- Search Search Please fill out this field.

What Are Logistics?

- Logistics in Management and Business

Special Considerations

The bottom line.

- Supply Chain

Logistics: What It Means and How Businesses Use It

:max_bytes(150000):strip_icc():format(webp)/wk_headshot_aug_2018_02__william_kenton-5bfc261446e0fb005118afc9.jpg)

Investopedia / Zoe Hansen

Logistics refers to the overall process of managing how resources are acquired, stored, and transported to their final destination. Logistics management involves identifying prospective distributors and suppliers and determining their effectiveness and accessibility. Logistics managers are referred to as logisticians.

"Logistics" was initially a military-based term used in reference to how military personnel obtained, stored, and moved equipment and supplies. The term is now used widely in the business sector, particularly by companies in the manufacturing sectors, to refer to how resources are handled and moved along the supply chain .

Key Takeaways

- Logistics is the overall process of managing how resources are acquired, stored, and transported to their final destination.

- Poor logistics in a business can impact its bottom line.

- Logistics is now used widely in the business sector, particularly by companies in the manufacturing sectors, to refer to how resources are handled and moved along the supply chain.

Understanding Logistics in Management and Business

In simple terms, the goal of logistics management is to have the right amount of a resource or input at the right time, getting it to the appropriate location in proper condition, and delivering it to the correct internal or external customer.

For example, in the natural gas industry , logistics involves managing the pipelines, trucks, storage facilities, and distribution centers that handle oil as it is transformed along the supply chain. An efficient supply chain and effective logistical procedures are essential to reduce costs and to maintain and increase efficiency. Poor logistics lead to untimely deliveries, failure to meet the needs of clientele, and ultimately cause the business to suffer.

The concept of business logistics has been transformed since the 1960s. The increasing intricacy of supplying companies with the materials and resources they need, along with the global expansion of supply chains, has led to a need for specialists known as supply chain logisticians.

In the modern era, the technology boom and the complexity of logistics processes have spawned logistics management software and specialized logistics-focused firms that expedite the movement of resources along the supply chain.

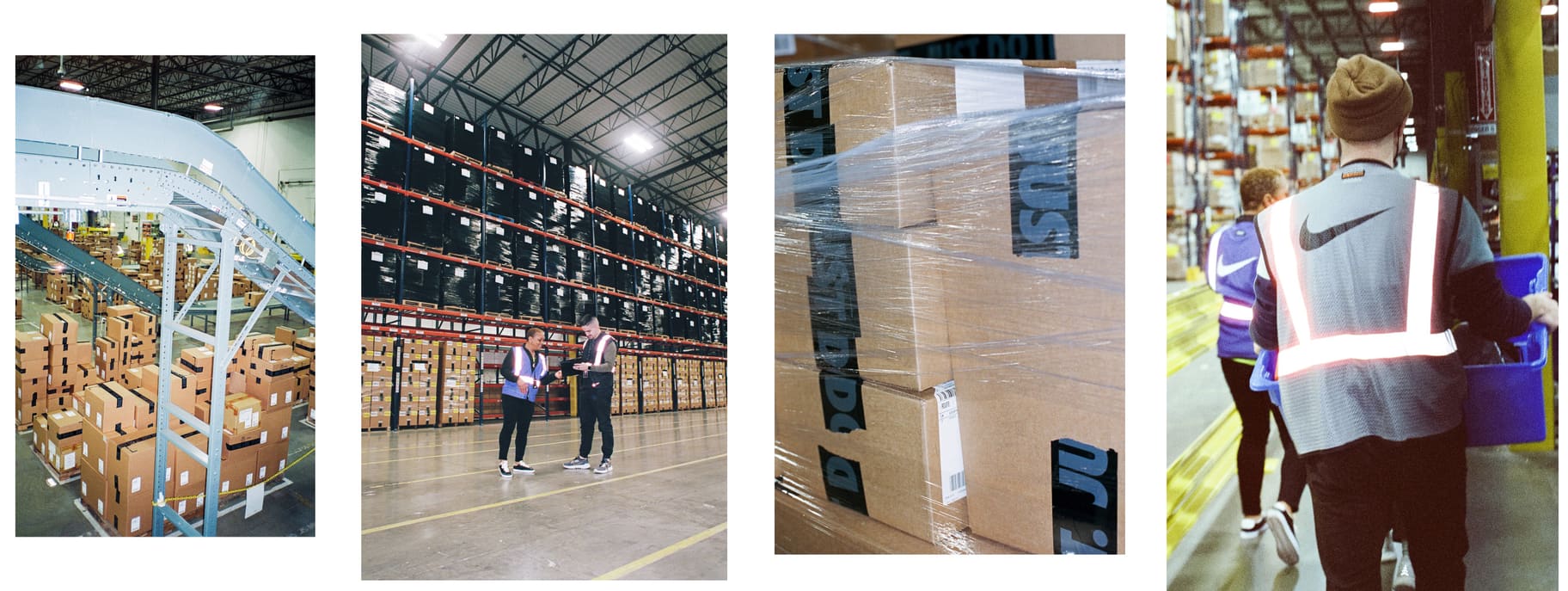

One reason large online retailers like Amazon have come to dominate the retail landscape is the overall innovation and efficiency of their logistics along every link of the supply chain.

Manufacturing companies may choose to outsource the management of their logistics to specialists or manage logistics internally if it is cost-effective to do so.

The tasks for which a logistician is responsible vary depending on the business. Primary responsibilities include overseeing and managing inventory by arranging for appropriate transportation and adequate storage for the inventory.

A qualified logistician plans out the logistics process and coordinates the steps as inventory and resources move along the supply chain.

Specialized training in supply chain management and logistics often includes core or elective courses, or even discrete programs of study, in business education. A business degree that emphasizes these skills—or in some cases, a technical degree in systems analysis or database management—is usually necessary to begin what is often a well-paid career as a logistician.

What Is Logistics in Business?

In business, logistics is the process of transporting and storing raw materials, finished goods, inventory, and other resources. Logistics in a business is typically made up of many components, including customer service, demand forecasting, warehousing, material handling, inventory control, order processing, and transportation.

Why Is Logistics Important?

Logistics is critical to a company's bottom line. It enables the movement of materials or goods, the satisfaction of contracts, and the fulfillment of services. Effective logistics management ensures smooth movement along the supply chain and can provide a competitive advantage.

What Jobs Are Available in the Logistics Industry?

Careers in logistics can include truck driver, customer service representative, dispatcher, freight agent, supply chain manager, transportation analyst, procurement manager, logistician, and operations manager, among others. A degree in logistics or business administration will be helpful for many roles in logistics, including logistician, a career that is expected to grow much faster than average.

When a company optimizes its logistics, it improves efficiency along all points of the supply chain. Understanding how to get the right resource to the right place at the right time can be a differentiator for a business, adding value to the customer while at the same time cutting costs and boosting the bottom line.

U.S. Army Maneuver Center of Excellence. " Maneuver Self Study Program ."

U.S. Bureau of Labor Statistics. " What Logisticians Do ."

U.S. Bureau of Labor Statistics. " How to Become a Logistician ."

U.S. Bureau of Labor Statistics. " Logisticians ."

:max_bytes(150000):strip_icc():format(webp)/Supplychain-5ff2c0cc5d47448ba4bff72d36f386fd.jpg)

- Terms of Service

- Editorial Policy

- Privacy Policy

- Your Privacy Choices

Logistics .

What is logistics logistics definition and examples..

Logistics Definition

Logistics refers to the strategic movement of goods and services from one place to another. The term was originally used to describe the transportation of military supplies to soldiers on the front line, but with the rise of e-commerce and online shopping, logistics is now integral to the global supply chain process, and it encompasses the procurement, storage and distribution of materials that power the economy.

What Is Logistics?

Logistics is the process of coordinating how goods and products are obtained, stored and distributed. Manufacturers rely on logistics while overseeing complex operations in order to maintain efficiency, reduce costs and ensure that consumers’ needs are met.

Due to the prominence of e-commerce companies , like Amazon, logistics embodies more than the actual movement of products from one place to another.

An important part of logistics is the steps taken in order to maximize customer satisfaction. This includes elements such as demand planning, order fulfillment, inventory management and customer service operations. These elements ensure that the goods consumers need are stocked and orders are fulfilled in a timely manner.

Logistics management software has aided the expansion of what the logistics industry entails and how goods are brought to consumers. Some examples of software for the logistics industry include transportation management systems, enterprise resource planning software , yard management systems and warehouse management systems. The growth of this technology has created a need for specialized roles and companies focused on building and implementing logistics software.

As technology continues to transform our world, its influence on the logistics industry will only become greater, prompting a shift in how companies quickly and efficiently deliver their products to consumers.

Supply Chain Management vs. Logistics

Supply chain management and logistics are often thought of as one in the same, but the terms actually capture two distinct parts of what it means to move resources.

Supply chain management is the larger network that connects global vendors, transportation companies, distributors and warehouses. This network functions as the framework that logistics works under.

Logistics is the process companies undertake to deliver goods to consumers. This process involves purchasing and delivering materials, packaging and shipping goods as well as transporting goods and products to distributors.

Why Logistics Is Important

Logistics may not be the first thing that comes to mind when a purchase is made online or in a brick-and-mortar store, but it is undeniably intertwined with everything we buy. Logistical considerations affect global supply chains, what items are in stock and when as well as where manufacturers chose to build their facilities. These influences are just one way that logistics displays importance in our global economy.

Utilizing logistics properly is essential to the function of businesses across the globe — and effectively managed logistics typically leads to positive business outcomes. With the growing complexity of the global supply chain , properly implemented and managed logistics are more important than ever.

The importance of logistics also stretches to simplifying communication and reducing costs. Effective logistics help foster relationships between suppliers, shipping services and warehousers through automated systems. The connectivity of logistics improves delivery and fulfillment of orders, which in turn reduces overhead costs. Costs are also reduced by the ability to use logistical systems to purchase goods based on supply forecasts and improved inventory management.

Best Logistics Companies Hiring for Open Roles View Top Logistics Companies Hiring Now

Types of Logistics

The logistics industry has transformed over the past century. During the 1960s, the supply chain was indelibly changed when IBM developed the world’s first computerized inventory management and forecasting system, which made it simpler to track orders, inventory and distribution. Since then, the industry has been propelled even further into the future, bringing with it an entirely new perspective on how we exchange goods across the globe.

Types of Logistics Companies

- e-Commerce logistics

- Freight logistics

- Third-party logistics

- Carrier logistics

- Freight forwarders

Today, the logistics realm is heavily influenced by AI and machine learning , which many logistics companies use to offer more accurate forecasting and enhanced order management. With these technological advances and more, the supply chain has been given the chance to prosper worldwide.

Logistics in e-Commerce

Given the rise of e-commerce and the rapid growth of the online ordering space, logistics has become one of the world’s fastest-growing industries. Many organizations have emerged in response to logistics’ continuous transformation, dedicated to optimizing the supply chain in unimaginable ways. Perhaps the most well-known logistics leader to have emerged over the past few decades is e-commerce giant Amazon . While Amazon was initially founded as an online marketplace for books, the company has become a household name across the globe, altering the way in which products are transported and delivered to consumers.

Amazon has become famous for its logistics strategy, which is made possible by the company’s global network of distribution, sortation and fulfillment centers. Amazon’s same-day and next-day delivery model rests on a complex logistics framework. Products are delivered to the company’s fulfillment centers before being moved to sortation centers. Once goods have made it through Amazon’s sortation centers, they are loaded onto a wide range of transportation modes, which can include the company’s own fleet of delivery trucks and airplanes.

Third-Party Logistics

Amazon has entirely redefined the logistics landscape, yet it’s not the only major third party logistics (3PL) provider making waves. Companies like UPS and FedEx have played a significant role in the transformation of logistics. These companies are capable of transporting goods from their point of origin, warehousing products and packaging them. Working with 3PL providers offers numerous advantages for both small and large businesses including the ability to obtain better rates, easily expand into new markets and improve customer service.

Logistics in Freight Shipping

While 3PL providers are capable of handling the entirety of a company’s supply chain operations, the different components of the logistics process can be carried out by individual players. For instance, freight companies solely handle the physical transportation of goods, while freight forwarders are dedicated to optimizing transport solutions and handling necessary documentation. In this sense, logistics could be seen as a complex web of moving parts, which operate in tandem with one another in order to boost efficiency and reduce costs within the supply chain.

By way of example, Flexport has developed an operating model designed to simplify global freight forwarding, while Transfix has created a marketplace that connects shippers with a national network of carriers.

Read Next Fragmented Tech Is the Way Forward in Hospitality

Logistic Tech Developments

Given the logistics industry’s seemingly endless transformation, logistics management is naturally made up of many different elements. These components include the planning, procurement and coordination of manufacturing materials, strategizing the development of a product and reclaiming materials and supplies involved in the manufacturing of a product. For logistics managers, keeping track of the many different aspects of a supply chain can be nearly impossible. Luckily, logistics tech has successfully reshaped the industry, turning it into a robust sector fueled by the rise of innovative new technologies.

Top Logistics Tech Companies

- Arrive Logistics

AI and Optimization in Logistics

As the demand for online delivery grows and consumers’ expectations become larger, the need to optimize logistics has never been greater. As a result, software developers have set to work creating platforms designed to make the supply chain more manageable. Real-time visibility software providers such as FourKites , project44 and FreightVerify empower supply chain operators to simply identify issues and quickly resolve them, saving organizations huge amounts of time during which they can focus on other aspects of the logistics process. Likewise, fleet management company Motive has made it easier to track cargo and drivers while improving efficiency and safety along the supply chain.

Considering all of the work that goes into Amazon’s e-commerce services, it may come as no surprise that the company relies heavily on the latest technology in order to accomplish its consumer delivery goals. Amazon has been using AI to power its product recommendations for years. The company has also adopted machine learning to build the handheld virtual assistant, Amazon Echo.

Warehouse Automation in Logistics

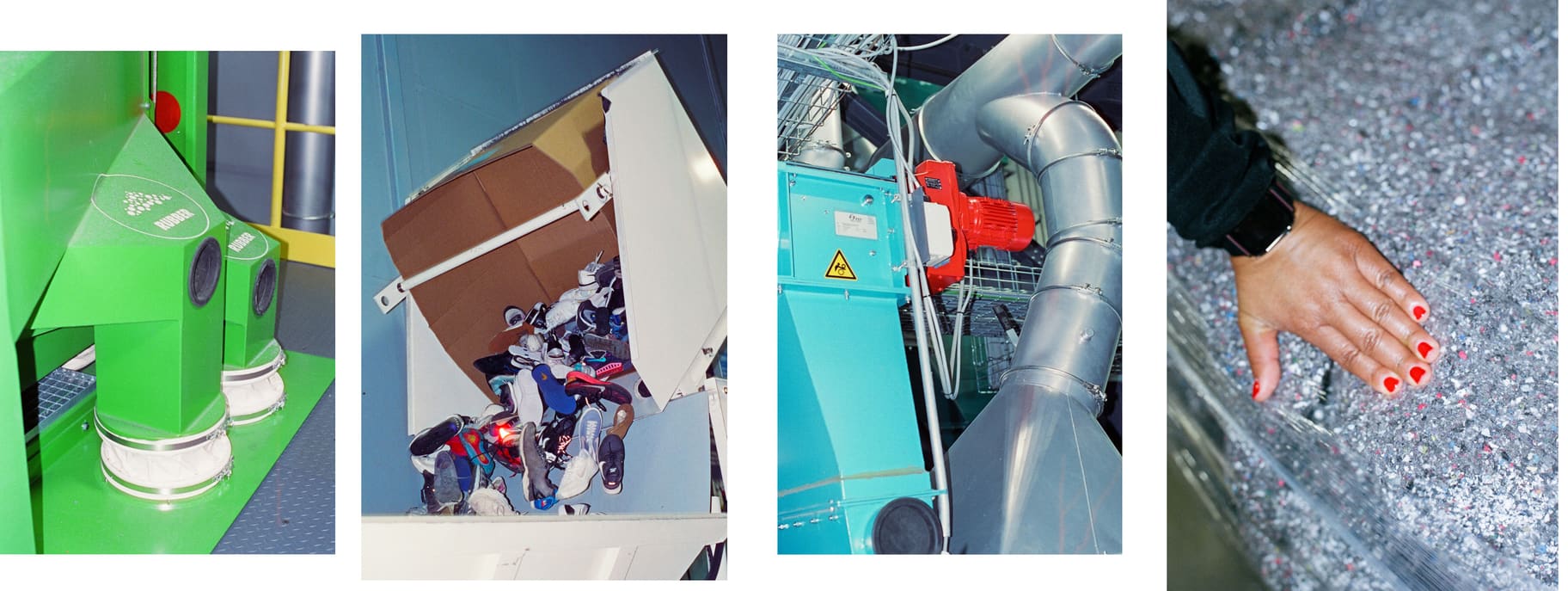

Amazon doesn’t solely use technology to maximize the customer experience. In fact, the company’s technological expertise extends to its packaging and delivery services. The e-commerce company made headlines in 2012 when it introduced automation into its supply chain upon acquiring Kiva Systems . Today, Amazon’s warehouses are filled with thousands of robots built to optimize the picking and packing process.

Amazon isn’t the only logistics leader that has unlocked the potential of robotics . In fact, the warehouse automation space has grown tremendously over the past several years and is expected to become increasingly more valuable over time. The growth of this sector is attributed largely to the steady rise of e-commerce, which has ignited the need to send products out quickly while lowering operating costs. The popularity of online grocery shopping in particular has bolstered the growth of warehouse automation, as online grocery retailers have been forced to meet consumers’ ever-increasing demands while competing with brick-and-mortar stores.

Autonomous Vehicles in Logistics

As warehouse automation continues to infiltrate the logistics industry, autonomous vehicles are becoming a supply chain essential. For companies like Amazon, self-driving vehicles are not only profitable within the warehouse, as they harbor the potential to make on-road delivery faster and more efficient. Companies like Starship Technologies are developing revolutionary new ways to autonomously transport goods, thus unleashing new possibilities within the logistics realm.

Drones in Logistics

Alongside the emergence of autonomous vehicles , the commercial use of drones has opened up new avenues for supply chain management. Within a warehouse setting, drones can be used for aerial inspection and can even carry out maintenance requests, all of which can save manufacturers vast amounts of time.

Given drones’ ability to quickly transport small items, many tech companies are trying their hand at developing aerial transportation modes. For instance, logistics startup Zipline has created unmanned drones designed to quickly deliver goods, reduce emissions and integrate with existing operations.

3D Printing in Logistics

While there are many options when it comes to packaging and delivering goods quickly, supply chain experts are still searching for ways to manufacture products at a speed that meet consumers’ growing expectations. For this reason, 3D printing has entered the logistics space as a possible solution. The process of gathering supplies and producing a product often requires the most time and effort within the supply chain setting.

If 3D printing were applied to the production process, consumers would have greater control over the supply chain. Potentially, a consumer could place an order for a product and then a local 3D printer shop would quickly create the product before sending it out for delivery. 3D printing could ultimately disrupt the logistics industry, as it offers manufacturers the opportunity to produce complex and customized goods faster than ever before.

39 Logistics Companies Getting Packages to Our Doorsteps

Here’s How 3 Global Giants Improve the Supply Chain With AI

Is nasa’s $34 billion budget worth it.

22 Top Supply Chain Companies to Know

How to Manage Design Assets During a Rebrand

17 Third Party Logistics (3PL) Companies to Know

16 top dropshipping companies.

Traffic Tech Professionals Bring an Elite Athletic Pedigree to Its People-First Logistics Platform

Tech Companies’ Great Benefits Should Apply to Every Employee

5 Uses of Blockchain in the Supply Chain

Carpool Logistics Wants to Make Auto Shipping More Sustainable

What is 3pl a guide to third-party logistics..

17 Examples of AI in Supply Chain and Logistics

Great companies need great people. that's where we come in..

Home PowerPoint Templates Logistics

48+ Logistics PowerPoint Templates & Presentation Slides

Download 100% editable Logistics Presentation Templates for PowerPoint and Google Slides. Work with professional-quality vector graphics to depict the different stages or problems that can arise in logistics management and how to propose innovative solutions to them. Our logistic PPT templates are tailored to turn complex data into easy-to-understand concepts. Check them now!

Global Logistics PowerPoint Template

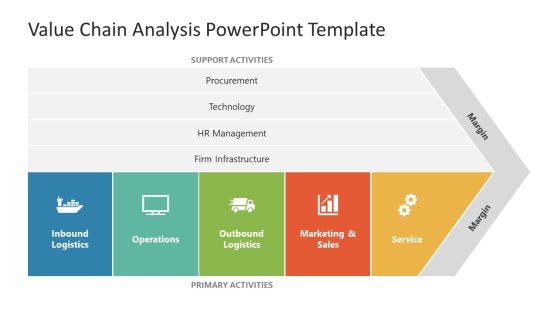

Value Chain Analysis PowerPoint Template

Logistics PowerPoint Template

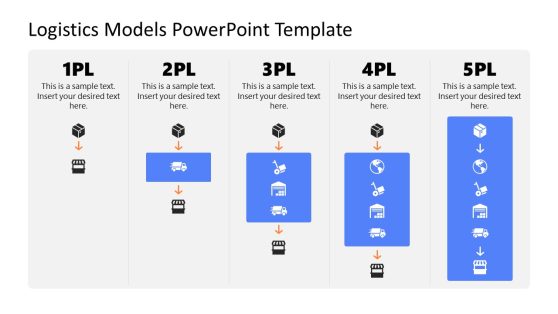

Logistics Models PowerPoint Template

Inventory ABC Analysis PowerPoint Template

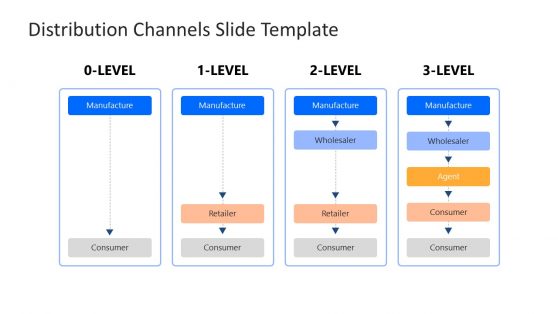

Distribution Channels PowerPoint Template

Supply Chain Control Tower PowerPoint Template

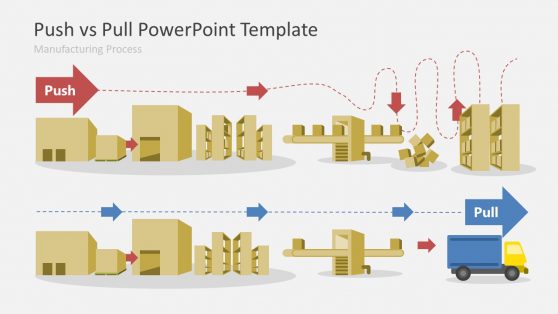

Pull vs Push PowerPoint Shapes Scene

Manufacturing Pull vs Push PowerPoint Template

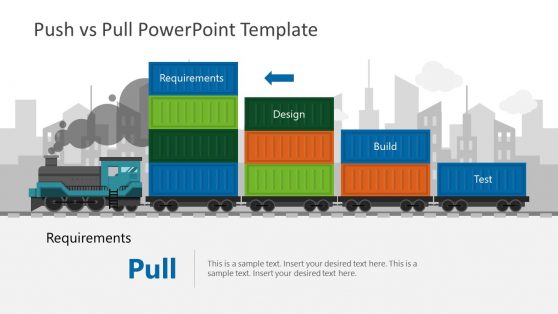

Push vs Pull Train Metaphor Shapes

Animated 3D Shipping Cardboard PowerPoint Template

Creative Cutout Layout for PowerPoint

Our logistics presentation templates are a comprehensive solution for showcasing supply chain management strategies, operational processes, and logistical frameworks. They are crafted to support a broad selection of logistics topics—from warehouse operations to transportation networks and supply chain optimization.

Thanks to these pre-designed logistics slide templates, professionals can save valuable time, focusing on refining the message and content curation rather than busying themselves with design decisions. The high-quality vector graphics enhance the credibility of your message by conveying a professional look. For instance, you can use these vector graphics to explain the entire chain supply process, from procurement to distribution, while highlighting bottlenecks and potential areas of improvement. Alternatively, these logistics presentation templates can help outline logistics optimization strategies, cost reduction, and other efficiency-oriented improvements.

What is a Logistics Presentation Template?

A logistics presentation template is a pre-made slide or slide deck for showcasing and explaining logistics operations, strategies, and data. These templates include icons, vector illustrations, charts, graphs, diagrams, and plenty of other effective communication tools.

How Do You Introduce Logistics in Presentations?

Start by setting a clear context about their importance and role within a business or project. You can then define logistics and their key components, highlighting the areas that are key topics in the presentation. Use relevant statistics to talk about the importance of efficiency in logistics operations and their impact on customer satisfaction.

Download Unlimited Content

Our annual unlimited plan let you download unlimited content from slidemodel. save hours of manual work and use awesome slide designs in your next presentation..

- Free Subscription

- Whitepapers

- Web-Cite City

- Knowledge Center

Logistics 101: Back to Basics

Logistics can confound the newly initiated and veterans alike. So take out your notebook, sharpen your pencil, and take this Inbound Logistics short course on the fundamental concepts driving logistics theory and practice today.

Until recently, logistics activities had one primary focus—to minimize unit transportation costs for shipments to downstream customers.

“This focus worked well until the mid-1900s,” explains Theodore Stank, associate professor of logistics and supply chain management at Michigan State University, “when people started thinking about logistics in the context of systems theory. Systems theory espouses managing an enterprise or organization as an integrated whole for total optimal performance—lowest total costs and optimum service level, for example—as opposed to managing discrete functions individually for lowest costs.

“Say a company decides to sit on inventory in order to build a transportation load and thereby obtain a lower freight rate,” Stank offers by way of example. “This approach is fine if you’re not accounting for the cost of inventory. But if you ask, ‘What is it costing us to have the inventory sit on the warehouse floor for a few more days, you start to see the real cost of that decision.”

“Companies began to realize that effective logistics is all about managing tradeoffs,” notes Philip Evers, associate professor of logistics management at the University of Maryland’s R.H. Smith School of Business. “When you minimize cost in one area, they often go up somewhere else. If you ship by rail, you may reduce your transportation costs, but your inventory carrying and packaging costs go up.”

This kind of sub-optimization is a by-product of a functional orientation, explains Ed Marien, professor and program director, Executive Education, School of Business, University of Wisconsin.

Systems theory began to appear in logistics practice in the 1970s and 1980s. At the same time, a major shift in how organizations viewed customer service began to take hold. Companies started to compete on the basis of customer service, and logistics naturally played a vital role in making such service both possible and profitable. Businesses learned that by combining the two approaches effectively, they could offer competitive service at a lower total cost than their competitors, and thus gain an advantage.

“We still have a way to go in realizing this dream,” Stank says. “We still need more integration of internal functional activities so the purchasing manager who is buying something to support a downstream sale, for example, knows what needs to happen to that raw material, and is measured or incented to pursue performance objectives that benefit the total system.”

Six Degrees of Preparation

At the heart of this systems theory approach to logistics is a fundamental change in how companies view, capture, and manage costs.

According to Marien, six stages in enterprise costing today pertain to logistics. These stages reflect an increasing shift toward a systems approach to management and are evolving as follows:

Stage 1: Direct cost or price of purchased materials.

Stage 2: Net delivered cost of goods purchased. This includes Stage 1 costs plus order processing, transportation, and packaging costs.

Stage 3: Total cost of ownership (TCO). TCO includes Stages 1 and 2, as well as inventory carrying/holding costs and warehousing.

Stage 4: Total cost of sales. This includes the items in Stages 1 through 3, as well as other value-added costs such as overhead and administrative, marketing, R&D and manufacturing/operations, leading to before-tax gross margin.

Stage 5: Inter-enterprise oriented costing. This level includes all of the above, but also extends out to incorporate collaborative costs, shared among a manufacturer’s immediate Tier 1 supplier, customer, and intermediaries. Relationships are managed for mutual gain across channel partners.

Stage 6: End-user lowest delivered price. This final stage of cost management extends the aggregated supply chain value-add costs across all trading partners. All parties in the channel work to orchestrate their efforts toward the goal of delivering the best product, profitably, at the right cost for the end user.

Marien explains the concept behind Stage 6 as follows. “Suppose I have a 12-year-old Whirlpool dryer. At present, Whirlpool is insulated from me, the end user, by intermediaries such as the dealer or retailer. If Whirlpool was managing the end-user relationship, it would know that my dryer is nearing the end of its useful life. The only product performance metric that’s important to me is product up time.

“The manufacturer, therefore, could contact me and say, ‘We know you have a 12-year-old dryer; we know that certain major parts will go out before too long, so here’s a coupon to put toward replacing the dryer before it breaks down.’ Alternatively, the manufacturer could schedule maintenance on the dryer before it breaks down.

“As you start managing the end-user relationship more proactively,” Marien continues, “think about the impact on the supply chain. The manufacturer doesn’t have to carry a lot of spare parts that it may or may not use. Instead, all it needs to do is run a failure analysis of the product in the field, and work with dealers and end users to manage planned parts or unit replacements.

“The consumer benefits from greater up time, the manufacturer and dealer cement their relationship with the end user, and the manufacturer doesn’t need to have all this inventory sitting around in a warehouse somewhere waiting for the unknown service event to occur.”

Few companies have evolved beyond Stage 3 or 4 on Marien’s cost ladder. “On a scale of one to 100 where 100 is total integration, we’re at a five right now,” he suggests. “My estimate is the spread among corporations breaks down like this: 60 percent are in Stage 1, 20 percent are in Stage 2, 10 percent and five percent in Stages 3 and 4 respectively, and the remaining few are beginning to explore Stages 5 and 6.”

Stanley Fawcett of Brigham Young University’s Marriott School of Management and Gregory Magnan at the Albers School of Management, Seattle University, agree with Marien’s assessment.

In a paper entitled Achieving World Class Supply Chain Alignment: Benefits, Barriers and Bridges , they write, “While supply professionals can, and do quote the familiar mantra of ‘suppliers’ supplier to customers’ customer,’ few companies are engaged in such extensive supply chain integration. True integration beyond the first tier in either direction is rare.

“Few companies have adopted a formal definition of SCM,” the authors note. “Even fewer have carefully mapped out their supply chains so that they know who their suppliers’ suppliers or customers’ customers really are. Most supply chains simply compete as loose coalitions of companies that temporarily join forces to gain advantage through cooperation.”

The sheer complexity of major companies’ supply chains thwarts end-to-end supply chain management, Fawcett and Magnan acknowledge. Most companies participate in multiple supply chains. Defining the boundaries and intensity of specific relationships within these multiple relationships complicates supply chain design and management.

A Process Approach

To make these cost and supply chain integration theories work, leading companies are adopting a process approach to managing their logistics/supply chain activities.

Four core business processes comprise supply chain management. Marien describes them as follows:

Demand Management (Forecast) — a collaborative, integrated process composed of these major tasks: corporate and financial planning, product/market planning, sales and operations planning, manufacturing planning, and supply planning, designed to provide forecasts and materials planning schedules to support the efficient flow of products and services throughout the supply chain.

Procurement (Source)— the process of developing strategic plans and forming alliances with suppliers to focus resources on minimizing total delivered costs, developing new products in support of the manufacturing “make” process while achieving simplified replenishment and transactional costs within the supply chain.

Manufacturing Flow Management (Make)— the process for obtaining maximum flexibility of production planning in using manufacturing capabilities and capacities to provide rapid response to changing market conditions and customer requirements.

Logistics Fulfillment Management (Deliver)— the supply chain process that plans, implements, and controls the efficient, effective flow and storage of goods, services, and related information from the point of origin to the point of consumption to meet customers’ requirements. This includes customer service ordering, shipment planning, transportation, warehousing, physical inventory control, packaging and unitization, and reverse logistics.

Managing these four core processes requires companies to adopt a cross-functional team or matrix organizational structure.

“Managers in a matrix organization,” explains Stank, “are not only responsible to a functional area within the company, but also to a horizontal process.

“A transportation manager, for instance, coordinates transportation activities within the organization as well as across the process for an entire product line or for a major customer. The transportation manager works with people in other areas of the company, and the flow is focused from upstream providers all the way down to the customer. But the individual’s ‘home’ department is still the transportation department.”

A classic example of this process approach in transportation is the management of inbound and outbound freight flows.

“Most companies still don’t understand what their inbound freight costs are because they are bundled into the cost of goods sold and managed FOB delivered,” Stank says. “What if a company viewed inbound and outbound as part of a continuous flow and managed it in its entirety? It could then take control of its inbound freight costs and negotiate with carriers to handle both the inbound and outbound legs of its transportation picture. By doing this, it could probably reap significant savings.”

Companies need to document and fully understand their current processes before undertaking any significant organizational change. This is especially critical when considering IT investments.

“Often,” says Stank, “companies bring the systems people in before they really understand their current processes and how they should be improved. The result? As much as 80 percent of new supply chain/corporate information solutions become shelfware.”

To make this evolution toward process management work, companies must change the way they reward employee performance.

“People are often recognized and rewarded for their performance in trimming costs and reducing their budgets,” Marien says. “This actually works against a broader enterprise view of managing costs.”

As a growing number of organizations reap the benefits of a process orientation/cross-functional team structure, this approach has gained a lot of credence in recent years.

“There is a greater willingness to share information rather than hoard it,” adds Stank. “Managers want to do the right thing, and it has become obvious that the old silo approach does not produce the best results.”

Gaining Visibility

Supply chain collaboration, integration, or other similar endeavors rely heavily on information visibility to be successful. Information, shared across the supply chain, can eliminate uncertainty.

“Uncertainty costs money,” Evers says. “Most companies manage uncertainty through inventory—by carrying more ‘just-in-case’ inventory. At each stage in the supply chain, uncertainty causes businesses to add inventory, creating a bullwhip effect where inventory levels are progressively amplified across the channel. This bullwhip effect carries a high price tag.”

Companies, however, can take steps to break this amplification cycle.

“Through better relationships with customers and suppliers, better information flows, better understanding of customers’ and suppliers’ needs, capabilities, and constraints, companies can start to whittle away at the costly by-products of uncertainty,” Evers says.

Today’s information systems can help companies gain the visibility they need to manage inventory more effectively.

“Knowing where inventory is located and how much you have is critical,” Evers continues. “I always argue that every company within the same supply chain should work off the same forecast. We know with 100-percent certainty that forecasts will be wrong. If each player operates independently, the bullwhip effect comes into play at each successive node in the pipeline. By sharing the forecast across the supply chain, at least everyone is on the same page and the bullwhip effect is mitigated.”

Here again, such sharing is both rare and difficult. At the internal level, while they may claim to work off a single forecast, marketing, production, and logistics frequently all work off slightly different numbers.

“You compound the problem when you add other organizations to the mix,” Evers warns. When creating forecasts—whether intra- or inter-organizational—the best place to start is with the end customer. “If you try to work off a single forecast, you have to really understand customer demand,” Evers says. “Start with the end customer and work backward through the supply chain.”

Pursuing an integrated inter-enterprise supply chain is not easy. Fawcett and Magnan suggest that companies follow a six-stage framework to help them achieve competitive supply chain collaboration.

Stage 1: Develop an overall understanding of the supply chain. Managers need to recognize the major players in the supply chain. They need to understand the value proposition of the entire supply chain as well as what role companies at each tier play. Mapping critical processes, core technologies, and linkages to the end customer also helps managers make sound SCM decisions.

Stage 2: Position the organization within the supply chain. Managers must re-evaluate their organization’s value proposition from a supply chain perspective, defining the organization’s core competencies. They must then develop specific processes to support these core competencies.

Stage 3: Build the supply chain infrastructure needed for success. Extended enterprises must develop customer and supplier success infrastructures. This means classifying upstream and downstream partners based on their importance, and establishing appropriate relationships with different classes of customers/suppliers. Some relationships merit intense effort while others are best served by efficient and standardized processes and systems. The initial classification should take into account profitability and long-term growth.

Stage 4: Create and communicate a common supply chain vision. Alignment begins with the creation of a common vision which is then ‘sold’ internally and shared with key supply chain partners.

Stage 5: Cultivate integrative mechanisms. This involves identifying internal and external barriers to collaboration, defining improvement opportunities, and then prioritizing specific programs to address these areas.

Stage 6: Constantly re-evaluate and continuously improve. Supply chains must be dynamic and flexible. To promote this, companies must institutionalize environmental technology and industry scans. Use benchmarking efforts to keep the company at the cutting edge of supply chain practice. In addition, companies must institute continuous improvement initiatives that unleash the creativity and knowledge of their work force.

Logistics and SCM will continue to evolve. The ideas discussed here will continue to play out in the global business world, and new variations on these themes will no doubt emerge.

“The bottom line in all of this,” concludes Evers, “is that you need to understand the bigger view of your company’s current processes. Look at key metrics, core processes, and alternatives that you can strategically address, pick out a strategy of where you want to go, then go out and look at the system providers and channel partners that can help you pull this all together.”

Visit Our Sponsors

- Contact sales

Start free trial

Logistics Management 101: A Beginner’s Guide

What Is Logistics Management?

Logistics management is the process of managing the activities that are required to transport goods from its source to the final customer. That process involves a series of logistics activities such as order processing, material handling, packaging, warehousing, transportation and customer service management.

The logistics management process is used for tangible goods such as raw materials, finished products, equipment and machinery to food or other consumable items. A person who works in this field is called a logistician or logistics manager.

Logistics Management vs. Supply Chain Management

Logistics management is a subset of the larger supply chain management. Supply chain management plans, implements and controls the efficient flow of storage, goods, services and related information from the point of origin to the point of consumption. This is done for the purpose of meeting the requirements of customers.

Logistics management in business works across industries. It aims to manage the fruition of project life cycles , supply chains and resultant efficiencies. As businesses grow more complex and expand into a global marketplace, business logisticians have evolved into something called supply chain logisticians.

With logistics management in manufacturing , the focus is twofold: inbound logistics for internal functions and outbound logistics for the external flow from the point of origin to the point of consumption. Logisticians focus on inventory management, purchasing, transportation, warehousing, consultation and the organization and mapping of these processes.

Get your free

Inventory Template

Use this free Inventory Template for Excel to manage your projects better.

Different Types of Logistics Management

Here’s a quick overview of the main types of logistics management, each emphasizing a different aspect of the supply chain management process.

Inbound Logistics Management

Inbound logistics management refers to the logistics activities that are necessary to transport materials, equipment and machinery from a supplier to a production facility.

Production Logistics and Management

Production logistics management manages the transportation of goods during the production process. This involves the staging of materials from production warehouses to the production line at the right time to streamline the production process .

Outbound Logistics Management

Outbound logistics management is the opposite of inbound logistics. It involves the transportation of goods from the production or distribution center to the final customer.

Third-Party Logistics Management

Third-party logistics management refers to the outsourcing of logistics management activities. Third-party logistics management can involve outsourcing inbound or outbound logistic activities.

Supply Management Logistics Management

This involves the planning, procuring and coordinating materials that are needed at a certain time at a particular place for the production of a task. This includes transportation of the materials as well as a place to store them. Additionally, evaluating the level of supply at the different stages of the process is required to ensure the needs of the customer are met, for example delivering materials to a construction site or parts for a manufacturing plant.

Distribution Logistics Management

This takes stored materials and transports them to where they need to go. The issues in this involve moving materials; including loading, unloading and transportation, as well as keeping track of the stock and how it’s used. This type of logistics management controls the movement of supplies from a central warehouse to the stores that sell the product to the public.

Customer Service Logistics Management

Customer service logistics management consists of ensuring products are delivered on time and damage-free to ensure customer satisfaction. To do this, organizations use logistics management tools and techniques to track customer interactions along the logistics management process of order processing, handling, transportation and delivery of goods.

Reverse Logistics Management

This is about the management of reclaiming materials and supplies from the customer back to production. For example, reverse logistics management is concerned with the return of unwanted or unused products from the end customer seeking a refund.

To model, analyze, visualize and optimize this complex logistical puzzle, the use of logistics management software is often used. ProjectManager has planning tools such as Gantt charts, kanban boards, timesheets and real-time dashboards to help you manage the tasks in your logistics management process. Get started for free today.

The Logistics Management Process: Logistics Activities

Logistics management is a process that consists of logistic activities, also referred to as functions that allow organizations to implement the types of logistics management explained above.

1. Warehousing or Warehouse Management

A warehouse is a physical place where goods are stored when they come out of production. But warehouse management can be strategically used by companies to excel in the market. For example, the location of a warehouse can play a significant role by allowing companies to deliver their products faster than their competitors. Warehousing automation can also help companies cut labor costs.

2. Order Processing & Fulfillment

Order processing and fulfillment is the process of receiving an order, ensuring payment terms have been met, checking the production capacity and availability of stock and preparing the order for transportation. Another important aspect of order processing & fulfillment is to document transactions and make sure the warehouse inventory is updated whenever an order is fulfilled.

3. Material Handling

Materials handling refers to the movement of goods in a warehouse. Companies need to plan their warehouse layouts carefully to help their employees clearly understand where to find the products that are ordered by customers. Some warehouses for big companies can be very large, so it’s important to plan carefully to avoid any logistic inefficiencies.

4. Packaging

In logistics management, the packaging doesn’t focus on the aesthetics of the product packaging for the final customers, but instead on how well the product is packaged for transportation in terms of storage space efficiency, breakage prevention, packing cost and ease of handling. If packaging meets these requirements, it can help companies save money and facilitate its logistics management process.

5. Transportation Management

Transportation is the process of delivering products or materials from their warehouse to the final customer. This is the most expensive logistics activity and therefore, is a step that should be planned carefully to minimize manufacturing costs . Logistic managers need to find the most efficient transportation schedule and method of transportation such as rail, truck water and air.

6. Inventory Management

Keeping an inventory of products at the warehouse is costly for businesses and may affect their profitability. For this reason, the goal of inventory control is to gauge customer demand to maintain an inventory level that satisfies it, but without causing overcosts. Some manufacturing methods such as lean manufacturing or just-in-time manufacturing allow businesses to manage their inventory costs.

Related: Inventory Template

The Distribution Network of Logistics Management

The various links and points of distribution in a logistics management network include the following:

- Factories that manufacture products

- Warehouses that store products

- Distribution centers to receive and return items for clients

- Transport to deliver the product

- Retail locations, from small to larger stores sell a product

These are the major hubs for the logistics of a product, though there can be vendors and intermediaries operating between these points.

Tips for Smart Logistics Management

Logistics management involves a lot of planning and the more steps, the better. By considering every stage of the product, its distribution and the return of materials and supplies, you’re more likely to increase efficiencies and increase revenues.

The larger the operation, the more complex and difficult the logistics management. Therefore, the more you need a strong logistics management plan. To be prepared and have the best plan possible, follow the below tips.

- Have a strong plan: Like any management, it succeeds or fails on the plan’s strength. The more thorough your plan, the less you’ll have to think on your feet. There will always be issues and only so many potential risks you can anticipate, but planning early and in detail can help mitigate delays and other obstructions to the clear flow of materials and supply.

- Make a plan B: No matter how good your initial plan is, there can always be something that comes along that it cannot manage. That’s why you need a contingency plan for every element of your logistics plans to respond to unforeseen problems that might arise. But it’s important to also know when to give up the original plan and move on to the secondary one.

- Hire a manager: It’s critical that this process has an experienced leader who can work with a variety of different parties, all of whom are involved in the logistics of the materials and supplies. That means interpersonal skills are a must. They should also have strong industry contacts to deal with any last-minute logistics changes in suppliers, etc.

- Automate: It goes without saying that automation is a built-in way to make workflow more efficient. They are so many processes that can be helped through task automation , from tracking to monitoring delivery to fleet and inventory management software.

- Learn from mistakes: This goes for almost everything. You’ll take missteps on your journey of managing logistics. That’s a given. What’s not assured is that you’ll learn from those mistakes, so they don’t happen again. Take time to look back on what you’ve done, where it worked and where it didn’t, and get feedback from your team.

Why Is Logistics Management Important?

The purpose of logistics management is about finding more efficient and effective ways to move resources and products from conception to completion and, finally, to the customer. But the driving force of these actions is to meet customer demand and provide the best service possible to retain customers and maintain their satisfaction by meeting their product requirements .

As customers demand better service, there’s a need to ship faster, more accurately and with a high level of quality. It’s through logistics management that customer satisfaction is achieved.

But that’s not the only benefit. It also helps to create visibility in the business’ supply chain . By analyzing historical data and tracking the real-time movement of goods, logistics managers can better the flow of materials and avoid potential disruptions.

Therefore, logistics management helps drive up revenue. It improves customer service and adds to the company’s good reputation and brand, which in turn creates new and more business. With more visibility into the supply chain, there’s the opportunity to save costs in operations , by controlling inbound funds, keeping inventory at the right level and organizing the reverse flow of goods.

How ProjectManager Helps Your Logistics Management

Logistics is just planning with literal deliverables. Therefore, successful logistics managers understand the importance of a project management software tool to help them collect, organize and move items from one place to the next efficiently. ProjectManager is award-winning software that’s designed to improve the organization of projects and teams to maximum effect.

Track Progress With Kanban Boards

When you’re dealing with an overwhelming amount of shipping, priorities and deadlines, you need a way to see where those pieces are at any given time. Our kanban tool visualizes the movement of your shipments with cards representing each item and columns that show where it is in your shipping cycle.

Dashboards and Reporting Keep Things Moving Smoothly

Since our software is online, every time there’s a status update, it reflects across the tool. We have dashboard and reporting tools that provide more data and make managing logistics simple. For example, you can get a high-level view of your costs, variance, tasks and more. The data is crunched automatically and displayed in easy-to-read graphs and charts.

Deliver your projects on time and under budget

Start planning your projects.

- Customer Favourites

Logistics Presentation

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

- You're currently reading page 1

Stages // require(['jquery'], function ($) { $(document).ready(function () { //removes paginator if items are less than selected items per page var paginator = $("#limiter :selected").text(); var itemsPerPage = parseInt(paginator); var itemsCount = $(".products.list.items.product-items.sli_container").children().length; if (itemsCount ? ’Stages’ here means the number of divisions or graphic elements in the slide. For example, if you want a 4 piece puzzle slide, you can search for the word ‘puzzles’ and then select 4 ‘Stages’ here. We have categorized all our content according to the number of ‘Stages’ to make it easier for you to refine the results.

Category // require(['jquery'], function ($) { $(document).ready(function () { //removes paginator if items are less than selected items per page var paginator = $("#limiter :selected").text(); var itemsperpage = parseint(paginator); var itemscount = $(".products.list.items.product-items.sli_container").children().length; if (itemscount.

- Block Chain (2)

- Business Plans (34)

- Business Slides (13911)

- Circular (965)

- Cluster (167)

- Company Profiles (16)

This site uses cookies to improve your experience. By viewing our content, you are accepting the use of cookies. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country we will assume you are from the United States. View our privacy policy and terms of use.

- Materials Handling

- Tracking and Tracing

What is Internal Logistics: Importance, Elements and Examples

DECEMBER 21, 2022

What is Internal Logistics : Importance, Elements and Examples | Image Source: Google Images. If you are wondering what internal logistics is and what role it plays in guaranteeing the supply chain in any company, in this article we will tell you everything you need to know about it. What is internal logistics ?

TGW Presents the Future Fulfilment Centre

Logistics Business Magazine

MARCH 9, 2023

The TGW Logistics Group will demonstrate its Future Fulfilment Centre – how it works, how users can benefit from its advantages, and what technology it uses – for visitors at the LogiMAT intralogistics trade fair in Stuttgart from 25 to 27 April. This means that it fulfils tasks independently, optimises processes and is constantly learning.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- Scaling Logistics for Success: A White Claw Story

MORE WEBINARS

Trending Sources

The Logistics of Logistics

Setlog presents OSCA software at LogiMAT

FEBRUARY 7, 2022

Software company Setlog will present its enhanced SCM software OSCA at the LogiMAT intralogistics trade fair in Stuttgart (31st May – 2nd June). OSCA brings users numerous benefits: For example , the CSR solution helps companies to implement the regulations of the Supply Chain Due Diligence Act, which will come into force in Germany in 2023.

Cognex presents new compact barcode reader

FEBRUARY 18, 2022

Cognex Corporation has introduced the DataMan 280 series of fixed-mount barcode readers, engineered to solve a broad range of ID applications, including tough 1D, 2D, and Direct Part Mark (DPM) code applications in manufacturing and logistics .

Linde presents concentrated expertise at LogiMAT

FEBRUARY 15, 2022

Linde Material Handling (MH) will be presenting its concentrated expertise to visitors at LogiMAT 2022 in several exhibition areas covering a total area of around 1,000 sq m. One example is the latest generation of IC engine-powered and electric counterbalanced trucks in the 2.0 load capacity range.

Mosca presents tailored solutions for safe transport

AUGUST 10, 2022

From empty cans to filled bottles: Mosca will be presenting two different solutions for securing beverage containers at DrinkTec, the world’s leading trade fair for the beverage industry, from 12 to 16 September (booth C6.351). For example , empty beverage cans must be transported as efficiently as possible in large quantities.

AI to Learning Logistics Centre

DECEMBER 18, 2023

Unitechnik Systems GmbH will be presenting UniWare-AI, the AI-based assistant for logistics systems, at LogiMAT 2024. The AI tool will support the system integrator’s customers in predicting order loads and bottlenecks in the material flow, for example . UniWare is the (artificial) brain of the logistics centre.

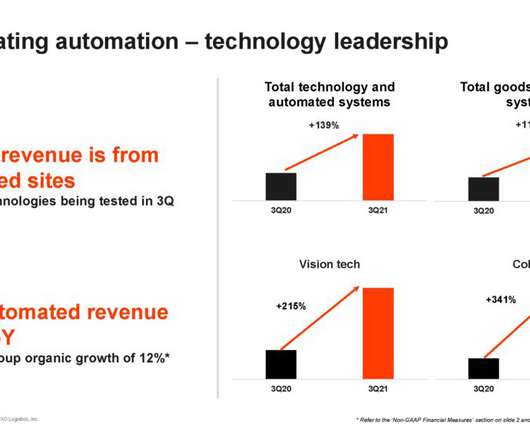

GXO Logistics Tips the Scales with Technology Investments

Logistics Viewpoints

NOVEMBER 10, 2021

GXO Logistics recently briefed Logistics Viewpoints ( ARC ) on its recent operating progress and its formula for success. I was familiar with GXO as the former logistics segment of XPO and knew about select examples of its warehouse automation investments. Source: GXO Logistics Q3 2021 Investor Presentation .

Reclaim Your Energy, Passion, and Time with Ann Holm

NOVEMBER 2, 2022

Past clients include schools ranging from Pre-K to post-secondary, small business owners, and teams in the logistics industry. Ann is the Co-author of the book, Educator Bandwidth: How to Reclaim Your Energy, Passion, and Time – don’t worry the lessons also apply to logistics and supply chain folks. Strategy 1 – Be present !

Predictability in a Time of Uncertainty: Machine Learning in Logistics

JANUARY 21, 2021

Large swings in supply and demand for different product categories and changes in distribution patterns left logistics managers grappling with the biggest challenge of their careers. Challenges that were made all the more difficult by one of the most basic yet complex questions in logistics , “How long will it take to get there?”

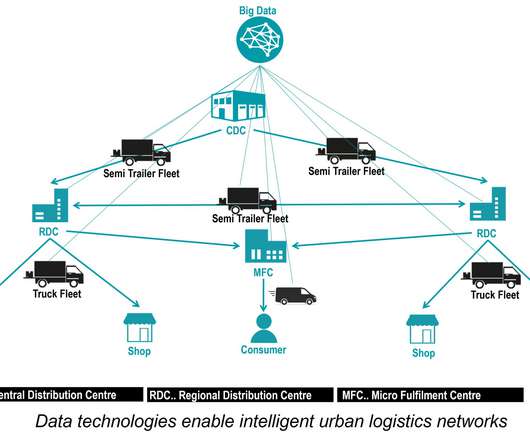

A New Era in Transport Logistics with Big Data and Self-Driving Trucks

DECEMBER 7, 2022

Fuel prices and a shortage of drivers are putting transport logistics under immense pressure. Taking all aspects into account is the only way for logistics companies to have a solid foundation for decision making and holistic optimization. Big data for real-time optimizations in transport logistics .

The 4 Ps of Logistics: An Overview of the Model for Success in Shipping

MTS Logistics

FEBRUARY 2, 2024

There are many different models that ensure success in any company, but for the purposes of simplicity, we have chosen one model: the 4 Ps of logistics (product, price, promotion, and place). Product The P for product can simply refer to the product itself or can be present in more subtle ways. It is basically whatever is being sold.

Robots Take Center Stage at MODEX 2024

MARCH 27, 2024

MODEX is the leading trade show for supply chain, logistics , and material handling solutions in North America. Examples of Supply Chain Robots at MODEX 2024 Several exhibitors at MODEX 2024 showcased their innovative solutions for supply chain robotics, demonstrating the diversity and potential of this field.

DHL Express Presents its New Strategy 2025

Airfreight Logistics

NOVEMBER 20, 2019

DHL Express has presented its new Strategy 2025 on the occasion of the opening of its € 123 million state-of-the-art hub at Cologne-Bonn Airport. By investing more than € 1 billion annually in technology and infrastructure and by putting the new green logistics center into operation, DHL clearly demonstrates its ambitions.

Editor’s Choice: When to Switch From In-House to Managed Logistics Transportation Services

AUGUST 19, 2021

Today’s article is from GlobalTranz and looks at the difficult decision of transitioning in-house logistics to managed services. The supply chain is evolving, and the standards used for managed logistics transportation services today are more data- and technology-driven than those of the past. Take an example .

2022 Distinguished Providers of the Year Announced by Trinity Logistics

Trinity Logistics

JANUARY 31, 2022

Trinity Logistics is proud to announce their 2022 Distinguished Providers of the Year. Those awarded are well known amongst the company as providers that are highly valued partners for Trinity Logistics . Each of the winners will be presented with a crystal award to commemorate their success and achievement with Trinity Logistics .

2021 Distinguished Providers of the Year Announced by Trinity Logistics

Trinity Logistics is proud to announce their 2021 Distinguished Providers of the Year. Those awarded are well known amongst the company as providers that are highly valued partners for Trinity Logistics . Each of the winners will be presented with a crystal award to commemorate their success and achievement with Trinity Logistics .

Combilift’s CB70E wins Italian Terminal and Logistics Award

OCTOBER 16, 2023

Combilift, the largest global manufacturer of multidirectional trucks, articulated forklifts and straddle carriers is thrilled to announce that the Combi-CB70E has been honoured with the coveted Italian Terminal and Logistics Award.

Logistics Software: How to Make Handling Peak Times Easy

JUNE 9, 2022

Transparent data prepared especially for your logistics operation will get you easily through your peaks. The hype usually revolves around just one item and can easily be managed by a modern logistics system. How can we rapidly bring our logistics operation up to its full speed during such a peak? Peaks are all so different.

Supply Chain Visibility: Past, Present, and Future

Talking Logistics

APRIL 25, 2018

Those were just some of the questions I discussed with Cindi Hane, Vice President of Product Management for Elemica , in a recent episode of Talking Logistics . Cindi offered a simple example of a company and carrier collaborating on dock scheduling. And how are advancements in technology helping to improve this important capability?

LogiMAT ’24 Has Your Back

JANUARY 26, 2024

Exhibitors from nearly every sector of the industry are coming to LogiMAT 2024 to present their latest products and solutions for ergonomically optimized intralogistics processes, healthy workplaces, and injury prevention. Some 100,000 logistics -related jobs in Germany alone remain unfilled.

Seven Theses on Ergonomics in Logistics

JUNE 22, 2023

KG and talks about ergonomics in logistics and the distribution centre. Those who can’t meet basic ergonomic requirements no longer have a chance to present themselves on the market as an attractive employer”, Johannes Schweiger says. How, for example , must future user interfaces or tools be designed? Those days are over. “We

This Week in Logistics News (September 16 – 22)

SEPTEMBER 22, 2023

A notable example of greenwashing is when McDonald’s introduced paper straws to reduce plastic pollution. And now on to this week’s logistics news. The union plans to disclose the locations of new strikes during an online presentation to members that morning. That’s all for this week.

Navigating Trends and Projections in Logistics for 2024

FEBRUARY 19, 2024

Image source: Flickr | Navigating Trends and Projections in Logistics for 2024 The logistics industry is always changing due to fluctuations in the market, technology advancements, and the never-ending quest for efficiency. Growth of E-commerce: E-commerce kept growing, increasing the need for effective logistical services.

Raising Productivity in Logistics Operations: The BHAG Approach

Logistics Bureau

JANUARY 25, 2021

I recently attended a great presentation during which the presenter referred to a BHAG —a big hairy audacious goal. The person who gave the presentation I attended offered the example of a speech by late US President John F. For example , their increase in productivity was 217 percent.

Editor’s Choice: WMS Budget – Room for an Implementation?

APRIL 27, 2023

Transitioning from legacy systems presents hurdles that add to the true cost. For example , monthly subscription fees, any software support charges, and data migration fees. Presenting the case for your WMS Implementation Once you’ve calculated the costs and have a rough idea of the total, you’ve got to make the case internally.

Drive Systems at LogiMAT

JANUARY 18, 2024

At the LogiMAT trade show in Stuttgart the drive specialist Nord will present its reliable and energy-efficient drive systems units for the industry. For this purpose, NORD DRIVESYSTEMS designed suitable drive solutions – and will present them from 19 to 21st March 2024 at LogiMAT in Stuttgart.

Challenges of Peak Season Logistics

NOVEMBER 27, 2023

As the holiday shopping season rapidly approaches, shippers and carriers are yet again gearing up to tackle the formidable logistical and customer service challenges that inevitably come with peak season volumes. The logistics involved are staggering, but data can act as the common thread that ties such a complex operation together.

Sustaining machines – logistics and autonomous systems

Logistics in War

APRIL 16, 2021

This article is adapted from a presentation given at the Williams Foundation seminar on ‘Next Generation Autonomous Systems’ delivered in Canberra in April 2021. It becoming easier to find such opportunities given the vibrancy of the industry sector, and the enthusiasm robotics presently generates in defence circles.

Automated Hand-Scanning Upgrade

FEBRUARY 16, 2024

The automation of hand scanning processes increases productivity at inbound and outbound areas of logistics hubs dramatically. Hand-held barcode readers are still widely used to ensure the traceability of goods and packages, for example in retail, warehousing and parcel sorting operations.

Key Takeaways from Oracle CloudWorld 2023

SEPTEMBER 25, 2023

Nevertheless, Mr. Ellison presented a fascinating vision centered on how technology can be used to digitally disrupt a 10,000-year-old industry. At last year’s CloudWorld, Oracle presented their vision for transforming the healthcare industry by applying AI to vast amounts of anonymized patient record data. Uber has an ecosystem.

MTS Logistics Teaches and Trains the Young Generation to Make a Difference for the World’s Oceans and Environment

OCTOBER 12, 2022

MTS Logistics recently held an educational environmental training and cleanup event on the beach in Izmir, Turkey. This past Saturday, October 8th, in Izmir, Turkey, MTS Logistics held its second annual Clean Oceans Project (called Temiz Deniz Projesievent in Turkish) in Seferihisar.

Logistics Experience in XXL Format

JUNE 24, 2022

On an area of 17,000 square meters at the Mannheim Maimarkt site, the intralogistics specialist is presenting its extensive portfolio of products, solutions and services – for example , using the case of a bottle manufacturer to demonstrate the process from goods receipt to the last mile in the store.

Beyond Efficiency: The Human Element’s Impact on Logistics

NOVEMBER 1, 2023

Beyond Efficiency: The Human Element’s Impact on Logistics | Image source: Pexels Modern technology, smart equipment, task automation, and management systems. These are only a handful of the amazing technology advancements that the logistics industry has experienced lately. What is the role of the human factor in logistics ?

Toyota extols safer logistics at seminar

MARCH 21, 2022

The Safer Logistics Theatre will be an expert-led, free-to-attend seminar programme featuring a range of high profile speakers who will provide valuable insights into maintaining an optimal health and safety regime within the warehouse and across the supply chain.

Inbound Logistics: Everything You Need to Know

DECEMBER 2, 2022

Everything You Need to Know About Inbound Logistics | Source: Picpedia. The tasks associated with the delivery of raw materials are handled by inbound logistics or supply logistics to guarantee their availability throughout the production process. Duties of inbound logistics . Components of the inbound logistics .

What is Lean Logistics? 5 Ways to Manage Lean Logistics Effectively

APRIL 13, 2023

What is Lean Logistics ? 5 Ways to Manage Lean Logistics Effectively | Image source: Unsplash The application of lean management ideas to supply chain performance is known as lean logistics . Lean Logistics analyzes and removes non-value-added operations in order to enhance the flow of commodities and save expenses.

New Developments from META at LogiMAT

FEBRUARY 9, 2023

Since last year and under the name META-ILS (Innovative Logistic Solutions), META, the warehouse technology specialist based in Arnsberg, Germany, has been covering the newly developed field of material conveyor technology. This will now be the focus of the company’s exhibition presentation .

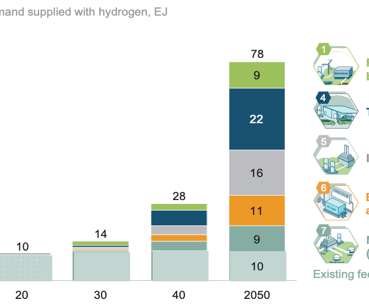

Logistics, transport, and the decarbonization of the planet

Logistics at MPEPS at UPV

MARCH 8, 2022

How can the logistics & transport will keep up with the goals of COP26 and the 2030 vision? Although my current position makes me function more as a strategic mind, my study background has been 100% focused on logistics . So, I asked myself, how will the hydrogen industry affect and support logistics as we know it today?

Driving Risk Out of S&OP Forecasts

Supply Chain and Logistics

FEBRUARY 2, 2019

MIT’s Supply Chain blog presented a nice research study by Minhaaj Khan and Srideepti Kidambi and supervised by Dr. Tugba Efendigil. Their study is a good example of using less data rather than more to design a simple readily explainable approach … Continue reading →

This Week in Logistics News (April 30 – May 6)

MAY 6, 2022

And now on to this week’s logistics news. Advances in gripping technology and arm speed are making it easier to handle a broader array of items, for example , allowing companies to maximize their investment and reduce their reliance on human labor for mundane picking tasks. The Czinger 21C costs $1.7 million, not including any add-ons.

Cabka-IPS to Present FachPack Transport and Storage Solutions

AUGUST 14, 2018

Cabka-IPS will be presenting selected products from its extensive product range of transport and storage solutions at FachPack in Nuremberg (September 25-27). These are precisely tailored to the requirements of certain industry segments, for example the chemical or automotive industries. Thanks to its collapsible rings, the CabCube 2.0

transport logistic and TIACA organise joint San Francisco event

MARCH 7, 2022

From 22 to 25 March 2022, the global air cargo and logistics industry will meet at the 2+2 event in San Francisco. The 2+2 event will be one of the largest gatherings of experts and decision-makers in the air cargo and logistics industry.

U-Freight sees e-commerce logistics opportunities

APRIL 19, 2021

Commenting on a recent report that suggests the global e-commerce logistics market grew by 27.3% in 2020 and will hit EUR557 billion by 2025, Simon Wong, CEO of the U-Freight Group , says his company is ready to meet the ever-increasing challenges of providing logistics services to this rapidly expanding sector of global trade.

Stay Connected

Join 84,000+ Insiders by signing up for our newsletter

- Participate in Logistics Brief

- Add a Source

- Add a Resource

- See All

- 2019 Logistics Brief MVP Awards

- 2020 Logistics Brief MVP Awards

- 2021 Logistics Brief MVP Awards

- 2022 Logistics Brief MVP Awards

- Sun. Apr 21

- Fri. Apr 19

- Thu. Apr 18

- Wed. Apr 17

- Apr 13 - Apr 19

- Supply Chains

- Distribution

- Transportation

- More Topics

Input your email to sign up, or if you already have an account, log in here!

Enter your email address to reset your password. a temporary password will be e‑mailed to you., be in the know on, logistics brief.

Expert insights. Personalized for you.

We organize all of the trending information in your field so you don't have to. Join 84,000+ users and stay up to date on the latest articles your peers are reading.

Get the good stuff

Subscribe to the following Logistics Brief newsletters:

You must accept the Privacy Policy and Terms & Conditions to proceed.

You know about us, now we want to get to know you!

Check your mail, we've sent an email to . please verify that you have received the email..

We have resent the email to

Let's personalize your content

Use social media to find articles.

We can use your profile and the content you share to understand your interests and provide content that is just for you.

Turn this off at any time. Your social media activity always remains private.

Let's get even more personalized

Choose topics that interest you., so, what do you do.

Are you sure you want to cancel your subscriptions?

Cancel my subscriptions

Don't cancel my subscriptions

Changing Country?

Accept terms & conditions.

It looks like you are changing your country/region of residence. In order to receive our emails, you must expressly agree. You can unsubscribe at any time by clicking the unsubscribe link at the bottom of our emails.

You appear to have previously removed your acceptance of the Terms & Conditions.

We noticed that you changed your country/region of residence; congratulations! In order to make this change, you must accept the Aggregage Terms and Conditions and Privacy Policy. Once you've accepted, then you will be able to choose which emails to receive from each site .

You must choose one option

Please choose which emails to receive from each site .

- Update All Sites

- Update Each Site

Please verify your previous choices for all sites

Sites have been updated - click Submit All Changes below to save your changes.

We recognize your account from another site in our network , please click 'Send Email' below to continue with verifying your account and setting a password.

You must accept the Privacy Policy and Terms & Conditions to proceed.

This is not me

What is logistics? Meaning, Processes, Functions and Examples

So much of your customers’ experience with your business is impacted by your logistics. Here’s how to optimize your logistics strategy to ensure the right products get to the right customers at the right time – all whilst saving your business money.

What does logistics mean.

Logistics refers to the planning framework that enables businesses to store and transport their goods to their customers. It covers procurement, inventory management, distribution, warehousing, transportation, packaging and risk management .

For SMBs – particularly those within the e-commerce sector – logistics should be considered essential to reducing costs, staying competitive and getting products to customers on time.

Sign up to the Discover newsletter

- Fortnightly insights, tips and free assets

- We never share your data

- Shape a global audience for your business

- Unsubscribe any time

Logistics is:

- Moving products and/or materials from one place to another

- Getting raw materials from suppliers to your business

- Dependent on reliable transportation

- Reliant on warehousing and storage

- Part of the wider supply chain management process

- Worthy of serious investment

Logistics is not:

- An afterthought or something to be left to the last minute

- The supply chain. It’s a part of the supply chain

- A function your business needs to do itself – it can easily be outsourced

Logistics vs supply chain management

Sometimes logistics is confused with ‘supply chain’, which refers to the wider chain of goods and materials before they land with your business.

Supply chain = the bigger picture. The entire network of activities involved in the sourcing and procurement of raw materials, conversion of those materials into finished goods, and the distribution of those finished goods. The supply chain is often something your business has little or no control over.

Logistics = this is the part of the supply chain that your business does have direct control over, and covers the packaging, transportation, inventory management and storage of your supplies and products.

Why is logistics important?

Industry research found that over 60% of US and European companies lost up to 20% in revenue in 2020 due to logistical disruptions 1 . Granted, the effects of Covid made it an unprecedented year, but it still highlights how important an optimized logistics strategy is to a business’s bottom line – especially SMBs and start-ups with tight profit margins.

Furthermore, the efficiency of your logistics operation is closely linked to your customers’ experience with your business. Take inventory management, for example: did you know that 37% of online consumers who encounter an out-of-stock message will shop with another brand? 2 There’s also the transportation of the goods, the packaging, the delivery….all aspects of logistics which, if you don’t get right, will impact your customers somewhere down the line. Time to take your logistics seriously!

What is logistics management?

Logistics management is the strategic side of logistics, involving the procurement, movement, and storage of materials, parts, and finished inventory (goods and services) from their point of origin to point of consumption.

The ‘Seven Rs’ is a popular way to define the goal of logistics management:

- Get the right product

- At the right quantity

- At the right time

- In the right condition

- To the right place

- And to the right customer

- At the right cost

Get all of these, well, right, and your business will stay competitive.

How to optimize your logistics strategy

First, you need to establish your goals in order to find the best paths to reach them. They may be:

- To reduce costs

- To generate higher revenue

- To reduce overstocking

- To improve customer delivery times

…or most likely a combination of all! For SMBs and startups where profit margins are already very small, reducing costs is often a priority.