sections and details in one place.

- The Getting Started Guide View will provide you with step-by-step instructions and tips on how to effectively use the template and create a successful business plan.

- Customize the template by adding custom fields like Reference, Approved, and Section to provide additional information and track important details.

- Update statuses and custom fields as you make progress and receive feedback from stakeholders.

- Monitor and analyze your business plan to ensure it aligns with your goals and attracts investors.

- Business Plan Template for Distance Learning

- Business Plan Template for Medication Errors

- Business Plan Template for Little Caesars

- Business Plan Template for Technology

- Business Plan Template for Gym Owners

Template details

Free forever with 100mb storage.

Free training & 24-hours support

Serious about security & privacy

Highest levels of uptime the last 12 months

- Product Roadmap

- Affiliate & Referrals

- On-Demand Demo

- Integrations

- Consultants

- Gantt Chart

- Native Time Tracking

- Automations

- Kanban Board

- vs Airtable

- vs Basecamp

- vs MS Project

- vs Smartsheet

- Software Team Hub

- PM Software Guide

- Starting a Business

- Growing a Business

- Small Business Guide

- Business News

- Science & Technology

- Money & Finance

- For Subscribers

- Write for Entrepreneur

- Entrepreneur Store

- United States

- Asia Pacific

- Middle East

- South Africa

Copyright © 2024 Entrepreneur Media, LLC All rights reserved. Entrepreneur® and its related marks are registered trademarks of Entrepreneur Media LLC

- How to Use Your Business Plan Most Effectively

- The Basics of Writing a Business Plan

- 12 Reasons You Need a Business Plan

- The Main Objectives of a Business Plan

- What to Include and Not Include in a Successful Business Plan

- The Top 4 Types of Business Plans

- A Step-by-Step Guide to Presenting Your Business Plan in 10 Slides

- 6 Tips for Making a Winning Business Presentation

- 12 Ways to Set Realistic Business Goals and Objectives

- 3 Key Things You Need to Know About Financing Your Business

- How to Perfectly Pitch Your Business Plan in 10 Minutes

- How to Fund Your Business Through Friends and Family Loans and Crowdsourcing

- How to Fund Your Business Using Banks and Credit Unions

- How to Fund Your Business With an SBA Loan

- How to Fund Your Business With Bonds and Indirect Funding Sources

- How to Fund Your Business With Venture Capital

- How to Fund Your Business With Angel Investors

- How to Use Your Business Plan to Track Performance

- How to Make Your Business Plan Attractive to Prospective Partners

- Is This Idea Going to Work? How to Assess the Potential of Your Business.

- When to Update Your Business Plan

- How to Write the Management Team Section to Your Business Plan

- How to Create a Strategic Hiring Plan

- How to Write a Business Plan Executive Summary That Sells Your Idea

- How to Build a Team of Outside Experts for Your Business

- Use This Worksheet to Write a Product Description That Sells

- What Is Your Unique Selling Proposition? Use This Worksheet to Find Your Greatest Strength.

- How to Raise Money With Your Business Plan

- Customers and Investors Don't Want Products. They Want Solutions.

- 5 Essential Elements of Your Industry Trends Plan

- How to Identify and Research Your Competition

- Who Is Your Ideal Customer? 4 Questions to Ask Yourself.

- How to Identify Market Trends in Your Business Plan

- How to Define Your Product and Set Your Prices

- How to Determine the Barriers to Entry for Your Business

- How to Get Customers in Your Store and Drive Traffic to Your Website

- How to Effectively Promote Your Business to Customers and Investors

- What Equipment and Facilities to Include in Your Business Plan

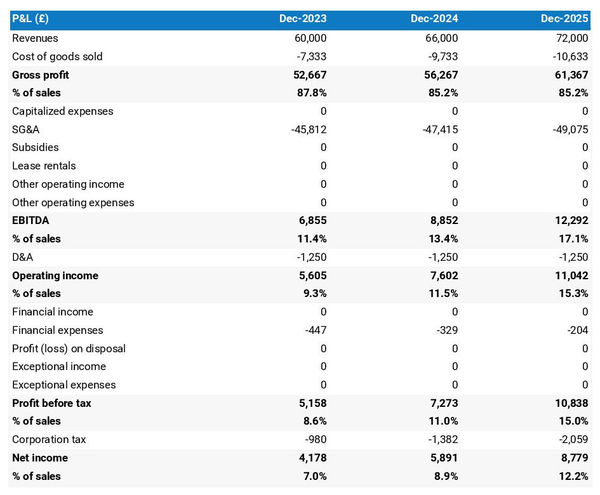

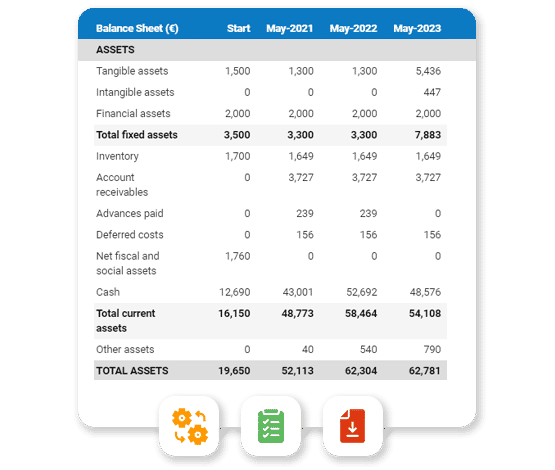

- How to Write an Income Statement for Your Business Plan

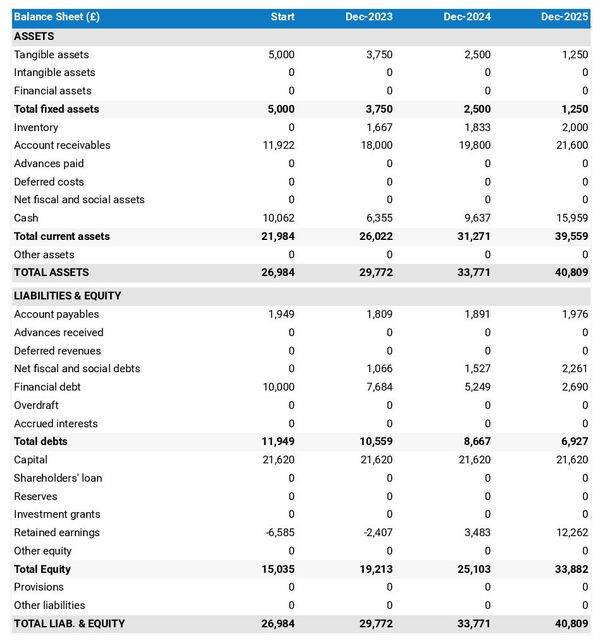

- How to Make a Balance Sheet

- How to Make a Cash Flow Statement

- How to Use Financial Ratios to Understand the Health of Your Business

- How to Write an Operations Plan for Retail and Sales Businesses

- How to Make Realistic Financial Forecasts

- How to Write an Operations Plan for Manufacturers

- What Technology Needs to Include In Your Business Plan

- How to List Personnel and Materials in Your Business Plan

- The Role of Franchising

- The Best Ways to Follow Up on a Buisiness Plan

- The Best Books, Sites, Trade Associations and Resources to Get Your Business Funded and Running

- How to Hire the Right Business Plan Consultant

- Business Plan Lingo and Resources All Entrepreneurs Should Know

- How to Write a Letter of Introduction

- What To Put on the Cover Page of a Business Plan

- How to Format Your Business Plan

- 6 Steps to Getting Your Business Plan In Front of Investors

How to Write an Operations Plan for Manufacturers If your company makes things, you'll want to detail the manufacturing production process.

By Eric Butow • Oct 27, 2023

Opinions expressed by Entrepreneur contributors are their own.

This is part 8 / 11 of Write Your Business Plan: Section 5: Organizing Operations and Finances series.

Companies that make things have certain characteristics that set them apart from others, including retailers and service firms. They take raw materials and labor and transform them into sellable products. Although they may also distribute the products and sell directly to customers (thus involving the retail and service aspects of operations), most manufacturers concentrate on the production end and farm out the retail and service to other firms.

Process Points

The lead actor in manufacturing is the process of production. Product development, marketing, and distribution play essential roles, but the production process sets manufacturers apart from all other enterprises. And the better your production process, the better a manufacturer you will be. It's the star that leads to your company's success.

Related: How to Write an Operations Plan for Retail and Sales Businesses

A manufacturing production process consists of several components. One step is usually fabrication, or the making of products from raw materials. There is also assembly of components, testing, and inspection of finished goods.

Manufacturing processes can become highly detailed, as is the case with the many parts found in mobile technology. If you're an operations-minded entrepreneur, you may revel in these details. But control your enthusiasm for such details when writing a business plan. Stick to the critical processes that are essential to your production or give you a unique competitive advantage.

These include:

- Personel and materials

- Equipment and Facilities

The following manufacturing company checklist might help organize your company's operation details.

- Marketing plan completed

- Staffing completed (or staffing plan completed)

- Organization chart completed

- Product plan completed

- Basic manufacturing operations listed in sequence

- Raw materials purchased

- Equipment obtained

- Labor skills available and assigned

- Timelines and deadlines assigned

- Potential roadblocks identified

- Managerial controls in place

- Sales policies reviewed

- Customer relations policies outlined

- Service delivery policies developed

- Administering monitoring and control policies

- Follow-up procedures checked

Your checklist will most likely differ depending on your business. A small contractor, for example, makes things but is less complex, so might have a checklist like this:

- Develop work schedule

- Set up equipment

- Acquire necessary materials

- Monitor work schedule

Be sure to tailor your checklist to your business's requirements.

Related: What Equipment and Facilities to Include in Your Business Plan

More in Write Your Business Plan

Section 1: the foundation of a business plan, section 2: putting your business plan to work, section 3: selling your product and team, section 4: marketing your business plan, section 5: organizing operations and finances, section 6: getting your business plan to investors.

Successfully copied link

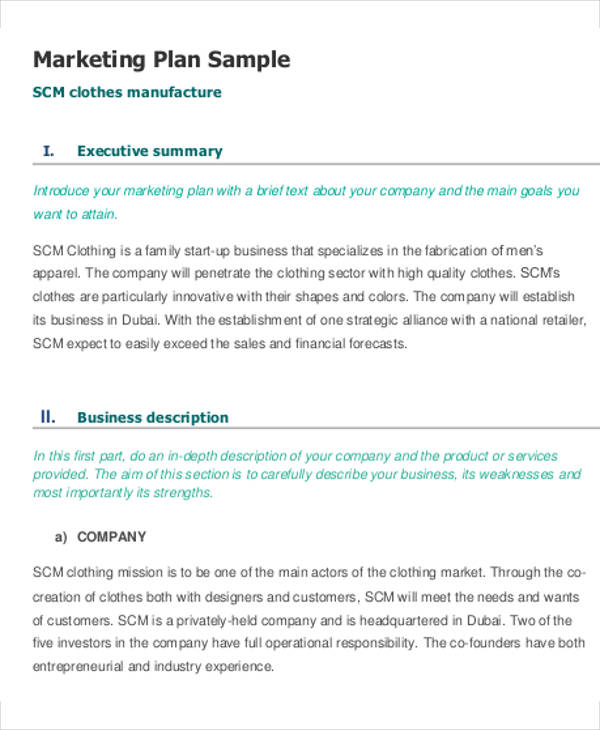

manufacturing business plan example

The U.S. manufacturing industry has been a linchpin of the nation’s economic development, tracing its roots back to the Industrial Revolution. From humble artisan workshops, the U.S. manufacturing sector has evolved into sophisticated, technology-driven enterprises, marked by continual growth propelled by innovation, automation, and a steadfast commitment to producing top-quality goods.

Noteworthy among the leaders in this sector are manufacturing giants such as General Electric (GE), boasting diverse manufacturing interests spanning aviation, healthcare, power, and renewable energy. Boeing , a major player in aerospace and defense, is complemented by General Motors and Ford Motor Company, two automotive behemoths. Procter & Gamble (P&G) extends its influence in the consumer goods realm, while Johnson & Johnson takes center stage in pharmaceuticals, medical devices, and consumer goods. Caterpillar , IBM , 3M , and Honeywell International further enrich the manufacturing landscape with expertise in construction, technology, and diverse product offerings.

In business planning for manufacturing enterprises, meticulous strategies are imperative. Developing a robust manufacturing business plan involves careful consideration of factors such as production processes, supply chain management, and market positioning. Such plans serve as blueprints for success, encompassing key elements like quality control and financial projections . Recognizing the significance of a comprehensive business plan for manufacturing, companies employ various manufacturing business model and manufacturing plan examples tailored to their specific industry needs.

Business Plan for Manufacturing

A well-crafted manufacture business plan serves as the cornerstone for any manufacturing enterprise, offering a strategic roadmap for navigating the dynamic and competitive terrain of the production and industry landscape. While recognizing that there’s no one-size-fits-all approach, using manufacturing business plan example becomes crucial for navigating the process effectively..

Manufacturing business plans take many forms including advanced manufacturing . The manufacturer business model is shifting as new production processes introduce updated deadlines and expectations.

How Technology is Transforming Production Business Plans

Crafting a quality business plan for a manufacturing company requires a strategic approach that integrates technology and business goals. Here are the key components:

Digital Twin Technology

By integrating digital twin technology into a business plan for production company, simulation and prototyping become integral components. This approach enables virtual testing before physical production, accelerating development timelines while ensuring cost-effective and high-quality outcomes.

Internet of Things (IoT)

Real-time monitoring powered by IoT sensors forms a cornerstone in manufacturing plans. This facilitates data-driven decision-making, optimizing performance, predicting maintenance needs, and upholding stringent quality control standards.

Artificial Intelligence (AI) and Machine Learning (ML )

The integration of AI and ML algorithms is paramount for predictive analytics and quality control. These technologies analyze production data, predict equipment failures, and guarantee the production of high-quality goods.

Robotics and Automation

Robotics and automation elevate production line efficiency, reducing labor costs and enhancing precision. Making business plan revolves around embracing these technologies to streamline processes.

Advanced Manufacturing Technologies

Through 3D printing, you can achieve intricate designs with precision. Leveraging nanotechnology enhances material properties at a molecular level, allowing your manufacturing business to surpass expectations in strength, weight, and durability.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies play a crucial role in training and maintenance. This can enhance employee skills and troubleshoot issues efficiently, contributing to the overall success of manufacturing operations.

By incorporating these technological advancements into your ultimate business plan for manufacturing business, you are positioned for sustained success in the digital age.

Manufacturing Business Plan Template [Updated 2024]

Manufacturing Business Plan Template

If you want to start a Manufacturing business or expand your current Manufacturing company, you need a business plan.

The following Manufacturing business plan template gives you the key elements to include in a winning Manufacturing business plan.

You can download our business plan template (including a full, customizable financial model) to your computer here.

Below are links to each of the key sections of a sample manufacturing business plan. Once you create your plan, download it to PDF to show banks and investors.

I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

Comments are closed.

Manufacturing Business Plan Home I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

- See all articles

- Business tips

- Inventory management

- Manufacturing

- Product updates

Strategies for manufacturing: How to plan for the future

James humphreys.

Senior Content Manager

The reality is that very few manufacturing businesses will be successful without a solid strategy in place. But why are strategies for manufacturing important? How have they evolved, and what manufacturing strategies are easy for companies to implement?

In this article, we’ll answer all these questions and more.

What is a manufacturing strategy?

A manufacturing strategy has been previously defined as “a long-range plan to use the resources of the manufacturing system to support the business strategy and, in turn, meet the business objectives. (Cimorelli and Chandler, 1996).

The connection that binds all the eras together is manufacturing strategy. Whether it’s a humble artisan in a side-street pottery shop or a technological wiz-kid wanting to build a smart factory, they both need a manufacturing strategy.

As already identified, strategies for manufacturing have been around for many years.

The definition of a what is a manufacturing strategy has also been around for a long time. According to Hayes and Wheelwright, 1984 , it is “a sequence of decisions that, over time, enables a business unit to achieve the desired manufacturing structure, infrastructure, and set of specific capabilities.”

Nowadays, manufacturing strategy is often intertwined with a company’s digital strategy, with the tactical management of production and technology at the heart of everything a company achieves.

As was noted by Gündüz Ulusoy back in 2003, formulating a marketing strategy requires making three strategic choices in three key areas: Competitive priorities, manufacturing objectives, and action plans.

Competitive priorities include choices on:

- Quality levels

- Reliability

- Design change

- Deliveries

- New products

Manufacturing objectives involve decision-making on:

- Unit costs

- Market share

- Profitability

- Product development time

And action plans include making decisions about:

- Production

- Energy saving

- Employee empowerment

- Staff training

Once these decisions have been made and a company’s priorities have been identified, an overarching marketing strategy can be formulated.

The history of manufacturing strategy

Whether you are a B2B (business-to-business) or a D2C (direct-to-consumer) manufacturing company , the chances are high that you have a structured manufacturing process in place. Hopefully, this relates back to your manufacturing strategy. This relationship between process and strategy has existed for hundreds of years.

The art of manufacturing has humble beginnings. Way before industrialization was conceptualized, skilled artisans worked to produce commodities. They relied on their craftmanship and secrecy to ensure that their products were in demand and couldn’t be copied.

The first example of a manufacturing strategy was probably when forward-thinking artisans realized they could sub-contract their work to others, thus producing more products and increasing their profits.

Manufacturing was transformed dramatically and definitively in the 18th century during the Industrial Revolution. The invention of machines that could do the work on a mass scale meant that industries such as glassmaking, mining, textiles , and agriculture could produce much more on a much cheaper scale. The mass production concept followed, bringing us to where we are today.

Interestingly, we are on the brink of another transformation in the industrial sector, with the birth of the Fourth Industrial Revolution, 4IR, or Industry 4.0. This is the notion that interconnectivity, smart automation, and digital process management will considerably strengthen production flow, improve quality, and reduce costs. In short, the various parts of a supply chain will interact without human interference.

This may seem almost like a sci-fi fantasy to some, but we are speeding quickly toward this new norm. Who knows what the future of manufacturing looks like? But, the reality is that strategies for manufacturing will always be a priority in the transformation of this fast-paced industry.

Why is a manufacturing strategy important?

A manufacturing strategy is the backbone of how a business operates when you break it down. To ensure your manufacturing strategy is aligned with the overall business strategy, it must be focused on:

- maximizing quality

- minimizing costs

- avoiding wastage

- improving flexibility

All the while being motivated by more lofty goals such as increasing market share and profitability.

Strategies for marketing ensure that a company avoids inefficiencies, optimizes production, and ultimately reaches the goals it is aiming for.

As Steve Lam, Senior Vice President of Patheon’s Biologics Business, states, whether you are processing medicines , clothing , beauty products , or the latest tech-gadgets , “considering your manufacturing strategy early on in development pays dividends down the line.”

So why is a manufacturing strategy important? The answer to this is another question:

Would your business survive without it?

Easy strategies for manufacturing that companies can implement

When choosing a new manufacturing strategy, it’s important to remember it’s not a case of a one-size-fits-all approach but rather finding one that is relevant for your business.

Just because a manufacturing strategy is world-class for some doesn’t mean it will be for others. Be sure to strategize with intent and ensure that your manufacturing strategy gives your company the competitive edge it needs in an increasingly competitive environment. Start by articulating your competitive advantage and then build your strategy around it.

Every decision, from the machinery you use to the automation system you choose, needs to take you one step closer to maximizing that competitive advantage.

So, what are some manufacturing strategy examples that you could implement?

1. Adopt technology

It is crucial to have an agile IT function that can respond flexibly to your business’s demands. Identifying which technologies are applicable and useful to your manufacturing processes is often the first building block in a sturdy manufacturing strategy. Is there a service or app out there that you have not yet considered?

2. Shrink your costs and production waste

This is a no-brainer. If your business has holes in its manufacturing processes that let money flow out of them, then this part of your manufacturing strategy must be robust. Production times, processes, and product quality are things that cannot be compromised on.

3. Stock inventory

Adopting the principles of lean inventory saves you a fortune and gives you a serious competitive edge. Having a better understanding of your stock levels and responding to your customer’s needs more intuitively could result in huge improvements for your business.

4. Automate your processes

The automation of day-to-day tasks can make your business leaner and more efficient. Services like Katana cloud inventory platform can be the bridge that finally connects your procurement, order processing, supply chain, customer service, production, and operations together. Automatically monitoring the movement of your inventory will minimize waste like never before. Furthermore, Katana’s software easily integrates with e-commerce platforms like Shopify and WooCommerce to reduce the risk of stock-outs and to keep your products moving to the customers who want them.

5. Look to the future

Industry 4.0 is just the latest in many changes in the industrial and manufacturing world. Do your research and ensure your manufacturing strategies are robust yet flexible enough so you can pivot if you need to.

Designing manufacturing strategies for success

Strategies for manufacturing are essential to keep a business moving. The most successful businesses over time have been the ones that have chosen strategies that support their long-term ambitions.

Innovative software, visibility, and control are often the backbones of any successful manufacturing strategy, but how you implement these must be unique to your business.

For example, adopting a manufacturing ERP software would be the perfect manufacturing strategy for businesses struggling to keep track of the movement of their inventory.

The key is to be smart about it — Be sure to identify the manufacturing strategies that fit your business model right now and will help you to stay ahead of the competition in the future. Evaluating and measuring your success every step of the way will ensure that you can provide your customers with the products they need before they even know they need them!

James Humphreys has produced content on manufacturing and inventory management practices for 5+ years. He began his journey into writing via the creative industry, writing and producing plays, some of which toured the UK and Europe.

Related Articles

23 small manufacturing business ideas you can use, digital manufacturing: a new way to work, manufacturing control: creating a plan to optimize output, what is ppe manufacturing, and why is it important, operations in manufacturing: how to stay in control, manufacturing analytics: the metrics you need, going lean with cellular manufacturing, packaging and contract manufacturing: thinking outside the box, trending articles, electronic components inventory: how to do it right, sustainable manufacturing: the why, the how, and the who, how to know when it’s time for better clothing warehouse organization, untangle the complex web of pharma supply chain and logistics, 11 warehouse mistakes and how to fix them, erp vs. wms: which one is right for your business, inventory liquidation: why, when, and how to do it, woocommerce inventory sync solutions for your business.

Updated on September 27, 2023

Manufacturing Business Plan: How to Draft One

A business plan serves as your roadmap to success. Starting a manufacturing business without a business plan is like driving off on a road trip without a destination in mind. It’s critical to put time and effort into building a worthwhile business plan. We will explore how to build a manufacturing business plan. Plus, explore why you need one in the first place.

Key Points: A business plan is a document you create as a roadmap to your business goals. You can use your business plan to brainstorm solutions for potential problems on paper. While you will likely make adjustments along the way, a business plan puts you on the path to success.

Understanding Manufacturing Business Plans

Businesses of all shapes and sizes create business plans. Without a business plan, you are essentially flying blind as you build out your business. A carefully thought-out business plan can help you avoid potential pitfalls.

What’s the Purpose of a Manufacturing Business Plan?

A manufacturing business plan is a document that will help you chart a course to success.

- Chart a course to success : You can use this document to define success and make a clear path to achieving those goals.

- Consider potential challenges : You can use the document to find solutions for problems before they throw a wrench in your business.

- Showcase your idea : While potential investors and lenders might ask to see this document, it’s also a useful tool for business owners to outline their vision of success.

Who Needs a Manufacturing Business Plan?

Everyone who wants to build a manufacturing business should create a manufacturing business plan. Here’s a look at the process:

- Getting started : If you are just diving into your business idea, a business plan serves as a useful way to organize your thoughts.

- Along the way : If you jumped into your business without creating a plan, it’s never too late. Consider building a business plan from where you currently are.

Important Factors to Consider When Writing a Business Plan for a Manufacturing Company

As you write your business plan , keep these factors in mind.

- Patience : It can take time to build out a comprehensive business plan. That’s okay. Be patient with yourself throughout the process.

- Stay flexible : Your business will not operate in a vacuum. When things change, stay flexible and make any necessary adjustments along the way.

Essential Elements of a Manufacturing Business Plan

Every manufacturing business plan should include some basic elements. Below is a breakdown of what should be included.

Executive Summary

An executive summary involves a short description of your manufacturing business.

- Why it matters : You can use the executive summary to make a good impression on readers.

- What to include : Get the ball rolling by providing your mission statement, a summary of your business financial situation, and the products you plan to manufacture.

Chase the vision, not the money, the money will end up following you. – Tony Hsieh, Zappos CEO

Business Description

A description of your business goes beyond your goals, it gets into a detailed description of the products you plan to offer.

- Why it matters : Even if you don’t have a physical product in hand, this section should illuminate exactly what you plan to sell. Anyone who reads this document should know exactly what you are selling.

- What to include : Share what makes your product special, from a customer’s point of view. While this idea might be your baby, you need to create a product that customers want to buy.

The only thing worse than starting something and failing… is not starting something. – Seth Godin, Squidoo founder, author and blogger

Market Analysis

An overview of the competition can help you understand where your business can stand out.

- Why it matters : Scope out the competition to determine where you can outshine your competitors. For example, if your competitors are missing a key product feature, try to include that in your product.

- What to include : Find statistics about the industry, potential customer demographics, and current industry trends.

Marketing and Sales Strategies

You don’t have a business until you make sales to your customers.

- Why it matters : Outline exactly how you plan to get your product into the hands of eager customers.

- What to include : Build out a strategy on how you plan to reach customers and make sales. Maybe you already have a list of people who have asked about this type of product, or you know exactly where your target customer hangs out online.

Operational Plan

The operational plan includes how you plan to go from idea to delivered product.

- Why it matters : Manufacturing businesses rely on efficient operations to create worthwhile profits.

- What to include : Map out how you will get your hands on a physical product that meets all of your requirements. Don’t forget to write down the final steps of getting that physical product in your customer’s hands.

Management and Organization

The right team can make all the difference to your business.

- Why it matters : Any potential investors or lenders will want to confirm your team has the necessary experience to succeed.

- What to include : Start by highlighting any management team members. From there, include an organizational hierarchy that highlights any decision-makers and a complete staffing plan.

Financial Projections

Finally, your business plan should include some basic financial projections.

- Why it matters : Anyone with a stake in the company, including yourself, wants to know what the potential rewards are.

- What to include : Share your financial projections in great detail. At the very least, you should include any manufacturing loans , equipment financing plans , start-up costs, revenue projections, a sample profit and loss statement, a balance sheet, and a break-even analysis. Be realistic when tallying up any of these numbers.

Benefits of Having a Manufacturing Business Plan

- Providing a roadmap : A business plan gives you some direction to aim for as you build your business.

- Attracting investors and securing funding : Investors and lenders will want to see a carefully developed business plan before committing to any funding.

- Guiding day-to-day operations and decision-making : As you build the business, you can refer to this document as a guide when it’s time to make decisions.

- Mitigating risks : You can potentially spot problems before hitting the obstacle in real life. This gives you a chance to think of effective solutions.

- Identifying opportunities : When you evaluate the market, you should look for any opportunity to stand apart from the crowd.

- Monitoring progress and setting measurable goals : It’s easy to get lost in the process of building your business. A written plan gives you a way to measure your progress.

Anything that is measured and watched, improves. – Bob Parsons, GoDaddy founder

How to Write a Manufacturing Business Plan

As you build out your business plan, here are some steps to follow:

- Start with a template : A free online template can give you a starting point if you aren’t sure where to get started.

- Visualize success : As you write out each section, you should keep your vision of success in your mind’s eye. Consider building a vision board to keep on hand during the process.

- Make the time : It will take time and energy to build a worthwhile business plan. Give this task the time it deserves.

Tips for Crafting a Compelling Manufacturing Business Plan

- Do your homework : Back up all of the claims you make in your business plan with facts. A business plan isn’t the place to dream, it’s the place to set realistic goals.

- Focus on your competition : A close look at your competition is a useful way to see where you can make your own mark on the industry. Look for gaps in their strategy that you could fill for customers.

- Be conservative with your numbers : It’s better to exceed expectations than to miss the mark.

- Ask for help : If you run into questions, reach out to a mentor for help.

Mistakes to Avoid When Creating Your Manufacturing Business Plan

- Don’t skip legal advice : The legal structure of your business might require a professional opinion. It’s a good idea to reach out to professionals with any questions you have.

- Don’t skimp on the numbers : The financial projections are a key component of your business plan. Always be realistic and honest with yourself as you build out these projections.

- Avoid industry jargon : Anyone should be able to understand your vision when they read your business plan clearly.

Bottom Line

A manufacturing business plan offers a roadmap that points to your ultimate business success. It’s tempting to do a sloppy job on this document that only you might read. But it’s critical to do your research and organize your thoughts in a business plan. If you are starting a manufacturing business , don’t skip this step.

This app literally changed my like. It provides a great experience. I absolutely love it!

About the Author

Sarah Sharkey

Sarah Sharkey is a personal finance writer who enjoys helping people make better financial decisions.

Related Articles

What Does Manufacturing Mean in Business?

Manufacturing Grants: Fueling Industry Growth

Manufacturing Startups: What Are They & How to Start One

Manufacturing Equipment Financing: Know Your Options

How to Start a Manufacturing Business: A Step-by-Step Guide

- Contact sales

Start free trial

Production Planning in Manufacturing: Best Practices for Production Plans

As the creation of products and services has become more extensive and varied, the manufacturing industry has become more competitive. There are many things to keep an eye on such as material requirements planning, supply chain management and inventory control. Operations continue to become more complex, and this means manufacturing companies require more thorough production planning.

A production plan is the best way to guarantee you deliver high-quality products/services as efficiently as possible.

What Is Production Planning?

Production planning is the process of deciding how a product or service will be manufactured before the manufacturing process begins. In other words, it is how you plan to manage your supply chain, raw materials, employees and the physical space where the manufacturing process takes place.

Production planning is very important for manufacturers as it affects other important aspects of their business such as:

- Supply chain management

- Production scheduling

- Material requirements planning

- Production lead time

- Capacity planning

ProjectManager is a project management software that helps manufacturers cover every aspect of production planning. Plan with Gantt charts, execute with kanban boards and manage your resources along the way. No other software offers sophisticated project and resource management features in one intuitive package. Get started today for free.

Why Is Production Planning Important?

If a manufacturing operation wishes to expand, that evolution demands careful production planning and production scheduling. Someone must take on the responsibility of managing resources and deciding how they will be allocated. This process is a big part of capacity planning —how much can be made in a certain period of time, with the available resources?

Without production planning, it is easy to use too much of a resource for one product and not leave enough for another, or fail to schedule your resources properly, which results in delays that affect your overall production management process. It’s just as easy to let resources go to waste. These issues indicate a lack of efficiency in your production planning process.

Production planning is the best way to ensure resources are used appropriately, products and services are high-quality and nothing goes over budget .

Get your free

- Production Schedule Template

Use this free Production Schedule Template for Excel to manage your projects better.

Types of Production Planning

Every operation is unique, and the same production plan isn’t right for everyone. In order to get the most from project planning, you need to decide which method is best for your manufacturing process. Here’s a quick intro to the different types of production planning.

The job method is often used when manufacturing a single product, for which a unique production plan is created. This production planning method is generally used in smaller-scale productions, but it can also be applied to larger manufacturing facilities. The job method is especially advantageous when a production order requires specific customizations.

Batch Production Method

Batch production consists in manufacturing goods in groups, instead of being produced individually or through continuous production . This method is useful when manufacturing products on a large scale.

Flow Method

The flow method is a demand-based manufacturing model that minimizes the production lead time by speeding up the production line. The manufacturing process starts based on work orders, and once it starts, it doesn’t stop until all finished goods are produced. This is called continuous production and it’s achieved by using machinery and little intervention to minimize waiting time.

Process Method

The process method is more or less what most people picture when they think about production—an assembly line. With the process method, there will generally be different types of machinery completing separate tasks to put together the finished goods.

Related: 10 Free Manufacturing Templates for Excel

Mass Production Method

The mass production method is primarily focused on creating a continuous flow of identical products. It’s similar to the flow method, but at a much bigger scale, which cuts production costs. When uniformity is just as critical as efficiency, you need to use “standardized processes” to guarantee all products look exactly the same.

What Is a Production Plan?

A production plan is a document that describes how production processes will be executed, and it’s the final outcome of the production planning process. It describes the human resources, raw materials and equipment that will be needed and the production schedule that will be followed.

The person responsible for production planning must also be very familiar with the operation’s inner workings, project resources and the products/services they produce. This usually entails collaborating with people on the floor, in the field or in different departments to create products and deliver services.

This free production schedule template helps you keep track of the status of your production orders, starting and ending production inventories, due dates and more.

How to Make a Production Plan

When you set out to create a production plan, make sure to follow these steps to make it as robust as possible.

1. Estimate/Forecast Product Demand

Understanding product demand planning is the best way to decide which product planning method is the best choice for your operation. You’ll need to use diverse sales forecasting techniques to better understand what will be the future demand for your product. From here, you’ll be able to estimate which resources are required and how they’ll be used in the manufacturing process.

2. Access Inventory

Accessing inventory is about more than simply taking stock: you should make an inventory management plan so that you don’t experience shortages or let things go to waste. For this step, focus on the inventory control and inventory management techniques you can use to handle inventory in the most efficient way possible.

3. Create a Production Budget

A production budget is a document that’s used to calculate the number of units that should be produced by a company to meet the customer demand for a period of time such as a month, quarter or even a year.

Creating a production budget involves doing an assessment of the current product inventory, the production capacity, sales forecasts and the ending inventory that should remain at the end of the time period. Once you analyze these variables and use the production budgeting formula, you’ll know what’s the required level of production for a given time period.

4. Resource Planning

A successful production plan requires you to be familiar with the resource planning details of the manufacturing process. Note the minimum number of people and raw material requirements necessary to create a product or execute a service. You need to also consider what machines and systems are essential for executing your production plan.

Related: Free Resource Plan Template for Excel

5. Estimate Production Costs

Once you’ve determined what the required level of production is and the resources that will be needed, you’ll need to estimate the cost of production . It’s important to make sure the production process will be profitable before creating a production schedule.

6. Create a Production Schedule

Now it’s time to create a production schedule based on the sales forecasts, production capacity and production budget that you’ve outlined. Making a production schedule is key to making sure your manufacturing team delivers products on time, but also guides efforts in other areas such as supply chain management and logistics management.

7. Production control

As production takes place, monitor how the results compare to the production schedule and resource management projections. This is something that should continually take place and be documented during the production process. Production control is especially important for the fifth step in the production planning process.

8. Adjust the Plan to Make Production More Efficient in the Future

The final step of production planning is to reflect on the information you gained in step four and strategize what can be done to make the production plan run more smoothly in the future. Production planning is about manufacturing a product or service, yes, but it should also be a learning experience for creating even better production plans for next time.

Common Production Planning Mistakes

You must stay vigilant of common missteps, as you go through the production planning process. Here are three mistakes often made during production planning. Luckily, they can be prevented.

Not Expecting the Unexpected

This means having risk management strategies in place if things go awry. The goal is to never have to employ them, of course, but it’s better to have them and not need them. Production planning is not complete if it doesn’t anticipate risks, issues and changes. When you plan for them, you’re ready to problem-solve if and when they happen.

Getting Stuck Behind the Desk

You should work with intelligent production planning tools, but that doesn’t mean you should only rely on enterprise resource planning software for production planning and not oversee resources and manufacturing operations in person. When production planning is only done from behind a screen, the end result will not be as informed as it could be. The best production planning is active and collaborative.

Neglecting Equipment

In order to get the most from your equipment, you need to take care of it. This means tracking usage and keeping up with regular maintenance. This looks different depending on the industry and product or service, but the principle is the same: continually take care of your equipment before it becomes a problem that will slow down production.

Production Planning Best Practices

No matter what product or service is being manufactured, there are many tried-and-true best practices to increase your operational efficiency . When creating a production plan, keep these two in mind.

Make Accurate Forecasts

When you don’t properly estimate the demand for your product or service, it is impossible to create a detailed production plan. Demand planning is never static. You need to consider buying trends from previous years, changes in demographics, changes in resource availability and many other factors. These demand planning forecasts are the foundation of skillful production planning.

Know Your Capacity

Capacity planning means knowing the maximum capacity your operation can manage—the absolute most of a product or service it can offer during a period of time. This is the only way to anticipate how much of each resource you will need in order to create X amount of products.

When you don’t know the production capacity , your production planning is like taking a shot in the dark.

Use ProjectManager for Production Planning and Scheduling

As the nature of manufacturing goods and services changes, you need modern tools to plan production and make schedules. ProjectManager is an award-winning project management software that offers all the tools you need for excellent production planning and scheduling. With it, you can plan projects, create schedules, manage resources and track changes with one tool.

Plan with Gantt Charts

Manage your product manufacturing across a timeline with our Gantt chart view. With it, you can view your resources to help you track your cost of production to make sure you’re never overspending. You can then link any dependent tasks to avoid bottlenecks in your manufacturing.

Get a Birds-Eye-View

To keep your production plan on track, you need to have a high-level view so that you can pinpoint setbacks before or as they occur. Our real-time dashboard collects your data and converts it into colorful graphs and charts that give you at-a-glance analytics.

Easily Measure and Report Your Progress

Any operation will have stakeholders, and they want to be kept in the loop. ProjectManager’s project status reports make it easy to share key data points. They can be generated in a single click, making it simple to generate them before important meetings.

Related Production Planning Content

The production planning process involves many different activities such as estimating the quantity of goods to be produced, the resources that will be needed, the production schedule and much more. That’s why we’ve created dozens of blogs, guides and templates on production-related topics. Here are some of them.

- Production vs. Manufacturing

- How to Make a Production Flow Chart for Manufacturing

- Best Production Scheduling Software Rankings

- How to Create a Master Production Schedule (MPS)

Manage every detail of your operation with ProjectManager’s powerful cloud-based project management tools. Our suite of tools is trusted by tens of thousands of teams, from NASA to Volvo, to aid them in the planning, scheduling, tracking and reporting on the progress and performance of their production plans. Our software makes lets you get out from behind your desk and make adjustments on the go. Try it for yourself for free for 30 days!

Deliver your projects on time and under budget

Start planning your projects.

All Formats

Plan Templates

15+ manufacturing business plan templates.

If you’re striking out on your own to start a business, whatever sort it might be, you will benefit from having a business plan template to work from. Such a tool will aid you in your crucial planning and takeoff stages. But there’s more to a business than getting started, and how you proceed from there will largely grow out of the conditions you’ve set for yourself in your business plan. This becomes especially important when you are getting into commodity production. Nowhere else is your command of production lines, personnel, and funding going to be so hard-pressed as in a simple manufacturing business.

Plan Template Bundle

- Google Docs

Construction Business Plan Template Bundle

Construction Business Continuity Plan Bundle

Construction Marketing Business Plan Template Bundle

Manufacturing Business Plan Template

Factory Business Plan Template

Business Plan Outline in Word

Printable Business Plan Template in Word

Simple Business Plan Template

Business Continuity Plan Template

Editable Marketing Business Plan Template

Retail Business Plan Template

Food Manufacturing Business Plan Template

Clothing Manufacturing Business Plan Template

Brick Manufacturing Business Plan Template

Manufacturing Business Continuity Plan Template

What Goes into a Manufacturing Business Plan?

- Executive summary . Here is where you condense your business’s intended purposes and goals. What is your mission-vision statement?

- Company description. Define the nature of your intended business, the commodities you are producing, where you will be located, etc.

- Market analysis . Where do you fit in the larger economy and what your relationship will be to existing businesses and competition? Define your target market and your role in fulfilling a real economic need.

- Strategy and implementation. Here you propose your methodology to achieve your goals.

- Management and organization. Assign your founding team and determine its structure and member responsibilities.

- Financial plan and projections. Estimate a budget and forecast your earnings.

- See also Manufacturing Business Marketing Plan to go from production to marketing.

- Also, see Manufacturing Business Continuity Plan above to establish a sustainable company.

Garment Manufacturing Business Plan Template

Furniture Manufacturing Business Plan Template

Manufacturing Business Marketing Plan Template

Manufacturing and Operation Plan Template

How to Use These Plan Templates

- They will give you the outline of an effective, comprehensive, and adequately detailed business plan.

- They will provide key insights into the real considerations you have to take into account per business type.

General FAQs