Root-cause problem solving in the Ops 4.0 era

Passionate about the “human factor”: helping people develop broad skills and deep functional expertise. Experienced operations practitioner, faculty member, and author.

Wouter Michiels, a consultant based in the Brussels Office, has more than 10 years’ experience in petrochemical manufacturing, engineering, and supply chains.

April 15, 2019 To improve, organizations must consistently seek out and solve their problems—an insight that underpins lean management ’s emphasis on root-cause problem solving (RCPS). Indeed, companies that have used RCPS to build a problem-solving culture that lasts are able to avoid continuous firefighting by effectively preventing fires from starting.

But RCPS takes discipline and patience, which some leaders resist: a manager may be reluctant to use this model if she’s convinced that she has already identified an “operational solution.” Nevertheless, persuading her to join her team on a problem-solving journey can help uncover a more effective and sustainable set of solutions—most importantly by including the people who know the problem best: shop-floor employees. Their perspective often shows that the initial idea would not have addressed the problem’s real causes, and would have met with a lot of resistance from the people charged with implementation.

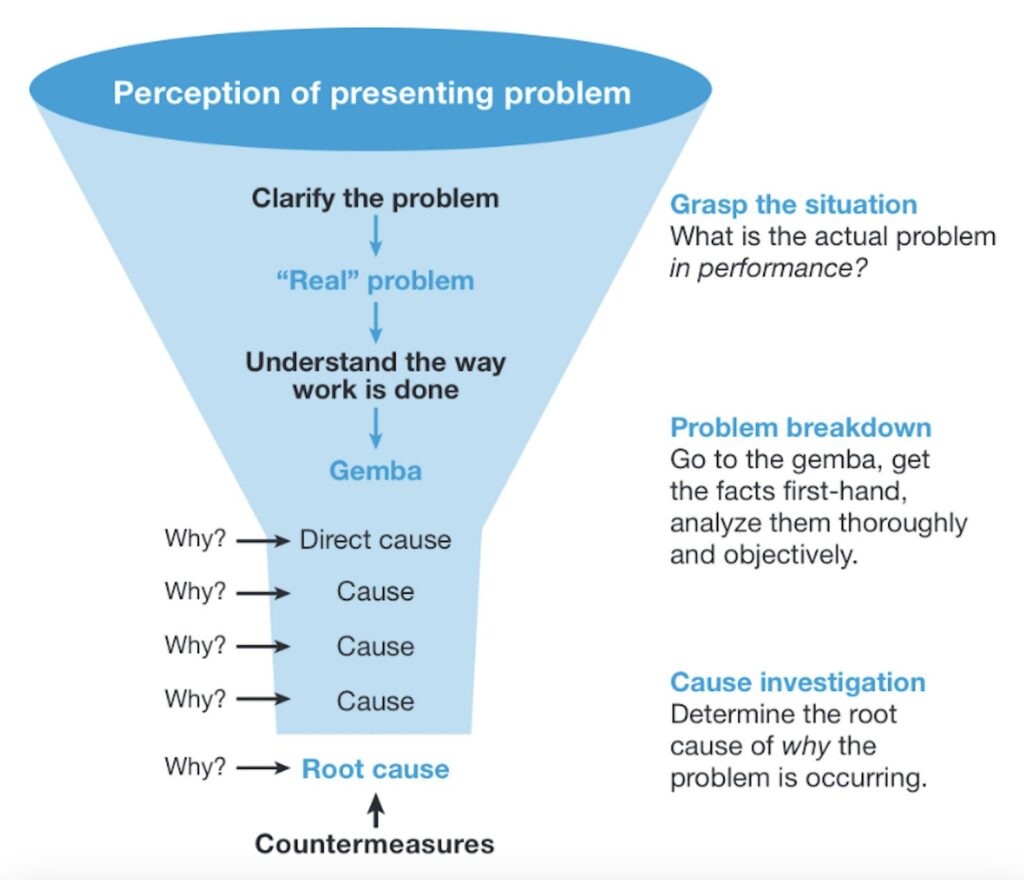

Ops 4.0 technologies are making it easier to overcome that resistance and invigorate root-cause problem solving performance. What follows is a non-exhaustive overview of how different technologies ( italicized ) could be applied in each of the five RCPS elements (exhibit).

1. Identifying and defining the problem

The rise of advanced analytics and business-intelligence applications allows companies can detect many more problems than in the past, and in a more effective way—so long as they have sufficient internal support to interpret the output . Examples include fraud detection in banking and insurance, as well as deviations from normal operating conditions of equipment in manufacturing plants. For the latter, the increased availability of high-frequency, high-precision sensors , together with the rise of the Internet of Things provides companies with larger data sets from which to identify problems.

2. Assessing root cause(s)

Once the problem is defined, root causes are often identified via the five-why methodology. Instead of using the traditional colored sticky notes to facilitate this exercise, companies can now use interactive whiteboards incorporating speech-to-text or handwriting-to-text algorithms, together with high-quality touch commands . Moreover, the whiteboards can link to data warehouses , thereby enabling self-service analytics or even machine-learning algorithms for performing the analyses required in confirming or rejecting potential root causes.

3. Designing solutions

Augmented- and virtual-reality applications can help designers’ creation process become even more productive. Faster iterations between the drawing board and a more real-life representation shorten lead times toward final design. Rapid prototyping and 3D printing can accelerate this process even further by bringing intermediate versions of the solution to life.

4. Testing solutions

Once a solution has been designed, it is crucial to test its efficiency and effectiveness. The increase in computing power enables companies to perform extensive computational simulations . Using digital twins helps organizations create virtual mirrors of their operations, allowing them to test ideas more realistically before implementation.

5. Sustaining, sharing, and continuously improving

The digital communication and collaboration platforms that are now in widespread use can often be linked with interactive tools such as digital whiteboards, minimizing the time teams spend on documentation so they can instead focus on the creative parts of problem solving. Having past records of problem-solving sheets available at only one touch avoids solving the same problem all over again.

The above list shows how the ancient art of root-cause problem solving can take shape in today’s environment. The question for most organizations is how to start, especially with technologies that can sound like science fiction. A learning center designed to replicate an actual, digitally enabled working environment can provide the first step, helping people experience the impact these technologies can achieve in a practical and realistic setting.

Connect with our Operations Practice

- MY LCI Login

- LCI Design & LCI Engineering Design Award

- Our Mission & Vision

- Our Strengths

- History of LCI

- How We Serve

- Board of Directors

- LCI Congress 2024

- Lean in Design Forum 2024

- Respect For People

- Communities

- New to Lean

- Learn by Pathway

- For Designers

- For Constructors

- Field Crew Huddle

- Assessments

- Classroom Learning

- Instructor Program

- LCI Publications

- Learning Videos

- Partner Programs

- Simulations

- Certification FAQs

- Certification Practice Quiz

- Designation Directory

- Lean Construction

- Lean Design

- Lean Project Delivery

- What is Lean?

- Founder’s White Papers

- Lean Construction Journal

- LCI Research

- Newsletter Archives

- Past Event Presentations

- Blog & Buzz

- Lean Consultant Members

- Member Directory

A Root Cause Analysis Framework: 5 Why

Introduction to root cause analysis & 5 whys.

In design and construction, problems are somewhat like viruses. Workers know that problems are bound to happen but can’t necessarily predict when, where, or to what extent they’ll occur. Small problems are nothing to be scared of, much like a head cold. But even small issues in the process deserve to be investigated with your team.

When problems do arise, workers may feel the urge to dismiss the symptoms and assume that they’ll fix themselves in time. This can lead to a snowball effect in which the problem, unchecked, becomes more aggressive and more damaging to the project’s outcome.

By the time the team is ready to deal with the problem, they may be forced to waste resources they could have saved if they had attacked the problem right away. The goal of Lean thinking is to increase collaborative problem solving and improve communication channels , providing teams with the means to recognize and address problems immediately so they do not transform into more destructive issues later.

Root Cause Analysis Definition

A systematic method of analyzing possible causes to determine the root cause of a problem.

Root Cause Analysis

Root Cause Analysis (RCA) is a tool that helps teams discover not only what went wrong, but also provides members with the framework to develop a countermeasure to prevent future occurrences of the issue – similar to how the immune system learns to recognize viruses it has seen before to prevent them from causing harm in the future.

Applying Root Cause Analysis

The first step to effectively applying Root Cause Analysis is to learn how to identify problems. The ability to see problems in a process is required for Kaizen thinking to take place and for continuous improvement to drive processes forward.

The moment a problem is identified, teams should gather all of their collective knowledge together to extinguish the issue as quickly as possible before it snowballs into something worse.

5 Why Analysis

Developed by Japanese professor Kaoru Ishikawa , 5 Why Analysis is a simple but effective RCA method and can be used for both small and moderately sized problems. Complex issues may require 5 Why Analysis to be conducted in conjunction with other Lean problem solving methods such as A3 Thinking and PDCA (Plan, Do, Check, Adjust).

When conducting 5 Why Analysis or any other type of Root Cause Analysis, it’s important to operate with the process in mind rather than the people. Finger pointing is counterproductive and does not align with a culture of Respect for People .

Lean methods encourage workers to continuously improve upon the process so that the outcome delivers maximum value to the stakeholder. If a problem has arisen on the job site, it’s a sign that a closer analysis of the process is necessary.

What is 5 Why Analysis?

A root cause analysis tool used to dig for the root cause of a condition by asking why successively (at least five times) whenever a problem exists in order to get beyond the apparent symptoms. As each answer to the why question is documented, an additional inquiry is made concerning that response.

5 Whys Example

Let’s examine a practical root cause analysis example of a problem that workers may encounter on the construction site and how 5 Why Analysis can be used to tackle the source of the issue.

- Problem Statement : 3rd floor electrical work did not finish on time. (Why?)

- First Why : We were missing two workers from the crew. (Why?)

- Second Why : The electrical PM sent them to a repair. (Why?)

- Third Why : The PM did not know eight men were needed. (Why?)

- Fourth Why : The PM was not involved in the planning. (Why?)

- Fifth Why : Only the foreman was invited. (Root Cause)

This example is a good illustration of why it’s important to continue digging for the root cause when performing a Root Cause Analysis.

If the team had stopped asking “why” at an earlier stage of the process, the team may have made the assumption that the two workers were missing from the crew because they were neglecting their jobs. There likely would have been finger pointing at specific members of the team for failing to complete the work in time. In reality, the root cause was a problem with the process rather than with the people.

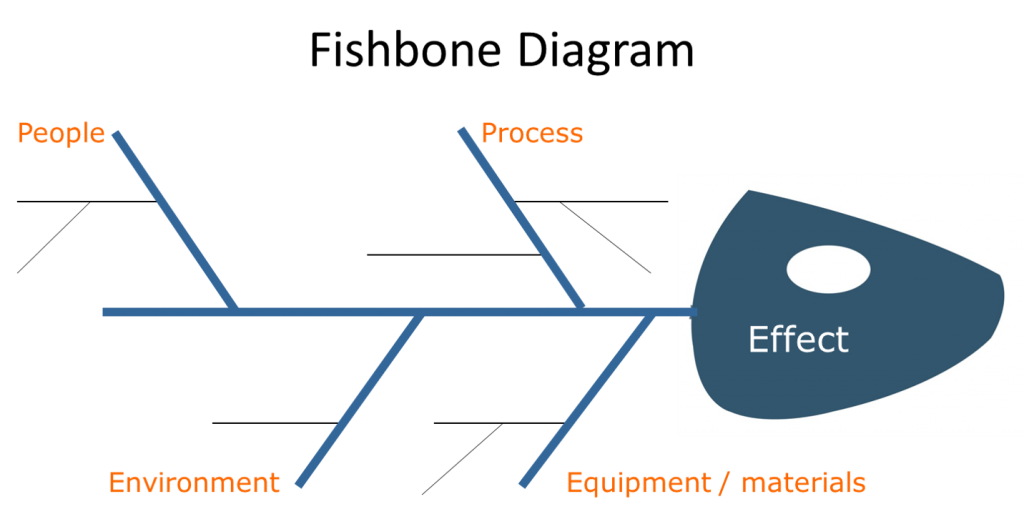

Fishbone Diagram

A fishbone diagram for root cause analysis allows teams to investigate and consider several possible root causes to a singular problem. Used in conjunction with 5 Whys and PDCA thinking, this Root Cause Analysis template helps to provide a fuller picture of what went wrong and how to address it.

Benefits & Drawbacks

5 why analysis benefits.

- 5 Why Analysis forces teams to advance past the symptoms that they may otherwise stop at as “root causes” and dive deeper into the causes of those symptoms.

- The process allows teams to identify the relationship between various factors that can lead to a chain reaction.

- 5 Why Analysis helps teams prevent future similar problems from occurring. This follows the Lean mindset of continuous improvement.

- The process is easy to learn and implement. You don’t need any sort of analytical background to utilize it.

5 Why Analysis Drawbacks

- The process isn’t easily repeatable. A person analyzing the problem through a different lens may come to a different conclusion. Sometimes there are more than one possible causes to complex problems, which is why 5 Why Analysis is often used in combination with other Lean methods for bigger problems.

- You can only operate within the information you know; you can’t find the actual root cause if you are lacking important information.

- Generally, a single root cause is identified at the end of the process when, in reality, some problems result from a number of errors (also common in bigger problems).

Learn Root Cause Analysis & 5 Why

The Lean Construction Institute is committed to transforming the design and construction industry by providing Lean educational resources , conducting research , and facilitating local and national Lean events . Explore supplementary resources to further your understanding of root cause analysis and 5 why analysis below.

Lean Assessments

How strong is your Lean knowledge? Take a Lean assessment to determine your current state so you have a baseline for improvement. Lean assessments are available for individuals, teams, and organizations alike. Whether you’re new to Lean or are an experienced Lean practitioner, Lean assessments are a great way to get started at LCI!

William R. (Bill) Seed, Executive Editor

Executive Editors: Kristin Hill, Katherine Copeland and Christian Pikel

More lean topics.

From 5s to IPD, explore popular Lean design and construction topics below.

- Quality Management

Home » Free Resources » »

What is Root Cause Analysis? Process, Example & Everything You Need to Know

- Written by Contributing Writer

- Updated on March 7, 2023

Root cause analysis (RCA) is a problem-solving methodology used to identify the underlying cause of a problem, incident, or adverse event. Simply put, it is pinpointing the root of the problem to solve and prevent it from happening again.

When faced with a problem, we usually try to get to the bottom of it. For example, in the unfortunate event that we break our bones, we would be in immense pain. We might take measures to control the pain and blood loss. But our efforts don’t stop at simply having a painkiller and applying a bandage. We rush to the ER as soon as possible, get the necessary treatment to mend the broken bones, and make sure we are careful not to have such an accident.

What we did here is we analyzed the problem: the pain and took steps to fix the root cause, which is the broken bones. Here the pain is the symptom, and the fractured bone is the root cause.

Now that we are familiar with what it stands for let us dive deep into root cause analysis, or RCA, which is the systematic approach employed in various industries like healthcare, manufacturing, governmental organizations, aviation, etc. We also examine its definition, history, benefits, approaches, process, principles, tips, and how to learn more .

Defining RCA Analysis

Root cause analysis is a problem-solving process that seeks to identify the underlying cause of a problem or issue. It’s a systematic approach that goes beyond just identifying symptoms and aims to uncover the root cause of the problem. The objective is to prevent future occurrences of the situation by addressing its root cause.

RCA analysis involves collecting and analyzing data to identify a problem’s underlying cause. The process typically consists of a team of experts who use various tools and techniques to gather and analyze data. Once the root cause has been identified, the team develops a plan to address the root cause and prevent future occurrences of the problem.

Also Read: What Is Process Capability and Why It’s More Interesting Than It Sounds

History of Root Cause Analysis

The origins of root cause analysis can be traced back to the late 19th century when it was used in the manufacturing industry to improve production processes. In the 20th century, it was further developed and applied to a broader range of industries, including healthcare and aviation.

In the 1950s when manufacturers started to use it to understand industrial events. The primary goal of RCA is to determine the fundamental cause of a problem, which is referred to as the “root cause.”

One of the earliest adopters of RCA was Toyota, who employed the “5 whys” method, where the investigation of a breakdown or undesired event is conducted by asking “why” at least five times. This approach forces quality personnel to delve deeper and understand the underlying causes, layer by layer. Today, RCA is widely used in various industries to identify and eliminate problems, improve processes, and prevent recurrence.

RCA was first used in the healthcare industry to address adverse events and improve patient safety. The Institute of Healthcare Improvement (IHI) developed the RCA process in the late 1980s, and it quickly became a standard tool for improving patient safety and quality of care.

The Joint Commission, a US-based nonprofit that accredits healthcare organizations and programs, requires a root cause analysis (RCA) to be conducted whenever an accredited hospital experiences a specific type of adverse event. These are known as “sentinel” incidents, as they reveal a dangerous flaw in the care provided and prompt an immediate investigation and response.

RCA was developed in response to the growing number of plane crashes and incidents in the aviation industry. The National Transportation Safety Board (NTSB) was established in 1967. It has since been using RCA to investigate plane crashes and incidents to identify their root causes and prevent future occurrences.

Benefits of Root Cause Analysis

Before we go to explore how various industries and organizations benefit from implementing RCA, let us discuss the primary goals of root cause analysis.

The three main goals of RCA are:

- Identifying the root cause: The first goal is to discover the primary source of the problem or event. This is essential to understand the underlying causes and find practical solutions.

- Understanding the issues: The second goal of RCA is to fully comprehend the nature of the issues and develop a plan to fix, compensate, or learn from them. This requires a comprehensive analysis of the root cause and the factors contributing to it.

- Applying learnings: The third goal of RCA is to use the information gained from the analysis to prevent similar problems from occurring in the future. This includes making systemic changes to processes and systems and implementing measures to mitigate the risk of future adverse events.

Root cause analysis offers numerous benefits to organizations and industries. Some of the key benefits include:

- Improving quality: RCA helps organizations identify the root cause of problems and implement solutions to prevent future occurrences, improving quality and efficiency.

- Reducing risk: Organizations can reduce the risk of future incidents and adverse events by identifying the root cause of the problem and hence improving overall safety and security.

- Enhancing customer satisfaction: Organizations can better manage their product issues by addressing the root cause of problems. Thus organizations can improve customer satisfaction and trust.

- Improving organizational learning : RCA provides organizations with a systematic process for learning from problems and incidents, enabling them to improve their processes and procedures continuously.

- Increasing efficiency and productivity: Organizations can improve their processes and procedures by addressing the root cause of problems, leading to increased efficiency and productivity.

Also Read: Demystifying the Theory of Constraints

Top Approaches of Root Cause Analysis

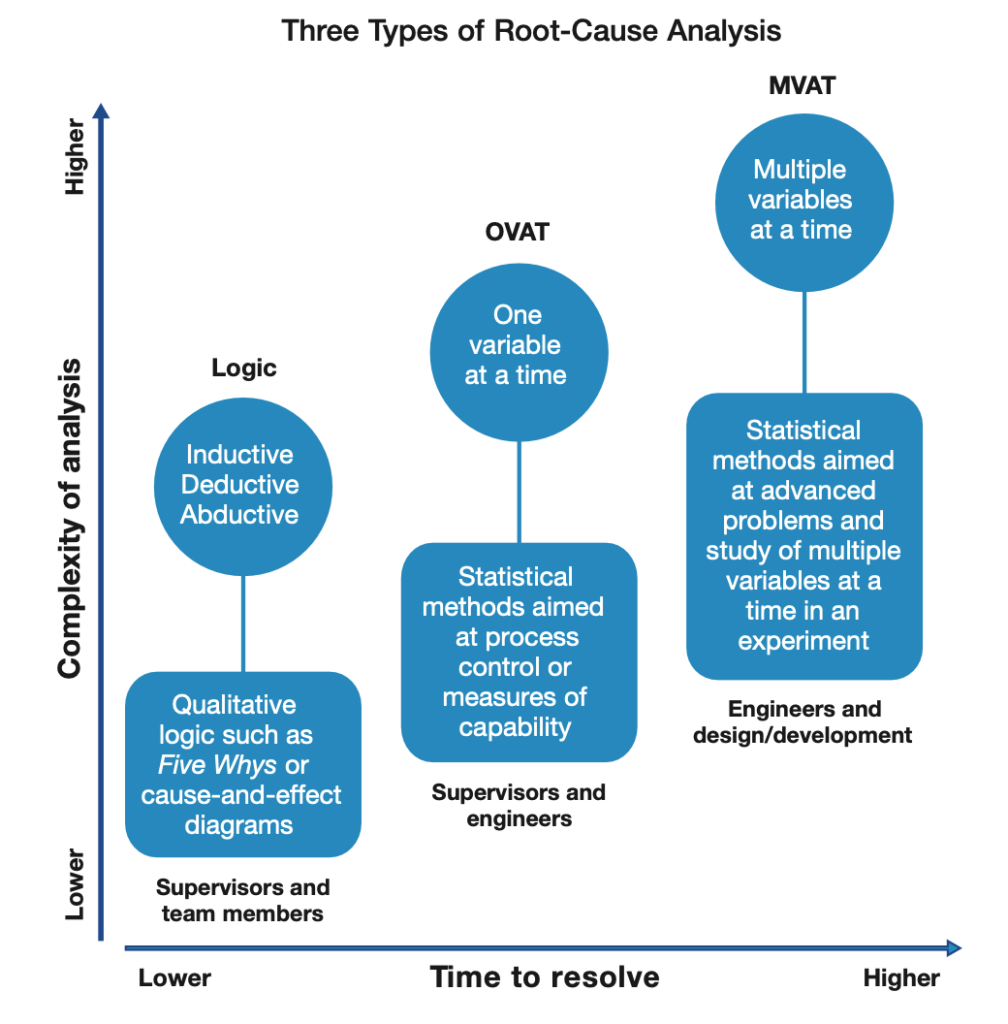

There are several approaches to root cause analysis, each with its unique methodology and tools. Let’s discuss some of the most commonly-used types of root cause analysis.

The 5 Whys Root Cause Analysis

The 5 Whys root cause analysis approach is beneficial for solving simple problems or identifying root causes in a short amount of time. This simple yet effective approach involves asking “why” questions to identify the root cause of a problem. The process is repeated until the root cause is identified. For example, in a service industry setting, in case of a complaint, by asking “why” five times, the team could drill down layer by layer to understand the underlying causes of the problem, such as poor communication, inadequate training, or poor service quality.

Fishbone Diagram

The Fishbone Diagram is a visual tool that helps teams identify potential root causes of a problem. It is called so because it resembles a fishbone. The fishbone diagram organizes and categorizes possible causes, making it easier to identify the root cause. For example, a fishbone diagram could be used in a manufacturing setting to categorize and analyze the various factors contributing to a machine breakdown, such as equipment design, operator error, or poor maintenance.

Pareto Analysis

The Pareto Analysis approach uses statistical analysis to identify the most significant root causes of a problem. The Pareto principle states that 80 percent of issues are caused by 20 percent of root causes. Pareto analysis helps teams focus on the most critical root causes, reducing the time and resources required to address the problem. For example, in a healthcare setting, a Pareto analysis could determine that 20 percent of patient falls are caused by 80 percent of the root causes, such as slippery floors, poor lighting, or lack of staff supervision.

Fault Tree Analysis (FTA)

This type of root cause analysis is a graphical representation of the relationships between different system components and how they contribute to a problem or failure. FTA helps teams understand the interdependencies between various components and identify the root cause of a problem. For example, in an aviation setting, an FTA could be used to analyze the interdependencies between different components of a plane, such as the engines, fuel system, and control surfaces, and to identify the root cause of a crash.

Conducting Root Cause Analysis: Process

We can break the process of conducting RCA into the following steps:

- Define the problem: The first step is clearly defining the problem and understanding what needs to be addressed.

- Gather data: Once the problem is defined, the next step is to gather data. This involves collecting information about the problem, including date, time, and location, as well as any relevant documentation, reports, or other information.

- Form a team: The next step is forming a team of experts responsible for conducting the RCA. The team should include individuals with expertise in the problem area, as well as representatives from different departments or parts of the organization.

- Use a root cause analysis tool: The team should use a root cause analysis tool, such as a fishbone diagram, Pareto analysis, or fault tree analysis, to help identify potential root causes.

- Identify root causes: Once potential root causes have been identified, the team should use the data and information collected to validate and verify the root causes.

- Develop solutions: Once the root cause has been identified, the team should develop solutions to address the root cause and prevent future occurrences of the problem.

- Implement solutions: The final step is to implement the solutions and monitor their effectiveness to ensure that the problem has been fully resolved.

Also Read: Value Stream Mapping in Six Sigma

Root Cause Analysis Principles

Conducting RCA involves following several fundamental principles:

- Root cause focus: Root cause analysis focuses on discovering and correcting the root causes of a problem rather than just treating the symptoms.

- Short-term relief: While focusing on root causes is essential, it’s also important to provide short-term relief for the symptoms.

- Multiple root causes : Multiple root causes can contribute to a problem, so it’s important to identify all of them.

- No blame: The focus should be on understanding how and why a problem occurred rather than who was responsible.

- Evidence-based: Root cause claims should be supported by concrete cause-and-effect evidence.

- Actionable information: The results of the analysis should provide enough information to inform a corrective course of action.

- Future prevention: Consideration should be given to how the root cause can be prevented from recurring.

Tips for Root Cause Analysis

- Start with a clear definition of the problem: It is essential to have a crystal-clear understanding of the problem before starting the RCA process. This will help ensure that the team is focused on addressing the right issue and that the root cause is accurately identified.

- Gather all relevant data: Data is essential for a successful RCA. The team should gather as much relevant data as possible, including the date, time, and location of the problem, as well as all pertinent documentation, reports, or other information.

- Involve experts from different areas: Involving experts from different areas of the organization, such as operations, maintenance, and engineering, will help ensure that the root cause is accurately identified and that all potential root causes are considered.

- Use multiple tools and techniques: Different RCA tools and techniques, such as fishbone diagrams, Pareto analysis, and fault tree analysis, can provide different perspectives and insights into the root cause of a problem. The team should consider using multiple tools and techniques to ensure they completely understand the problem.

- Be thorough and systematic: RCA should be approached systematically, using a structured process and methodology to identify root causes. The team should be detailed and methodical in their approach to ensure that all potential root causes are considered and that the root cause is accurately identified.

- Focus on prevention: The goal of RCA is not just to identify the root cause of a problem but to prevent future occurrences. The team should focus on developing solutions that will prevent the problem from happening again in the future.

Also Read: Demystifying Kaizen Lean Six Sigma

Master Root Cause Analysis Skills to Become a Lean Six Sigma Expert

For a Lean Six Sigma expert, the ability to identify the underlying causes of problems and develop effective solutions for improving processes and outcomes is a prized skill. As such, you need to understand and know how to perform root cause analysis.

If you’re interested in becoming a Lean Six Sigma expert, an online Lean Six Sigma certification can provide you with the knowledge, skills, and tools you need to succeed in this role.

An online bootcamp like the one delivered by Simplilearn, in collaboration with the University of Massachusetts, covers the core concepts of Lean Six Sigma, including problem-solving methodologies, process improvement techniques, and statistical analysis tools. This IASSC-accredited program teaches how to identify and eliminate waste, reduce defects, and improve process efficiency across various industries.

With business mentoring from industry experts from KPMG, you’ll be able to tackle real-world business problems confidently. This fast-track program is perfect for quality professionals, business analysts, and executives looking to carve successful careers.

Ready to start your journey toward becoming a master in quality management? Enroll today!

You might also like to read:

Ultimate Guide to Six Sigma Control Charts

DMADV: Everything You Need to Know

Describing a SIPOC Diagram: Everything You Should Know About It

Process Mapping in Six Sigma: Here’s All You Need to Know

How to Use the DMAIC Model?

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Recommended Articles

What Is Lean Management? Principles & Everything You Need to Know

Discover the essence of lean management – a powerful approach to streamline processes and maximize efficiency. Explore its principles and benefits in our comprehensive guide.

What is Process Mapping in Six Sigma? Here’s Everything You Need to Know

Demystifying Process Mapping in Six Sigma: Learn to optimize workflows and enhance quality. Dive into this essential quality management tool.

Six Sigma Black Belt Salaries in 2024: Everything You Need to Know!

Get to know about salaries and factors affecting six sigma black belt salary and the skills required to have an incremental effect on your pay scale.

A Guide to Failure Mode and Effects Analysis

Explore Failure Mode and Effects Analysis with our easy-to-understand guide. Learn what it is, why it’s useful, how to use it, and its key applications.

A Guide to Design of Experiments in Six Sigma

In today’s hypercompetitive world, organizations must streamline their operations and workflows to stay ahead of the game. Lean Six Sigma and the design of experiments are methodologies that can help them do this. Learn more in this article.

A Guide to Six Sigma Projects

Originally developed for manufacturing processes, the Six Sigma methodology is now leveraged by companies in nearly all industries. In this article, we will share information about successful Six Sigma projects, methods, and more.

Lean Six Sigma Certification

Learning Format

Online Bootcamp

Program benefits.

- Green and Black Belt exam training material included

- Aligned with IASSC-Lean Six Sigma

- Masterclasses from top faculty of UMass Amherst

- UMass Amherst Alumni Association membership

- Root Cause Analysis – Part 1

- Lean six Sigma Yellow Belt Course

Introduction

Introduction to analyze in dmaic.

The Analyze phase of the DMAIC (Define, Measure, Analyze, Improve, Control) methodology is an important step in the Lean Six Sigma process. It is the stage at gathered data is analysed in order to comprehend the current state of a process and identify areas for improvement. The primary goal of this phase is to identify the underlying cause of the problem and understand how it affects the process. Understanding the underlying cause allows organisations to develop and implement effective solutions to improve the process.

Statistical process control, process mapping, and cause and effect diagrams are used in this phase to analyse the data and identify the root cause of the problem. As a Lean Six Sigma Yellow Belt, it is critical to understand the Analyze phase because it serves as the foundation for the subsequent DMAIC phases. This training course will teach you how to conduct a thorough process analysis, identify the root cause of problems, and make data-driven decisions to improve the process.

Table of Contents

Root cause analysis in dmaic.

Root Cause Analysis (RCA) is a critical component of the Analyze phase of Lean Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, Control) methodology. RCA’s primary goal is to identify the underlying cause of a problem or issue rather than simply treating the symptoms. Understanding the root cause allows organisations to implement effective and long-term solutions to improve processes and boost efficiency.

The purpose of this section of the course is to introduce the concepts and tools of RCA to support the Lean Six Sigma Yellow Belt methodology application. It will give you a thorough understanding of the significance of RCA in process improvement, as well as the various techniques and tools for identifying and analysing root causes. Participants will leave this course with the knowledge and skills needed to conduct a successful RCA and contribute to process improvement initiatives in their organisation.

What is Root Cause Analysis?

Root Cause Analysis (RCA) is a technique for determining the root cause of a problem or issue. RCA seeks to understand the source of the problem rather than simply treating the symptoms. Organizations can implement effective and sustainable solutions that address the underlying issue rather than just treating the symptoms by identifying the root cause.

This can lead to improved processes, increased efficiency, and cost savings. Quality control, safety incidents, production problems, and customer complaints are all examples of where RCA can be used. RCA is used in a wide range of industries, including healthcare, manufacturing, service, and construction.It is a critical tool for process improvement and is frequently used in conjunction with other methodologies such as Lean Six Sigma, Total Quality Management, and ISO 9000 .

Why is Root Cause Analysis Important?

RCA is a critical problem-solving technique that is especially popular among organisations that are new to implementing Lean Six Sigma. Because it is a logical, structured approach that all members of the organisation can easily understand, RCA is frequently one of the first tools adopted by organisations.

There are several reasons why Root Cause Analysis is an important approach to solving problems in the workplace, such as:

Improves processes : By determining the root cause of a problem, RCA allows organisations to develop and implement effective and long-term solutions that improve processes and increase efficiency.

Reduces costs: Addressing the root cause of a problem can prevent it from recurring, saving the organisation time and money.

Increases safety: RCA can be used to determine the root cause of safety incidents, allowing organisations to take corrective action to avoid similar incidents in the future.

Improves customer satisfaction: RCA can be used to identify the source of customer complaints, allowing businesses to take action to improve the customer experience.

Compliance: RCA can be used to determine the root cause of non-compliance issues and then implement corrective action to bring the process back into compliance.

Continuous improvement: RCA is a key tool in continuous improvement efforts as it helps organisations to understand the current state of a process and identify areas for improvement.

Data-driven decision making: Organizations can make data-driven decisions to improve processes and achieve their goals by identifying the root cause of a problem.

Overall, RCA is an important tool for process improvement because it can assist organisations in identifying and eliminating issues that are affecting their operations, allowing them to improve their performance and achieve their objectives.

Root Cause Analysis Tools

What tools are used in root cause analysis.

There are several tools and techniques that can be used to conduct an RCA, each with their own strengths and weaknesses. We will go over some of the most common RCA tools and techniques, such as the Fishbone Diagram ( Ishikawa Diagram or Cause and Effect Diagram), Pareto Chart, Scatter Plot, 5 Whys, Flowcharting, Fault Tree Analysis, Failure Modes and Effects Analysis (FMEA), and Statistical Process Control (SPC).

Each of these tools and techniques can be used to identify various root causes and provide valuable insights into the issue at hand. Other tools and techniques may be used to complete a comprehensive Root Cause Analysis, depending on the context, industry, and specific problem, these tools are also in the context of a Lean Six Sigma Yellow belt course, and you would learn more about Root Cause Analysis on a Lean Six Sigma Green Belt.

Fish Bone Diagram

What is a fishbone diagram.

A Fishbone Diagram (also known as an Ishikawa Diagram or a Cause and Effect Diagram) is a tool for identifying potential causes of a problem. It is also known as an Ishikawa diagram or a cause and effect diagram. It is a graphical representation that helps in the organisation and identification of various factors that may be contributing to a problem.

The diagram is in the shape of a fish skeleton, with the problem or effect written at the head and potential causes branching off the spine. The various branches represent various categories of causes, such as equipment, people, processes, and the environment.

The Fishbone diagram is an effective tool for breaking down a complex problem into smaller, more manageable chunks. It helps in the organisation of data and the identification of various factors that may be contributing to the problem. It is also an excellent tool for team brainstorming and gathering feedback. It can be applied to any industry or problem.

To create a Fishbone diagram, first define the problem and write it at the fish’s head. Then, brainstorm the various cause categories, such as people, process, equipment, and environment, and write them as branches off the spine. Finally, you must brainstorm and write down specific causes that fall into each category.

The Process of Completing a Fishbone RCA

Performing a Fishbone Root Cause Analysis (RCA) consists of several steps:

Define the issue: Define the problem you’re attempting to solve. This statement should be specific and measurable.

Identify the various causes: Identify the various causes that may be contributing to the problem. People, equipment, process, environment, materials, method, management, and measurement are all common categories.

Specific causes: For each cause category, brainstorm specific causes that fall under each category.

Make a Fishbone diagram: Make a Fishbone diagram of the specific causes. Write the problem or effect at the top of the fish, and the various causes as branches off the spine. Sub-branches are written for specific causes that fall into each category.

Identify the most likely cause(s): Use the Fishbone diagram to identify the problem’s most likely cause or causes.

Create a plan of action: Create a plan of action to address the problem based on the identified causes. This can include taking corrective actions, changing processes, or putting in place a new system or procedure.

Put the plan into action: Put the action plan into action and track the results.

Monitor and improve on a regular basis: Keep an eye on the process and look for any ways to improve .

Example of a Fishbone Diagram

- Below is an example of a Fishbone diagrams that has been completed by a team looking into the problem of long production lead times (average lead time is 25 days which is excreeding the target lead time of 15 days identifyed by the voice of the customer (VOC) .

- This Fishbone was developed using a cross functional team of operators, operations managers, engineers, supply chain managers etc.

- The team first agreed and understood the problem they were looking to identify the root cause of.

- They then brainstormed all the potential causes for not meeting the targeted lead time, this is usually recorded on a sticky note if done in person or can be done in various softwate.

- The team then shared their reasons that they brainstormed, adding any justification or clarification for other team members, as the reasons are shared this can then provide further potential reasons with the power of group think where a team member might build on a previous presented reason or develop a variation to it.

Note: Sometimes a reason may seem like it fits in more than one category, in this instance, place it in the most relvant category.

- Reasons can then be priortised by the team as it is usually unlikely there are enough reasources to explore each and every listed reason. Prioritisation can be done with the teams getting three votes each and vote can choose to vote on what they think are causing the largest impact on the problem, three votes could all be spent on one reason or spread across multiple. At the end of the voting those reasons can then be explored

- Themes are then explored and varified by the project team to provide more context and evidence that the reason my be impacting the problem. For example “lack of equipment availablity”, upon review of data it turned out that 40% of equipment breakdowns result in delays of more than one day.

- This is repeted among the priortised list until enough reasons have been identified and verified with data to sufficiently solve the problem. For example again with “lack of equipment availablity” data was collected to understand how much production time per month was lost due to this. Reasons for breakdowns can then be explored with Pareto analysis to see the top reasons for down time.

- Actions can then be taken to reduce equipment down time in the improve stage which we will explore later in the course.

What is 5 Whys?

The 5 Whys technique is a simple and efficient problem-solving method that can be applied in a wide range of industries and settings. It is especially useful in determining the root cause of complex and multifaceted problems because it helps to break the problem down into smaller, more manageable parts.

The key to the 5 Whys technique is to keep asking “why” until you find the root cause of the problem. It is critical to avoid making assumptions or jumping to conclusions, as this can lead to incomplete or inaccurate information. You can gain a deep understanding of the problem and identify the root cause by continuing to ask “why?” and drilling down to the underlying causes.

5 Whys is an extremely useful tool for organisations looking to improve their processes and increase efficiency, reduce costs, increase safety and customer satisfaction, compliance, and as a key tool in continuous improvement efforts. It promotes a problem-solving culture and can be used to identify and address issues before they become major issues. To gain a more comprehensive understanding of a problem, the 5 Whys technique can be used in conjunction with other problem-solving tools such as the Fishbone diagram or Flowcharting.

What are the benefits of 5 Whys?

5 Whys is a very popular Root cause analysis tool in organisations for a varity of reasons such as:

Easy to understand and use: One of the main benefits of the 5 Whys technique is that it is easy to understand and use. The process is simple and does not necessarily require any special training or equipment. It can be used by individuals or groups, and it is an excellent tool for brainstorming and gathering team input. This makes it a useful and accessible tool for problem solving in a variety of contexts.

Encourages critical thinking: The 5 Whys technique encourages critical thinking by repeatedly asking “why,” which helps to surface underlying issues that are not immediately apparent. It encourages people to look beyond the surface of a problem and investigate deeper causes. This can lead to a better understanding of a problem and can assist in identifying and addressing issues before they become major issues.

Teamwork: Repeatedly asking “why” encourages collaboration and the exchange of ideas, which can lead to better problem-solving. It is an excellent tool for team brainstorming and gathering feedback. Different perspectives and expertise can be brought to the table by involving multiple people in the problem-solving process, leading to more comprehensive and effective solutions.

Continuous improvement: The 5 Whys technique is an excellent tool for organisations looking to improve their processes and increase efficiency, reduce costs, increase safety and customer satisfaction, and ensure compliance. It is also a key tool in continuous improvement efforts. It promotes a problem-solving culture and can be used to identify and address issues before they become major issues. It also assists organisations in determining areas for improvement and making data-driven decisions. It can also be combined with other problem-solving tools, such as the Fishbone diagram or Flowcharting, to gain a more comprehensive understanding of a problem and develop an effective plan of action.

Last but not least, Identifying the root cause: The goal of the 5 Whys technique is to repeatedly ask “why” to get to the bottom of a problem. Rather than addressing symptoms, this aids in determining the root cause of the problem. Organizations can develop effective and sustainable solutions that improve processes and increase efficiency, reduce costs, increase safety and customer satisfaction, compliance, and serve as a key tool in continuous improvement efforts by understanding the root cause. This is an important step in problem solving because it ensures that the correct problem is addressed and that the solution is long-term effective.

How to complete 5 Whys?

While conducting a 5 Whys analysis is a simple process, it’s important to remember that it’s not a one-size-fits-all solution. The key to successfully conducting a 5 Whys analysis is to be thorough and systematic in your approach.

Define the issue: Define the problem you’re attempting to solve. This statement should be specific and measurable. Ensure that the problem is well-defined and understood by all team members.

Collect data: Gather information about the problem. This includes things like observations, interviews, and measurements. It is critical to collect data from various sources to ensure that you have a complete understanding of the problem.

Begin with “why”: Begin by asking “why” the problem is occurring. Make a note of the answer to the first “why” question. When asking “why,” it is critical to be specific and avoid making assumptions or guesses.

Continue to ask “why”: Continue to ask “why” based on the answer to the previous “why” question until you have asked “why” five times. It is critical to be patient and persistent in asking “why” until you find the source of the problem.

Identify the root cause: The fifth “why” should reveal the problem’s root cause. When identifying the root cause, it is critical to be critical and ensure that the root cause identified is the actual cause of the problem.

Create a plan of action: Create a plan of action to address the problem based on the identified root cause. This can include taking corrective actions, changing processes, or putting in place a new system or procedure. Make certain that the action plan is specific, measurable, achievable, relevant, and time-bound.

Example of 5 Whys?

Here’s an example of 5 Whys being applied to a problem in a manufacturing company:

Problem: The production line is experiencing frequent downtime

- Why is the production line experiencing frequent downtime?

- The machines are breaking down frequently.

- Why are the machines breaking down frequently?

- The machines are not being properly maintained.

- Why are the machines not being properly maintained?

- The maintenance schedule is not being followed.

- Why is the maintenance schedule not being followed?

- The maintenance team is not properly trained on how to maintain the machines.

- Why is the maintenance team not properly trained?

- The company has not provided proper training for the maintenance team.

Root Cause: The company has not provided proper training for the maintenance team.

Plan of Action:

- Provide training for the maintenance team on how to properly maintain the machines.

- Implement a strict maintenance schedule and ensure that it is being followed.

- Regularly check and evaluate the maintenance team’s performance.

- Invest in tools and equipment to improve the maintenance process.

Implementation:

- Set up training sessions for the maintenance team on how to properly maintain the machines.

- Establish a strict maintenance schedule and ensure that it is being followed.

- Monitor the maintenance team’s performance and provide feedback.

- Purchase necessary tools and equipment to improve the maintenance process.

By using 5 Whys the company was able to identify the root cause of the problem, which was a lack of proper training for the maintenance team, and develop a plan of action to address it, which improved production and reduced downtime.

Pareto Chart

What is a pareto chart.

A Pareto chart is a graphical representation tool invented in the early twentieth century by Vilfredo Pareto , an Italian economist. Pareto discovered that 80% of the effects result from 20% of the causes, which became known as the Pareto principle. Pareto charts are used to identify and prioritise the most important factors influencing a problem or effect. It combines a bar chart and a line graph, with the bars representing the various factors and the line representing the cumulative total.

Pareto charts are used to identify the “vital few” factors that cause the majority of a problem and prioritise them for further investigation and improvement. For example in the picture above, the vital few factors are Turntable, blocker alignment and foil dispenser. They are frequently used in quality control, process improvement, and project management to identify and address the most serious issues. It’s a useful tool for visualising data distribution and identifying areas for improvement.

The key components of a Pareto chart are:

- The bars representing the different factors contributing to the problem or effect

- The x-axis represents the different factors

- The y-axis represents the frequency or count of each factor

- The bars are arranged in descending order of frequency or count

- The line is plotted on top of the bars, showing the cumulative total

- The chart typically includes a threshold line to indicate the point at which a significant percentage of the problem or effect occurs.

How to Use a Parteo Chart?

Using a pareto to analyze data and identify the most common root causes of a problem is a fairly simple process, especially if you have software such as excel.

- Create a table with column titles: Categories, frequency, cumulative frequency and percent

2. List the categories in the first column

3. Input the frequency into the second column

4. Calculate the cumulative frequency in the third column, row one being =B2, row two being =B2+B3, row three being =B3+B4 and so on. You should have something like the one below with the number increasing.

5. In the percent column calculate the percent of each category against the total. E.g. =B2/C14. This formula should be the frequency number divided by the total number from the cumulative frequency.

6. Now select the Categories and percent column and click insert, Recommended Charts, you should then have a screen like below, select Pareto and click Ok.

If you had any difficulties following these steps, don’t worry we got you covered with a free template of a Pareto in Excel below. However, it is useful to understand how these are created.

Download: Pareto Chart Template

Example of a Pareto Chart used for RCA

Above is an example of a Pareto chart usef for Root cause analysis to help understand the main causes of customer complaints. Data was collected on the last six months to data of customer complaints to understand what the reasons for complaints where.

The data was then analyzed with a pareto chart which showed that 51% of complaints where due to customer service not being helpful and 32% due to customer waiting too long on hold.

Therefore 80% of the problem was cause by these two cateogories which need to be addressed with actions

Problem: Increasing number of customer complaints in relation to the customer service line.

Example of Pareto chart for customer complaints

The data was then analyzed with a pareto chart which showed that 51% of complaints where due to customer service not being helpful and 32% due to customer waiting too long on hold.

Root Cause: The Root cause for 80% of complaints is due to customer service not being helpful and customers waiting too long on hold.

- Improve customer service by providing effective communication and problem-solving training to customer service representatives. Establish a system for monitoring and evaluating customer service interactions to identify areas for improvement.

- Reduce hold times by identifying the root causes of long hold times, such as high call volume, a lack of staff, or technical issues. Hire more employees, invest in call routing technology, or add a call-back system as solutions.

- Track customer complaints, customer service interactions, and hold times to continuously monitor and measure the progress of these efforts. Use this data to assess the effectiveness of your actions and make adjustments as needed.

- Communicate with customers to understand their needs and concerns, as well as to keep them informed of the steps being taken to improve the service.

- Continuously strive to improve customer service and reduce hold times by implementing new processes, systems, and technologies.

By using the Pareto chart the company was able to identify the main causes of the problem, which was a poor customer service knowledge and long wait times on hold, and develop a plan of action to address it, which improved customer satisfaction and reduced customer complaints.

Scatter Plot

What is a scatter plot.

A scatter plot, also known as a scatter diagram or a scatter chart, is a type of plot that is used to show the relationship between two variables. It’s a graphical representation of two sets of data, with one variable on the x-axis and the other on the y-axis. Each scatter plot point represents a pair of (x,y) values that are used to plot the point on the graph. Scatter plots can be used for a variety of purposes, including data visualisation, trend analysis, and statistical modelling, and are useful for identifying correlations or patterns between two variables.

Scatter plots are especially useful for identifying outliers in data, which are data points that deviate significantly from the pattern of the rest of the data. Scatter plots can also be used to identify linear and nonlinear relationships between variables, as well as clusters or groups of data points.

Scatter plots are widely used in a variety of disciplines, including statistics, engineering, economics, and science. They can be made with software such as Microsoft Excel, R, Python, and MATLAB. Scatter plots are a powerful tool for examining the relationship between two variables, and they aid in understanding the relationship between variables, which is critical for making decisions and predictions.

When to use a Scatter plot?

When you want to investigate the relationship between two variables, you use a scatter plot. It’s especially useful when you want to:

Identify patterns: Scatter plots can be used to identify patterns and trends in data, such as linear or non-linear relationships, clusters, or groups of data points.

Investigate correlation: Scatter plots can be used to examine the relationship between two variables. A positive correlation indicates that as one variable increases, so does the other. A negative correlation means that as one variable rises, the other falls. A scatter plot can also be used to detect a lack of correlation between two variables.

Identify outliers: Scatter plots can be used to identify outliers, which are data points that fall far outside the pattern of the rest of the data.

Compare data groups: Scatter plots can be used to compare data sets. A scatter plot, for example, can be used to compare the relationship between two variables for different types of data.

Data visualisation: Scatter plots are a useful tool for data visualisation and can be used to present data in a clear and easy-to-understand format.

Statistical modelling: Scatter plots can be used as a tool for statistical modelling, helping identify the relationship between variables and predicting outcomes.

What is the line of best fit on a Scatter Diagram?

The line of best fit, also known as the trend line or regression line, is a line that is used in a scatter plot to represent the general pattern or trend of the data. The line of best fit is usually straight, but it can be curved if the data shows a non-linear relationship. Finding the line that minimises the difference between the data points and the line yields the best fit line. The least-squares method is used to accomplish this by minimising the sum of the squared differences between the data points and the line.

The best fit line can be useful in several ways:

Identifying correlation: A line of best fit can be used to identify the strength and direction of a correlation between two variables. A positive correlation has a best fit line that slopes upward from left to right, while a negative correlation has a best fit line that slopes downward from left to right.

Making predictions: A line of best fit can be used to forecast the value of one variable based on the value of another.

Missing data estimation: A line of best fit can be used to estimate missing data.

Identifying outliers: A line of best fit can be used to identify outliers, which are data points that fall far outside the pattern of the rest of the data.

Finding underlying patterns: A line of best fit can be used to find underlying patterns in data, such as linear or non-linear relationships.

It’s important to note that a line of best fit should not be used to make predictions outside of the data’s range or to extend trends indefinitely, because the line may not accurately represent the data’s pattern in those areas.

How to Use a Scatter Plot?

Example of a scatter plot used for rca.

A scatter plot can be used to identify the relationship between the number of defects in a manufacturing process and the temperature of the machinery used in the process as an example of root cause analysis (RCA).

Gather information: For each batch of products, collect data on the number of defects per batch and the temperature of the machinery.

Organize the data: Make a table with the number of defects on the y-axis and the temperature of the machinery on the x-axis.

Create the scatter plot: Using software such as Microsoft Excel, plot the data points on the graph to create a scatter plot.

Label the axes as follows: The x-axis should be labelled “Temperature (°C)” and the y-axis should be labelled “Number of Defects.”

Analyze the scatter plot: Examine the scatter plot for patterns and relationships in the data. Outliers, clusters or groups of data points, and linear or non-linear relationships should all be identified.

Draw a line of best fit: On the scatter plot, draw a line of best fit to represent the overall pattern of the data.

Interpret the scatter plot: Interpret the relationship between the number of defects and the temperature of the machinery based on the shape of the scatter plot and the line of best fit. The best-fit line demonstrates a positive relationship between the number of defects and the temperature of the system.

Conclusion: Based on the relationship between the number of defects and the temperature of the machinery, it is possible to conclude that the temperature of the machinery is a contributing factor to the number of defects in the manufacturing process.

Develop a plan of action: Develop a plan of action to address the problem of defects, such as implementing a cooling system for the machinery, to keep the temperature within a certain range.

Implement the strategy and keep a close eye on it: Put the action plan into action and monitor the results for ways to improve.

To summarise, part one the DMAIC Analyze phase is a critical step in the Lean Six Sigma process. It enables businesses to assess the current state of a process and identify areas for improvement. Root Cause Analysis (RCA) is an important part of this phase because it assists organisations in understanding the underlying cause of a problem and developing effective solutions to improve processes and increase efficiency. Fishbone diagrams, Pareto charts, Scatter plots, 5 Whys, Understanding and putting these tools and techniques to use is critical for anyone looking to improve processes and increase efficiency in their organisation.

What's Next?

Now we have covered the first part of Root cause analysis, the next section will cover part two focusing on Fault Tree Analysis, Failure modes and effect analysis (FMEA) and Statistical process control (SPC) for analysis in DMAIC.

Finding this content useful? CTRL + D to bookmark to return to later!

Course Index

Lean Six Sigma

6 minute read

Lean Six Sigma 5 Whys - What They Are & How to Use Them [Free Template]

Cody Steele

Facebook Twitter LinkedIn WhatsApp Email

What are the 5 Whys?

5 Whys is a Lean Six Sigma technique for refining a problem statement. In different situations, you might apply the technique to identify root causes, testable hypotheses, or to give a clear definition of a problem.

The simple description of 5 Whys root cause analysis is that you ask “Why?” you are having a problem. Then, you answer the question, then ask “Why?” again.

By the time you have asked “Why?” the right amount of times, you should have an idea about how to proceed to solve the problem.

As with many Lean tools , 5 Whys root cause analysis is generally believed to have evolved alongside the rest of the Toyota Production System (TPS). Root Cause Problem Solving (RCPS) encompasses several other tools, such as Failure Modes and Effects Analysis (FMEA) and Ishikawa diagrams (sometimes called fishbone diagrams).

Download your free 5 Whys template

Use this 5 Whys template to get started with your own 5 Whys root cause analysis.

When to use 5 Whys

5 Whys root cause analysis is a useful tool anytime that the statement of a problem does not immediately reveal its solution.

Frequently, the absence of a solution is because the initial problem statement is a symptom of an underlying problem that has not been clearly identified or stated. The 5 Whys root cause analysis gets you to the real problem so that you can identify a real solution.

Simple 5 Whys example

A traditional example of 5 Whys root cause analysis follows a pattern like the following:

Problem: The engine stopped working.

- Why did the engine stop working? Because the engine overheated.

- Why did the engine overheat? Because the gears weren’t getting enough oil.

- Why weren’t the gears getting enough oil? Because the oil pump wasn’t feeding enough oil.

- Why wasn’t the pump feeding enough oil? Because the intake was clogged with metal shavings.

- Why was the intake clogged? Because the filter was worn out and needs replacing.

Tips for 5 Whys root cause analysis

This simple example illustrates two critical points about succeeding with 5 Whys root cause analysis.

1. Don’t stop too soon

In the simple example, we could see that the engine overheated and decide that the solution is to increase the amount of coolant going to the engine. Asking “Why?” until you reach the root cause is vital.

2. Find a solution

When you’ve identified the root cause, it should suggest a solution to the problem, or at least a hypothesis that you can test. If you don’t have an idea of what to do next, try to keep going.

How to use 5 Whys root cause analysis

Although you can use 5 Whys root cause analysis in both simple and complex situations, you’ll often need to use 5 Whys root cause analysis with difficult problems in complex processes. In such cases, keep in mind the following four principles.

1. Identify an important problem

The Pareto rule suggests the 80/20 relationship . Colloquially stated, 80 percent of your defects come from 20 percent of your problems. Take time to identify the most important problems first and solve those.

2. Work with a team

You might have one or two people who already think that they know how to fix the problem. But if you’re going to do root cause analysis, take care that you get enough people together to find the root cause.

Involve people who work on the process at different levels so that causes that might not occur to one person can arise while you’re looking for the root cause.

3. Broaden your search

In the simple example, there was only one answer to each “Why?” question, but that’s not a requirement. For many processes, especially if you have a diversity of perspectives, you can even arrive at multiple root causes. Capture this thinking in your analysis.

4. Check your work

Review all of your root causes with the team at the end to help identify what you think is most important. Don’t get so wrapped up in the process that you don’t review your results.

Although you’ll have collected a good team to use 5 Whys root cause analysis, that doesn’t mean that you shouldn’t get input from other people. If you have access to other resources, get their perspective on your possible root causes and their relative importance before you start to implement a solution.

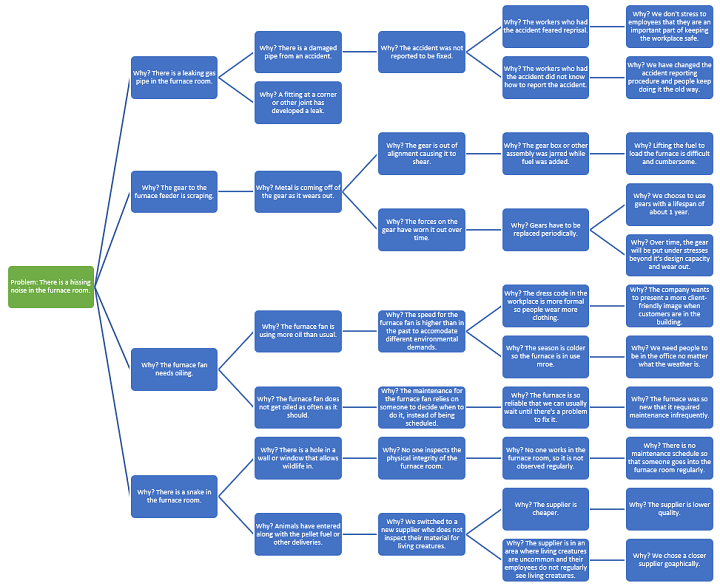

5 Whys diagram

As your problems and processes become more complex, it’s helpful to have a 5 Whys diagram or 5 Whys template that you can use to get started.

For a complex process or for a problem with many possible root causes, a 5 Whys diagram can become quite large. The point of the process is not to be neat. However, it’s to identify root causes and to help you arrive at solutions. To do that, you need to be thorough in your search. Here’s an example of what a 5 Whys diagram might look like in a moderately complex case:

5 Whys root cause analysis is only one way to do root cause analysis and only one of many tools that can help you get the most from your projects and processes.

To learn more Lean Six Sigma skills and tools, check out GoSkills range of courses , designed to prepare you for certification with IASSC/PeopleCert.

Prepare to get certified in Lean Six Sigma

Start learning today with GoSkills courses

Loved this? Subscribe, and join 443,990 others.

Get our latest content before everyone else. Unsubscribe whenever.

Cody is a technical communicator and statistician who wants to help people collect the right data and analyze it to make informed decisions. His specialities include statistics, technical communication, statistical reliability, JMP, SAS, and writing for translation.

Recommended

How Online Learning Can Help You Grow Professionally (and Personally)

To grow professionally doesn’t just mean climbing the corporate ladder. Explore four ways online learning fosters professional, and even personal, growth.

Process Improvement Skills Boil Down to These 3 Elements

How can you tell someone has process improvement skills? It really comes down to a combination of three important factors.

The Basics of Gage R&R

Gage Repeatability and Reproducibility studies (Gage R&R) are a type of Measurement Systems Analysis (MSA). This tutorial walks you through the basics.

© 2024 GoSkills Ltd. Skills for career advancement

How it works

For Business

Join Mind Tools

Article • 11 min read

Getting to the Root of a Problem Quickly

By the Mind Tools Content Team

5 Whys Root-Cause Analysis

Have you ever had a problem that refused to go away? No matter what you did, sooner or later it would return, perhaps in another form.

Stubborn or recurrent problems are often symptoms of deeper issues. "Quick fixes" may seem convenient, but they often solve only the surface issues and waste resources that could otherwise be used to tackle the real cause.

In this article and in the video, below, we look at the 5 Whys technique (sometimes known as 5Y). This is a simple but powerful tool for cutting quickly through the outward symptoms of a problem to reveal its underlying causes – so that you can deal with it once and for all.

Origins of the 5 Whys Technique

Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries, developed the 5 Whys technique in the 1930s. It became popular in the 1970s, and Toyota still uses it to solve problems today.

Toyota has a "go and see" philosophy. This means that its decision making is based on an in-depth understanding of what's actually happening on the shop floor , rather than on what someone in a boardroom thinks might be happening.

The 5 Whys technique is true to this tradition, and it is most effective when the answers come from people who have hands-on experience of the process or problem in question.

The method is remarkably simple: when a problem occurs, you drill down to its root cause by asking "Why?" five times. Then, when a counter-measure becomes apparent, you follow it through to prevent the issue from recurring.

The 5 Whys uses "counter-measures," rather than "solutions." A counter-measure is an action or set of actions that seeks to prevent the problem from arising again, while a solution may just seek to deal with the symptom. As such, counter-measures are more robust, and will more likely prevent the problem from recurring.

When to Use a 5 Whys Analysis

You can use 5 Whys for troubleshooting, quality improvement, and problem solving, but it is most effective when used to resolve simple or moderately difficult problems.

It may not be suitable if you need to tackle a complex or critical problem. This is because 5 Whys can lead you to pursue a single track, or a limited number of tracks, of inquiry when, in fact, there could be multiple causes. In cases like these, a wider-ranging method such as Cause and Effect Analysis or Failure Mode and Effects Analysis may b e more effective.

This simple 5 Whys technique, however, can often direct you quickly to the root cause of a problem. So, whenever a system or process isn't working properly, give it a try before you embark on a more in-depth approach – and certainly before you attempt to develop a solution.

The tool's simplicity gives it great flexibility, too, and 5 Whys combines well with other methods and techniques, such as Root Cause Analysis . It is often associated with Lean Manufacturing , where it is used to identify and eliminate wasteful practices. It is also used in the analysis phase of the Six Sigma quality improvement methodology.

How to Use the 5 Whys

The model follows a very simple seven-step process: [1]

1. Assemble a Team

Gather together people who are familiar with the specifics of the problem, and with the process that you're trying to fix. Include someone to act as a facilitator , who can keep the team focused on identifying effective counter-measures.

2. Define the Problem

If you can, observe the problem in action. Discuss it with your team and write a brief, clear problem statement that you all agree on. For example, "Team A isn't meeting its response time targets" or "Software release B resulted in too many rollback failures."

Then, write your statement on a whiteboard or sticky note, leaving enough space around it to add your answers to the repeated question, "Why?"

3. Ask the First "Why?"

Ask your team why the problem is occurring. (For example, "Why isn't Team A meeting its response time targets?")

Asking "Why?" sounds simple, but answering it requires serious thought. Search for answers that are grounded in fact: they must be accounts of things that have actually happened, not guesses at what might have happened.

This prevents 5 Whys from becoming just a process of deductive reasoning, which can generate a large number of possible causes and, sometimes, create more confusion as you chase down hypothetical problems.

Your team members may come up with one obvious reason why, or several plausible ones. Record their answers as succinct phrases, rather than as single words or lengthy statements, and write them below (or beside) your problem statement. For example, saying "volume of calls is too high" is better than a vague "overloaded."

4. Ask "Why?" Four More Times

For each of the answers that you generated in Step 3, ask four further "whys" in succession. Each time, frame the question in response to the answer you've just recorded.

What Is a 5 Whys Template?

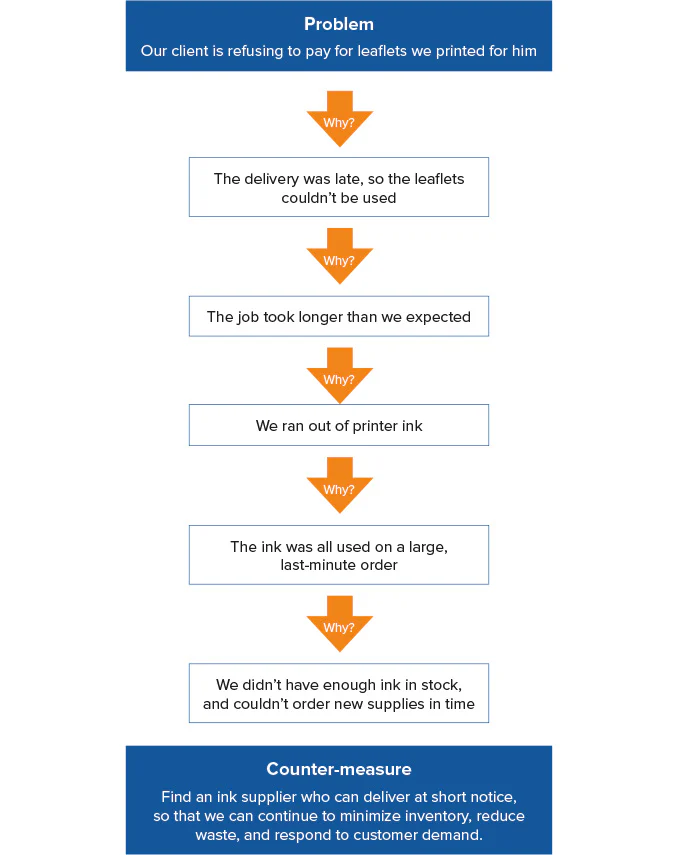

The diagram, below, shows an example of 5 Whys in action, following a single lane of inquiry.

Figure 1: 5 Whys Example (Single Lane)

The 5 Whys method also allows you to follow multiple lanes of inquiry. An example of this is shown in Figure 2, below.

In our example, asking "Why was the delivery late?" produces a second answer (Reason 2). Asking "Why?" for that answer reveals a single reason (Reason 1), which you can address with a counter-measure.

Similarly, asking "Why did the job take longer than expected?" has a second answer (Reason 2), and asking "Why?" at this point reveals a single reason (Reason 1). Another "Why?" here identifies two possibilities (Reasons 1 and 2) before a possible counter-measure becomes evident.

There is also a second reason for "Why we ran out of printer ink" (Reason 2), and a single answer for the next "Why?" (Reason 1), which can then be addressed with a counter-measure.

Figure 2: 5 Whys Example (Multiple Lanes)

Step 5. Know When to Stop

You'll know that you've revealed the root cause of the problem when asking "why" produces no more useful responses, and you can go no further. An appropriate counter-measure or process change should then become evident. (As we said earlier, if you're not sure that you've uncovered the real root cause, consider using a more in-depth problem-solving technique like Cause and Effect Analysis , Root-Cause Analysis , or FMEA .)

If you identified more than one reason in Step 3, repeat this process for each of the different branches of your analysis until you reach a root cause for each one.

6. Address the Root Cause(s)

Now that you've identified at least one root cause, you need to discuss and agree on the counter-measures that will prevent the problem from recurring.

7. Monitor Your Measures

Keep a close watch on how effectively your counter-measures eliminate or minimize the initial problem. You may need to amend them, or replace them entirely. If this happens, it's a good idea to repeat the 5 Whys process to ensure that you've identified the correct root cause.

Appreciation

A similar question-based approach known as "appreciation" can help you to uncover factors in a situation that you might otherwise miss.

It was originally developed by the military to assist commanders in gaining a comprehensive understanding of any fact, problem or situation. But you can also apply it in the workplace.

Starting with a fact, you first ask the question, "So what?" – in other words, what are the implications of that fact? Why is this fact important?

You then continue asking that question until you've drawn all possible conclusions from it.

The major difference between this and the 5 Whys technique is that appreciation is often used to get the most information out of a simple fact or statement, while 5 Whys is designed to drill down to the root of a problem.

Tips for Using the 5 Whys Technique

- Try to move quickly from one question to the next. That way, you'll have the full picture before you jump to any conclusions.

- The "5" in 5 Whys is really just a " rule of thumb ." In some cases, you may need to ask "Why?" a few more times before you get to the root of the problem. In other cases, you may reach this point before you ask your fifth "Why?" If you do, make sure that you haven't stopped too soon, and that you're not simply accepting "knee-jerk" responses.

- Know when to stop! The important point is to stop asking "Why?" when you stop producing useful responses.

Frequently Asked Questions About 5 Whys

1. what is the 5 whys technique.

The 5 Whys Technique is a problem-solving method involving repeatedly asking "why?" It's a way of quickly getting to the root cause of a situation.

2. Who Invented 5 Whys?

The 5 Whys technique was invented in the 1930s by Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries.

5 Whys Infographic

See our infographic on the 5 Whys and use it to get to the root of your problems!

Bear in mind that appreciation can restrict you to one line of thinking. For instance, once you've answered your first "So what?" question, you might follow a single line of inquiry to its conclusion. To avoid this, repeat the appreciation process several times over to make sure that you've covered all bases.

The 5 Whys strategy is a simple, effective tool for uncovering the root of a problem. You can use it in troubleshooting, problem-solving, and quality-improvement initiatives.

Start with a problem and ask why it is occurring. Make sure that your answer is grounded in fact, and then ask the question again. Continue the process until you reach the root cause of the problem, and you can identify a counter-measure that will prevent it from recurring.

Bear in mind that this questioning process is best suited to simple or moderately difficult problems. Complex problems may benefit from a more detailed approach, although using 5 Whys will still give you useful insights.

[1] Pojasek, R. (2000). 'Asking "Why?" Five Times,' Environmental Quality Management , Volume 10, Issue 1, 79–84. Available here . [Accessed July 1, 2022.]

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Root cause analysis.

Tracing a Problem to Its Origins

Using Root Cause Analysis

Find the Root of Your Problems

Add comment

Comments (0)

Be the first to comment!

Try Mind Tools for FREE

Get unlimited access to all our career-boosting content and member benefits with our 7-day free trial.

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

Team Briefings

Onboarding With STEPS

Mind Tools Store

About Mind Tools Content

Discover something new today

New pain points podcast - perfectionism.

Why Am I Such a Perfectionist?

Pain Points Podcast - Building Trust

Developing and Strengthening Trust at Work

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

International teams: a case study.

Case Study Looking at Issues Managers Face Leading Teams With Members Across the Globe

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

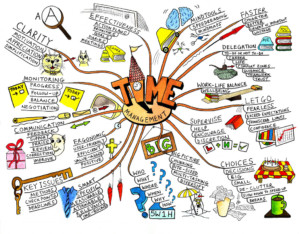

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Team Management