Nanosuspension: Principles, Perspectives and Practices

Affiliation.

- 1 School of Pharmaceutical Sciences, Lovely Professional University, Phagwara-144411, Punjab, India. [email protected].

- PMID: 26721266

- DOI: 10.2174/1567201813666160101120452

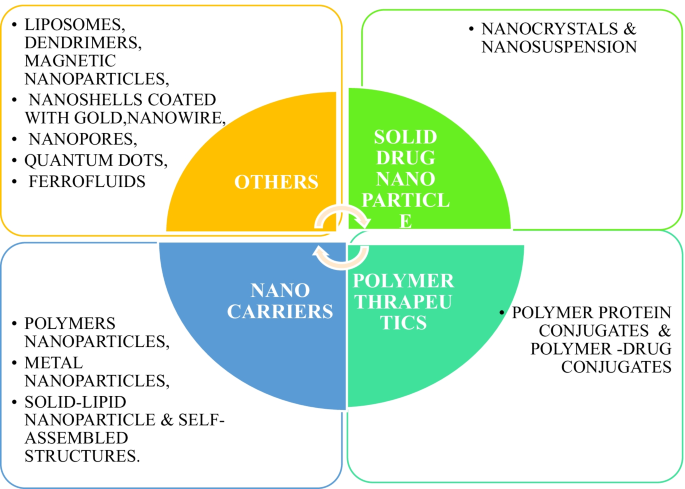

In the last three decades, nano-sizing of hydrophobic drugs has emerged as one of the most commonly used strategies to overcome their solubility and bioavailability related issues. Nanosuspensions offer versatile features and unique advantages over other approaches that have been utilized for this purpose. The unique inherent properties of nanosuspensions have been explored for a wide variety of applications. Commercial production of stable nanosuspensions has been made possible by the use of techniques such as media milling and high pressure homogenization. This article reviews various techniques being employed for production, characterization, merits and limitations of nanosuspensions and mechanisms that play a role in the physicochemical stability of nanosuspensions. The common strategies applied so far to overcome their stability and commercialization related aspects are also highlighted.

Publication types

- Drug Stability

- Nanoparticles* / administration & dosage

- Nanoparticles* / chemistry

- Nanoparticles* / therapeutic use

- Suspensions / administration & dosage

- Suspensions / chemistry

- Suspensions / therapeutic use

- Suspensions

Advertisement

A comprehensive review of nanosuspension loaded microneedles: fabrication methods, applications, and recent developments

- Published: 06 June 2023

- Volume 53 , pages 475–504, ( 2023 )

Cite this article

- Jyotsna G. Vitore 1 ,

- Sakshi Pagar 2 ,

- Nidhi Singh 3 ,

- Bharathi Karunakaran 1 ,

- Siddharth Salve 1 ,

- Navnath Hatvate 4 ,

- Satish Rojekar 5 &

- Derajram Benival ORCID: orcid.org/0000-0002-3527-9158 1

524 Accesses

3 Citations

Explore all metrics

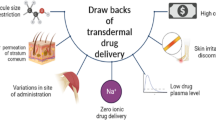

Nanosuspension-loaded microneedles (MNs) are an emerging and advanced strategy used extensively to formulate lipophilic molecules by embedding them into a suitable polymer matrix for improved transdermal delivery.

Area covered

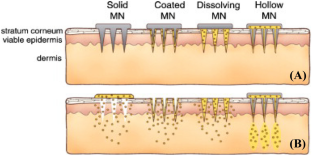

This review focuses on the nanosuspension/nanocrystal-loaded MN approach for improved delivery of hydrophobic molecules. This review discusses the different types of MNs that can be fabricated, such as dissolving, solid, coated, and hollow MNs and the criteria for the choice of the fabrication method.

Expert opinion

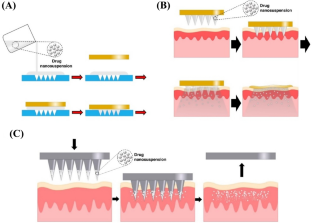

The drug loading of hydrophobic drugs can be significantly improved using this strategy. Recently, nanosuspension/nanocrystal-loaded MNs have been considered a well-recognized approach in drug delivery owing to their numerous advantages, including controlled drug release, non-invasiveness, and ability to be self-administered. The preparation of nanosuspension-loaded dissolving MNs has been widely carried out using knife-casting methods. In the present review, the various characterization methods, including the in vitro, ex vivo and in vivo techniques, are briefly discussed. Further, the review also describes the potential applications of nanosuspension-loaded MNs.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price excludes VAT (USA) Tax calculation will be finalised during checkout.

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Reprinted from Kim et al. (2012) (Copyright permission obtained)

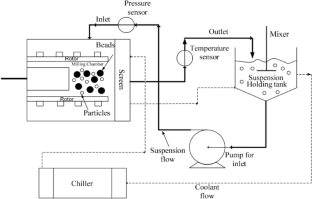

Reprinted from Li et al. ( 2016 ) (Copyright permission obtained)

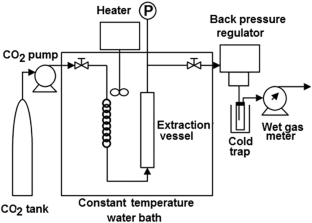

Reprinted from Permana et al. ( 2020 ) (Copyright permission obtained)

Reprinted from Misra and Pathak ( 2020 ) (Copyright permission obtained)

Reprinted from Donnelly and Larrañeta (2018) (Copyright permission obtained)

Similar content being viewed by others

Nanocrystals and nanosuspensions: an exploration from classic formulations to advanced drug delivery systems

Benjamin Rossier, Olivier Jordan, … Carlos Rodríguez-Nogales

Unravelling the role of microneedles in drug delivery: Principle, perspectives, and practices

Molakpogu Ravindra Babu, Sukriti Vishwas, … Sachin Kumar Singh

Biomimetic microneedles: exploring the recent advances on a microfabricated system for precision delivery of drugs, peptides, and proteins

Chukwuebuka Emmanuel Umeyor, Varsha Shelke, … Vandana B. Patravale

Data Availability

Not applicable. No research data was used for this publication.

Abdelghany S, Tekko IA, Vora L, Larraneta E, Permana AD et al (2019) Nanosuspension-based dissolving microneedle arrays for intradermal delivery of curcumin. Pharmaceutics 11:308

Article CAS PubMed PubMed Central Google Scholar

Agrawal Y, Patel V (2011) Nanosuspension: an approach to enhance solubility of drugs. J Adv Pharm Technol Res 2:81–87

Article PubMed PubMed Central Google Scholar

Alkilani AZ, McCrudden MTC, Donnelly RF (2015) Transdermal drug delivery: innovative pharmaceutical developments based on disruption of the barrier properties of the stratum corneum. Pharmaceutics 7:438–470

Article CAS PubMed Google Scholar

Altuntaş E, Tekko IA, Vora LK, Kumar N, Brodsky R et al (2021) Nestorone nanosuspension-loaded dissolving microneedles array patch: a promising novel approach for “on-demand” hormonal female-controlled peritcoital contraception. Int J Pharm 614:121422

Article PubMed Google Scholar

Amalraj A, Pius A, Gopi S, Gopi S (2017) Biological activities of curcuminoids, other biomolecules from turmeric and their derivatives—a review. J Tradit Complement Med 7:205–233

Ameri M, Fan SC, Maa Y-F (2010) Parathyroid Hormone PTH (1–34) Formulation that enables uniform coating on a novel transdermal microprojection delivery system. Pharm Res 27:303–313

Anastasiou E, Lorentz KO, Stein GJ, Mitchell PD (2014) Prehistoric schistosomiasis parasite found in the Middle East. Lancet Infect Dis 14:553–554

Andrianov AK, Marin A, DeCollibus DP (2011) Microneedles with intrinsic immunoadjuvant properties: microfabrication, protein stability, and modulated release. Pharm Res 28:58–65

Anjani QK, Sabri AHB, Domínguez-Robles J, Moreno-Castellanos N, Utomo E et al (2022) Metronidazole nanosuspension loaded dissolving microarray patches: an engineered composite pharmaceutical system for the treatment of skin and soft tissue infection. Biomater Adv 140:213073

Aukunuru J, Nanam P, Rambabu B, Sailu C, Aukunuru J (2014) Preparation and characterization of amorphous ezetimibe nanosuspensions intended for enhancement of oral bioavailability. Int J Pharm Investig 4:131

Aust MC, Fernandes D, Kolokythas P, Kaplan HM, Vogt PM (2008) Percutaneous collagen induction therapy: an alternative treatment for scars, wrinkles, and skin laxity. Plast Reconstr Surg 121:1421–1429

Bhakay A, Merwade M, Bilgili E, Dave RN (2011) Novel aspects of wet milling for the production of microsuspensions and nanosuspensions of poorly water-soluble drugs. Drug Dev Ind Pharm 37:963–976

Bystrova S, Luttge R (2011) Micromolding for ceramic microneedle arrays. Microelectron Eng 88:1681–1684

Article CAS Google Scholar

Chen X, Prow TW, Crichton ML, Jenkins DWK, Roberts MS et al (2009) Dry-coated microprojection array patches for targeted delivery of immunotherapeutics to the skin. J Control Release 139:212–220

Chen J, Huang W, Huang Z, Liu S, Ye Y et al (2017) Fabrication of tip-dissolving microneedles for transdermal drug delivery of meloxicam. AAPS PharmSciTech 19:1141–1151

Chingunpitak J, Puttipipatkhachorn S, Chavalitshewinkoon-Petmitr P, Tozuka Y, Moribe K et al (2008) Formation, physical stability and in vitro antimalarial activity of dihydroartemisinin nanosuspensions obtained by co-grinding method. Drug Dev Ind Pharm 34:314–322

Chonkar AD, Rao JV, Managuli RS, Mutalik S, Dengale S et al (2016) Development of fast dissolving oral films containing lercanidipine HCl nanoparticles in semicrystalline polymeric matrix for enhanced dissolution and ex vivo permeation. Eur J Pharm Biopharm 103:179–191

Chu LY, Prausnitz MR (2011) Separable arrowhead microneedles. J Control Release 149:242–249

Costabile G, d’Angelo I, Rampioni G, Bondi R, Pompili B et al (2015) Toward repositioning niclosamide for antivirulence therapy of Pseudomonas aeruginosa lung infections: development of inhalable formulations through nanosuspension technology. Mol Pharm 12:2604–2617

Dabholkar N, Gorantla S, Waghule T, Rapalli VK, Kothuru A et al (2021) Biodegradable microneedles fabricated with carbohydrates and proteins: revolutionary approach for transdermal drug delivery. Int J Biol Macromol 170:602–621

Damiri F, Rahman MH, Zehravi M, Awaji AA, Nasrullah MZ et al (2022) MXene (Ti 3 C 2 T x )-embedded nanocomposite hydrogels for biomedical applications: a review. Materials 15:1666

Dangol M, Yang H, Li CG, Lahiji SF, Kim S et al (2016) Innovative polymeric system (IPS) for solvent-free lipophilic drug transdermal delivery via dissolving microneedles. J Control Release 223:118–125

Davis SP, Martanto W, Allen MG, Prausnitz MR (2005) Hollow metal microneedles for insulin delivery to diabetic rats. IEEE Trans Biomed Eng 52:909–915

DeMuth PC, Su X, Samuel RE, Hammond PT, Irvine DJ (2010) Nano-layered microneedles for transcutaneous delivery of polymer nanoparticles and plasmid DNA. Adv Mater 22:4851–4856

Donnelly RF, Larrañeta E (2018) Microarray patches: potentially useful delivery systems for long-acting nanosuspensions. Drug Discov Today 23:1026–1033

Donnelly RF, Garland MJ, Morrow DI, Migalska K, Singh TR et al (2010a) Optical coherence tomography is a valuable tool in the study of the effects of microneedle geometry on skin penetration characteristics and in-skin dissolution. J Control Release 147:333–341

Donnelly RF, Raj Singh TR, Woolfson AD (2010b) Microneedle-based drug delivery systems: microfabrication, drug delivery, and safety. Drug Deliv 17:187–207

Doraiswamy A, Jin C, Narayan RJ, Mageswaran P, Mente P et al (2006) Two photon induced polymerization of organic–inorganic hybrid biomaterials for microstructured medical devices. Acta Biomater 2:267–275

Du J, Li X, Zhao H, Wang L, Tian S et al (2015) Nanosuspensions of poorly water-soluble drugs prepared by bottom-up technologies. Int J Pharm 495:738–749

Faizi HS, Vora LK, Nasiri MI, Wu Y, Mishra D et al (2022) Deferasirox nanosuspension loaded dissolving microneedles for intradermal delivery. Pharmaceutics 14:2817

Fan Y, Cui Y, Hao W, Chen M, Liu Q et al (2021) Carrier-free highly drug-loaded biomimetic nanosuspensions encapsulated by cancer cell membrane based on homology and active targeting for the treatment of glioma. Bioact Mater 6:4402–4414

FDA (2020) Overview of device regulation, Device Advice Comprehensive Regulatory Assistance. FDA

FDA (2021) Microneedling devices: getting to the point on benefits, risks and safety. FAO

Fomani AA, Mansour RR (2011) Fabrication and characterization of the flexible neural microprobes with improved structural design. Sens Actuators A 168:233–241

Fotooh Abadi L, Damiri F, Zehravi M, Joshi R, Pai R et al (2022) Novel nanotechnology-based approaches for targeting HIV reservoirs. Polymers 14:3090

Gadhiya DT, Patel JK (2021) Bagada AA (2021) An impact of nanocrystals on dissolution rate of lercanidipine: supersaturation and crystallization by addition of solvent to antisolvent. Future J Pharm Sci 7:1–17

Google Scholar

Gao L, Zhang D, Chen M (2008) Drug nanocrystals for the formulation of poorly soluble drugs and its application as a potential drug delivery system. J Nanopart Res 10:845–862

Gill HS, Prausnitz MR (2007a) Coating formulations for microneedles. Pharm Res 24:1369–1380

Gill HS, Prausnitz MR (2007b) Coated microneedles for transdermal delivery. J Control Release 117:227–237

Gill HS, Prausnitz MR (2008) Pocketed microneedles for drug delivery to the skin. J Phys Chem Solids 69:1537–1541

Gittard SD, Narayan RJ, Jin C, Ovsianikov A, Chichkov BN et al (2009) Pulsed laser deposition of antimicrobial silver coating on Ormocer microneedles. Biofabrication 1:041001

Giudice E, Campbell J (2006) Needle-free vaccine delivery. Adv Drug Deliv Rev 58:68–89

Gol D, Thakkar S, Misra M (2018) Nanocrystal-based drug delivery system of risperidone: lyophilization and characterization. Drug Dev Ind Pharm 44:1458–1466

Gora S, Mustafa G, Sahni JK, Ali J, Baboota S (2016) Nanosizing of valsartan by high pressure homogenization to produce dissolution enhanced nanosuspension: pharmacokinetics and pharmacodynamic study. Drug Deliv 23:940–950

Gorantla S, Dabholkar N, Sharma S, Rapalli VK, Alexander A et al (2021) Chitosan-based microneedles as a potential platform for drug delivery through the skin: trends and regulatory aspects. Int J Biol Macromol 184:438–453

Han M, Hyun D-H, Park H-H, Lee SS, Kim C-H et al (2007) A novel fabrication process for out-of-plane microneedle sheets of biocompatible polymer. J Micromech Microeng 17:1184–1191

He J, Zhang Z, Zheng X, Li L, Qi J et al (2021) Design and evaluation of dissolving microneedles for enhanced dermal delivery of propranolol hydrochloride. Pharmaceutics 13:579

Howells O, Blayney GJ, Gualeni B, Birchall JC, Pey FE et al (2022) Design, fabrication, and characterisation of a silicon microneedle array for transdermal therapeutic delivery using a single step wet etch process. Eur J Pharm Biopharm 171:19–28

Huang T, Wang Y, Shen Y, Hui A, Guo Y et al (2020) Preparation of high drug-loading celastrol nanosuspensions and their anti-breast cancer activities in vitro and in vivo. Sci Rep 10:8851

Hwa K-Y, Chang VHS, Cheng Y-Y, Wang Y-D, Jan P-S et al (2017) Analyzing polymeric matrix for fabrication of a biodegradable microneedle array to enhance transdermal delivery. Biomed Microdevices 19:84

Jacob S, Nair AB, Shah J (2020) Emerging role of nanosuspensions in drug delivery systems. Biomater Res 24:3

Jiang J, Gill HS, Ghate D, McCarey BE, Patel SR et al (2007) Coated microneedles for drug delivery to the eye. Investig Ophthalmol vis Sci 48:4038

Article Google Scholar

Kakad SP, Gangurde TD, Kshirsagar SJ, Mundhe VG (2022) Nose to brain delivery of nanosuspensions with first line antiviral agents is alternative treatment option to neuro-AIDS treatment. Heliyon 8:e09925

Karakucuk A, Celebi N, Teksin ZS (2016) Preparation of ritonavir nanosuspensions by microfluidization using polymeric stabilizers: I. A design of experiment approach. Eur J Pharm Sci 95:111–121

Kathuria H, Kochhar JS, Fong MHM, Hashimoto M, Iliescu C et al (2015) Polymeric microneedle array fabrication by photolithography. J vis Exp 105:e52914

Kaushik S, Hord AH, Denson DD, McAllister DV, Smitra S et al (2001) Lack of pain associated with microfabricated microneedles. Anesth Analg 92:502–504

Khare P, Chogale MM, Kakade P, Patravale VB (2022) Gellan gum-based in situ gelling ophthalmic nanosuspension of Posaconazole. Drug Deliv Transl Res 12:2920–2935

Kim YC, Quan FS, Compans RW, Kang SM, Prausnitz MR (2010) Formulation of microneedles coated with influenza virus-like particle vaccine. AAPS PharmSciTech 11:1193–1201

Kim HM, Lim YY, An JH, Kim MN, Kim BJ (2012a) Pharmacology and therapeutics transdermal drug delivery using disk microneedle rollers in a hairless rat model. Int J Dermatol 51:859–863

Kim YC, Park JH, Prausnitz MR (2012b) Microneedles for drug and vaccine delivery. Adv Drug Deliv Rev 64:1547–1568

Kirkby M, Hutton ARJ, Donnelly RF (2020) Microneedle mediated transdermal delivery of protein, peptide and antibody based therapeutics: current status and future considerations. Pharm Res 37:117

Kuk DH, Ha ES, Ha DH, Sim WY, Lee SK et al (2019) Development of a resveratrol nanosuspension using the antisolvent precipitation method without solvent removal, based on a quality by design (QbD) approach. Pharmaceutics 11:688

Kulkarni D, Damiri F, Rojekar S, Zehravi M, Ramproshad S et al (2022) Recent advancements in microneedle technology for multifaceted biomedical applications. Pharmaceutics 14:1097

Kulshreshtha AK, Singh ON, Wall GM (2010) Pharmaceutical suspensions: from formulation development to manufacturing. Springer, New York

Book Google Scholar

Li G, Badkar A, Nema S, Kolli CS, Banga AK (2009) In vitro transdermal delivery of therapeutic antibodies using maltose microneedles. Int J Pharm 368:109–115

Li M, Azad M, Davé R, Bilgili E (2016) Nanomilling of drugs for bioavailability enhancement: a holistic formulation-process perspective. Pharmaceutics 8:17

Li J, Liu B, Zhou Y, Chen Z, Jiang L et al (2017) Fabrication of a Ti porous microneedle array by metal injection molding for transdermal drug delivery. PLoS ONE 12:1–15

Li S, Zhang J, Fang Y, Yi J, Lu Z et al (2020) Enhancing betulinic acid dissolution rate and improving antitumor activity via nanosuspension constructed by anti-solvent technique. Drug Des Dev Ther 14:243–256

Liang L, Chen Y, Zhang BL, Zhang XP, Liu JL et al (2020) Optimization of dip-coating methods for the fabrication of coated microneedles for drug delivery. J Drug Deliv Sci Technol 55:101464

Liu D, Xu H, Tian B, Yuan K, Pan H et al (2012) Fabrication of carvedilol nanosuspensions through the anti-solvent precipitation–ultrasonication method for the improvement of dissolution rate and oral bioavailability. AAPS PharmSciTech 13:295

Liu Q, Guan J, Sun Z, Shen X, Li L et al (2019) Influence of stabilizer type and concentration on the lung deposition and retention of resveratrol nanosuspension-in-microparticles. Int J Pharm 569:118562

Lødeng R, Bergem H (2018) Stabilisation of pyrolysis oils. In: Rossendahl L (ed) Direct thermochemical liquefaction for energy applications. Woodhead Publishing, Cambridge, pp 193–247

Chapter Google Scholar

Long J, Song J, Zhang X, Deng M, Xie L et al (2020) Tea saponins as natural stabilizers for the production of hesperidin nanosuspensions. Int J Pharm 583:119406

Mahajan K, Rojekar S, Desai D, Kulkarni S, Vavia P (2020) Efavirenz loaded nanostructured lipid carriers for efficient and prolonged viral inhibition in HIV-infected macrophages. Pharm Sci 27:418–432

Mahajan K, Rojekar S, Desai D, Kulkarni S, Bapat G et al (2021) Layer-by-layer assembled nanostructured lipid carriers for CD-44 receptor-based targeting in HIV-infected macrophages for efficient HIV-1 inhibition. AAPS PharmSciTech 22:171

Mahesh KV, Singh SK, Gulati M (2014) A comparative study of top-down and bottom-up approaches for the preparation of nanosuspensions of glipizide. Powder Technol 256:436–449

Marin A, Andrianov AK (2011) Carboxymethylcellulose–chitosan-coated microneedles with modulated hydration properties. J Appl Polym Sci 121:395–401

Martin B, Seguin J, Annereau M, Fleury T, Kuen RL et al (2020) Preparation of parenteral nanocrystal suspensions of etoposide from the excipient free dry state of the drug to enhance in vivo antitumoral properties. Sci Rep 10:18059

McCrudden MTC, Larrañeta E, Clark A, Jarrahian C, Rein-Weston A et al (2018) Design, formulation and evaluation of novel dissolving microarray patches containing a long-acting rilpivirine nanosuspension. J Control Release 292:119–129

Menon I, Bagwe P, Gomes KB, Bajaj L, Gala R et al (2021) Microneedles: a new generation vaccine delivery system. Micromachines 12:435

Migdadi EM, Courtenay AJ, Tekko IA, Mc Crudden MTC, Kearney MC et al (2018) Hydrogel-forming microneedles enhance transdermal delivery of metformin hydrochloride. J Control Release 285:142–151

Misra SK, Pathak K (2020) Supercritical fluid technology for solubilization of poorly water-soluble drugs via micro- and nanosized particle generation. ADMET DMPK 8:355–374

PubMed PubMed Central Google Scholar

Moffatt K, Donnelly RF (2021) Microneedle technology. In: Eric C (ed) Drug delivery devices and therapeutic systems. Academic, New York, pp 345–366

Möschwitzer J, Achleitner G, Pomper H, Müller RH (2004) Development of an intravenously injectable chemically stable aqueous omeprazole formulation using nanosuspension technology. Eur J Pharm Biopharm 58:615–619

Mou D, Chen H, Wan J, Xu H, Yang X (2011) Potent dried drug nanosuspensions for oral bioavailability enhancement of poorly soluble drugs with pH-dependent solubility. Int J Pharm 413:237–244

Murakami Y, Shimoyama Y (2017) Production of nanosuspension functionalized by chitosan using supercritical fluid extraction of emulsion. J Supercrit Fluids 128:121–127

Nguyen X, Banga AK (2018) Delivery of methotrexate and characterization of skin treated by fabricated PLGA microneedles and fractional ablative laser. Pharm Res 35:68

Nir Y, Paz A, Sabo E, Potasman I (2003) Fear of injections in young adults: prevalence and associations. Am J Trop Med Hyg 68:341–344

Ohn J, Jang M, Kang BM, Yang H, Hong JT et al (2021) Dissolving candlelit microneedle for chronic inflammatory skin diseases. Adv Sci 8:2004873

Omatsu T, Chujo K, Miyamoto K, Okida M, Nakamura K et al (2010) Metal microneedle fabrication using twisted light with spin. Opt Express 18:17967

Panda BP, Krishnamoorthy R, Bhattamisra SK, Shivashekaregowda NKH, Seng LB et al (2019) Fabrication of second generation smarter PLGA based nanocrystal carriers for improvement of drug delivery and therapeutic efficacy of gliclazide in type-2 diabetes rat model. Sci Rep 9:17331

Panda A, Sharma PK, McCann T, Bloomekatz J, Repka MA et al (2022) Fabrication and development of controlled release PLGA microneedles for macromolecular delivery using FITC-Dextran as model molecule. J Drug Deliv Sci Technol 68:102712

Pardeshi S, Damiri F, Zehravi M, Joshi R, Kapare H et al (2022) Functional thermoresponsive hydrogel molecule to material design for biomedical applications. Polymers 14:3126

Park JH, Choi SO, Seo S, Choy YB, Prausnitz MR (2010) A microneedle roller for transdermal drug delivery. Eur J Pharm Biopharm 76:282–289

Patel HM, Patel BB, Shah CN, Shah DP (2016) Nanosuspension technologies for delivery of poorly soluble drugs—a review. Res J Pharm Technol 9:625–632

Patil AS, Hegde R, Gadad AP, Dandagi PM, Masareddy R et al (2021) Exploring the solvent–anti-solvent method of nanosuspension for enhanced oral bioavailability of lovastatin. Turk J Pharm Sci 18:541–549

Patravale VB, Date AA, Kulkarni RM (2010) Nanosuspensions: a promising drug delivery strategy. J Pharm Pharmacol 56:827–840

Pavan Kumar M, Madhusudan Rao Y, Apte S (2007) Improved bioavailability of albendazole following oral administration of nanosuspension in rats. Curr Nanosci 3:191–194

Pawar K (2017) Microneedles-based devices: regulatory insights. J Pharm Drug Deliv Res 06:1

Permana AD, McCrudden D (2019) Enhanced intradermal delivery of nanosuspensions of antifilariasis drugs using dissolving microneedles: a proof-of-concept study. Pharmaceutics 11:346

Permana AD, Paredes AJ, Volpe-Zanutto F, Anjani QK, Utomo E et al (2020) Dissolving microneedle-mediated dermal delivery of itraconazole nanocrystals for improved treatment of cutaneous candidiasis. Eur J Pharm Biopharm 154:50–61

Permana AD, Paredes AJ, Zanutto FV, Amir MN, Ismail I et al (2021) Albendazole nanocrystal-based dissolving microneedles with improved pharmacokinetic performance for enhanced treatment of cystic echinococcosis. ACS Appl Mater Interfaces 13:38745–38760

Peters K, Leitzke S, Diederichs JE, Borner K, Hahn H et al (2000) Preparation of a clofazimine nanosuspension for intravenous use and evaluation of its therapeutic efficacy in murine Mycobacterium avium infection. J Antimicrob Chemother 45:77–83

Pireddu R, Schlich M, Marceddu S, Valenti D, Pini E et al (2020) Nanosuspensions and microneedles roller as a combined approach to enhance diclofenac topical bioavailability. Pharmaceutics 12:1140

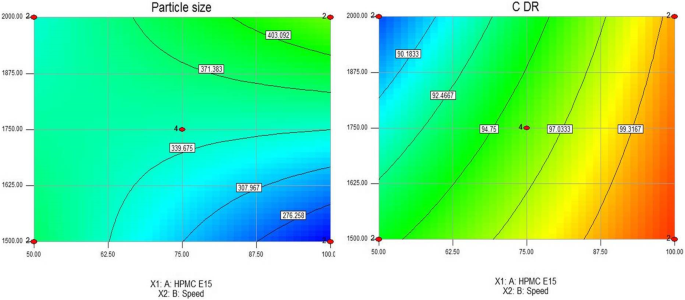

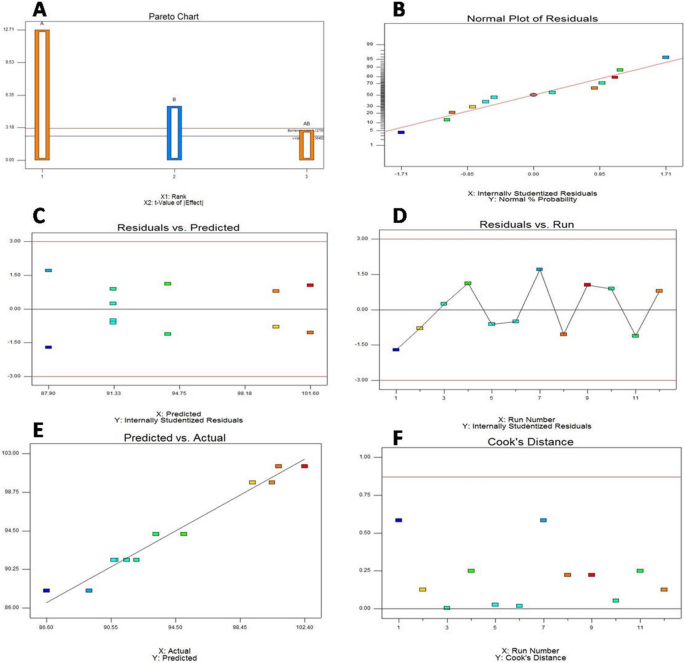

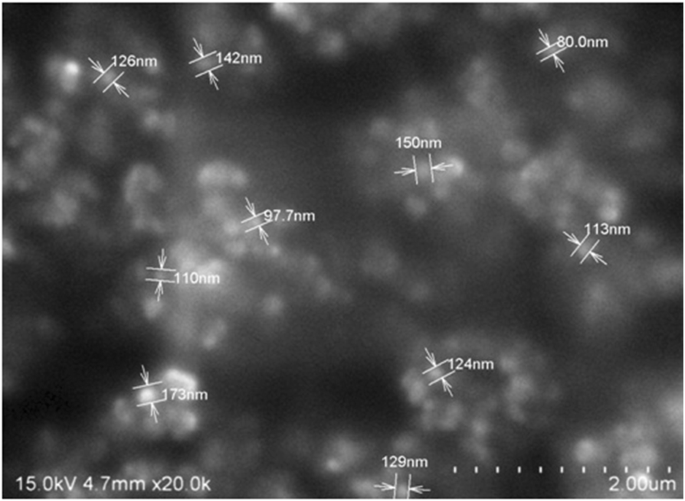

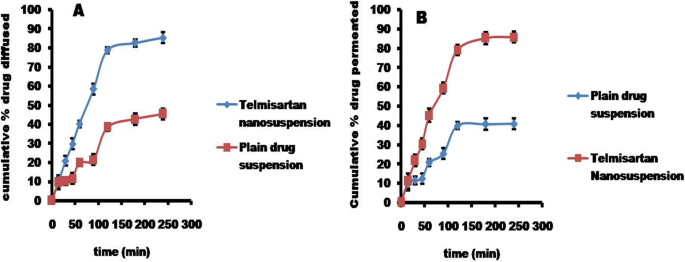

Porwal O (2022) Box-Behnken design-based formulation optimization and characterization of spray dried rutin loaded nanosuspension state of the art. S Afr J Bot 149:807–815

Qin M, Ye G, Xin J, Han W, Li M, Sui X, Dong H, Fu Q, He Z et al (2023) Comparison of in vivo behaviors of intramuscularly long-acting celecoxib nanosuspensions with different particle sizes for the postoperative pain treatment. Int J Pharm 636:1–8

Rabinow BE (2004) Nanosuspensions in drug delivery. Nat Rev Drug Discov 3:785–796

Rahim H, Sadiq A, Khan S, Amin F, Ullah R et al (2019) Fabrication and characterization of glimepiride nanosuspension by ultrasonication-assisted precipitation for improvement of oral bioavailability and in vitro α-glucosidase inhibition. Int J Nanomed 14:6287

Ramadon D, Ulayya F, Sakinah A, Iskandarsyah I, Harahap Y et al (2023) Combination of dissolving microneedles with nanosuspension and co-grinding for transdermal delivery of ketoprofen. Pharmaceuticals 16:378

Rojekar SV, Trimukhe AM, Deshmukh RR, Vavia PR (2021a) Novel pulsed oxygen plasma mediated surface hydrophilizatıon of ritonavır for the enhancement of wettability and solubility. J Drug Deliv Sci Technol 63:102497

Rojekar S, Fotooh Abadi L, Pai R, Mahajan K, Kulkarni S et al (2021b) Multi-organ targeting of HIV-1 viral reservoirs with etravirine loaded nanostructured lipid carrier: an in vivo proof of concept. Eur J Pharm Sci 164:105916

Rojekar S, Pai R, Abadi LF, Mahajan K, Prajapati MK et al (2021c) Dual loaded nanostructured lipid carrier of nano-selenium and etravirine as a potential anti-HIV therapy. Int J Pharm 607:120986

Rojekar S, Vora LK, Tekko IA, Zanutto FV, McCarthy H et al (2021d) Etravirine-loaded dissolving microneedle arrays for long-acting delivery. Eur J Pharm Biopharm 165:41–51

Rojekar S, Abadi LF, Pai R, Prajapati MK, Kulkarni S et al (2022) Mannose-anchored nano-selenium loaded nanostructured lipid carriers of etravirine for delivery to HIV reservoirs. AAPS PharmSciTech 23:230

Sattar A, Chen D, Jiang L, Pan Y, Tao Y et al (2017) Preparation, characterization and pharmacokinetics of cyadox nanosuspension. Sci Rep 7:2289

Saurer EM, Flessner RM, Sullivan SP, Prausnitz MR, Lynn DM (2010) Layer-by-layer assembly of DNA- and protein-containing films on microneedles for drug delivery to the skin. Biomacromol 11:3136–3143

Sharma M, Mehta I (2019) Surface stabilized atorvastatin nanocrystals with improved bioavailability, safety and antihyperlipidemic potential. Sci Rep 9:16105

Sharma P, Zujovic ZD, Bowmaker GA, Marshall AJ, Denny WA et al (2011) Evaluation of a crystalline nanosuspension: polymorphism, process induced transformation and in vivo studies. Int J Pharm 408:138–151

Shegokar R, Singh KK (2011) Surface modified nevirapine nanosuspensions for viral reservoir targeting: In vitro and in vivo evaluation. Int J Pharm 421:341–352

Shekhawat P, Pokharkar V (2019) Risk assessment and QbD based optimization of an eprosartan mesylate nanosuspension: in vitro characterization, PAMPA and in vivo assessment. Int J Pharm 567:118415

Singare DS, Marella S, Gowthamrajan K, Kulkarni GT, Vooturi R et al (2010) Optimization of formulation and process variable of nanosuspension: an industrial perspective. Int J Pharm 402:213–220

Singh SK, Srinivasan KK, Gowthamarajan K, Singare DS, Prakash D et al (2011) Investigation of preparation parameters of nanosuspension by top-down media milling to improve the dissolution of poorly water-soluble glyburide. Eur J Pharm Biopharm 78:441–446

Singh TRR, McMillan H, Mooney K, Alkilani AZ, Donnelly RF (2017) Fabrication of microneedles. In: Dragicevic NI, Maibach H (eds) Percutaneous penetration enhancers physical methods in penetration enhancement. Springer, Berlin, pp 305–323

Sonavane K, Phillips J, Ekshyyan O, Moore-Medlin T, Roberts Gill J et al (2012) Topical curcumin-based cream is equivalent to dietary curcumin in a skin cancer model. J Skin Cancer 2012:1–9

Sun W, Mao S, Shi Y, Li LC, Fang L (2011) Nanonization of itraconazole by high pressure homogenization: stabilizer optimization and effect of particle size on oral absorption. J Pharm Sci 100:3365–3373

Tekko IA, Permana AD, Vora L, Hatahet T, McCarthy H et al (2020) Localised and sustained intradermal delivery of methotrexate using nanocrystal-loaded microneedle arrays: potential for enhanced treatment of psoriasis. Eur J Pharm Sci 152:105469

Trimukhe A, Rojekar S, Vavia PR, Deshmukh RR (2021) Pulsed plasma surface modified omeprazole microparticles for delayed release application. J Drug Deliv Sci Technol 66:102905

Tucak A, Sirbubalo M, Hindija L, Rahic O, Hadziabdic J et al (2020) Microneedles: characteristics, materials, production methods and commercial development. Micromachines 11:961

Ullah A, Kim CM, Kim GM (2018) Porous polymer coatings on metal microneedles for enhanced drug delivery. R Soc Open Sci 5:171609

Vallhov H, Xia W, Engqvist H, Scheynius A (2018) Bioceramic microneedle arrays are able to deliver OVA to dendritic cells in human skin. J Mater Chem B 6:6808–6816

Verma S, Gokhale R, Burgess DJ (2009) A comparative study of top-down and bottom-up approaches for the preparation of micro/nanosuspensions. Int J Pharm 380:216–222

Vora LK, Vavia PR, Larrañeta E, Bell SEJ, Donnelly RF (2018) Novel nanosuspension-based dissolving microneedle arrays for transdermal delivery of a hydrophobic drug. J Interdiscip Nanomed 3:89–101

Vora LK, Moffatt K, Tekko IA, Paredes AJ, Zanutto FV et al (2021) Microneedle array systems for long-acting drug delivery. Eur J Phar Biopharm 159:44–76

Walsh L (2019) Microneedling: a versatile and popular treatment option. J Aesthet Nurs 8:280–284

Wang Y, Zheng Y, Zhang L, Wang Q, Zhang D (2013) Stability of nanosuspensions in drug delivery. J Control Release 172:1126–1141

Wang M, Hu L, Xu C (2017) Recent advances in the design of polymeric microneedles for transdermal drug delivery and biosensing. Lab Chip 17:1373–1387

Wang P, Cao X, Chu Y (2019a) Ginkgolides-loaded soybean phospholipid-stabilized nanosuspension with improved storage stability and in vivo bioavailability. Colloids Surf B 181:910–917

Wang C, Cui B, Guo L, Wang A, Zhao X et al (2019b) Fabrication and evaluation of lambda-cyhalothrin nanosuspension by one-step melt emulsification technique. Nanomaterials 9:145

Watanabe T, Ohno I, Wakiyama N, Kusai A, Senna M (2002) Stabilization of amorphous indomethacin by co-grinding in a ternary mixture. Int J Pharm 241:103–111

Wei F, Wang Q, Liu H, Yang X, Cao W et al (2022) High efficacy combined microneedles array with methotrexate nanocrystals for effective anti-rheumatoid arthritis. Int J Nanomed 17:2397–2412

Wu Y, Vora LK, Mishra D, Adrianto MF, Gade S et al (2022) Nanosuspension-loaded dissolving bilayer microneedles for hydrophobic drug delivery to the posterior segment of the eye. Biomater Adv 137:212767

Xenikakis I, Tsongas K, Tzimtzimis EK, Katsamenis OL, Demiri E et al (2022) Transdermal delivery of insulin across human skin in vitro with 3D printed hollow microneedles. J Drug Deliv Sci Technol 67:102891

Xia D, Quan P, Piao H, Piao H, Sun S et al (2010) Preparation of stable nitrendipine nanosuspensions using the precipitation–ultrasonication method for enhancement of dissolution and oral bioavailability. Eur J Pharm Sci 40:325–334

Xiang H, Xu S, Li J, Pan S, Miao X (2022) Particle size effect of curcumin nanocrystals on transdermal and transfollicular penetration by hyaluronic acid-dissolving microneedle delivery. Pharmaceuticals 15:206

Yadav V, Sharma PK, Murty US, Mohan NH, Thomas R et al (2021) 3D printed hollow microneedles array using stereolithography for efficient transdermal delivery of rifampicin. Int J Pharm 605:120815

Yao L, Zhao X, Li Q, Zu Y, Fu Y et al (2012) In vitro and in vivo evaluation of camptothecin nanosuspension: a novel formulation with high antitumor efficacy and low toxicity. Int J Pharm 423:586–588

Yurdacan HM, Murat Sari M (2021) Functional green-based nanomaterials towards sustainable carbon capture and sequestration. In: Murat Sari M, Cenk T, Hakan CC, Luigi S, Ole T (eds) Sustainable materials for transitional and alternative energy. Gulf Professional Publishing, Oxford, pp 125–177

Zhang J, Xie Z, Zhang N, Zhong J (2017) Nanosuspension drug delivery system: preparation, characterization, postproduction processing, dosage form, and application. In: Ecaterina A, Alexandru Mihai G (eds) Nanostructures for drug delivery. Elsevier, Amsterdam, pp 413–443

Zhang XP, Zhang BL, Chen BZ, Zhao ZQ, Fei WM et al (2022) Dissolving microneedle rollers for rapid transdermal drug delivery. Drug Deliv Transl Res 12:459–471

Download references

Acknowledgements

The authors would like to thank the Department of Pharmaceutics, National Institute of Pharmaceutical Education and Research-Ahmedabad (NIPER-A), Gujarat, 382355, India, for providing resources for literature search and review writing.

Author information

Authors and affiliations.

Department of Pharmaceutics, National Institute of Pharmaceutical Education and Research-Ahmedabad (NIPER-A), Ahmedabad, Gujarat, 382355, India

Jyotsna G. Vitore, Bharathi Karunakaran, Siddharth Salve & Derajram Benival

Department of Pharmaceutical Sciences and Technology, Institute of Chemical Technology, Mumbai, 400019, India

Sakshi Pagar

Department of Pharmaceutics, National Institute of Pharmaceutical Education and Research, Kolkata, 700054, India

Nidhi Singh

Institute of Chemical Technology, Mumbai, Marathwada Campus, Jalna, 431203, India

Navnath Hatvate

Department of Pharmacological Sciences, Icahn School of Medicine at Mount Sinai, New York, NY, 10029, USA

Satish Rojekar

You can also search for this author in PubMed Google Scholar

Contributions

JGV: Data curation, Formal analysis, Methodology, Writing—original draft; SP: Data curation, Formal analysis, Methodology, Writing—original draft; NS: Data curation, Formal analysis, Methodology, Writing—original draft; BK: Data curation, Formal analysis, Methodology, Writing—original draft; SS: Data curation, Formal analysis, Methodology, Writing—original draft; SR, DB: Conceptualization, Data curation, Formal analysis, Validation, Investigation, Visualization, Methodology, Writing—original draft, Writing—review and editing.

Corresponding authors

Correspondence to Satish Rojekar or Derajram Benival .

Ethics declarations

Conflict of interest.

All authors (J.G. Vitore, S. Pagar, N. Singh, B. Karunakaran, S. Salve, N. Hatvate, S. Rojekar, and D. Benival) declare no conflict of interest.

Statement of human and animal rights

This article does not contain any studies with human and animal subjects performed by any of the authors.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Vitore, J.G., Pagar, S., Singh, N. et al. A comprehensive review of nanosuspension loaded microneedles: fabrication methods, applications, and recent developments. J. Pharm. Investig. 53 , 475–504 (2023). https://doi.org/10.1007/s40005-023-00622-1

Download citation

Received : 19 January 2023

Accepted : 17 May 2023

Published : 06 June 2023

Issue Date : July 2023

DOI : https://doi.org/10.1007/s40005-023-00622-1

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Nanosuspension

- Dissolving microneedles

- Transdermal drug delivery

- Nanocrystals

- Controlled release

- Long-acting

- Find a journal

- Publish with us

- Track your research

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- v.27(1); 2019 Jun

Formation of nanosuspensions in bottom-up approach: theories and optimization

Ali ahmadi tehrani.

1 Department of Pharmaceutics, Faculty of Pharmacy, Shahid Sadoughi University of Medical Sciences, Yazd, Iran

2 Pharmaceutical Research Center, Shahid Sadoughi University of Medical Sciences, Yazd, Iran

Mohammad Mahdi Omranpoor

Alireza vatanara.

3 Department of Pharmaceutics, Faculty of Pharmacy, Tehran University of Medical Sciences, Tehran, Iran

Mohammad Seyedabadi

4 Department of Pharmacology, School of Medicine, Bushehr University of Medical Sciences, Bushehr, Iran

Vahid Ramezani

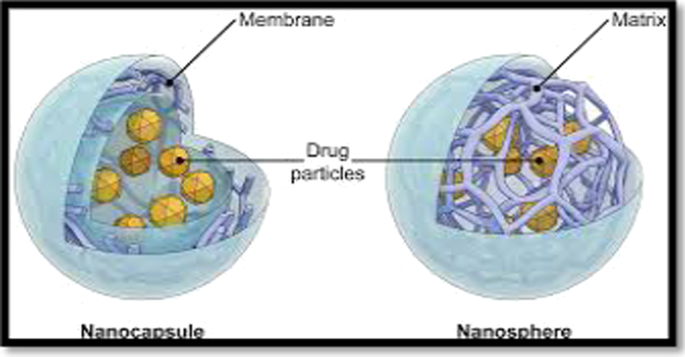

Nanosuspensions, liquid dispersions with nanometer size distribution, are becoming trendy in pharmaceutical practice to formulate poorly water-soluble drugs and to enhance their bioavailability. Generally, nanosuspensions are produced in two main approaches; top-down or bottom-up. The former is based on size-reduction of large particles via milling or high pressure homogenization. The latter is focused on the mechanisms of nucleation and particle growth.

In this review, the critical factors influencing the kinetics or dynamics of nucleation and growth are discussed. Subsequently, the mechanisms of nanosuspension instability as well as strategies for stabilization are elaborated. Furthermore, the effects of stabilizers on key parameters of instability as well as the process of choosing an appropriate stabilizer is discussed.

Steric and electrostatic stabilizations or combination of them is essential for nanosuspensions formulation to prevent coagulation. Accordingly, some characteristics of stabilizers play critical role on stability and optimization of nanosuspensions; i.e., HLB and concentration. Nevertheless, after reviewing various articles, it is ascertained that each formulation requires individual selection of surfactants according to the parameters of the particle surface and the medium.

Conclusions

Based on the results, application of excipients such as stabilizers requires proper optimization of type and concentration. This implies that each formulation requires its own optimization process.

Graphical Abstract

Introduction

Bioavailability is one of the limiting factors in drug development with chemicals having poor water solubility [ 1 – 5 ]. An array of solubilizing agents as well as various techniques have been employed to increase the solubility of such drugs, including surfactants, co-solvents, pH adjusted solutions, emulsions, liposomes, cyclodextrins and solid dispersions [ 6 , 7 ]. However, the majority of these techniques require additional excipients, which themselves can be a safety challenge [ 2 ]. In addition, these techniques offer little or no help in formulations where the parent molecules are poorly soluble in both aqueous and non-aqueous media [ 8 ].

The tendency of solute dissolution in specific solvent is determined by similar or dissimilar molecular interactions between the solute and solvent. In this way, environmental condition such as pressure and temperature influence the cohesion and adhesion force and eventually the intermolecular interactions. Of particular note, any further addition of solute above the solvent capacity leads to precipitation. All together Noyes–Whitney equation (Eq. 1 ), is very practical to get the valuable information about the process of dissolution.

Nanosuspensions, liquid dispersions with nanometer size distribution, help enhance the bioavailability of poorly soluble chemicals. In this regard, particle size as well as size distribution significantly influence the dissolution rate; thereby are among key determinants of the bioavailability. In particular, fine particles with high specific surface areas exhibit faster dissolution rate, which is demonstrated by Noyes–Whitney equation (Eq. 1 ) [ 7 , 9 – 11 ].

According to this equation (Eq. 1 ), dissolution rate of a particle (dc/dt) is inversely related to diffusion distance (h), and directly to the particle surface area (A) and saturation solubility [ 12 ]. Also, solubility is correlated to the rate of dissolution, albeit in some cases the case is more complex. Solubility is thermodynamically defined as the maximum amount of solute that can hold the pure solvent. So, solubility is affected by environmental conditions such as pH, temperature, ionic strength of solvent and solute. However, the rate of dissolution is a kinetic process. This implies that the extent of solubility of one solute can be poor or good independent of the rate of dissolution.

However, according to Ostwald–Freundlich equation (Eq. 2 ), in apposition to microparticles, the saturation solubility and equilibrium solubility of spherical particles with size of smaller than 1000 nm can influence the particle size.

That C s is solubility, C ∞ is solubility of the solid which consist of large particles, σ is interfacial tension substance and ρ is the solid density [ 13 ]. Also, according to Prandtl equation (Eq. 3 ) hydrodynamic boundary layer thickness will decrease and surface specific dissolution rate will increase by reduction of particle size [ 14 ].

Where L is length of the surface in the direction of flow, k is denotes a constant, V is relative velocity of the flowing liquid against a flat surface and h H is the hydrodynamic boundary layer thickness.

Also, the formation of nanosuspensions not only increases the surface area but also enhances the saturation solubility of the solute in medium, resulting in better bioavailability [ 12 , 15 – 18 ]. Moreover, the increase of mucoadhesivity and attachment to surfaces/cell membranes are other characteristics of nanosuspensions aiding in efficacious drug delivery [ 7 , 9 , 10 ]. Furthermore, nanosuspensions require no co-solvents, and allow higher drug loading compared with other formulations [ 19 ]. Better antitumor activity is also reported with nanosuspensions due to higher extravasation and remaining of particles at the vicinity of tumor [ 20 ].

Formulation of pharmaceuticals as nanosuspension was introduced in 1990, and the first product of this form appeared in the market in 2000 [ 10 ]. Ever since, a variety of micro- and/or nano- particles with proper size distribution have been widely used for drug delivery of poorly soluble chemicals [ 21 ]. These included of Rapamune® (sirolimus), Emend® (aprepitant), Megace®ES (Megestrole), Triglide® and Tricor® (fenofibrate), [ 8 , 22 – 24 ]. In the most cases, particles are stabilized using appropriate polymers and/or surfactants in nanosuspensions [ 8 , 25 ].

Generally, nanosuspensions are produced via either top-down or bottom-up processes [ 1 , 2 ]. While the former mainly includes size reduction via milling, the latter involves precipitation and supersaturation. The main factors determining an effective top-down formulation process are elaborated elsewhere [ 26 ]. Here, we review the mechanisms of nanosuspension formulation in bottom-up approach and, also, we elaborate the parameters influencing the quality and stability of these formulations.

Mechanism of nanoparticle formation

Top-down approaches are based on the size-reduction and breaking down of large materials into particles with nanometer dimensions via milling, high pressure homogenization and pulsed laser fragmentation [ 27 , 28 ]. Milling is performed using a rotating instrument in which particles are mixed with milling pearls with constant rotation, resulting in crystals or amorphous particles with reduced size [ 2 , 26 , 29 , 30 ]. However, high speed rotation may generate lots of heat, causing degradation of thermal-sensitive agents [ 2 ]. Also, milling can cause surface activation of drug particles, influencing several physiochemical properties of them such as their flow ability [ 31 ]. High-pressure homogenization (HPH) is also applied for nanocrystal production. In particular, the piston-gap homogenizer and microfluidizer are two main types of homogenizers frequently used for particle size reduction [ 29 ]. In this regard, several parameters are critical in HPH including pressure, cycle number, stabilizer type, temperature of process and stabilizing concentration [ 32 , 33 ]. Pulsed Laser Ablation (PLA) and Pulsed Laser Deposition (PLD) are advanced techniques based on the absorption of the energy by the material and transformation to thermal and/or chemical energy to break (inter) molecular bonds of the bulk material. This method usually leads to smaller particles with a wide size distribution which can be considered a disadvantages [ 28 ].

The Gibbs free energy will change during the size reduction in top-down process due to formation of new surfaces. This will result in thermodynamic instability of nanosuspension. Therefore, proper stabilizers are required to reduce the particle free energy [ 34 ]. The process of top-down nano formulation is discussed elsewhere [ 26 ] and is beyond the scope of this review.

The bottom-up approach is based on precipitation of supersaturated solutions [ 35 ]. It is frequently employed for the production of nanosuspensions both in bulk solutions or in single droplets [ 36 ]. This method is used in a number of pharmaceutical processes such as solvent–anti-solvent technique, supercritical fluid processing, spray drying, and emulsion–solvent evaporation [ 8 , 37 ]. Of particular note, nanoparticles are obtained after several steps including supersaturation, nucleation, diffusion of the solute molecules and nanoparticle growth [ 38 ].

The bottom-up approach offers various advantages such as production of monodisperse particles, i.e., narrow range of size distribution, application of low energy and low processing temperature for thermolabile drugs, and no need for advanced equipment and generally an economically procedure. Recently, some pharmaceutical products have been produced and marketed in this method, such as Griseofulvin (Gris-PEG®) and Nabilone (Cesamet®) [ 39 ]. In addition, an investigation has proved the nanosuspension of Danazol (gonadotropin inhibitor) has more improvement in comparison with micro-suspension of marketed Danazol [ 40 , 41 ]. Interestingly, fenoibrate [ 42 ] and Nitrendipine nanosuspensions were manufactured with the aid of combination methods [ 43 ].

However, generation of different unstable polymorphs, hydrates and solvates such as needle shaped particles caused by rapid growth can be undesirable. Also, application of non-solvents or anti-solvents are not favorable, given that even a few amount of residual medium can lead to physicochemical instability. Therefore, non-solvents are removed either via evaporative precipitation into aqueous solution (EPAS) or supercritical fluid (SCF) which need high pressure pump, temperature and fine nozzle designing.

Combination method

It is, however, noteworthy that some studies suggest a combination of top-down and bottom-up approaches as an optimal method for the particle preparation with size and stability. In this way, NANOEDGE™, H 69, CT (combination technology), H 96 and H 42 technology have been introduced to combine bottom-up and top down technology to reach effective reduction of particle size, e.g., preparation of atorvastatin nanoparticles via combination of anti-solvent precipitation after probe sonication method [ 44 ]. When these two methods are implemented simultaneously, a number of distinct nuclei with a certain size are created and inhibit the formation of nuclei with larger size. In addition, the combination of these methods leads to reach a narrow polydispersity index (PDI) and the range of particle size lies within a certain range that decreases the particle growth [ 2 , 24 , 35 , 44 , 45 ].

Nucleation and particle growth

Particle formation in bottom-up approach is initiated by nucleation followed by particle growth, which is, indeed, considered as the most important step in nanosuspension formulation [ 46 ]. As described by Reiss [ 47 ] and laMer and Dinegar [ 48 ], particle formation begins with short nucleation bursts and consequent molecule-by-molecule diffusion leading to particle growth. However, nucleation may result in either crystals or amorphous nanoparticles.

The first step of nucleation is monomer aggregation in supersaturated systems. So, the likelihood of addition of one monomer to the nucleus is directly proportional to its concentration in the bulk solution as well as its ability to diffuse to the nucleus surface [ 46 ]. In this regard, when the primary nucleus is spherical, the rate of diffusion of monomer ( Q ) follows the Fick’s law (Eq. 4 ); where R is the primary nucleus radius, D is the diffusion coefficient of monomers, C b is the concentration of monomer in the bulk solution, and S 0 is the solubility [ 46 , 49 ].

The free energy per monomer in the solution is higher than that in crystalline phase. Therefore, monomeric molecules tend to aggregate to maintain a low-energy state. Likewise, a small nucleus has higher surface area compared to large ones, resulting in higher interface interaction with solute molecules and higher level of energy. Hence, small nuclei combine together to reduce the system’s free energy, ultimately leading to the particle growth [ 46 ].

It is noteworthy that coagulation of nanoparticle are also determined by other factors, described in Navier-Stokes (NS) equations such as mass, momentum and energy conservation of Newtonian-fluids. NS equations are applicable for incompressible or compressible, low or high speed, inviscid or viscous flows. The compact form of Navier-Stokes equations for Newtonian fluid is (Eq. 5 ):

Where ρ is density, ∂ V ∂ t is change of velocity with time, ( V . ∇ ) V is convective term, ∇P is pressure term (fluid flows in the direction of largest change in pressure), ρg is bode force term (external forces acting on the fluid, such as gravity and electromagnetic) and μ∇ 2 V is viscosity controlled velocity diffusion. This equation (Eq. 5 ) represents how all Newtonian fluids move [ 50 ].

Kinetics of nucleation and particle growth

The rate of formation and growth of the nuclei is determined by Arrhenius model (Eq. 6 ). Here, K is the nucleation constant, E a is the activation energy, and A 0 is the pre-exponential factor. These parameters are, in turn, influenced by the number and orientation of particles, surface tension, medium viscosity, temperature, pressure and external driving forces [ 51 , 52 ]. In particular, E a diminishes at higher supersaturation, leading to higher nucleation probability and speed [ 53 ].

The effect of temperature

It is expected for particle growth to decrease at higher temperatures because of particle re-dissolution. However, the Brownian motions will also increase with temperature, leading to improvement of particle orientation and the force of intermolecular interactions, which are in favor of particle growth. Furthermore, temperature increases the particles hydrodynamic diameter (diameter of particle that is coated with hydrated counter ion), resulting in lower particle repulsion, ultimately leading to particle adhesion and nanoparticles growth. In fact, the effect of temperature on nucleation depends on the degree of supersaturation of solution [ 51 , 52 ].

The effect of surface tension

The rate of nucleation is a critical determinant of particle size and size distribution. In this regard, Arrhenius equation (Eq. 7 ) describes the effects of different variables on nucleation rate [ 54 ]. Of particular note, nucleation rate constant ( dN dt ) depends on the concentration of stabilizers. In fact, increase of stabilizer concentration in the solution decreases surface tension, thereby inhibits nucleation rate and increases crystallization time [ 53 ]. In addition, surfactants alter γ , the surface free energy, thereby modulate the nucleation speed [ 54 ].

The effect of supersaturation

The ratio of anti-solvent to solvent increases at high degree of supersaturation, resulting in a greater nucleation rate, which eventually enhances the number but decreases the size of particles. In fact, higher degree of supersaturation (S in Eq. 7 ) enhances nucleation rate, and eventually results in smaller particle size [ 45 ]. In this regard, small changes in S dramatically alters nucleation rate; Kwon and Hyeon showed that an increase of S by two folds (from 2 to 4) lead to a significant increase of nucleation rate up to 10 70 times [ 54 ]. It is noteworthy that particle growth is directly proportional to both particles count and their size. Thus, a shrink in particle size appears to neutralize the effects of supersaturation on particle number. Nevertheless, the overall outcome of an increase in supersaturation favors particle growth [ 45 ].

The effect of molecular diffusion

The nanoparticles diameter is determined according to LSW (Lifshitz–Slyozov–Wagner) model [ 51 , 55 – 57 ]; where n depends on the formation and growth of the particles.

When n is 2, particle growth is mainly controlled by ions diffusion in the matrix; i.e., diffusion of ions in solution. Meanwhile, when n is 3, the particle growth depends on volumetric diffusion in the matrix; i.e., diffusion of ions on the particle surface. Accordingly, n = 4 implies that dissolution kinetics at both particles surface and the matrix ought to be counted in particle growth, demonstrating dissolving-precipitation phenomena at the solid-liquid interface [ 51 , 56 ]. It is noteworthy that n can never be 1 and the 1/n exponent would always be less than 1, because particle size does not follow first order kinetics model. In fact, a decrease in the surface/volume ratio due to particle growth tends to negatively influence the ripening rate ( k ) due to reducing the available surface for deposition.

In this regard, k is correlated to diffusion coefficient of solute molecules in the medium, bulk solublity of dispersed phase ( C ∞ ), the solid-liquid interfacial tension (γ) and the molar volume of dispersed phase ( V m ) [ 55 ]. As demonstrated in Eq. 9 , k is almost constant in specified isothermal systems.

The surface nucleation, a critical component of particle growth, varies in different systems and depends on the dimensions of length and time, τ and k 1 respectively (Eq. 10 ) [ 58 , 59 ].

The crystal growth depends, also, on the concentration of bulk solution as well as its related concentration to crystal surface. In particular, the rate of crystal growth ( R G ) is determined by Eq. 11 ; where k G is the coefficient of growth rate, C b is the solute concentration in bulk solution, C ∗ is the solute concentration in equilibrium after nanosuspension formation, and g is the total growth condition [ 60 ].

The crystal growth is composed of two sequential steps. The first step involves solute transfer to the interfacial solid-liquid surface; i.e., the diffusion of monomers to the surface. In the next step, the solute integrates with the solution and separates from the crystal lattice.

Thermodynamics of nucleation and particle growth

The effect of free energy.

The bottom-up approach in nanosuspension formulation is based on the supersaturation of the solution followed by precipitation of the nanoparticles. Assessment of the thermodynamics of homogenous nucleation has revealed that the Gibbs free energy of nanoparticles is determined by the sum of surface free energy of nanoparticles and bulk free energy (Eq. 12 ). Accordingly, the bulk free energy ( ∆G v ) is calculated by Eq. 13 . In particular, ∆G v is directly proportional to temperature (T), Boltzmann constant ( k B ), degree of supersaturation (S), and inversely to the molar volume ( v ) [ 46 , 54 , 61 ].

The rate of particle formation, stabilization, and size, depend on the sum of free energy (Eqs. 14 and 15 ). In fact, the higher the total free energy, the lower the rate of particle formation. It should be noted that the surface free energy of particles in solution is more than in crystal form. Thus particles tend to form large agglomerates or precipitate in the form of crystals. Of particular note, the radius of critical nuclei ( r crit ), nuclei with maximal free energy per monomer without further re-dissolution in medium, is directly proportional to their free energy ( ∆G crit ) [ 46 , 54 , 61 ].

The precipitation of nanoparticles correlates with the degree of supersaturation. Indeed, the lower the degree of supersaturation, the slower the rate of nucleation. In this regard, “metastable zone” is a concentration range at which nucleation does not occur regardless of time. During the nanosuspension generation process, the concentration of solute molecules rise to form “clusters” which are prerequisites for nanoparticle formation [ 46 ].

According to the Eq. 7 , the rate of clustering of molecules as well as its thermodynamics depends on the degree of supersaturation and the molar volume of the nucleus. In fact, solute molecule continues to cluster until ∆G crit becomes negative. In this regard, ∆G crit , Gibbs free energy to form the critical nucleus, is calculated by Eq. 16 ; where γ sl is the surface tension between liquid and solid surface [ 46 ].

As demonstrated in Eq. 16 , the degree of supersaturation is inversely related to ∆G crit . Thus, solutions become thermodynamically unstable and tend to crystallize when the degree of supersaturation increases [ 53 ].

The steady state concentration in which clusters are stable ( C n ∗ ) is close to the equilibrium concentration, and is calculated using Eq. 17 . Here, ∆G crit represents the free energy of forming a critical cluster from free monomers, and C tot is the total concentration of substance in the system, which is approximately equal to the free monomer concentration [ 46 ].

For the assessment of ∆G crit , the capillarity approximation has been used. In other words, the free energy of a cluster is established on the free energy of a macroscopic solid and the cluster–water interfacial tension [ 62 ]. The formation of critical clusters per unit of time represents the transport of monomers to the clusters, and is calculated by nucleation rate (J) in unit of bulk volume in steady state concentration (Eq. 18 ); where Z is Zeldovich factor, and ψ ∗ = r crit /(λ + r crit ) [ 46 ].

The nucleation rate is related to diffusion and λ (effective length) as well as the interfacial tension ( γ sl ) and C b / S 0 , which is dependent to degree of supersaturation. It is noteworthy that when a change in λ is compensated by simultaneous change in γ sl , the nucleation rate maintains a constant value [ 46 ].

Some polymers with surface adsorption can enhance nucleation rate. In fact, these polymers ought to modulate one or more of the parameters discussed above. When, a specific polymer produces distinct effects on each parameter, the geometric sum of effects determines the final outcome [ 53 ].

Thermodynamics of surfactant adsorption and nucleation

Generally, nanosuspension is assuming a dispersion of hydrophobic nanoparticles in water as a hydrophilic medium. The enormous increase of surface area due to reduction of particle size results in increase of particles’ free energy while The interfacial tension remains constant, and is considered the main reason of thermodynamic instability of nanosuspensions [ 8 ]. Accordingly, to reduce the total surface energy of the system, nanoparticles tend to accumulate and reduce the total surface area with flocculation aggregation or crystal growth. Thus, crystallization as the main step in bottom-up approach can itself result in instability of nanosuspension, if is not appropriately controlled. In this regard, stabilizers are added to reduce the free energy of the system by decreasing the interfacial tension. This is fulfilled through electrostatic or steric stabilization or both [ 55 ].

The effect of surfactant lipophilicity and concentration

The adsorption of surfactants and polymers on the surface of nanoparticles play a pivotal role in the formation and stabilization of nanosuspensions. Furthermore, not only the surfactant adsorption to the solid surface but also its orientation influences the energy in the case of ∆G, ∆H and ∆S. In this regard, the hydrophilic: lipophilic balance (HLB) of surfactants is a critical parameter [ 63 ]. In fact, a change in the energy levels of the adsorbate species, the interfacial plate, and free surfactant in the bulk solution ultimately leads to the selective partitioning of the adsorbate into the interfacial region [ 63 ].

The mixture of surfactant/polymer and drug crystallites determines the melting point depression, and depends on their concentration, though their relationship is not necessarily linear [ 64 ]. The concentration of surfactant at the interface ( C interface )is in balance with its’ bulk concentration ( C bulk ), and is calculate by Eq. 19 . In this regard, the negative value of Gibbs free energy indicates the favorable conditions for absorption of surfactant from the bulk medium to the interface.

- The effect of dispersion medium

The absorption of surfactants in the solid-liquid interface depends on several factors in the solid plate, in the surfactant, and in the medium. The latter includes the nature of solvent, pH, temperature, ionic strength, lateral interaction between the adsorbed molecules, and presence of other dissolved materials, i.e., electrolytes or short chain additives such as alcohol an urea [ 63 , 65 ].

An array of interactions is demonstrated at the interface such as electrostatic, covalent, hydrogen or non-polar bonds [ 64 , 65 ], among which hydrogen bonds strongly influence the nucleation process [ 53 ]. Albeit, a specific type of interaction is dominant for each polymer. In this regard, polymers like PVP, with only one hydrogen bonding functional group per monomer, are not strongly adsorbed onto the crystal faces, and are less likely to induce habit modification [ 53 ]. For example, Lindfors L. et al., found that the growth rate significantly decreased in the presence of 0.01% ( w /w) PVP, whereas nucleation rate was not affected. This is explained by similar values of D, λ, γ sl , and C b / S 0 with and without PVP, small critical radius, and the fact that there is no significant polymer adsorption on these small particles [ 46 ].

Although hydrogen bonds play the main role in surface adsorption, the sum of all additive forces determines the level of free energy. For instance, Celecoxib is more likely to produce hydrogen bonds with the hydroxyl group of hydroxypropyl cellulose (HPC) than with the ether group of Pluronic F-127 (PLU), but the latter produce stronger effects on crystallization. This indicates that the final effect on crystallization is determined by the sum of interactions [ 64 ]. Thus, ∆G ads is considered when analyzing the surface energy (Eq. 20 ). In fact, the level of energy is a combination of electric attraction force between solid plate and the surfactant ( ∆G elec ), covalent bonding ( ∆G chem ), cohesive chain-chain interaction among adsorbed long chain surfactant species ( ∆G c − c ) and similar interactions between the hydrocarbon chains and hydrophobic sites on the solid plate ( ∆G c − s ), hydrogen bonding ( ∆G H ), and the solvation or de-solvation energy ( ∆ G H 2 O ) [ 65 ].

This implies that several processes at the interface including ion exchange (the exchange of surfactants with opposite charges), ion pairing (the absorption of surfactants in non-occupied positions), acid-base interaction (Lewis acid and base interaction with hydrogen bonds), π electron polarization (the force between side chains with positive charge), dispersion force (such as London and Van Der Waals forces), hydrophobic interactions (interaction between the non-polar side chains of surfactant and hydrophobic surface of nanoparticles) [ 63 ].

The effect of interfacial layer thickness

The thickness of interfacial layer ( τ ) is of notable importance. In this regard, the level of energy at the interface depends on the concentration of surfactant as well as the interfacial thickness (Г i ) (Eq. 21 ) [ 65 ].

The interface is a very dynamic region. In fact, diffusion, convection, adsorption, and desorption of stabilizer on the new surface of nanoparticle can occur simultaneously [ 66 – 68 ]. The physicochemical property of new particle surfaces, medium and surfactant is critical to minimize the Gibbs free energy. Thus, stabilization of a specific nanosuspension demands selection of a stabilizer with appropriate properties [ 69 ]. Moreover, the mixture ought to be incubated for a specific time span to ensure proper coverage of the surface; the length of which depends on physicochemical properties of the surfactant such as molecular weight and hydration value as well as the viscosity of medium [ 70 ].

The effect of surface polarity

Surface polarity influences the surface interaction of not only ionic but also non-ionic surfactants. In fact, the absorption of nonionic surfactant on the articles depends on the chemical potential of bulk solution, and is defined by Flory-Huggins Eq. (Eq. 22 ); where, the s represents surface, and q is the number of solute segments in contact with the surface. The m is the number of segment-surface nearest neighbors divided by the lattice coordination number, and r is the molecular size ratio of solute to solvent. The net interaction between components 1 (water as solvent) and 2 (surfactant as solvate) is expressed as χ 1, 2 . In this regard, χ 1, s − χ 2, s indicates the change of surface contact from solvent to solute, and χ 1 , 2 − χ 1 , 2 s represents the differential strength of solute-solvent interaction in the bulk solution and in the surface phase [ 71 ].

This model is applied for the absorption of nonionic surfactant to the non-polar surface such as polystyrene. In this regard, approximately 20% of free energy of absorption of nonionic surfactants on latex surface is due to the replacement of surface-water contacts with surface-surfactant contacts, i.e., (χ 1, s − χ 2, s ). The remaining 80% is related to the orientation of surfactant molecules at the surface, expressed as χ 1 , 2 − χ 1 , 2 s .

At the interface, the hydrophilic parts of surfactant molecule are in contact with water, whereas hydrophobic parts orient toward particle surface [ 71 ]. This indicates lower possibility of unfavorable contacts of hydrocarbon chain to the aqueous solution. Therefore, the water–surfactant interaction at the surface will be weaker than that in bulk solution (χ s < χ).

The χ parameter is the sum of fractional effects of interactions between water-hydrophilic moiety of surfactant, water-hydrophobic moiety of surfactant, water-water, and hydrophilic-hydrophobic moieties. Hence, χ is related to the HLB of surfactant and the HLB will be HLB = 20 ω hydrophilic in which ω hydrophilic is the weight fraction of hydrophilic part of surfactant [ 71 ].

Nanosuspension instability

The process of particle formation in nanosuspensions generally follows 2 steps, nucleation and particle growth. In this regard, uncontrolled growth can cause instability of the suspension (Fig. 1 ) [ 60 , 61 ]. Instability at some, but not all, levels is reversible with appropriate intervention. Thus, proper control of the processing time is critical to get nanoparticles with desirable size without instability.

Schematic of particle precipitation process. Reprinted with permission from [ 159 ]. Copyright (2009) American Chemical Society

Particle growth in nanosuspensions is explained by various mechanisms, including aggregation [ 55 , 56 ], coalescence [ 56 , 61 , 72 ], crystal growth [ 55 , 60 , 73 ], Ostwald ripening [ 55 , 74 , 75 ], orientated attachment [ 56 , 76 ], self-assembly, and mesoscopic transformation of nanoparticles via a restructuring process [ 77 – 79 ]. Depending on the system, one or several mechanisms may be involved in nucleation and growth of particle size [ 56 ].

Particle agglomeration is the outcome of attractive forces between the particles in the absence of considerable energy barrier; the latter is proven to be more important [ 80 ]. In this regard, high levels of hydrophobicity of particles decrease the wettability of their surface, resulting in aggregation [ 81 ]. Accordingly, hydrophobic particles tend to agglomerate to reduce the system free energy, as shown in the case of naproxen particles [ 82 ].

The lyophobic nanosuspension is produced by dispersion of hydrophobic materials in hydrophilic aqueous medium. In this system, increase of the surface area, because of nano-formulation, enhances the contacts between particles and outer medium, ultimately resulting in high surface energy. This can cause thermodynamic instability [ 8 ] and aggregation of nanoparticles [ 81 ].

Mechanisms of nanosuspension instability/stabilization

As discussed above, the mechanisms of nanoparticle growth and instability are similar. In fact, inappropriate growth can cause instability of the system. Hence, both formation and instability of nanoparticles can be determined by similar variables and principles.

- Nanoparticle growth in lamer mechanism

The nucleation and particles growth is divided into 3 steps according to lamer mechanism. At first, increase in monomer concentration in supersaturated solution causes nucleation bursts in the medium. This results in a decrease of monomer concentration, and if continued, halts the process of nucleation. If monomer concentration is high enough to prevent nucleation arrest, the nuclei will grow due to monomer diffusion of supersaturated solutions [ 54 , 83 ]. Thus, monomer concentration as well as factors influencing its diffusion plays pivotal roles not only in nucleation and growth but also in system stability. In this regard, storage at low temperatures, removal of residual solvents, applications of steric barrier around the particles, higher viscosity and lower diffusion coefficients of the medium ought to reduce monomer diffusion to the surface and inhibit particle growth (Eqs. 9 , 10 and 11 ).

- Ostwald ripening

Ostwald ripening was introduced in 1900 by Gibbs–Thomson law, and is based on the changes in the solubility of nanoparticles according to their size. It can cause significant instability in nanosuspensions [ 2 ], especially in long term storage [ 55 ]. In fact, higher solubility of nanoparticles causes re-dissolving and elimination of small particles. In the meantime, large particles tend to grow inappropriately because of low level of surface energy [ 84 , 85 ].

Owing to application of surfactants in nanosuspension formulations and because of their adsorption at particles surface, Ostwald ripening is illustrated by Lifshitz–Slyozov–Wagner (LSW) theory (Eq. 23 ). Here, r is the radius of spherical nanocrystal, t is the time of radius changing, and K D is the diffusion coefficient. The ω is monomer flux coefficient which demonstrates the ease of material movements in the surfactant layer [ 74 ].

In LSW theory, the term ∫ 0 ∞ ρ 2 h ρ dρ is specific for each system. For instance, in the case of bare-nanocrystals it equals to 9/4. However, if surfactants are utilized, one ought to consider the thickness of surfactant layer on the nanoparticle surface (δ) (Eq. 24 ) [ 74 ].

The kinetics of Ostwald ripening is determined by two basic parameters; the ability of solute molecules to diffuse to the particle surface, and the rate of crystal growth/dissolution by attachment-detachment of the solute. In this regard, the ripening is controlled by the slower step. That is, Ostwald ripening becomes diffusion controlled, if crystal growth/dissolution is rapid; and it becomes interface controlled, when solute diffusion is faster than its incorporation/elimination to/from the particles [ 55 ].

- The effects of surfactants

According to Eq. 24 , surfactants influence diffusion coefficient as well as solubility and surface tension. It is also noteworthy that growth depends on t, though not linearly. Thereby, surfactants have an enormous effect on the process of ripening. In fact, they decrease growth by reducing Ostwald ripening [ 74 ]. In contrast, according to the LSW theory, the concentration of the dispersed phase directly influence the rate of Ostwald ripening [ 2 ]. Therefore, surfactants with higher solubilizing property, causing a rise in particle concentration in bulk solution, increase the rate of Oswald ripening [ 2 ].

- The effects of size distribution

Size distribution is another determinant of particle growth. In this regard, Ostwald ripening requires poly disperse particles with some solubility in medium [ 55 ]. Because large particles tend to grow and small particles tend to fade, a narrow size distribution is essential to prevent particle growth due to Ostwald ripening and to maintain the stability of nanosuspension [ 86 ].

- Digestive ripening

Digestive ripening is another mechanism describing the effects of particle size on the stability of nanosuspensions. In contrast to Ostwald ripening, digestive ripening argues that it is possible to reconstruct particles in order to increase the stability of system. In fact, the ultimate goal is to enhance dissolving of large particles and growth of small particles [ 87 ].

- Finke-Watzky two step mechanism

Finke-Watzky mechanism illustrates nucleation and growth as consequent events. In this mechanism, the particle growth is autocatalytic with the formed nucleus, and is defined by Eqs. 25 and 26 [ 88 ]. The formation of nucleus is a chemical process, and is beyond the scope of this review. However, a fraction of substance A is primarily converted to substance B. Then A and B bind together, and two moles of B are ultimately formed. Consequently, particles grow in size during this process.

- Coalescence and orientated attachment

Coalescence and orientated attachment describe particle growth in a similar manner. The former defines particle attachment with no orientation, yet the latter demands crystallographic alignment of particles for their attachment, including continuous crystallographic planes [ 76 ].

Equation 27 shows the relationship between the rate constant (K 2 ) of orientated attachment reaction and particle radius (r); the N A is the Avogadro constant. In particular, the rate of particle growth is directly proportional to particle radius and diffusion coefficient (D A ) [ 56 ].

Equation 28 represent relationship between rate constant (K 2 ) of orientated attachment reaction and viscosity. On the other hand, the correlation between D A in Eq. ( 27 ) and viscosity is illustrated with Stokes-Einstein model (Eq. 31 ). Also, Eq. 28 argues that particle growth is directly related with temperature (T) and is inversely associated with viscosity ( η ). Furthermore, viscosity of the solvent as well as the solid volumetric fraction ( ϕ ) determine the total viscosity of system (Eq. 29 ), thereby influencing the kinetics of particle growth [ 56 ].

It is noteworthy that viscosity depends also on temperature, according to Arrhenius model described in Eq. 30 [ 56 ]. Thus, the effects of viscosity on growth rate ought to be adjusted to temperature. In fact, increase of viscosity at low temperatures (around the melting point of solvent) significantly inhibits particle growth. In contrast, viscosity tends to remain moderately constant at high temperatures, conferring a linear relationship between growth rate (K 2 ) and temperature (Fig. 2 ) [ 56 ].

- The Influence of solids concentration in dispersion medium

Temperature dependence of the reaction rate constant. Reprinted with permission from [ 56 ]. Copyright (2005) John Wiley and Sons

Solid content of the system is another determinant of viscosity in Einstein equation (Eq. 29 ). In fact, the solid volumetric fraction ( ϕ ), assuming particles as highly dispersed rigid spheres, increases viscosity and, thereby, inhibits particle growth in colloidal nanosuspensions [ 56 ]. It is, therefore, suggested that dilution of nanosuspension, by reducing the total viscosity, promotes particle growth and increase particle size. For instance, Daebis et al., showed that reducing the viscosity of Itraconazol nanosuspension through serial dilution resulted in particle growth from 682.3 nm ± 55 nm (PDI 0.38 ± 0.05) to 828 nm ± 86.3 μm (PDI 0.48 ± 0.104) [ 89 ].

- The effect of stabilizers on system viscosity

According to Stokes-Einstein model (Eq. 31 ), the diffusion of a molecule is inversely proportional to its diameter (d). Also, temperature (T) influences the diffusion through alteration of systems viscosity [ 90 ]. For instance, HPMC enhances the viscosity much more than do Poloxamer 407 and PVA (Fig. 3a ). Hence, the former more effectively inhibits the diffusion of the solute molecules and particle growth [ 90 ]. In contrast, Poloxamer 407, with the lowest viscosity, results in higher growth rate (Eq. 28 ). In this regard, temperature more significantly influences the viscosity of solutions containing HPMC (Fig. (Fig.3b) 3b ) [ 90 ].

- Intra particle re-shaping

Dynamic viscosity of crystallization medium containing different polymers ( a ), and at different temperatures ( b ) ( n = 3). Reprinted with permission from [ 90 ]. Copyright (2012) Springer Nature